Forging Fearlessly into new Frontiers w FJO

#26

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

slo.

time is flying by and i need to get back on the dyno so i wanted to take the pump completely out of the equation. after evaluating my new system i will try to mod my Shurflo pump and see if it is up to the job.... it probably is.

hc

time is flying by and i need to get back on the dyno so i wanted to take the pump completely out of the equation. after evaluating my new system i will try to mod my Shurflo pump and see if it is up to the job.... it probably is.

hc

#27

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

update:

i expect to be back on the dyno this week.

i now run a different alcohol pump. the new pump is a Bosch 044 variant (PN 0 580 254 909). the 044 puts out 53 GPH while the "909" pumps 39 GPH. since i use two 700 CC/Min solenoids/injectors my max is 23 GPH. the 909 is an inline external pump and as such has a nipple on the inflow side. i used a barb fitting. since you will need a short length of rubber hose to connect the two you need to know:

the only rubber hose to use w alcohol is SAE 30R9 spec. this is readily obtainable at NAPA or just about any auto parts store. do NOT use normal rubber hose or very bad things will happen almost immediately.

pump only runs in boost of course.

i selected a Weldon Adj pressure regulator ( PN A 2040) meth happy adj to 200 PSI.

the other key is a return line back to the alcohol fuel cell.

i now have constant pressure to my alcohol injectors and it is back to the dyno.

top line is return from press reg. dash 6. bottom is feed. small top line is vent to outside.

left line is feed from cell. top line is return to cell. right line is to injectors. this all gets neatly covered my the black plastic OEM panel.

note filter and line pressure sensor/logger

i expect to be back on the dyno this week.

i now run a different alcohol pump. the new pump is a Bosch 044 variant (PN 0 580 254 909). the 044 puts out 53 GPH while the "909" pumps 39 GPH. since i use two 700 CC/Min solenoids/injectors my max is 23 GPH. the 909 is an inline external pump and as such has a nipple on the inflow side. i used a barb fitting. since you will need a short length of rubber hose to connect the two you need to know:

the only rubber hose to use w alcohol is SAE 30R9 spec. this is readily obtainable at NAPA or just about any auto parts store. do NOT use normal rubber hose or very bad things will happen almost immediately.

pump only runs in boost of course.

i selected a Weldon Adj pressure regulator ( PN A 2040) meth happy adj to 200 PSI.

the other key is a return line back to the alcohol fuel cell.

i now have constant pressure to my alcohol injectors and it is back to the dyno.

top line is return from press reg. dash 6. bottom is feed. small top line is vent to outside.

left line is feed from cell. top line is return to cell. right line is to injectors. this all gets neatly covered my the black plastic OEM panel.

note filter and line pressure sensor/logger

Last edited by Howard Coleman; 09-22-08 at 03:39 PM.

#28

Junior Member

Join Date: Dec 2007

Location: Irvine, California

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Thank you for the update. By the way, I am now running two 700 cc/min FJO injectors/solenoids as well and having Wolf V500 control them both. The pump only runs under boost. So far all data logs show a nice, steady methanol pressure curve up to 25 psi of MAP.

#29

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

brief update

dynoed last thursday. 23 4th gear runs, 2000 to 8000.

the FJO system performed FLAWLESSLY. constant 107 alcohol line pressure after the regulator.

we immediately never gave one thought to the alcohol part of the tuning and were able to concentrate on tuning.

we ran out of wastegate spring at 20 psi and made 498 rear whp.

knock was less than 21 thanks to the alcohol. egts 1550/1600. exhaust manifold back pressure was 21 psi at 20 psi boost thanks to my twin Garrett TO4 setup.

timing was V conservative at 12 IGL and 11 degrees split.

i hope to get out on a roadcourse (Blackhawk Farms) oct 11-12 where the groundbreaking aspects of the alcohol system should shine. 20 psi on a road course, heh heh.

lots more later including a trip back to the dyno to run where the turbos are happiest... 27 psi.

stay tuned,

howard coleman

dynoed last thursday. 23 4th gear runs, 2000 to 8000.

the FJO system performed FLAWLESSLY. constant 107 alcohol line pressure after the regulator.

we immediately never gave one thought to the alcohol part of the tuning and were able to concentrate on tuning.

we ran out of wastegate spring at 20 psi and made 498 rear whp.

