Finally Going Single! Part 2

#176

The -10 line for both pumps combined should be way more than adequate. If it was too small, you'd probably see a pressure spike and then the pumps would die out or more probably, simply not flow as much as they'd like to (and still hit 40psi no problem).

I'm betting you have some sort of wiring problem.

I'm betting you have some sort of wiring problem.

#177

hmm interesting though. Let us know how it comes out. I'd like to do my wiring like this as well. A seperate fuse for each pump with a led.. thats a great idea. Keep trouble shooting to a bare min. What micron fuel filter are you using? what about your fuel pick-up socks? i've heard of a few collapsing after a time. Also..it may be a good idea to go ahead and change the other 2 plugs. which ones are you using again? I'm going to be ordering the Greddy 6720's 10s leading and 10.5's trailing

#178

@ TwinCharged - What concerned me about that was that I saw a flow capacity chart for 0.5" id fuel line that said max flow was only 72 GPH. However, -10 fuel line has an id of 0.56" which is approximately 125% more than the capacity of 1/2" line for a total of ~88 GPH. I have 2 - 255 Ltr/Hr pumps that each flow 70 GPH @40 psi and ~7.5 Amps, so, according to those numbers, I am adding a lot of restriction on the pumps even without any added restriction in front of the pressure regulator (ie. fuel filter) which is why I think I was blowing the fuse. Simply put, (I think) one pump is using the entire capacity of the fuel line while there is only a little more head room for the second pump which is virtually dead-heading against the other one which puts more of an electrical load on the pumps. Looking at the specs in more detail would suggest that in order to blow a 30 Amp fuse with both pumps running, I would have to have a pressure of ~120 PSI at the pump outlet which creates a load of 15.7 Amps per pump. This also indicates that there is too much restriction in the line, a clogged fuel filter, or both. However, it's just a theory right now. The electrical wiring all checks out just fine. No shorts to ground anywhere in the system. And besides, I have an electrical engineering background so that better not be the problem.

@ mannykiller - I will post an electrical diagram of the wiring as soon as I can get the time to create it. One of my pumps is brand new and the other does have ~5-6 years of sitting in the tank, but only ~1 year of use. When I put the pumps in, the older one still looked brand new, but I will check the sock anyway. As far as the plugs are concerned, I changed all 4 of them the other day just to be sure. They are all B10EGV's. What's odd is the new set, and the old set had a different finish on the metal body which I thought was a little peculiar. The fuel filter is a 10 micron from Summit found here: http://www.summitracing.com/parts/SUM-230116R/

I also have to say that I'm very suspicious of my fuel filter as well simply because I just made all of my fuel lines and I suspect there is still some dust in them from the rubber when I cut the hoses. I tried to flush them out before, but there might still be more in there I suppose. This would also explain the high load on the pumps but the inability to get more than 26 psi at the FPR.

Also, here is the chart for the Walbro 255 Ltr/Hr pumps if anyone would like to check it out for themselves.

http://autoperformanceengineering.com/html/fpspecs.html

@ mannykiller - I will post an electrical diagram of the wiring as soon as I can get the time to create it. One of my pumps is brand new and the other does have ~5-6 years of sitting in the tank, but only ~1 year of use. When I put the pumps in, the older one still looked brand new, but I will check the sock anyway. As far as the plugs are concerned, I changed all 4 of them the other day just to be sure. They are all B10EGV's. What's odd is the new set, and the old set had a different finish on the metal body which I thought was a little peculiar. The fuel filter is a 10 micron from Summit found here: http://www.summitracing.com/parts/SUM-230116R/

I also have to say that I'm very suspicious of my fuel filter as well simply because I just made all of my fuel lines and I suspect there is still some dust in them from the rubber when I cut the hoses. I tried to flush them out before, but there might still be more in there I suppose. This would also explain the high load on the pumps but the inability to get more than 26 psi at the FPR.

