Questions on making an Exhaust System...

#1

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

Ok, all I have to back up my welding skills is that I passed the I-CAR test at school. Now, how hard will it be to make an exhaust that starts from the downpipe, all the way to the end. This is going on an 87 N/A FC. I want a resonator, or silencer thing so it won't be loud.

I plan on this to be 2.5" diameter pipe, that goes to the, either 2.75" or 3" muffler, no dual.

I don't have a mandrel to bend the pipe

So, could I pull this off?

I plan on this to be 2.5" diameter pipe, that goes to the, either 2.75" or 3" muffler, no dual.

I don't have a mandrel to bend the pipe

So, could I pull this off?

#3

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

#4

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

The best advice when building an exhaust is to start at the front of the car and built it in sections. Make the downpipe, then midpipe, then catback. Fully weld each section before moving on to the next. If you don't, then it's almost certain that it won't fit together. Stainless moves a lot during welding. Tack heavily and let the area cool before you move downstream.

If you plan out your route and work in short sections, it's not that hard.

If you plan out your route and work in short sections, it's not that hard.

#5

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

Good advice Aaron Cake.

What I don't get is how I can plan out the hangers, and what flanges i need. I've been studying the Mazdatrix pics, and the Haynes manual pics, and I can't picture what the straight cat would look like. I don't know were I can cut corners, I guess is what I'm trying to say.

What I don't get is how I can plan out the hangers, and what flanges i need. I've been studying the Mazdatrix pics, and the Haynes manual pics, and I can't picture what the straight cat would look like. I don't know were I can cut corners, I guess is what I'm trying to say.

#6

for hangers I used round stock from home depot, put it in a vice and used a wrench to make the 90º bends and a burn-O-matic and hammer to form it around the pipe, its cheap and easy to work. as far as flanges go ball type makes this stuff SO easy, but they are a little hard on the bank and if done wrong *or using a cheep kit* flow will suffer as well.

#7

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

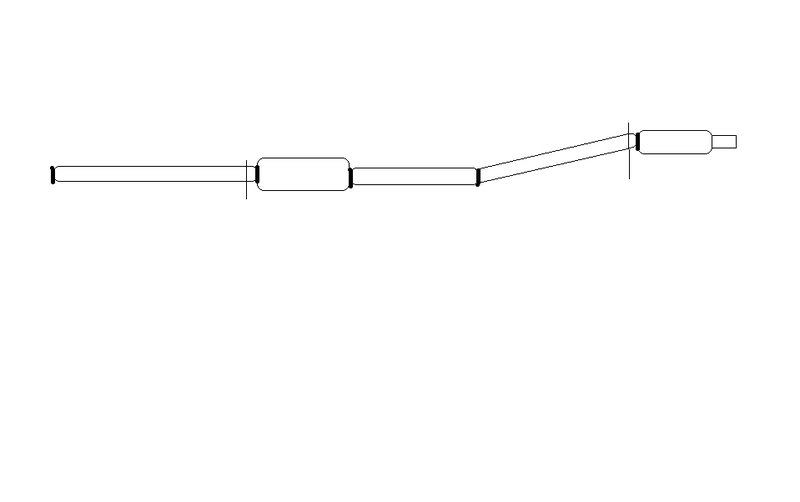

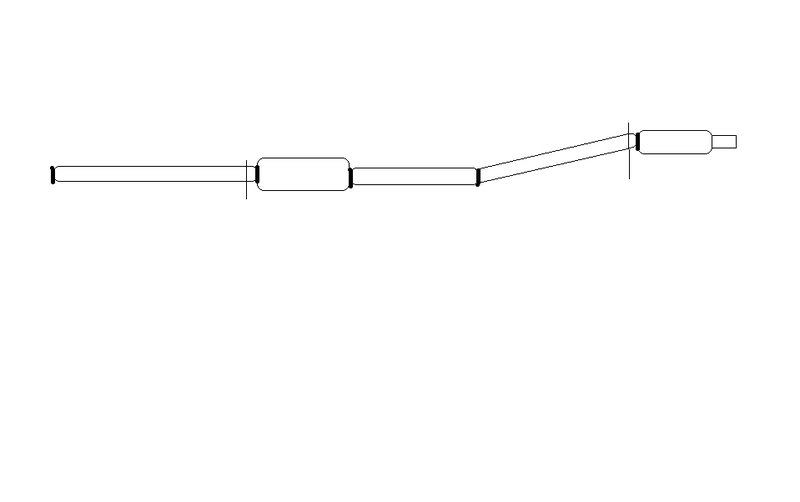

Here is the rough draft:

How long should the pipes be?

How big should the resonator be?

Thanks for the help. I'm a visual learner

The welder I will use is a metal arc welder.

How long should the pipes be?

How big should the resonator be?

Thanks for the help. I'm a visual learner

The welder I will use is a metal arc welder.

Last edited by lonetlan; 02-10-09 at 06:59 PM. Reason: still confused

Trending Topics

#9

Banned. I got OWNED!!!

Join Date: Jun 2008

Location: usa

Posts: 329

Likes: 0

Received 0 Likes

on

0 Posts

Magnaflow cans too

1 - 3" in, dual 2.5" out

2 - 2.5" in 2.5" out

Why use cheap carbon steel when stainless can be had in a day or two? Especially if the rest of the exhaust is stainless?

