12a Turbo Project

#26

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

I got an OMP block off plate too, I'll have it installed soon.

Removed all of the hard power steering lines and made a little loop for the 2 wires from the steering box.

I also installed an amp and my subs..

Installed a 2nd gen alternator with a re-speed dual belt pulley.

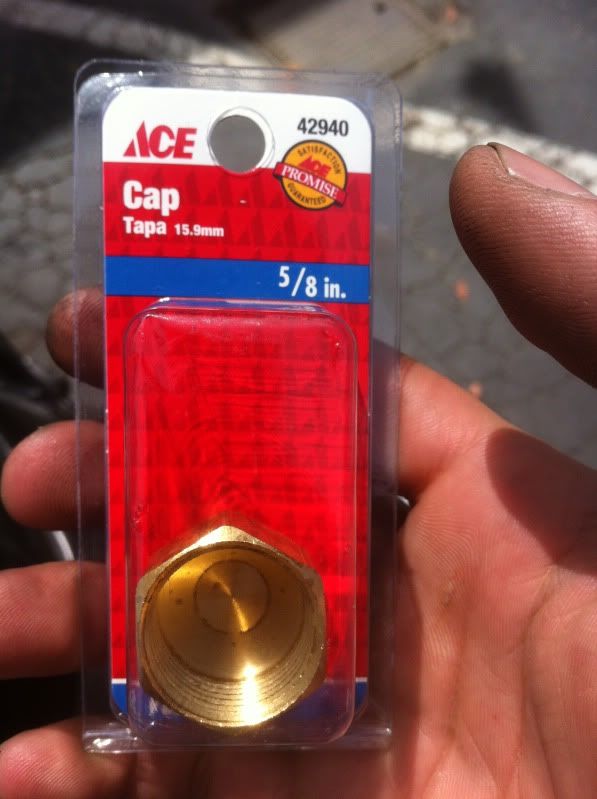

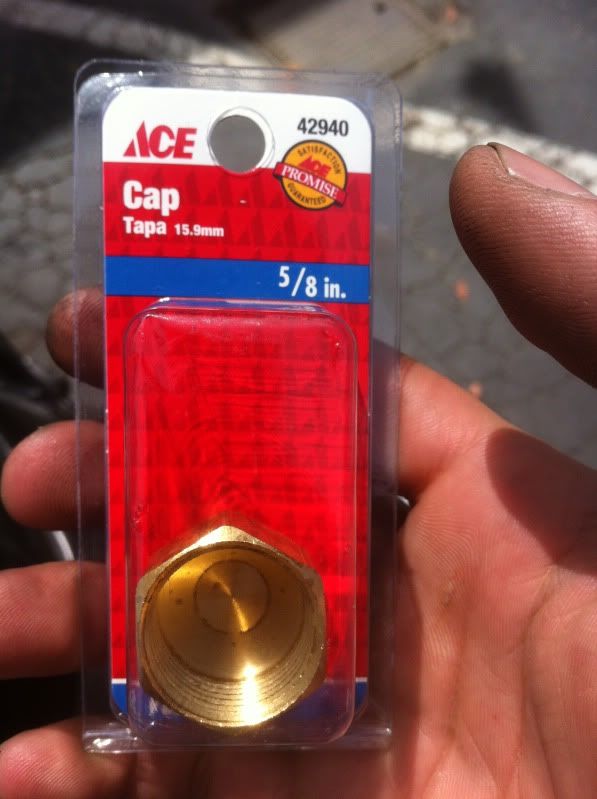

My speedo cable isn't connected and so I capped my transmission with this

because it was leaking a bit.

My oil cooler was missing the mount on the passenger side and I got around to installing another one I had laying around.

Just did an oil change, as well as flushed the transmission fluid and changed the differential fluid.

My waterpump was leaking so I had to replace that as well.

Interior is getting there.

My friend works at a shop and balanced my tires. One of them needed 4 ounces

Removed all of the hard power steering lines and made a little loop for the 2 wires from the steering box.

I also installed an amp and my subs..

Installed a 2nd gen alternator with a re-speed dual belt pulley.

My speedo cable isn't connected and so I capped my transmission with this

because it was leaking a bit.

My oil cooler was missing the mount on the passenger side and I got around to installing another one I had laying around.

Just did an oil change, as well as flushed the transmission fluid and changed the differential fluid.

My waterpump was leaking so I had to replace that as well.

Interior is getting there.

My friend works at a shop and balanced my tires. One of them needed 4 ounces

#27

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

My cat loving the Rx7.

[

Finally did some progress that was worthwhile.

Got a pretty nice find at PickíNíPull, a brown 84 with a TII swap. Walbro 255lph FP, and what looks like some type of relay for it, 2nd gen oil cooler with brackets to mount to subframe, thermostat housing tapped and threaded with coolant sensor, a brown hood, non-cracked stereo surround, downpipe, hard fuel lines under car. Iím probably forgetting some stuff as well.