Also, here is the chart for the Walbro 255 Ltr/Hr pumps if anyone would like to check it out for themselves.

http://autoperformanceengineering.com/html/fpspecs.html

#179

Cool to see that you did the research, something seems off though. I was using a 450lph pump on the stock 5/16" line with no problems.

I can't remember exactly which pumps you are running, but tons of people use twin 255 lph (walbro and supra) pumps on the stock 5/16" line.

I can't remember exactly which pumps you are running, but tons of people use twin 255 lph (walbro and supra) pumps on the stock 5/16" line.

#180

I agree with you that something seems off because I can't imagine needing more than a -10 line either. I'm hoping someone will see my error and point it out so I can stop thinking about having to spend more $ on the fuel lines. The pumps are the Walbro 255 Ltr/Hr high pressure pumps.

#181

I can't quite remember from my fluids class. but there is something about calculating the capacity of a pipe needing velocity of flow through it. In order to get velocity, I think you can back into it using the pressure, size of pipe, and friction (you can assume 0 for a SS pipe that isn't very long).

Unless you determined velocity and then calculated the flow capacity of the pipe, you might be forgetting to include the effect that pressure has on the flow capacity of the pipe (increases it). This would explain why your calculation is showing a low flow capacity for the pipe, adding pressure into the equation would increase the flow capacity.

Of course, I could be way off here, it's been years since I did a fluids problem.

Unless you determined velocity and then calculated the flow capacity of the pipe, you might be forgetting to include the effect that pressure has on the flow capacity of the pipe (increases it). This would explain why your calculation is showing a low flow capacity for the pipe, adding pressure into the equation would increase the flow capacity.

Of course, I could be way off here, it's been years since I did a fluids problem.

#182

Oh, and if you just looked up the flow capacity of the pipe online, you may have taken the carburated flow numbers, as opposed to fuel injection. Which means the same thing as what I posted above, the significant pressure associated with fuel injection was ignored.

#183

I just found a calculator here: http://www.lmengines.com/fuel_lines_calc that is a great tool for sizing your fuel line. I greatly over estimated on my fuel rail height and line length using the calculator and found that I should only incur a total pressure loss of 2.2 psi in an 18' long -10 fuel line @ 70 gph on 2 pumps. This doesn't account for any fittings, but I think I have plenty of room left over. Whew! I feel better now that I have found some positive information. I'm betting my fuel filter is clogged.

