An Idea I had as of why pre-turbo water injection works so well

#1

Not only because it changes the compressor map due to aproaching isothermal compression but I was thinking that it may even help increase intecooler efficiency because water is better at rejecting heat than air.

So as it passes thru the intercooler it rejects more heat than air alone and thus cools itself again so that it still works inside the combustion chamber cooling hot spots, slowing down combustion and performing work as it expands as steam...

what do you think?

So as it passes thru the intercooler it rejects more heat than air alone and thus cools itself again so that it still works inside the combustion chamber cooling hot spots, slowing down combustion and performing work as it expands as steam...

what do you think?

#6

Did you try comparing AIT with WI with AIT w/o WI?

Next, did you try with no WI at the elbow and compare AIT w/ and w/o pre-comp WI?

As for your theory, I am not so sure it would be the case.

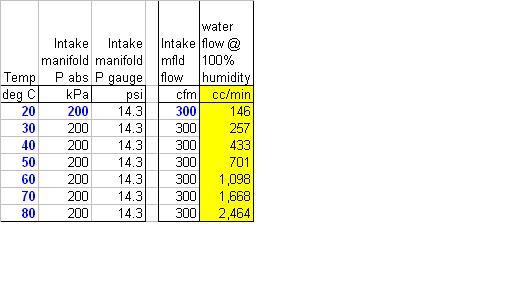

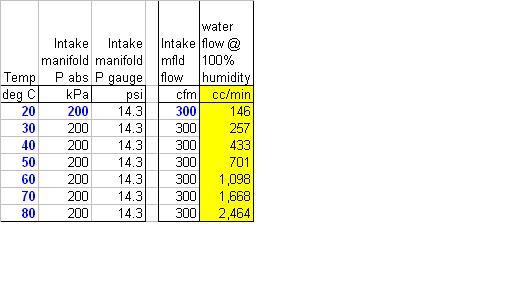

You are injecting only 175 cc/min pre-com. All your water may have evaporated while inside the compressors. See table below. Even with modest 300 cfm air-vapor mixture,

you would need complete evaporation of some 700 cc/min to get 100% humidity at 50 C. If all water has evaporated, there is no more latent heat of evaporation available to contribute cooldown inside the IC.

Conversely, at higher injection flow and higher humidity (again, assuming that all water has evaporated inside the compressor, which is a big IF), the IC could actual work less than optimal.

If you assume 100% humidity at the IC inlet, some of the water vapor would actually condense inside the IC as a result of temperature decreasing. In such case latent heat would be released inside the IC, causing additional heat to be removed by the IC.

- Sandro

Next, did you try with no WI at the elbow and compare AIT w/ and w/o pre-comp WI?

As for your theory, I am not so sure it would be the case.

You are injecting only 175 cc/min pre-com. All your water may have evaporated while inside the compressors. See table below. Even with modest 300 cfm air-vapor mixture,

you would need complete evaporation of some 700 cc/min to get 100% humidity at 50 C. If all water has evaporated, there is no more latent heat of evaporation available to contribute cooldown inside the IC.

Conversely, at higher injection flow and higher humidity (again, assuming that all water has evaporated inside the compressor, which is a big IF), the IC could actual work less than optimal.

If you assume 100% humidity at the IC inlet, some of the water vapor would actually condense inside the IC as a result of temperature decreasing. In such case latent heat would be released inside the IC, causing additional heat to be removed by the IC.

- Sandro

#7

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

http://www.not2fast.com/turbo/glossary/turbo_calc.shtml

This calculator allows change many variables of turbo system, also position of water injection. It clearly indicates that locating WI between turbo and IC is worst in all cases, Pre-compressor best for non-intercooled setup and WI placed last should be best in intercooled setup.

Also there are nice charts similar to what Sandro made...

http://www.not2fast.com/thermo/water...opt_mass.shtml

This calculator allows change many variables of turbo system, also position of water injection. It clearly indicates that locating WI between turbo and IC is worst in all cases, Pre-compressor best for non-intercooled setup and WI placed last should be best in intercooled setup.

Also there are nice charts similar to what Sandro made...

http://www.not2fast.com/thermo/water...opt_mass.shtml

Trending Topics

#8

Be careful when using that calculator. As clearly indicated by the author, the simplified assumption of the calculator is that all water injected vaporizes up to saturation (which is capped up by the saturation pressure of water, which is dependent on temperature only) and that the entire heat of vaporization is "extracted" from the air flow. That is clearly a stretch especially if WI is at the manifold. All members have been reporting that they don't see any change in AIT from WI in that location. The model is not realistic in this case and the worst score of the TC->WI->IC combination is due just to that. The best location for achieving vaporization is pre-compressor, as the compressor should act as a good evapoarator/humidifier. However, even with that the reports from members are ambiguous. Some have reported AIT drops, others have not. There are too many interactions at play, which are very difficult to model. First, it remains to be seen how much cooldown you can achieve in the compressor. In order to find this out you need to have temperature readings and compare that with ambient air temperature. Then you can give some thoughts about the IC. For instance, if pre-com water injection can indeed make the compression isothermal (Temp out of compressor = T amb), then clearly you don't really need an IC. If not, an IC should still be valuable. Although, if the humidity approaches 100% at the exit of the compressor, as you cool down the air-water vapor mixture inside the IC, some of the vapor would condense and reduce the efficiency of the IC (because there would be the additional thermal load from the negative latent heat of vaporization)

