Nozzle vs AIT sensor placement on water only setup

#1

Nozzle vs AIT sensor placement on water only setup

I know, I know, it's been discussed before, but during a search I couldn't really find the definitive answer I was looking for.

My car/setup: Stock twins, stock ports, PFC, PFS SMIC, 14psi, 328whp. I will be running a very basic WI system...old school, comes on at x-psi with a single nozzle and motor speed (running a M5 nozzle) I will not be "tuning up" for it. I am merely looking for the added knock resistance, cleaning benefits, as well as hoping to curb some of the increasing intake temps I see during 20-30 minute track sessions during the summer.

I'm running a efini tb elbow on the car (like stock but metal) and plan on putting my WI nozzle there. I'm currently running the AIT in the stock location but it's been on my hit-list to move it so I figure this is a good time.

My question is should I put the AIT before or after the nozzle? How far apart should they be? The way I figure it I have a few options

option 1: leave the AIT sensor in its stock location and install the nozzle in the "big bend" portion of the elbow just before the throttle body. The downside to this is I still have the issue of heat soak on the AIT after parking the car and when first driving. The upside is it's simple and easy.

option 2: Move the AIT to the "big bend" portion of the elbow and place the nozzle as far toward the intercooler as reasonably possible in order to give as much space between the two as can be had. The upside to this is all the benefits of the moved AIT with more accurate readings and less heatsoak. Some people believe that this will also more accurately reflect AITs when I'm injecting water if there is any reduction in temps (notice I'm really looking for them to just stop rising). Possible downsides: Does the water kill/hurt the AIT over time? What about if I follow Chuck's advice of "sanding" down the AIT for more accurate change readings?

option 3: Place the AIT shortly before the nozzle and place them both somewhere in the elbow. I was figuring the "big bend" area as it has the most space. The theory here is that it'd give me accurate AIT readings and not have the nozzle affect the sensor in any way....however am I really getting accurate readings if it's not taking into account any way for the injectant?

Sorry for the long complicated post guys, feel free to offer comments/advice or other options you see as fit.

My car/setup: Stock twins, stock ports, PFC, PFS SMIC, 14psi, 328whp. I will be running a very basic WI system...old school, comes on at x-psi with a single nozzle and motor speed (running a M5 nozzle) I will not be "tuning up" for it. I am merely looking for the added knock resistance, cleaning benefits, as well as hoping to curb some of the increasing intake temps I see during 20-30 minute track sessions during the summer.

I'm running a efini tb elbow on the car (like stock but metal) and plan on putting my WI nozzle there. I'm currently running the AIT in the stock location but it's been on my hit-list to move it so I figure this is a good time.

My question is should I put the AIT before or after the nozzle? How far apart should they be? The way I figure it I have a few options

option 1: leave the AIT sensor in its stock location and install the nozzle in the "big bend" portion of the elbow just before the throttle body. The downside to this is I still have the issue of heat soak on the AIT after parking the car and when first driving. The upside is it's simple and easy.

option 2: Move the AIT to the "big bend" portion of the elbow and place the nozzle as far toward the intercooler as reasonably possible in order to give as much space between the two as can be had. The upside to this is all the benefits of the moved AIT with more accurate readings and less heatsoak. Some people believe that this will also more accurately reflect AITs when I'm injecting water if there is any reduction in temps (notice I'm really looking for them to just stop rising). Possible downsides: Does the water kill/hurt the AIT over time? What about if I follow Chuck's advice of "sanding" down the AIT for more accurate change readings?

option 3: Place the AIT shortly before the nozzle and place them both somewhere in the elbow. I was figuring the "big bend" area as it has the most space. The theory here is that it'd give me accurate AIT readings and not have the nozzle affect the sensor in any way....however am I really getting accurate readings if it's not taking into account any way for the injectant?

Sorry for the long complicated post guys, feel free to offer comments/advice or other options you see as fit.

#2

I believe HC has the AIT sensor right after the IC while the nozzles are installed before the throttle plates. AIT will pickup Air temps before water injection and you can just modify the PFC air temp correction maps.

I plan on doing the same, except that I have both pre-turbo and pre-throttle injection.

I plan on doing the same, except that I have both pre-turbo and pre-throttle injection.

