FuelTech

#27

Rotary Enthusiast

The bottom one has 2 teeth removed. Looks like this but only red and white connected.: https://www.rx7club.com/attachments/...rm-12-1cas.jpg

#28

The bottom one has 2 teeth removed. Looks like this but only red and white connected.: https://www.rx7club.com/attachments/...rm-12-1cas.jpg

Then it's using a single reluctor and the missing tooth is a its sync pulse, hence the missing tooth setting.

#29

Rotary Enthusiast

It seems you cannot tune using lambda values in fuel tech since the minimum value for the afr is 1.7xx no matter if you select lambda as the measurement unit. Anybody else notice that?

#33

Along your journey what have been some of your best tips for learning the fueltech system? I am currently nearing the end of my first ground up build and it's a 13b rew and I'm stuck on timing and how to adjust. I was given a base map for my setup but I'm unfamiliar with terms such as "locking the timing" and setting on the crank position. The FD trigger wheel only has an indicator on 20 degrees BTDC (advanced) and I have been trying to adjust it via just the ft550 ecu in "ignition calibration" but haven't tried it with the laptop software to lock it and adjust.

#35

Rotary Enthusiast

Fueltech is now on the worlds fastest rotary. I think we deserve a Fueltech subforum. I've just purchased an FT550 to replace the PFC

The following users liked this post:

mr2peak (11-22-22)

#37

Rotary Enthusiast

#38

Rotary Enthusiast

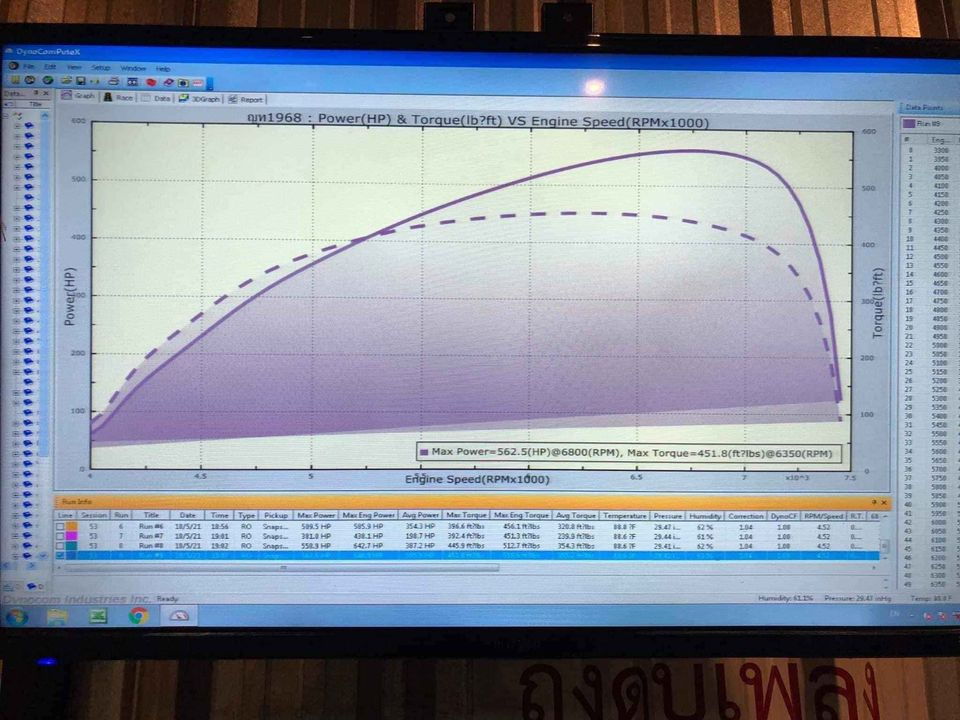

My friend just cracked 600 on an EFR 8374 ewg with a fuel tech.

Fueltech has a bunch of pre-selected packages for the rotary, no less than 6 options. For comparison, they offer a single 4 cylinder package. I think they like Rotaries.

https://www.fueltech.net/collections/import

If they support us like this, I think we should support them with a Fueltech subforum

Fueltech has a bunch of pre-selected packages for the rotary, no less than 6 options. For comparison, they offer a single 4 cylinder package. I think they like Rotaries.

https://www.fueltech.net/collections/import

If they support us like this, I think we should support them with a Fueltech subforum

The following users liked this post:

mr2peak (11-28-22)

#40

Rotary Enthusiast

8374 is a 79lb/min turbo. Iím sure it was a halo run with water being sprayed onto the intercooler during the run with all the tricks. Number creep also happens when people talk..

