Mission May: Complete Twin Turbo FD V8

#1

Mission May: Complete Twin Turbo FD V8

I'm in the middle of making a twin turbo kit for my FD. It currently has a iron block lq9 6.0L which has aluminum heads and uses a manual t56 transmission.

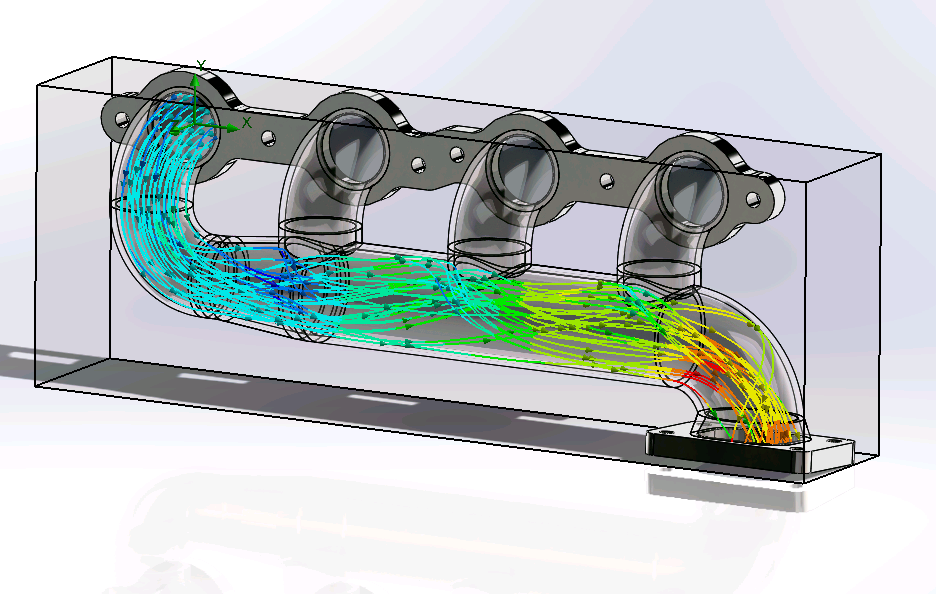

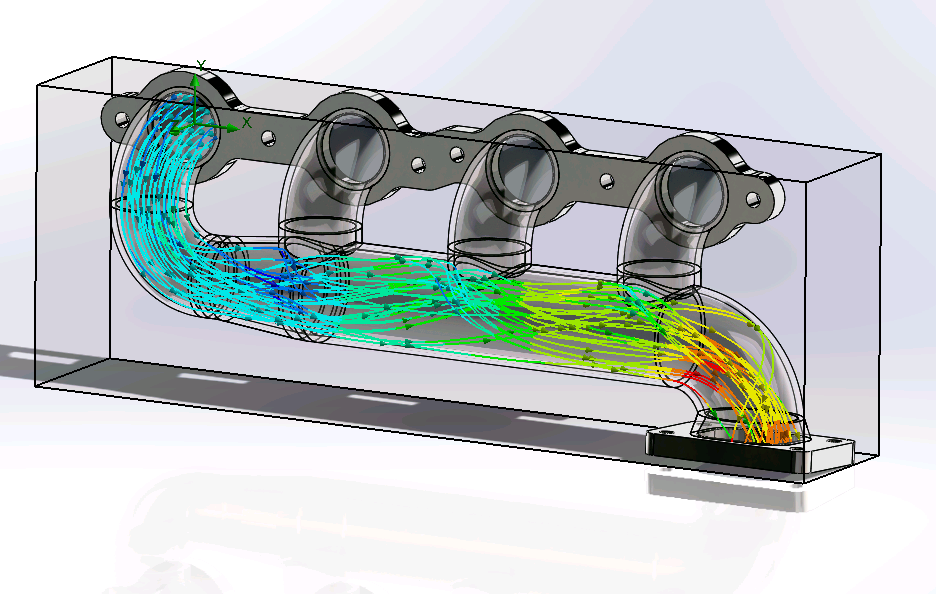

One of the hardest things is turbo placement. I wanted to make manifolds that don't take up much room and don't get in the way of servicing the engine (ie spark plugs). I came up with log style manifolds. Did some flow calculations/simulations, and they would do the job:

It was time to make them physically now. I've made a bunch of manifolds before where I notched the pipes manually, but it was time to speed things up and first make a notching jig for the lathe:

Here are the manifolds coming together and being completed:

One of the hardest things is turbo placement. I wanted to make manifolds that don't take up much room and don't get in the way of servicing the engine (ie spark plugs). I came up with log style manifolds. Did some flow calculations/simulations, and they would do the job:

It was time to make them physically now. I've made a bunch of manifolds before where I notched the pipes manually, but it was time to speed things up and first make a notching jig for the lathe:

Here are the manifolds coming together and being completed:

#3

Here is the intercooler mounted:

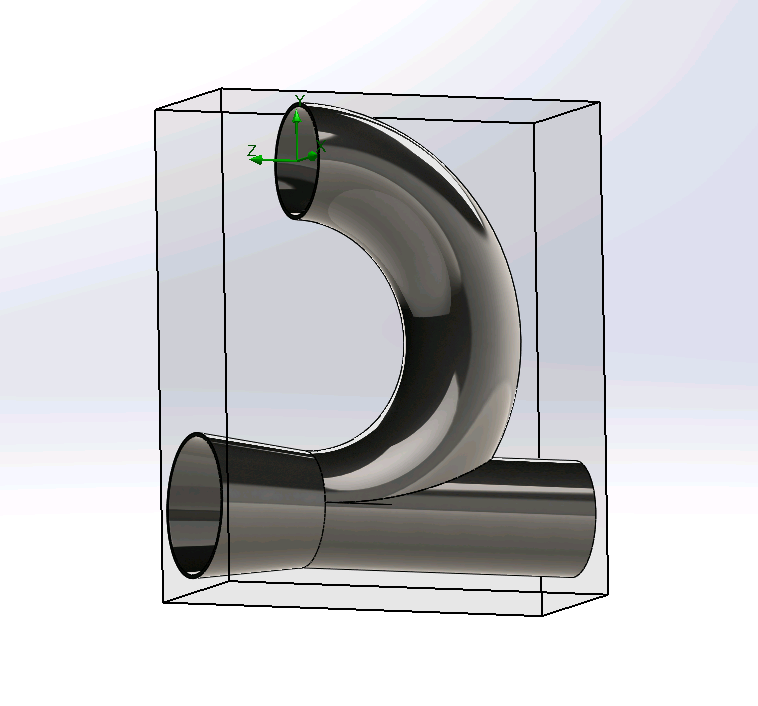

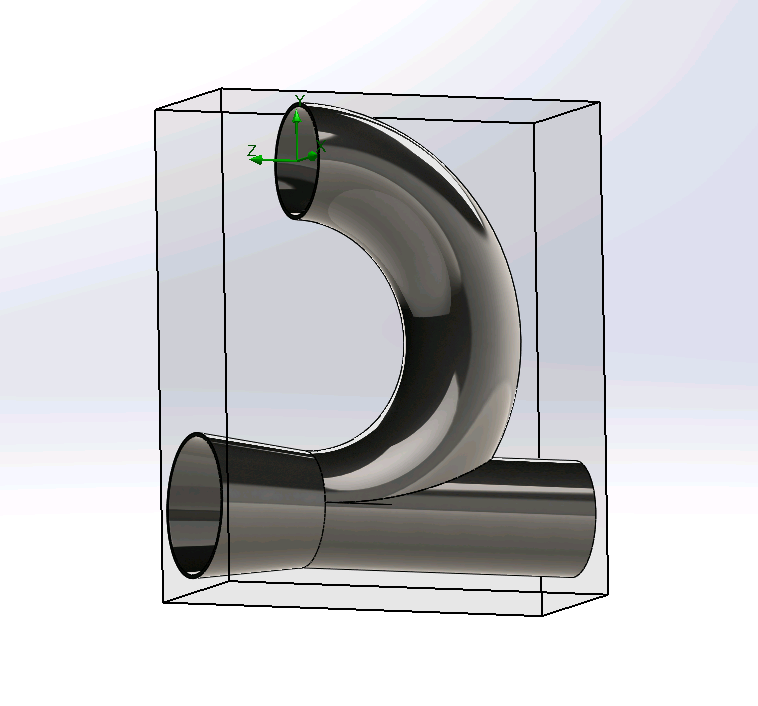

Since I used a single inlet intercooler due to space constraints, I had to make a Y pipe which didn't hinder flow. From my flow calculations/simulation it results in .1 psi drop if the inlets are at 20psi, which isn't too bad.