knock was less than 21 thanks to the alcohol. egts 1550/1600. exhaust manifold back pressure was 21 psi at 20 psi boost thanks to my twin Garrett TO4 setup.

timing was V conservative at 12 IGL and 11 degrees split.

i hope to get out on a roadcourse (Blackhawk Farms) oct 11-12 where the groundbreaking aspects of the alcohol system should shine. 20 psi on a road course, heh heh.

lots more later including a trip back to the dyno to run where the turbos are happiest... 27 psi.

stay tuned,

howard coleman

#30

registered user

iTrader: (1)

Join Date: Jan 2006

Location: San Diego

Posts: 2,469

Likes: 0

Received 0 Likes

on

0 Posts

Nice numbers, when does it start spooling?

brief update

dynoed last thursday. 23 4th gear runs, 2000 to 8000.

the FJO system performed FLAWLESSLY. constant 107 alcohol line pressure after the regulator.

we immediately never gave one thought to the alcohol part of the tuning and were able to concentrate on tuning.

we ran out of wastegate spring at 20 psi and made 498 rear whp.

knock was less than 21 thanks to the alcohol. egts 1550/1600. exhaust manifold back pressure was 21 psi at 20 psi boost thanks to my twin Garrett TO4 setup.

timing was V conservative at 12 IGL and 11 degrees split.

i hope to get out on a roadcourse (Blackhawk Farms) oct 11-12 where the groundbreaking aspects of the alcohol system should shine. 20 psi on a road course, heh heh.

lots more later including a trip back to the dyno to run where the turbos are happiest... 27 psi.

stay tuned,

howard coleman

dynoed last thursday. 23 4th gear runs, 2000 to 8000.

the FJO system performed FLAWLESSLY. constant 107 alcohol line pressure after the regulator.

we immediately never gave one thought to the alcohol part of the tuning and were able to concentrate on tuning.

we ran out of wastegate spring at 20 psi and made 498 rear whp.

knock was less than 21 thanks to the alcohol. egts 1550/1600. exhaust manifold back pressure was 21 psi at 20 psi boost thanks to my twin Garrett TO4 setup.

timing was V conservative at 12 IGL and 11 degrees split.

i hope to get out on a roadcourse (Blackhawk Farms) oct 11-12 where the groundbreaking aspects of the alcohol system should shine. 20 psi on a road course, heh heh.

lots more later including a trip back to the dyno to run where the turbos are happiest... 27 psi.

stay tuned,

howard coleman

#31

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

here's a bit more on the oct 25 session and what i am up to today....

2008 UPDATE:

things are looking up in 08 for my twin TO4 turbo project. last year was the first year on the dyno. we did 3 dyno sessions each averaging 4+ hours w ace tuner Luke Stubbs at BeyondRedline Green Bay Wisconsin.

challenges for 07 were tuning my Alkycontrol 100% methanol AI system and dealing w a declining torque curve after a decent ascent. due to a few problems real and illusory we were only able to tune to about 15.8 psi and made about 420/360. i did switch the rear turbines from stage 3 to stage 5 in the middle of the 07 process.

last thursday i was back on the (new) eddy current Beyond Redline dyno. we made 23 2000-8000 4th gear pulls.

the big new deal was a new generation alcohol system from FJO. unlike most systems which use nozzles the FJO system uses fuel injectors. nozzles are great for watering your lawn. fuel injectors are great for precisely tuning your motor. as in milliseconds of "ontime."