#3

I know howard subscribes to the theory of putting the sensor ahead (airflow-wise) of the nozzle.

I guess my thoughts were that having the AIT sensor after the nozzle is that I'd actually be able to tell if the WI was helping me curb my intake temp increases....perhaps I'm wrong on that? . If I do that will it destroy the sensor? Does it take the sensor a while to "dry" out after an injection event, and in the meantime it would give a wrong reading?

. If I do that will it destroy the sensor? Does it take the sensor a while to "dry" out after an injection event, and in the meantime it would give a wrong reading?

I guess my thoughts were that having the AIT sensor after the nozzle is that I'd actually be able to tell if the WI was helping me curb my intake temp increases....perhaps I'm wrong on that?

. If I do that will it destroy the sensor? Does it take the sensor a while to "dry" out after an injection event, and in the meantime it would give a wrong reading?

. If I do that will it destroy the sensor? Does it take the sensor a while to "dry" out after an injection event, and in the meantime it would give a wrong reading?

#4

I doubt water could hurt the sensor, its coated in a couple mm of plastic. and even if you strip the plastic there is still some sort of epoxy holding it together.

IMO on a water only setup you shouldnt have to adjust the tune at all, so i would put the AIT sensor first and the nozzle second.

IMO on a water only setup you shouldnt have to adjust the tune at all, so i would put the AIT sensor first and the nozzle second.

#5

Bosozoomku

iTrader: (10)

Join Date: Oct 2008

Location: Seattle, WA

Posts: 632

Likes: 0

Received 0 Likes

on

0 Posts

I'm working on a very similar setup, too: on/off pump at peak torque. I'm really not sure that the water will cool the air charge very much, so I was planning on basically option 1. Good luck!

#6

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

I'm pretty sure running straight water post-turbo won't do much for air charge cooling, but it will help lower EGT's and more importantly reduce pre-ignition. But, running small jets of water pre-turbo does help reduce IAT's, and gives the same benefits of post-turbo. Only problem is the theory that water will slowly destroy your compressor blade. I've yet to see some solid proof of it doing so, although I'm sure it's out there. Trick is to get a good enough WI system to finely mist it, along the lines of Rice Racing.

#7

I decided a while back that I'm not going to run pre-turbo. I see benefits to those systems, but it's not what I'm looking to do, so my choice will definitely be post intercooler.

I also wondered yesterday "am I over-thinking this?" Even if I place the sensor post nozzle by about 5 inches in the elbow, would it even react enough to make a difference?

I also wondered yesterday "am I over-thinking this?" Even if I place the sensor post nozzle by about 5 inches in the elbow, would it even react enough to make a difference?

Trending Topics

#8

bump for any more input/advice/experience.

At this point I'm leaning toward installing the kit without moving the AIT sensor until later when I do my turbos....so it'd be an option 1 with a later migration to option 3 when I have everything apart again.

At this point I'm leaning toward installing the kit without moving the AIT sensor until later when I do my turbos....so it'd be an option 1 with a later migration to option 3 when I have everything apart again.

#9

Racing Rotary Since 1983

iTrader: (6)

i suggest the temp sensor be pre water.

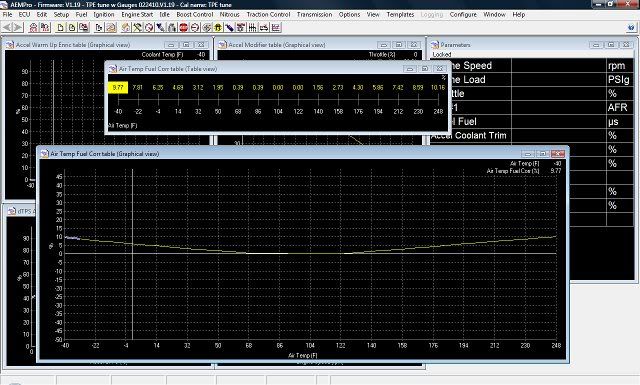

if you do it after the water you will need to adjust temp Corrections table which is less accurate in adj than the base fuel table.

hc

if you do it after the water you will need to adjust temp Corrections table which is less accurate in adj than the base fuel table.

hc

#10

thanks for you input howard.