- Sandro

- Sandro

#9

Senior Member

Join Date: Nov 2008

Location: Czech republic

Posts: 357

Likes: 0

Received 0 Likes

on

0 Posts

Be careful when using that calculator. As clearly indicated by the author, the simplified assumption of the calculator is that all water injected vaporizes up to saturation (which is capped up by the saturation pressure of water, which is dependent on temperature only) and that the entire heat of vaporization is "extracted" from the air flow. That is clearly a stretch especially if WI is at the manifold. All members have been reporting that they don't see any change in AIT from WI in that location. The model is not realistic in this case and the worst score of the TC->WI->IC combination is due just to that. The best location for achieving vaporization is pre-compressor, as the compressor should act as a good evapoarator/humidifier. However, even with that the reports from members are ambiguous. Some have reported AIT drops, others have not. There are too many interactions at play, which are very difficult to model. First, it remains to be seen how much cooldown you can achieve in the compressor. In order to find this out you need to have temperature readings and compare that with ambient air temperature. Then you can give some thoughts about the IC. For instance, if pre-com water injection can indeed make the compression isothermal (Temp out of compressor = T amb), then clearly you don't really need an IC. If not, an IC should still be valuable. Although, if the humidity approaches 100% at the exit of the compressor, as you cool down the air-water vapor mixture inside the IC, some of the vapor would condense and reduce the efficiency of the IC (because there would be the additional thermal load from the negative latent heat of vaporization)

- Sandro

- Sandro

#10

Did you try comparing AIT with WI with AIT w/o WI?

Next, did you try with no WI at the elbow and compare AIT w/ and w/o pre-comp WI?

Conversely, at higher injection flow and higher humidity (again, assuming that all water has evaporated inside the compressor, which is a big IF), the IC could actual work less than optimal.

If you assume 100% humidity at the IC inlet, some of the water vapor would actually condense inside the IC as a result of temperature decreasing. In such case latent heat would be released inside the IC, causing additional heat to be removed by the IC.

If you assume 100% humidity at the IC inlet, some of the water vapor would actually condense inside the IC as a result of temperature decreasing. In such case latent heat would be released inside the IC, causing additional heat to be removed by the IC.

also, humidity in PR is very high all the time which could help, no?

#11

2. No, when ambient humidity is high, water is already in vapor state. No cooldown from evaporation to be expected; if any, as you inject more water pre-com, and IF it evaporates during the compressor (this can only be determined by taking Temp measurement pre-IC w/ or w/o WI pre-com) and approaches 100% humidity, the likelihood of process 1. above (condensation as temp decrease in the IC) increases.

The only case where your theory may work is if you still have liquid water at the exit of the compressor AND the humidity is low so that there is still a likelihood for water to evaporate and humidity to rise even though the temperature decreases in the IC. Again, this can be determined only by comparing Temp pre-IC and after, i.e. AIT, w/ and w/o pre-com WI.

- Sandro

#13

Try calculate Tout for an IC with - say 70% efficiency - 20 C Tamb and different Tin.

It's Tout = Tin + eff x (Tamb - Tin). E.g. if Tin = 150 C then Tout = 59 C; if Tin = 155 C then Tout = 60.5 C

- Sandro

#14

Because the IC is working to remove latent heat, it doesn't help your IAT or charge density until it condenses out some water first. What the IC is going to do at best is keep the air saturated (100% humidity) at or near its sensible discharge temperature (e.g., IAT). The beauty of the evaporative cooling process is that it removes a comparatively large amount of sensible heat and sequesters it as latent heat--a form more agreeable to a stable combustion process, however, the heat is still there and cannot be ignored.

#15

Rotary Freak

iTrader: (28)

Join Date: Jun 2009

Location: Ontario, Canada

Posts: 2,089

Likes: 0

Received 0 Likes

on

0 Posts

Some1 needs to do a back to back test of just water. One pre turbo, and one post turbo!

I am a pawn and need answers lol.

Sandro, you seem to give a case that preturbo might not be the best. Yet you are building a preturbo setup. Are you undecided as to what the best place is to put the nozzle or are you going to test it out?

#16

One thing about preturbo is it's a good way to really atomize the water. I personally run preturbo, mainly because it's required in my mechanical setup. I like simple systems that basically run themselves. I have no idea which is better if you have a pump driven setup, but personally it would seem the further away from the engine, the more time it has to atomize and pull whatever heat from the air that it can. If you have a pump driven setup, it would be pretty easy to test various locations to see what works best for you.

I personally don't think it matters much. Either will work well. If one makes 10 more HP then the other that's hardly anything when you're making 500+ hp. Go with whatever is more convenient.

I personally don't think it matters much. Either will work well. If one makes 10 more HP then the other that's hardly anything when you're making 500+ hp. Go with whatever is more convenient.

#17

Some1 needs to do a back to back test of just water. One pre turbo, and one post turbo!

I am a pawn and need answers lol.

Sandro, you seem to give a case that preturbo might not be the best. Yet you are building a preturbo setup. Are you undecided as to what the best place is to put the nozzle or are you going to test it out?

- Sandro

#18

Maybe the biggest advantage of pre compressor is this theoretical shifting of the compressor map to effictively make it act like a bigger compressor.

And on that note, has anyone done any ACTUAL testing to see if thats true?

And on that note, has anyone done any ACTUAL testing to see if thats true?

Thread

Thread Starter

Forum

Replies

Last Post

sherff

Adaptronic Engine Mgmt - AUS

9

02-24-19 12:09 PM

immanuel__7

2nd Generation Specific (1986-1992)

89

09-05-15 10:23 AM

befarrer

Microtech

3

08-22-15 05:52 PM

auxiliary, compressor, dyno, dynos, injection, intake, intercooler, post, postcompressor, pre, precompressor, preturbo, temp, turbo, water