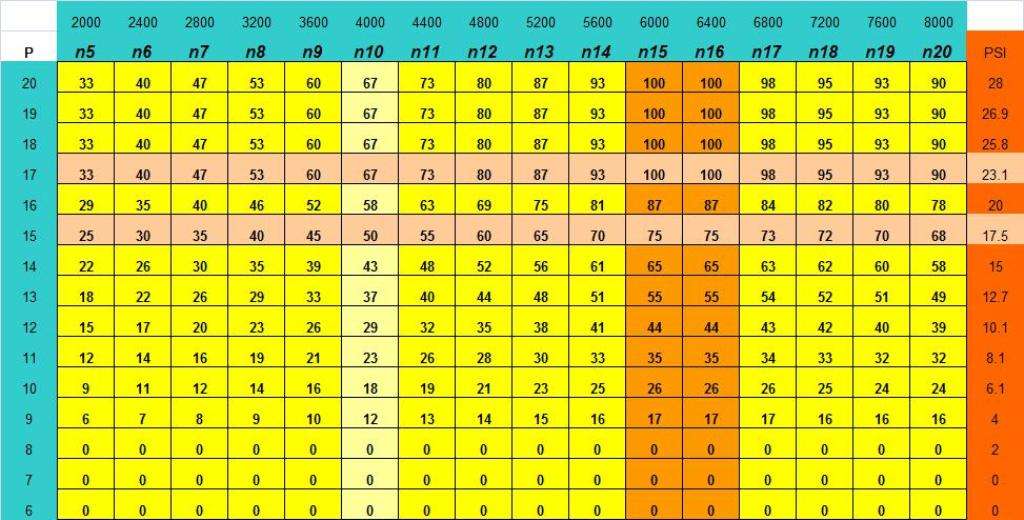

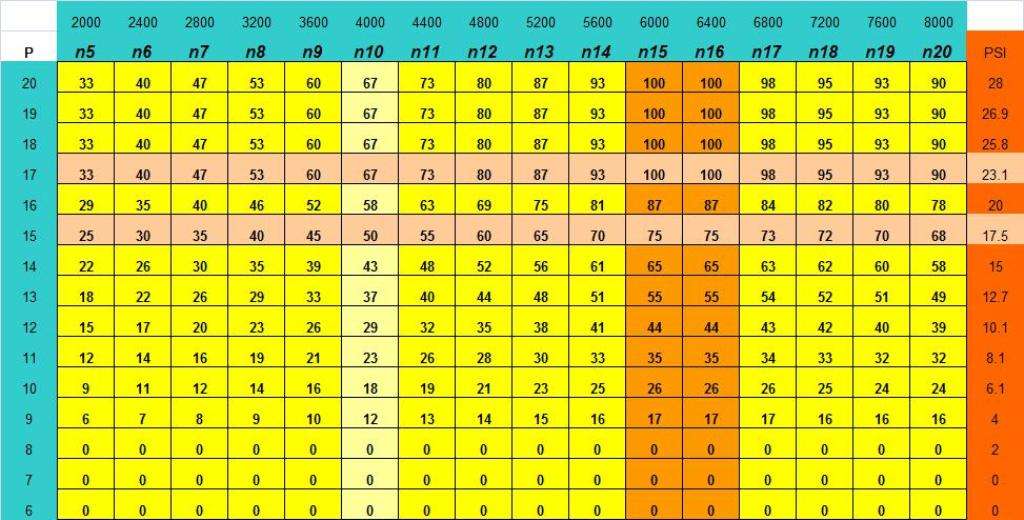

here's what the tuning table looks like. the values are % of max deliverability.

the older gen (spray and pray) systems work o k for drag racing where your right foot is always on the floor. since the only variability as to delivery is an electric pump they really can't parallel fuel needs on a road course where you are always on and off the gas.

(if you are just using the setup to spray water to cool your engine they are fine... if you are partially fueling your engine w magic methanol on the street or a road course.... no way)

anyway, i was on the dyno initially in july. we found that the alcohol pressure behind the injectors (2 700 CC/Min) was varying and with it our AFRs.

back to the drawing board.

remove Shurflow pump. insert a Bosch variant of the 044.... the 909. add a Weldon Adj alcohol compatible pressure regulator. add return to AI fuel cell line.

result: absolutely constant alcohol line pressure and back to tuning on the dyno.

so, we did 23 runs last thursday. after the first run we never even thought about the alcohol system. it was there. it was constant. and combined w pump 93 octane it was magic.

20 pounds of boost. PFC knock reading between 7000 and 8000 was between 10 and 20! on pump gas

my descending torque readings from last year have vanished. i spent too much time chasing that last year. it turned out to be boost related.

BTW, my exhaust backpressure at 20 psi boost is 21!!!!

my turbos are designed to put out 82-84 pounds per minute at 27 psi. unfortunately, my actuator springs are maxxed at 20 psi. i am using the stock FD actuators adapted to my ATP Ultimate Wastegates. they do 10 psi w the boost controller turned off.

i removed one of them yesterday with the idea of screwing the rod in to make it shorter and preload the actuator spring for more boost but found the travel to be only .31 inches. if i were to shorten the rod to stiffen the spring i would lose travel and probably WG flow so i will need to find stiffer (different) actuators.

since i want to get ontrack in the next few weeks 27 psi and 600 rw will have to wait.