Here is the hot pipe tacked up:

Here is the cold pipe tacked up:

Since I used a single inlet intercooler due to space constraints, I had to make a Y pipe which didn't hinder flow. From my flow calculations/simulation it results in .1 psi drop if the inlets are at 20psi, which isn't too bad.

Here is the hot pipe tacked up:

Here is the cold pipe tacked up:

#6

i've swapped from rotary to v8 (wow, the wiring was a bitch.),

painted the car myself from scratch (took all of last summer and a crap load of work)

and i've had it for 5 years now

it's not going anywhere -- too much blood, sweat, and tears -- will be passing it on to future kids lol

-- will be passing it on to future kids lol

painted the car myself from scratch (took all of last summer and a crap load of work)

and i've had it for 5 years now

it's not going anywhere -- too much blood, sweat, and tears

-- will be passing it on to future kids lol

-- will be passing it on to future kids lol

Trending Topics

#8

Nice fabrication. I need to learn how to weld. What is the purpose of the car? Drag. I thought the reason to go to V8 was simplicity, dependably. Going turbo complicates things no? I gather by the iron block this is not meant for track.

Post pictures. Always love a build.

Post pictures. Always love a build.

#10

This might make people mad, but just know that this is only my perspective. I didn't stick with the rotary because I think it's a ticking time bomb, because of the shear amount of seals in them that can fail. Some people say "they blow up because of bad tuning" etc, but when you have an atomizer plate break off during cruise driving, that to me is a different problem.

I like the simplicity of the lsx engine. It's an extremely easy engine to work on, rebuild, has a lot more support. To make 700bhp reliably, it is the best platform in my opinion.

#15

i have a lathe, drill presses, plasma cutter, ac/dc tig welder, bead roller, sand blaster, band saw, belt sander.

i'm planning to build a cnc mill this summer after the car is done in may. let me know if you need anything, any time, will be glad to help out the community over the summer when i'm not as busy

#17

High Comp Booster

iTrader: (4)

Join Date: Apr 2009

Location: Oakville, Ontario

Posts: 1,907

Likes: 0

Received 0 Likes

on

0 Posts

that block can make alot more than just 700hp lol

just curious what kind of clutch you're going to have behind it to handle all that torque lol something that will need a vacuum booster like a 300zx? LOL!

just curious what kind of clutch you're going to have behind it to handle all that torque lol something that will need a vacuum booster like a 300zx? LOL!

#18

thanks man!

i have a lathe, drill presses, plasma cutter, ac/dc tig welder, bead roller, sand blaster, band saw, belt sander.

i'm planning to build a cnc mill this summer after the car is done in may. let me know if you need anything, any time, will be glad to help out the community over the summer when i'm not as busy

i have a lathe, drill presses, plasma cutter, ac/dc tig welder, bead roller, sand blaster, band saw, belt sander.

i'm planning to build a cnc mill this summer after the car is done in may. let me know if you need anything, any time, will be glad to help out the community over the summer when i'm not as busy

What no 3D RP? Even the cupcake series to compliment your shop. I'm sure its compatible with SW.

Hope to see the beast this season

#19

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

It looks like you would have had plenty of space to merge each port runner into the main runner at an angle instead of 90 degrees. The flow improvement would have been dramatic. Or am I missing something like spark plug interference?

#22

you can see in this pic if i angle the runners clockwise (which i have to due to turbo placement), i decrease the plug clearance a lot

log manifolds in general are poop as you know already :p i didnt want to go with tubular style manifolds either cause they takes too much damn space and i wasnt aiming for anymore than 700bhp

#23

I was initially going to argue the ticking timebomb comment but your building something your dedicated in. Look forward to seeing it run. Built projects are so much more interesting then buying something that is already built. Looks good so far except for the log manifold but sometimes your forced to make compromises.

thewird

thewird