The following users liked this post:

mr2peak (11-28-22)

#42

Rotary Enthusiast

It was a 8374 EWG, I saw the turbo for sale and he picked it up. Not sure on A/R, the numbers might be a bit inflated, it wouldn't be the first time in the automotive world lmao

#43

Information Regurgitator

A Fueltech subforum would be cool. I bought a FT550 awhile back. I have my initial base map created but I just haven't managed to get the time to install it yet.

The following users liked this post:

mr2peak (12-08-22)

#44

Rotary Enthusiast

I also have an FT550. I will be re-pinning a Rywire harness to fit. The Rywire Haltech harness uses the same AMP 1.0 Superseal connectors as the FT600, 26pin and 34pin. The FT550 uses two 26pin connectors. I won't be using the knock sensor connection, OMP connections, fuel temp, IACV, and probably only 4 of the 6 injectors.

I will add a sub-harness to control Drive By Wire, EGTs, Wastage Pressure, Driveshaft Sensor, and any other inputs/ouputs not supported by the Rywire harness. I think the A/C will also be on this sub-harness, and possibly the single wire OMP PWM Arduino connection, I won't know until I have the Rywire harness with documentation in front of me. I am using every input on the FT550, and quite a few of the outputs, but it will do everything I need at the moment. An FT600 would mean I could run wheel speed sensors without an expander box, but that's a "next-phase" item for me along with MK60 ABS. FT450 will not work, it just doesn't have enough inputs for a street car.

I looked at a full custom harness, but modifying the Rywire is less than 1/2 the cost and will carry the bulk of important signals.

I will do my best to document the wiring, it's by far the hardest part of this project for me

I just need to find an affordable AMP Superseal 1.0 crimper, the prices are criminal..

I will add a sub-harness to control Drive By Wire, EGTs, Wastage Pressure, Driveshaft Sensor, and any other inputs/ouputs not supported by the Rywire harness. I think the A/C will also be on this sub-harness, and possibly the single wire OMP PWM Arduino connection, I won't know until I have the Rywire harness with documentation in front of me. I am using every input on the FT550, and quite a few of the outputs, but it will do everything I need at the moment. An FT600 would mean I could run wheel speed sensors without an expander box, but that's a "next-phase" item for me along with MK60 ABS. FT450 will not work, it just doesn't have enough inputs for a street car.

I looked at a full custom harness, but modifying the Rywire is less than 1/2 the cost and will carry the bulk of important signals.

I will do my best to document the wiring, it's by far the hardest part of this project for me

I just need to find an affordable AMP Superseal 1.0 crimper, the prices are criminal..

#45

Rotary Enthusiast

Also the smoothing is a sight to behold..

8374 EWG, Bridgeport, FT450. Spool is quite a bit slower than I would expect. E20 pump gas ~95ron, no auxiliary injection.

Last edited by mr2peak; 12-08-22 at 02:10 AM.

#47

Junior Member

Iím trying to setup my fd with the Ft recommended 12 at crank and 24 at cam. But Itís not running right and since there are 12 teeth at crank and 1 tooth for cam Iím wondering if thatís why my car is not running right. Weíre you able to test it?

#48

Where are you seeing 12 and 24 recommended? It should be a 12+1 for the FD - you'll have to fiddle with the crank index position (very important) and cam sync position (way less important, it's used for validation) settings though to get it to be timed properly, I don't recall offhand what the stock trigger wheel is.

Last edited by dguy; 04-19-23 at 07:29 PM.

#49

Just a quick question if anyone can help. I am currently wiring up the FT550 unterminated harness to my FD any I am a bit confused for the 12 Teeth sensor and 1 teeth sensor but correct me if i am wrong. Per their wiring diagram on connector A pin 19 (RPM signal Input) will go to go to the green wire of the 12 teeth connecter then pin 18(RPM Reference Input) will go to the black wire of the 12 teeth connector I just want to make sure that is correct. Then pin 17(cam Sync Signal Input) is what I'm a bit confused about. It is a white wire that has shield wire and the oem connector is red and white looking at the back side of the connecter. So Should the white wire from pin 17 be connected to the white wire of in the oem spot and the shield wire be connected to the red wire. Because I called them and asked them they gave me a bit of a different answer saying i should just ground the red wire to anywhere which was a bit odd but i am new to this type of stuff and their manual on rotaries isn't the best as it only shows ft600 connecter which is completely different . https://files.fueltech.net/manuals/FT450-2_rotores.pdf

#50

Rotary Enthusiast

Yes connect it to the shield. I wasn't using the FT harness so I grounded it to the sensor ground, FT550 B26.

The digram you linked to is for the FT450, doesn't matter for this question but be careful with that stuff.

The digram you linked to is for the FT450, doesn't matter for this question but be careful with that stuff.

The following users liked this post:

Tristen Foret (05-06-23)