i made 498 at 20 psi but do expect i can raise the output a bit as i am conservative on timing at 12 degrees w 11 split. further, my lead plug (NGK R6725 10.5 heat range) is black and oily. i am going to a hotter plug in the lead only.

finally, we have been tuning too cold on the egts. the target temps pre turbo have been 1420 F for spool and 1550 F at target boost. actually these are the temps for 100% meth (no gasoline at all)... so we will bump EGTs a bit since 70% of my fuel is 93 octane gasoline and we have seen zero knock.

it looks like my twins are proving out V my target. spool is either the same or slightly better than a recently posted GT42.

i really don't want 400 rw at 5000 anyway as it would be more difficult to drive on a road course.

the setup is great around town and should be exciting when it finally gets tuned out.

stay tuned more to come this year. OBTW, i have about 13,000 miles on my twins. and my motor has been in my car for 3 years now... 0ver 100 dyno pulls and it reads 17 inches of vacuum at idle.

pics of my FJO setup in the Auxiliary Injection section.

hc

2008 UPDATE:

things are looking up in 08 for my twin TO4 turbo project. last year was the first year on the dyno. we did 3 dyno sessions each averaging 4+ hours w ace tuner Luke Stubbs at BeyondRedline Green Bay Wisconsin.

challenges for 07 were tuning my Alkycontrol 100% methanol AI system and dealing w a declining torque curve after a decent ascent. due to a few problems real and illusory we were only able to tune to about 15.8 psi and made about 420/360. i did switch the rear turbines from stage 3 to stage 5 in the middle of the 07 process.

last thursday i was back on the (new) eddy current Beyond Redline dyno. we made 23 2000-8000 4th gear pulls.

the big new deal was a new generation alcohol system from FJO. unlike most systems which use nozzles the FJO system uses fuel injectors. nozzles are great for watering your lawn. fuel injectors are great for precisely tuning your motor. as in milliseconds of "ontime."

here's what the tuning table looks like. the values are % of max deliverability.

the older gen (spray and pray) systems work o k for drag racing where your right foot is always on the floor. since the only variability as to delivery is an electric pump they really can't parallel fuel needs on a road course where you are always on and off the gas.

(if you are just using the setup to spray water to cool your engine they are fine... if you are partially fueling your engine w magic methanol on the street or a road course.... no way)

anyway, i was on the dyno initially in july. we found that the alcohol pressure behind the injectors (2 700 CC/Min) was varying and with it our AFRs.

back to the drawing board.

remove Shurflow pump. insert a Bosch variant of the 044.... the 909. add a Weldon Adj alcohol compatible pressure regulator. add return to AI fuel cell line.

result: absolutely constant alcohol line pressure and back to tuning on the dyno.

so, we did 23 runs last thursday. after the first run we never even thought about the alcohol system. it was there. it was constant. and combined w pump 93 octane it was magic.

20 pounds of boost. PFC knock reading between 7000 and 8000 was between 10 and 20! on pump gas

my descending torque readings from last year have vanished. i spent too much time chasing that last year. it turned out to be boost related.

BTW, my exhaust backpressure at 20 psi boost is 21!!!!

my turbos are designed to put out 82-84 pounds per minute at 27 psi. unfortunately, my actuator springs are maxxed at 20 psi. i am using the stock FD actuators adapted to my ATP Ultimate Wastegates. they do 10 psi w the boost controller turned off.

i removed one of them yesterday with the idea of screwing the rod in to make it shorter and preload the actuator spring for more boost but found the travel to be only .31 inches. if i were to shorten the rod to stiffen the spring i would lose travel and probably WG flow so i will need to find stiffer (different) actuators.

since i want to get ontrack in the next few weeks 27 psi and 600 rw will have to wait.

i made 498 at 20 psi but do expect i can raise the output a bit as i am conservative on timing at 12 degrees w 11 split. further, my lead plug (NGK R6725 10.5 heat range) is black and oily. i am going to a hotter plug in the lead only.

finally, we have been tuning too cold on the egts. the target temps pre turbo have been 1420 F for spool and 1550 F at target boost. actually these are the temps for 100% meth (no gasoline at all)... so we will bump EGTs a bit since 70% of my fuel is 93 octane gasoline and we have seen zero knock.

it looks like my twins are proving out V my target. spool is either the same or slightly better than a recently posted GT42.