I also went jdm tyte and installed the crown shift boot. Originally I wanted to repair the stock one. I saw in the JY they had used cable ties to tie it to the broken tabs, but I could too frustrated trying to imitate it.

Thermostat housing

New Oil Cooler

Rx7 getting ready

Motor is out

Racing beat flywheel stopper + Chaining motor to a huge table + standing on motor with breaker bar = Loose flywheel nut

I pulled the oil pan off my old motor and noticed theres a rip in the mesh for the pick up tube. Iím going to buy a new one if I canít repair it.

I bought a racing beat flywheel and need to measure my old one to determine if itís the right size.

I also have removed most brackets and hard lines in the engine bay to get them painted.

I have a question as well. I read some people said using oil pan gaskets leak and to just use RTV. I have a brand new FelPro oil pan gasket. Should I install it with or without RTV, or not use it completely?

[

Finally did some progress that was worthwhile.

Got a pretty nice find at PickíNíPull, a brown 84 with a TII swap. Walbro 255lph FP, and what looks like some type of relay for it, 2nd gen oil cooler with brackets to mount to subframe, thermostat housing tapped and threaded with coolant sensor, a brown hood, non-cracked stereo surround, downpipe, hard fuel lines under car. Iím probably forgetting some stuff as well.

I also went jdm tyte and installed the crown shift boot. Originally I wanted to repair the stock one. I saw in the JY they had used cable ties to tie it to the broken tabs, but I could too frustrated trying to imitate it.

Thermostat housing

New Oil Cooler

Rx7 getting ready

Motor is out

Racing beat flywheel stopper + Chaining motor to a huge table + standing on motor with breaker bar = Loose flywheel nut

I pulled the oil pan off my old motor and noticed theres a rip in the mesh for the pick up tube. Iím going to buy a new one if I canít repair it.

I bought a racing beat flywheel and need to measure my old one to determine if itís the right size.

I also have removed most brackets and hard lines in the engine bay to get them painted.

I have a question as well. I read some people said using oil pan gaskets leak and to just use RTV. I have a brand new FelPro oil pan gasket. Should I install it with or without RTV, or not use it completely?

#29

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

Ordered an oil pickup tube and fc leading coil today.

Going to finish simple greening the engine bay. Possibly re-doing the connectors for the engine harness then shrink tube them.

Now that I have my other motor out I'll start mocking the turbo parts on it to get some ideas.

I wanted to put an old intake manifold/header on the motor then engine degrease/carb cleaner/ hit it with the pressure washer. Would this be okay, anything I should look out for? Besides getting water in exh/int/coolant/oil passages and ports and covering the distributor.

Edit: It's embarrassing having a 6 year old build thread with minimal progress but I love motorcycles and Starcraft and have poor time management. Also I'm about to have a kid so my funding will be dramatically cut, but luckily I stockpiled a fair amount of parts.

#30

Senior Member

Join Date: Sep 2008

Location: Glen Burnie, Maryland

Posts: 543

Likes: 0

Received 0 Likes

on

0 Posts

You should be fine with washin the motor with the stuff installed. Throw some hot water after you soak it in simple green. I would just spray it down with concentrated simple green and let it sit then throw hot water on scrub rinse agian with hot and scrub and wash down with garden hose. But thats just me lol. Some things take time. But in the end im sure it will be worth it

#31

Senior Member

Join Date: Sep 2008

Location: Glen Burnie, Maryland

Posts: 543

Likes: 0

Received 0 Likes

on

0 Posts

The best way i found to get the flywheel nut off was to use a 3/4 impact. Took i think 2 seconds? Lol. Im a lill lucky to know some ppl. And i didnt have the flywheel stopper used to motors compression to keep it still. To get the flywheel off is another story

#32

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

#34

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

Well since I half assed cleaning my engine bay before I figure now that the motor out this is the best time to do it.

Here is the before picture.

Stripped a bolt in the oil pan, and sucessfull got it out with the Ez-Out.

Painted Parts

have my RB alum flywheel mounted, waiting on the kit from RB so I can mount the clutch and PP

Unfortunately I left my clutch and pp sitting together in a somewhat moist environment so the PP and 1 side of the clutch does have surface rust. What should I do to remove it?

Got the Re-Speed pedestal with 2 1/8npt tapped threads for oil press and temp and drilled and tapped another 1/4pt for my oil supply line.

I also re-drilled and tapped the front cover to 3/8npt.

The Fc oil cooler has the thermostat removed and is being cleansed with Brake cleaner and multiple passes of boiling water. Should be mounted to the front subframe tomorrow with all new crush washers.

Here is the before picture.

Stripped a bolt in the oil pan, and sucessfull got it out with the Ez-Out.

Painted Parts

have my RB alum flywheel mounted, waiting on the kit from RB so I can mount the clutch and PP

Unfortunately I left my clutch and pp sitting together in a somewhat moist environment so the PP and 1 side of the clutch does have surface rust. What should I do to remove it?