Anyone have ideas for nozzle placement for my elbow? Would it be best to place it close to the throttle body so that it can be as evenly sprayed at the 3 plates as much as possible? Or would it be better to put it as far away as possible to have it mix with the air longer in an attempt at a better mix before entering the TB?

Also, I had planned on mounting the nozzle on the underside of the elbow, but is other placement better? Would it be better to have it on the outside bend of the elbow and pointing at the TB?

sorry for so many questions.

Anyone have ideas for nozzle placement for my elbow? Would it be best to place it close to the throttle body so that it can be as evenly sprayed at the 3 plates as much as possible? Or would it be better to put it as far away as possible to have it mix with the air longer in an attempt at a better mix before entering the TB?

Also, I had planned on mounting the nozzle on the underside of the elbow, but is other placement better? Would it be better to have it on the outside bend of the elbow and pointing at the TB?

sorry for so many questions.

#11

Racing Rotary Since 1983

iTrader: (6)

one nozzle:

best placement at 4:30 looking at the upstream opening of the elbow.

that way you bias against the 90 degree turn and bias toward the upper secondary butterflies.

two nozzles:

3 oclock and 6 oclock

location:

either in the silicone coupler just in front of the elbow or in the first 2 longitudinal

inches from the upstream start of the elbow.

hc

best placement at 4:30 looking at the upstream opening of the elbow.

that way you bias against the 90 degree turn and bias toward the upper secondary butterflies.

two nozzles:

3 oclock and 6 oclock

location:

either in the silicone coupler just in front of the elbow or in the first 2 longitudinal

inches from the upstream start of the elbow.

hc

Last edited by Howard Coleman; 04-01-09 at 10:49 AM.

#12

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

Howard, didn't Brian see slightly better results when running the 2 nozzles in series w/ same orientation as opposed to two at the same location clocked differently?

And I'm still not sure that water will reduce your AIT's enough to need to adjust the correction tables any, with only 1 small-ish nozzle post-compressor. I think your main benefit will be knock deterrent.

And I'm still not sure that water will reduce your AIT's enough to need to adjust the correction tables any, with only 1 small-ish nozzle post-compressor. I think your main benefit will be knock deterrent.

#13

Racing Rotary Since 1983

iTrader: (6)

Brian found that, w methnol, by moving his two nozzles farther upstream, about a foot, his performance was significantly improved.

water of course will yield significantly less charge air cooling and delivers more in the combustion chamber.

water will change your charge air temps to the point your air temp correction table will be a factor.

hc

water of course will yield significantly less charge air cooling and delivers more in the combustion chamber.

water will change your charge air temps to the point your air temp correction table will be a factor.

hc

#14

one nozzle:

best placement at 4:30 looking at the upstream opening of the elbow.

that way you bias against the 90 degree turn and bias toward the upper secondary butterflies.

location:

either in the silicone coupler just in front of the elbow or in the first 2 longitudinal

inches from the upstream start of the elbow.

hc

best placement at 4:30 looking at the upstream opening of the elbow.

that way you bias against the 90 degree turn and bias toward the upper secondary butterflies.

location:

either in the silicone coupler just in front of the elbow or in the first 2 longitudinal

inches from the upstream start of the elbow.

hc

Also, do you think there's benefit to going further toward the throttle body as far as longitudinal mounting so that I'm spraying into a bigger diameter pipe? I was thinking this would help against pooling on the pipe walls? Is there any worth in the idea of placing it basically right before the throttle body so as to take the bend in the elbow out of the equation?

You can feel free to tell me I'm over-thinking this....just taking advantage of the help while I can get it.

#17

Thanks again for your input howard. Just so I can make sure I'm correct you're saying I'd bias the nozzle toward the driver's side fender....which should shoot the spray upward and toward the inside of the bend of the elbow?

Also, do you think there's benefit to going further toward the throttle body as far as longitudinal mounting so that I'm spraying into a bigger diameter pipe? I was thinking this would help against pooling on the pipe walls? Is there any worth in the idea of placing it basically right before the throttle body so as to take the bend in the elbow out of the equation?

You can feel free to tell me I'm over-thinking this....just taking advantage of the help while I can get it.

Also, do you think there's benefit to going further toward the throttle body as far as longitudinal mounting so that I'm spraying into a bigger diameter pipe? I was thinking this would help against pooling on the pipe walls? Is there any worth in the idea of placing it basically right before the throttle body so as to take the bend in the elbow out of the equation?