i really don't want 400 rw at 5000 anyway as it would be more difficult to drive on a road course.

the setup is great around town and should be exciting when it finally gets tuned out.

stay tuned more to come this year. OBTW, i have about 13,000 miles on my twins. and my motor has been in my car for 3 years now... 0ver 100 dyno pulls and it reads 17 inches of vacuum at idle.

pics of my FJO setup in the Auxiliary Injection section.

hc

#32

Junior Member

Join Date: Nov 2007

Location: Louisville, KY

Posts: 8

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the update. Do you have any word on when FJO will have the 2nd Gen Controller ready to ship? I have been waiting since Feb. FJO has not responded to release date questions. Any intel would be appreciated.

Jim

Jim

#33

Junior Member

Join Date: Dec 2007

Location: Irvine, California

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Does the FJO system have two separate maps controlling each injector? That is how I am using Wolf to control my two FJO 700 cc/min injectors. Your duty cycles seem to correlate well to mine and we are both replacing 25% (IIRC). That is interesting as you are a 1.3L (??) rotary and I am a 2.8L in-line 6.

Our torque numbers may be similar as I am putting down 410 ft-lbs at the wheels at 3800-4000 rpm.

Very nice. I am glad that you managed to get everying sorted out.

Our torque numbers may be similar as I am putting down 410 ft-lbs at the wheels at 3800-4000 rpm.

Very nice. I am glad that you managed to get everying sorted out.

#34

registered user

iTrader: (1)

Join Date: Jan 2006

Location: San Diego

Posts: 2,469

Likes: 0

Received 0 Likes

on

0 Posts

Not suprising as a 1.3 liter rotary would idealy intake 2.6 liters of fluid per 2 crankshaft rotations, much like a 1.3 liter 2 stroke engine.

Does the FJO system have two separate maps controlling each injector? That is how I am using Wolf to control my two FJO 700 cc/min injectors. Your duty cycles seem to correlate well to mine and we are both replacing 25% (IIRC). That is interesting as you are a 1.3L (??) rotary and I am a 2.8L in-line 6.

Our torque numbers may be similar as I am putting down 410 ft-lbs at the wheels at 3800-4000 rpm.

Very nice. I am glad that you managed to get everying sorted out.

Our torque numbers may be similar as I am putting down 410 ft-lbs at the wheels at 3800-4000 rpm.

Very nice. I am glad that you managed to get everying sorted out.

#35

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

if i were wanting to get onboard the FJO AI train i would contact them directly. if my needs were water only i believe the FJO package as currently constituted would deliver un-varying pressure.

if you plan to use meth in any % i would suggest you acquire the FJO module, solenoids (2) and hose kit. you then need the Weldon adj pressure regulator and you might use the Shurflow pump. while i switched to a Bosch i have a distinct feeling the original FJO/Shurflow would work fine as long as you plumb in a return line w the regulator. if i get a chance before the snow flies i may reinstall the FJO pump to see...

i will be on a roadcourse w the setup oct 22. i am very interested to see if the motor w the FJO meth setup can make laps at 20 psi boost. most FDs run the road courses at one bar for engine longevity. i think, given the numbers i see as to oil temp, water, knock, egts that i can do it at 20 psi.

we will see shortly.

hc

if you plan to use meth in any % i would suggest you acquire the FJO module, solenoids (2) and hose kit. you then need the Weldon adj pressure regulator and you might use the Shurflow pump. while i switched to a Bosch i have a distinct feeling the original FJO/Shurflow would work fine as long as you plumb in a return line w the regulator. if i get a chance before the snow flies i may reinstall the FJO pump to see...

i will be on a roadcourse w the setup oct 22. i am very interested to see if the motor w the FJO meth setup can make laps at 20 psi boost. most FDs run the road courses at one bar for engine longevity. i think, given the numbers i see as to oil temp, water, knock, egts that i can do it at 20 psi.

we will see shortly.

hc

#36

Really good stuff Howard. I was really confused at first at your initial problem with pressure but I get it now. I want to use the FJO kit after I get my car dialed in on pump fuel (with any other gremlins) before I add another item to the list. I know all the information is in this thread but, I have a couple specific questions just to clarify for myself...

1) Are you using the Bosch 044 instead of the FJO pump? If so would you use anything else?

2) What pressure do you have meth set to on the regulator?

3) As always, if you could do it all over again would you change anything or do anything differently?