Got the Re-Speed pedestal with 2 1/8npt tapped threads for oil press and temp and drilled and tapped another 1/4pt for my oil supply line.

I also re-drilled and tapped the front cover to 3/8npt.

The Fc oil cooler has the thermostat removed and is being cleansed with Brake cleaner and multiple passes of boiling water. Should be mounted to the front subframe tomorrow with all new crush washers.

#36

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

I have also heard you can dump in boiling hot water so the thermostat opens and the water goes through it.

#37

vrrmmmmm

Thread Starter

Join Date: Jul 2005

Location: BAY

Posts: 665

Likes: 0

Received 0 Likes

on

0 Posts

Sp'd motor installed

Well I'm doing this in notepad after losing everything I wrote. Chrome crashed when uploading my pics.. My sweet pregnant gf left me this cute *** turtle (i love em) on my motor

I got the SP motor installed with RB alum flywheel, counter-weight, new clutch and PP.

I had to pull the motor once to correct the spacers for the flywheel. I had the washers inbetween the fly/pp as well as the spacers.

Pressure Plate and Clutch were sitting on each other for awhile and had a little surface rust.

Rx Seven, using a 3m abrasive wheel to clean off the clutch and pressure plate. (Thanks pal!) Then re-installed after being cleaned and installed correctly.

Motor looks like it had some damage to the oil pedestal mount. The top left (drivers side closest to fender) threaded hole on the motor was also jbwelded(?) back on and broke off during installation.

Also, the top left (driver side) threads to screw into tranny broke.

A little nervous of the condition of the engine, especially after seeing the waterpump rust.

I changed housings and replaced the WP with a reman I had on my other engine.

Pulling the pilot bearing wasn't too bad, putting it in was cake. Heres my harbor freight tool I used. I had to grind it down, and the 1st one broke, but after having my gf return it I was able to grind it again and pull the bearing out.

Got the 2nd gen oil cooler mounted properly to the subframe. Had to trim radiator mount on left side for lines to fit, I followed trochoid's write-up as a guideline. Here is the oil cooler mounted.

I got my engine bay a lot cleaner as well while the engine was out as well. I wanted to run the wires through the fender, but I had other things to do. I cleaned up the old harness, re-wrapped and put electrical tape on it. It looks a lot better.

I got some Prestone Super Cleaner. (Reads: Ideal for Neglected Cooling Systems) Bingo! Am going to do this tomorrow.

My oilpan is leaking. I didn't check to see if it was flat before installing it... So it's coming off so i can clean and check it. I used a felpro oil pan gasket along with black RTV.

I'm going to try to reinstall it with some hi-temp red rtv. hopefully it will resolve my oil pan leak. ima run some seafoam through the engine oil and vacuum lines before I replace oil pan gasket. Want to clean out this engine and oil cooler pretty well, especially considering I don't know anything about them.

I got the SP motor installed with RB alum flywheel, counter-weight, new clutch and PP.

I had to pull the motor once to correct the spacers for the flywheel. I had the washers inbetween the fly/pp as well as the spacers.

Pressure Plate and Clutch were sitting on each other for awhile and had a little surface rust.

Rx Seven, using a 3m abrasive wheel to clean off the clutch and pressure plate. (Thanks pal!) Then re-installed after being cleaned and installed correctly.

Motor looks like it had some damage to the oil pedestal mount. The top left (drivers side closest to fender) threaded hole on the motor was also jbwelded(?) back on and broke off during installation.

Also, the top left (driver side) threads to screw into tranny broke.

A little nervous of the condition of the engine, especially after seeing the waterpump rust.

I changed housings and replaced the WP with a reman I had on my other engine.

Pulling the pilot bearing wasn't too bad, putting it in was cake. Heres my harbor freight tool I used. I had to grind it down, and the 1st one broke, but after having my gf return it I was able to grind it again and pull the bearing out.

Got the 2nd gen oil cooler mounted properly to the subframe. Had to trim radiator mount on left side for lines to fit, I followed trochoid's write-up as a guideline. Here is the oil cooler mounted.

I got my engine bay a lot cleaner as well while the engine was out as well. I wanted to run the wires through the fender, but I had other things to do. I cleaned up the old harness, re-wrapped and put electrical tape on it. It looks a lot better.

I got some Prestone Super Cleaner. (Reads: Ideal for Neglected Cooling Systems) Bingo! Am going to do this tomorrow.

My oilpan is leaking. I didn't check to see if it was flat before installing it... So it's coming off so i can clean and check it. I used a felpro oil pan gasket along with black RTV.

I'm going to try to reinstall it with some hi-temp red rtv. hopefully it will resolve my oil pan leak. ima run some seafoam through the engine oil and vacuum lines before I replace oil pan gasket. Want to clean out this engine and oil cooler pretty well, especially considering I don't know anything about them.

Thread

Thread Starter

Forum

Replies

Last Post