You can feel free to tell me I'm over-thinking this....just taking advantage of the help while I can get it.

#18

another question. Is the M5 nozzle going to be too big for my setup? I orignally thought something more like a M4 would be perfect for what I wanted, but for some reason coolingmist only sells M3 and M5 nozzles

I do not intend on "tuning up" for the water.

I do not intend on "tuning up" for the water.

#19

4th string e-armchair QB

iTrader: (11)

Join Date: May 2005

Location: North Bay, Ontario

Posts: 2,745

Likes: 0

Received 0 Likes

on

0 Posts

you don't need to "tune" for water, it's not a fuel. It's a displacement adder. It's like cruising and the EGR coming on, only difference being it lowers combustion temperatures.

And no, one M5 (about 315cc) of water shouldn't cause any problems, Classicauto was injecting upwards of 500+cc's of water without any problems. If anything, you'd have problems with ignition.

And no, one M5 (about 315cc) of water shouldn't cause any problems, Classicauto was injecting upwards of 500+cc's of water without any problems. If anything, you'd have problems with ignition.

#21

you don't need to "tune" for water, it's not a fuel. It's a displacement adder. It's like cruising and the EGR coming on, only difference being it lowers combustion temperatures.

And no, one M5 (about 315cc) of water shouldn't cause any problems, Classicauto was injecting upwards of 500+cc's of water without any problems. If anything, you'd have problems with ignition.

And no, one M5 (about 315cc) of water shouldn't cause any problems, Classicauto was injecting upwards of 500+cc's of water without any problems. If anything, you'd have problems with ignition.

I guess at this point I'm just going to go ahead with the install, and if I get quench then I'll go to a M3 nozzle. Thanks for the input as always.

#22

interesting that they dont sell m4... when I ordered my kit I had them send me 2 M2 with a tee.

They do sell most other sizes though, M1, M2, M3, M5, M10 and two others with no specific ID, 0.75 and 9 GPH both rated at 150psi for their outside thread nozzles and they have other sizes in inside thread nozzles.

They do sell most other sizes though, M1, M2, M3, M5, M10 and two others with no specific ID, 0.75 and 9 GPH both rated at 150psi for their outside thread nozzles and they have other sizes in inside thread nozzles.

#23

Bosozoomku

iTrader: (10)

Join Date: Oct 2008

Location: Seattle, WA

Posts: 632

Likes: 0

Received 0 Likes

on

0 Posts

Brian found that, w methnol, by moving his two nozzles farther upstream, about a foot, his performance was significantly improved.

water of course will yield significantly less charge air cooling and delivers more in the combustion chamber.

water will change your charge air temps to the point your air temp correction table will be a factor.

hc

water of course will yield significantly less charge air cooling and delivers more in the combustion chamber.

water will change your charge air temps to the point your air temp correction table will be a factor.

hc

#24

I'm struggling with the engineering argument also. I believe HC's point is that by having the ECU ignore the cooling effect of the water/Meth (by mounting the AIT sensor upstream of the AI point) you are not adding extra fuel due to the charge density increase. The power gain due to WI is entirely due to your ability to run higher boost levels. No fuel or ignition map compensation will be done.

My problem is that while the intake charge is only moderately cooler (and therefore denser) due to water, using Methanol does reduce the charge temp significantly. This means, if uncorrected, you are running richer with meth. At least using AIT after the injector, your ECU knows the actual charge temp and corrects the mixture lambda.

All this is probably small potatoes compared to ignoring the ignition timing benefit of meth/water. It's the AIT correction to the ignition timing map that is being lost due to ignoring the temp drop of the meth/water mix. Why would you want to ignore this? Is it really that inconsequential?

My problem is that while the intake charge is only moderately cooler (and therefore denser) due to water, using Methanol does reduce the charge temp significantly. This means, if uncorrected, you are running richer with meth. At least using AIT after the injector, your ECU knows the actual charge temp and corrects the mixture lambda.

All this is probably small potatoes compared to ignoring the ignition timing benefit of meth/water. It's the AIT correction to the ignition timing map that is being lost due to ignoring the temp drop of the meth/water mix. Why would you want to ignore this? Is it really that inconsequential?