Thanks!

1) Are you using the Bosch 044 instead of the FJO pump? If so would you use anything else?

2) What pressure do you have meth set to on the regulator?

3) As always, if you could do it all over again would you change anything or do anything differently?

Thanks!

#37

registered user

iTrader: (1)

Join Date: Jan 2006

Location: San Diego

Posts: 2,469

Likes: 0

Received 0 Likes

on

0 Posts

When and if you go to test the FJO pump, you should use a shurlfo non bypass pump diaphragm.

It is a cheap part and quick and easy to install and is available cheap directly from shurflo.

It is a cheap part and quick and easy to install and is available cheap directly from shurflo.

if i were wanting to get onboard the FJO AI train i would contact them directly. if my needs were water only i believe the FJO package as currently constituted would deliver un-varying pressure.

if you plan to use meth in any % i would suggest you acquire the FJO module, solenoids (2) and hose kit. you then need the Weldon adj pressure regulator and you might use the Shurflow pump. while i switched to a Bosch i have a distinct feeling the original FJO/Shurflow would work fine as long as you plumb in a return line w the regulator. if i get a chance before the snow flies i may reinstall the FJO pump to see...

i will be on a roadcourse w the setup oct 22. i am very interested to see if the motor w the FJO meth setup can make laps at 20 psi boost. most FDs run the road courses at one bar for engine longevity. i think, given the numbers i see as to oil temp, water, knock, egts that i can do it at 20 psi.

we will see shortly.

hc

if you plan to use meth in any % i would suggest you acquire the FJO module, solenoids (2) and hose kit. you then need the Weldon adj pressure regulator and you might use the Shurflow pump. while i switched to a Bosch i have a distinct feeling the original FJO/Shurflow would work fine as long as you plumb in a return line w the regulator. if i get a chance before the snow flies i may reinstall the FJO pump to see...

i will be on a roadcourse w the setup oct 22. i am very interested to see if the motor w the FJO meth setup can make laps at 20 psi boost. most FDs run the road courses at one bar for engine longevity. i think, given the numbers i see as to oil temp, water, knock, egts that i can do it at 20 psi.

we will see shortly.

hc

#39

Junior Member

Join Date: Dec 2007

Location: Irvine, California

Posts: 45

Likes: 0

Received 0 Likes

on

0 Posts

Howard, just and FYI. I believe that I have had my FJO setup running longer than you and I just had a failure that could have resulted in a blown motor.

One of my solenoid driver modules (CWD0082) failed AND the pressure sensor failed. It would no longer "fire" the solenoid and the sensor only outputs 0.61 volts (equates to around 8 psi), both with and without the pump running.

As you are aware, I am using my EMS to control my methanol injection. My failsafe is based around the pressure sensor. If the pressure is less than 90 psi, the EMS switches maps to my fuel only map (less boost, more fuel, less timing). A failure of **just** the driver module would NOT have resulted in the maps switching.

I do have good news to report though. I am 2 months outside of the warranty period but FJO is replacing the module under warranty and I am purchasing a new sensor at their replacement cost ($42 shipped).

I need to figure out a way to modify my failsafe setup, or at least wire in a warning indicator, to include whether or not the module is working as well.

One of my solenoid driver modules (CWD0082) failed AND the pressure sensor failed. It would no longer "fire" the solenoid and the sensor only outputs 0.61 volts (equates to around 8 psi), both with and without the pump running.

As you are aware, I am using my EMS to control my methanol injection. My failsafe is based around the pressure sensor. If the pressure is less than 90 psi, the EMS switches maps to my fuel only map (less boost, more fuel, less timing). A failure of **just** the driver module would NOT have resulted in the maps switching.

I do have good news to report though. I am 2 months outside of the warranty period but FJO is replacing the module under warranty and I am purchasing a new sensor at their replacement cost ($42 shipped).

I need to figure out a way to modify my failsafe setup, or at least wire in a warning indicator, to include whether or not the module is working as well.

#42

Hey Howard, has there been any updates on FJO's new generation kit? I think its time to install the methanol injection system in the car and play with it over the winter so its ready for some big time road coursing in the summer  . Has there been any updates on your system as well? Thanks in advance.

. Has there been any updates on your system as well? Thanks in advance.

thewird

. Has there been any updates on your system as well? Thanks in advance.

. Has there been any updates on your system as well? Thanks in advance.thewird