#184

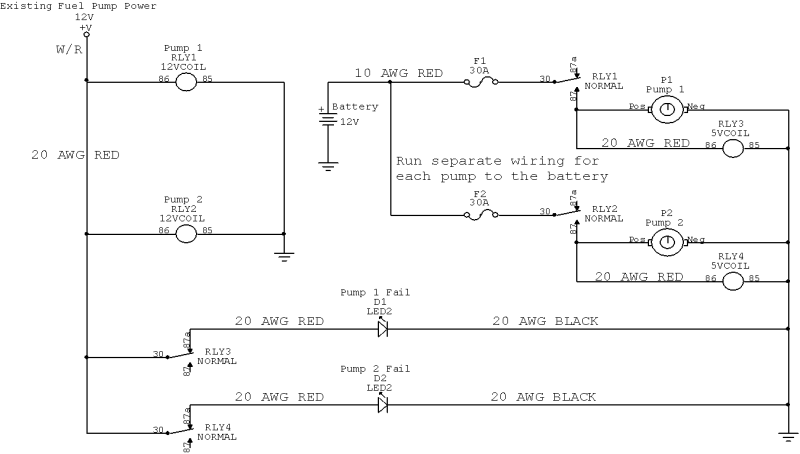

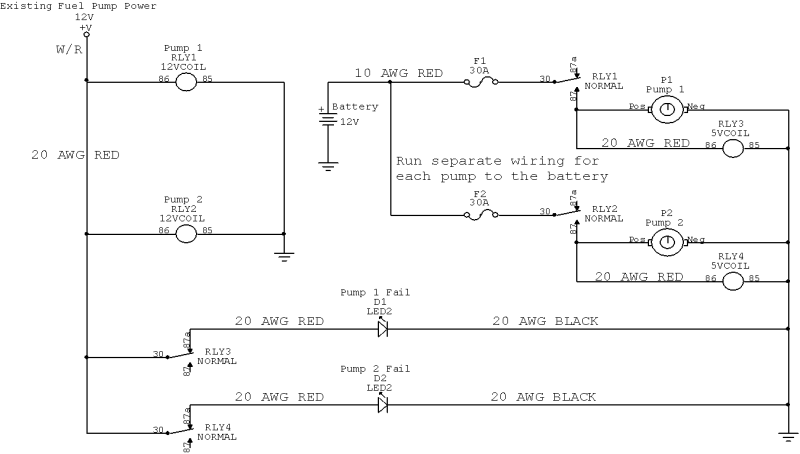

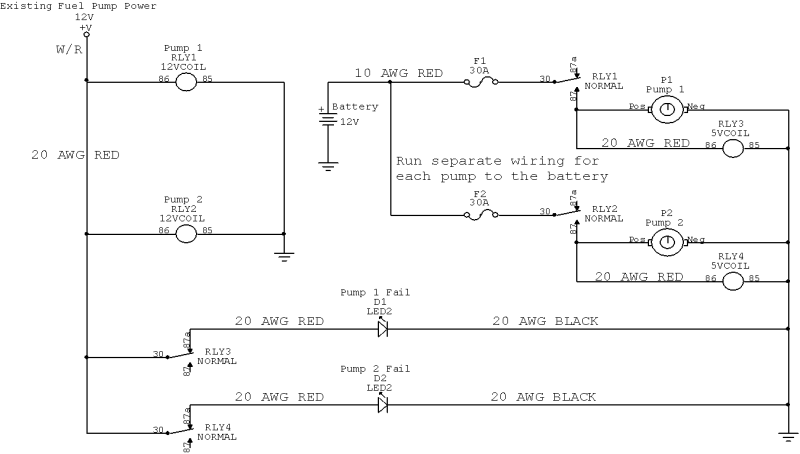

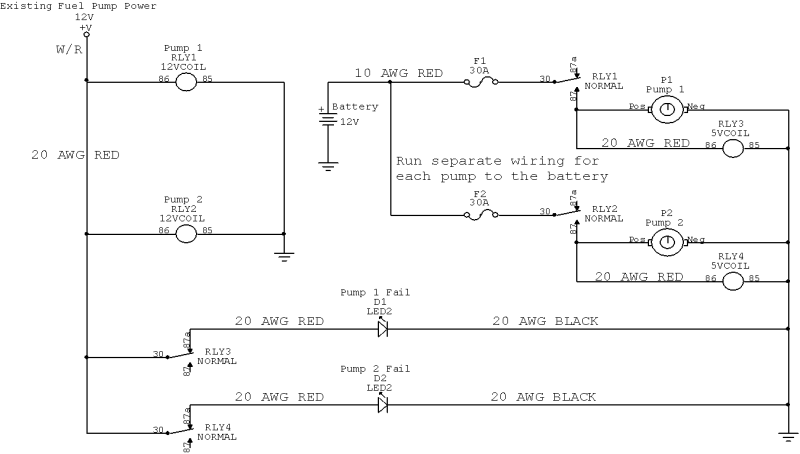

I had a few minutes this afternoon so I threw together a quick schematic for how I plan to rewire my pumps. I had intended to only use 1 relay per pump, however 2 per pump was required in order to have an indicator light to alert me in the event that power is lost to one of the pumps. Originally I was going to use the N/C (87a) contact to provide this signal, but it would require switching the negative leg on the pump using the relay. In that scenario, I would have +12VDC present in the tank at the pump at all times, even when the ignition was off and I didn't really like that idea.

#186

Original Gangster/Rotary!

iTrader: (213)

I also have to say that I'm very suspicious of my fuel filter as well simply because I just made all of my fuel lines and I suspect there is still some dust in them from the rubber when I cut the hoses. I tried to flush them out before, but there might still be more in there I suppose. This would also explain the high load on the pumps but the inability to get more than 26 psi at the FPR.