Onlinemetals.com

metalsdepot.com

metalssupermarket.com

all have stainless round stock in stock. There once was a Metals Supermarket around the corner from me, know they are ~80 miles away but UPS ground gets it to me overnight and they ARE CHEAPER THAN THE HOME CHEPOT. Of course you'll probably need an oxy/ace tourch to properly form it, I used 3/8" for my hangers.

1 - 3" in, dual 2.5" out

2 - 2.5" in 2.5" out

for hangers I used round stock from home depot, put it in a vice and used a wrench to make the 90º bends and a burn-O-matic and hammer to form it around the pipe, its cheap and easy to work. as far as flanges go ball type makes this stuff SO easy, but they are a little hard on the bank and if done wrong *or using a cheep kit* flow will suffer as well.

Onlinemetals.com

metalsdepot.com

metalssupermarket.com

all have stainless round stock in stock. There once was a Metals Supermarket around the corner from me, know they are ~80 miles away but UPS ground gets it to me overnight and they ARE CHEAPER THAN THE HOME CHEPOT. Of course you'll probably need an oxy/ace tourch to properly form it, I used 3/8" for my hangers.

#11

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

I'm going to do stainless steel. The onlinemetals place made this a little more complicated with all the cool options. I need to do some research.

#12

http://www.onlinemetals.com/merchant...d=19&top_cat=1

a lot of places use .049 wall. so .065 will work just fine. and you dont need any odd alloy. just know that SS is a lot softer than carbon and needs a lot less amps.

What set up do you have?

a lot of places use .049 wall. so .065 will work just fine. and you dont need any odd alloy. just know that SS is a lot softer than carbon and needs a lot less amps.

What set up do you have?

#13

Banned. I got OWNED!!!

Join Date: Jun 2008

Location: usa

Posts: 329

Likes: 0

Received 0 Likes

on

0 Posts

Verocious Motorsports has good prices on V-bands and straits,

Believe it or not, Magnaflow had the best prices on bends and "L's" Go through SummitRacing for those pieces

Believe it or not, Magnaflow had the best prices on bends and "L's" Go through SummitRacing for those pieces

#14

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

I'm going to use a friends welder, I don't know what it is, but I'll post up what it is when I use it.

How long of a pipe should I go get?

Also, There are no emissions tests here, so what should I use for the space where the catalytic converter goes? I'm trying to get the sort of deep idle noise, but a clean sound of acceleration. Will Magnaflow do this?

How long of a pipe should I go get?

Also, There are no emissions tests here, so what should I use for the space where the catalytic converter goes? I'm trying to get the sort of deep idle noise, but a clean sound of acceleration. Will Magnaflow do this?

#16

Too Many Questions

Thread Starter

Join Date: Jan 2009

Location: Claremore, Oklahoma

Posts: 737

Likes: 0

Received 0 Likes

on

0 Posts

How long of a pipe should I order? I'm thinking of 6'(72") These are the 2.5"OD and .065 wall that nillachaz recommended

Does the onlinemetals website also have those "U" shaped bent tubing, so I can smooth out this creation?

Does the onlinemetals website also have those "U" shaped bent tubing, so I can smooth out this creation?

#17

Banned. I got OWNED!!!

Join Date: Jun 2008

Location: usa

Posts: 329

Likes: 0

Received 0 Likes

on

0 Posts

3 posts above I said go through summit for the magnaflow elbows, "L's" etc.

You need to get under your car and start planning this thing out and decide how many feet of strait to order, and what degree and how many of each 45*, 90*, 180* bends to buy.

You need to get under your car and start planning this thing out and decide how many feet of strait to order, and what degree and how many of each 45*, 90*, 180* bends to buy.

#20

Rotary Enthusiast

iTrader: (3)

Join Date: Jan 2007

Location: st. louis

Posts: 1,000

Likes: 0

Received 0 Likes

on

0 Posts

i have a flex pipe in my dp, one on the recirculation thingy for my wastegate and i have some flexpipe in the rear because it was a hell of a lot cheaper than using mandrel bends

#21

Banned. I got OWNED!!!

Join Date: Jun 2008

Location: usa

Posts: 329

Likes: 0

Received 0 Likes

on

0 Posts

I've got a flexpipe right at the end of my downpipe right before the first Magnaflow can.

I don't know about it being cheaper than mandrel bends though, we MUST be talking about different flex pipe. I was paying ~$20 per bend

http://store.summitracing.com/partde...5&autoview=sku

The all stainless flex coupler I got was ~$65 for a 4 inch length. In all honesty it doesn't flex as much as I'd like so I'll probably cut it out and put an 8" one in instead

I don't know about it being cheaper than mandrel bends though, we MUST be talking about different flex pipe. I was paying ~$20 per bend

http://store.summitracing.com/partde...5&autoview=sku

The all stainless flex coupler I got was ~$65 for a 4 inch length. In all honesty it doesn't flex as much as I'd like so I'll probably cut it out and put an 8" one in instead

Thread

Thread Starter

Forum

Replies

Last Post

12abridgeport

1st Generation Specific (1979-1985)

2

08-17-15 06:28 PM