#188

I'm still waiting on some stuff to rewire my pumps so I spent the day finishing up my catch can. All that's left is to clean it up and polish it, but I'm not going to get into that until the car is running.

My indicator lights showed up this afternoon. I plan to install them in the spot where the cruise control button would go. The only problem is that I need a hole blank to put them in.

My indicator lights showed up this afternoon. I plan to install them in the spot where the cruise control button would go. The only problem is that I need a hole blank to put them in.

#190

I'm not sure just how detailed it will be, but I'll do my best. Here's some links to the parts I'm using If anyone is interested.

40 Amp Relays:

http://www.amazon.com/gp/product/B007IPZXWK

Indicator Lights:

http://www.amazon.com/gp/product/B003TVR28A

10 Gauge Fuse Holders:

http://www.amazon.com/gp/product/B0002KR88A

You can order the LED's in other colors as well.

As soon as my relays show up, I'll get to work on the writeup, but I don't think they'll be here until Monday or Tuesday of next week.

40 Amp Relays:

http://www.amazon.com/gp/product/B007IPZXWK

Indicator Lights:

http://www.amazon.com/gp/product/B003TVR28A

10 Gauge Fuse Holders:

http://www.amazon.com/gp/product/B0002KR88A

You can order the LED's in other colors as well.

As soon as my relays show up, I'll get to work on the writeup, but I don't think they'll be here until Monday or Tuesday of next week.

#191

I did a little prep work tonight since my relays showed up today.

I labeled the relays and their connectors.

...and crimped the 10 gauge wire to the inline fuse holders.

secured together with some heat shrink.

I also removed the old wiring from the connector on the fuel pumps but I didn't think that justified a picture.

I labeled the relays and their connectors.

...and crimped the 10 gauge wire to the inline fuse holders.

secured together with some heat shrink.

I also removed the old wiring from the connector on the fuel pumps but I didn't think that justified a picture.

#192

I woke up wide awake at 2am last night and it suddenly occurred to me that I set my fuel pressure incorrectly. When I set my base pressure to 40psi, I didn't remove the vacuum line from the regulator. I hate stupid mistakes. Especially ones that I have to wake up at 2am to figure out.

#194

@ mannykiller, Here's the write up (just for you)  https://www.rx7club.com/showthread.p...6#post11092176

https://www.rx7club.com/showthread.p...6#post11092176

It's late, so I hope I didn't make too many errors in it. Now that I've got it done, I found that I definitely have an issue with my pump #2. It blows the fuse as soon as the key is turned on. I'm thinking that pump #2 is locked up and all of the flow from pump #1 is pushing right back into the tank through pump #2 which is why I am unable to build any pressure. I guess I should have installed a check valve on each pump outlet to prevent this from happening. Tomorrow I'll disconnect pump #2's outlet and cap it off to see if I can build sufficient pressure or not using only pump #1.

Also, here's the latest schematic which is also in the write up:

https://www.rx7club.com/showthread.p...6#post11092176

https://www.rx7club.com/showthread.p...6#post11092176It's late, so I hope I didn't make too many errors in it. Now that I've got it done, I found that I definitely have an issue with my pump #2. It blows the fuse as soon as the key is turned on. I'm thinking that pump #2 is locked up and all of the flow from pump #1 is pushing right back into the tank through pump #2 which is why I am unable to build any pressure. I guess I should have installed a check valve on each pump outlet to prevent this from happening. Tomorrow I'll disconnect pump #2's outlet and cap it off to see if I can build sufficient pressure or not using only pump #1.

Also, here's the latest schematic which is also in the write up:

#195

I pulled the pumps out of the tank this morning and found out that pump #1 is definitely bad. I checked and rechecked the wiring several times to be certain and then capped the lines and powered up the pumps one at at time to identify which one was bad. Pump #1 blew the fuse right away, so I moved pump #1's connector over to pump #2 to see if it would power the other pump without blowing the fuse and it powered right up. Next, I used pump #2's wiring on pump #1 to see if it would blow the fuse as expected, and it did. This isolates pump #1 as the problem.

I also discovered that the reason I am unable to build any fuel pressure is because there isn't any fuel in the damn tank (an idiot move on my part once again). I thought I had fuel because the gauge was showing I had 3/4 of a tank, but I apparently got my pins crossed on the fuel sending unit when I inserted them into the bulkhead connector on the inside of the tank.

A new fuel pump on now on the way, so I should be back in business soon!

I also discovered that the reason I am unable to build any fuel pressure is because there isn't any fuel in the damn tank (an idiot move on my part once again). I thought I had fuel because the gauge was showing I had 3/4 of a tank, but I apparently got my pins crossed on the fuel sending unit when I inserted them into the bulkhead connector on the inside of the tank.

A new fuel pump on now on the way, so I should be back in business soon!

#196

I filled up the tank with 5 fresh gallons of premix this afternoon and isolated pump #1 so that I could continue tuning until the new pump arrives. However, after firing it up, I'm back to my old issue of not getting any ignition on the front rotor. Tomorrow afternoon I'll remove the UIM to get full access to the coils and give them a complete checkout.

#198

"Heard single turbo is better then twin? that correct? My fd is my first twin turbo car, had a single turbo 98 GS300 NA-T. "

It all depends on what you want out of your car. If you're looking for really big HP numbers, single is the way to go. If you're looking for nice smooth power all the way up through the RPM's, staying with the twins might be better, but I'm no expert in the subject by any means. If you want to simplify things and reduce the potential for spending your weekends troubleshooting a boost issue due to a faulty solenoid, or a vacuum leak, go single. Someone else may want to elaborate, but that is the basics as far as I know. Personally, I wanted to simplify the mess under the hood and achieve HP levels that can not be attained on the stock twins.

It all depends on what you want out of your car. If you're looking for really big HP numbers, single is the way to go. If you're looking for nice smooth power all the way up through the RPM's, staying with the twins might be better, but I'm no expert in the subject by any means. If you want to simplify things and reduce the potential for spending your weekends troubleshooting a boost issue due to a faulty solenoid, or a vacuum leak, go single. Someone else may want to elaborate, but that is the basics as far as I know. Personally, I wanted to simplify the mess under the hood and achieve HP levels that can not be attained on the stock twins.

#199

"Heard single turbo is better then twin? that correct? My fd is my first twin turbo car, had a single turbo 98 GS300 NA-T. "

It all depends on what you want out of your car. If you're looking for really big HP numbers, single is the way to go. If you're looking for nice smooth power all the way up through the RPM's, staying with the twins might be better, but I'm no expert in the subject by any means. If you want to simplify things and reduce the potential for spending your weekends troubleshooting a boost issue due to a faulty solenoid, or a vacuum leak, go single. Someone else may want to elaborate, but that is the basics as far as I know. Personally, I wanted to simplify the mess under the hood and achieve HP levels that can not be attained on the stock twins.

It all depends on what you want out of your car. If you're looking for really big HP numbers, single is the way to go. If you're looking for nice smooth power all the way up through the RPM's, staying with the twins might be better, but I'm no expert in the subject by any means. If you want to simplify things and reduce the potential for spending your weekends troubleshooting a boost issue due to a faulty solenoid, or a vacuum leak, go single. Someone else may want to elaborate, but that is the basics as far as I know. Personally, I wanted to simplify the mess under the hood and achieve HP levels that can not be attained on the stock twins.

#200

All of my coils check out, but I decided to relocate them to the driver's side frame rail. After I jacked up the car I saw this coming out of the wastegate:

Then I looked up at the turbo and noticed that there is oil coming off of the flange as well. WTF! There's only about 40 miles on this thing so far and NO boost!

Then I looked up at the turbo and noticed that there is oil coming off of the flange as well. WTF! There's only about 40 miles on this thing so far and NO boost!