First tune on e85. 505rwhp@15.6psi

#51

E85 Addict

Thread Starter

Ur dyno map looks quite uneven. Like the AF ratio is jumping abit up and down.

Im at 16 degreese timing at 1.2 bar and did 497rwhp with E85 and a AF ratio of 10.5. That was all we had time for due to a faulty filler neck on the radiator kept us bussy for a few hours to get it fixed.

Plan is to have it on the dyno again within 2 weeks. And bring the AF ratio up to about 11.5 and turn up the timing and reduce the split.

Now we also need to aim for as cool exhaust temps as we can get also. Below 850 degreece celcius would be nice.

But we will see.

JT

Im at 16 degreese timing at 1.2 bar and did 497rwhp with E85 and a AF ratio of 10.5. That was all we had time for due to a faulty filler neck on the radiator kept us bussy for a few hours to get it fixed.

Plan is to have it on the dyno again within 2 weeks. And bring the AF ratio up to about 11.5 and turn up the timing and reduce the split.

Now we also need to aim for as cool exhaust temps as we can get also. Below 850 degreece celcius would be nice.

But we will see.

JT

The afr's are jumping a bit from 10.4 - 10.8, EGT's are up at 900c atm. i did some tuning on the road advancing the timing to 11dgr.

What boost are you aiming for?

Keep us posted!

#52

Rotary Enthusiast

Gonna hook up the boost controller to get it even.

Next year im gonna go for 30 psi when i get 2 more injectors. I have the Excessive Lim in the car now. But need to remap alot once i put 2 more injectors in, and i also need to build the fuel system up again to support the added injectors.

JT

#53

#54

E85 Addict

Thread Starter

i have a 2035 weldon pump and weldon fuel pump controller, i can ajust voltage to the pump, when cruising around i usualy run on half speed.

yesterday i forgot to put in "race mode" when doing some WOT runs, i knew something was not right since the car wasn't running well over 5krpm, i actually made 3-4 of those and i cant believe i didn't check AFR the first thing i do, when my right eye caught well over 14AFR at 6000rpm and 20psi of boost i knew that this aint good!

pulled over and checked my vacuum, all good.

put on race mode and it ran just like before.

im lucky my engine is still alive!

yesterday i forgot to put in "race mode" when doing some WOT runs, i knew something was not right since the car wasn't running well over 5krpm, i actually made 3-4 of those and i cant believe i didn't check AFR the first thing i do, when my right eye caught well over 14AFR at 6000rpm and 20psi of boost i knew that this aint good!

pulled over and checked my vacuum, all good.

put on race mode and it ran just like before.

im lucky my engine is still alive!

#55

E85 Addict

Thread Starter

Not noticeable, but lower in the revs the timing is pretty low so i guess there are some heat building up (could explain boostpattern).. i don't log egt's, i probably should.

Pull on 17dgr 1bar EGT's 950c which is aweful high. afr high 10 low 11's. (egt down to 850 with 13 btdc)

Pull on 17dgr 1bar EGT's 950c which is aweful high. afr high 10 low 11's. (egt down to 850 with 13 btdc)

#57

E85 Addict

Thread Starter

car has been in the garage for a couple of weeks now, havn't even looked at it!

Thinking about making a new exhaust.. you know im running 3" from turbo and back.. Only gaining 8whp with 5psi raise in boost, boost dropping of on higher revs... with 513whp i should have plenty of backpressure. Don't you think?

(i could start by measuring it )

)

Im in the mood for some welding...

Thinking about making a new exhaust.. you know im running 3" from turbo and back.. Only gaining 8whp with 5psi raise in boost, boost dropping of on higher revs... with 513whp i should have plenty of backpressure. Don't you think?

(i could start by measuring it

)

)Im in the mood for some welding...

Last edited by gusfd3s; 07-04-08 at 03:39 PM.

#59

Rotary Enthusiast

#60

E85 Addict

Thread Starter

oh, did a conversion from nm (newton meter) to ft pounds, MAGIC!

#61

Racing Rotary Since 1983

iTrader: (6)

nice thread. lots of good numbers upon which to noodle. good luck to you and the alcohol project. i was expecting to be on the dyno yesterday but developed a pressure problem w my alcohol pump so i am delayed a bit.

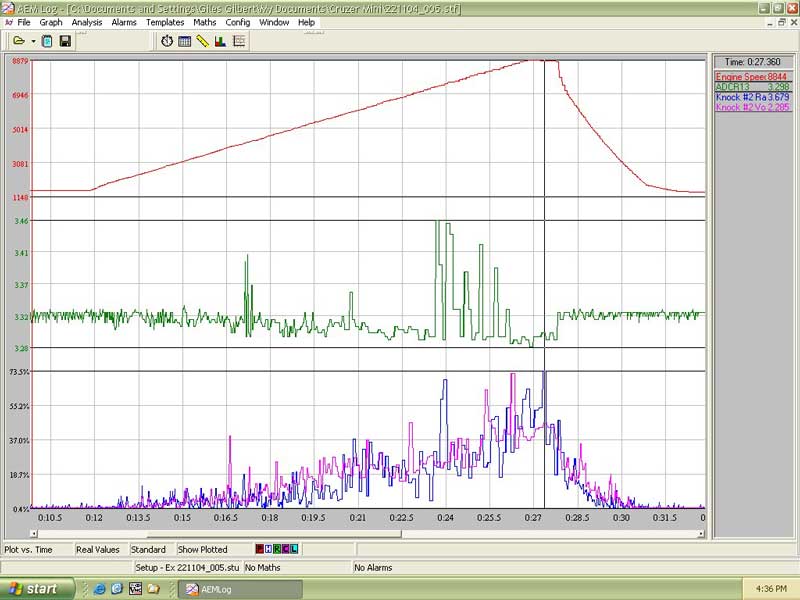

you have the same knock profile as i do. 40-50 vac going to close to zero toward the top of the run. i was around 10-20 until my last dyno run in sep and jumped to the 40-50 area in vac. i swapped 3 knock sensors and they all read similarly. upon careful looks at my logs i am not worrying as it really drops off under boost.

i do run a J&S Safeguard Knock Sensor & Retard and find it generally does not light up during the periods that the OEM sensor is showing 50 or a spike 70 under vacuum. when it does light up, which is seldom, i do take notice.

and speaking of notice, it appears that Chris is datalogging from his (Bosch) J&S Knock system.

that sounds like a great idea. i am on it.

hc

you have the same knock profile as i do. 40-50 vac going to close to zero toward the top of the run. i was around 10-20 until my last dyno run in sep and jumped to the 40-50 area in vac. i swapped 3 knock sensors and they all read similarly. upon careful looks at my logs i am not worrying as it really drops off under boost.

i do run a J&S Safeguard Knock Sensor & Retard and find it generally does not light up during the periods that the OEM sensor is showing 50 or a spike 70 under vacuum. when it does light up, which is seldom, i do take notice.

and speaking of notice, it appears that Chris is datalogging from his (Bosch) J&S Knock system.

that sounds like a great idea. i am on it.

hc

#62

Rotary Freak

Join Date: Nov 2001

Location: trinidad and tobago

Posts: 2,715

Likes: 0

Received 0 Likes

on

0 Posts

Most smart tuners in the rotary world allready know that knock control does not work on a rotary because the damaging knock is not spark induced and retarding the timing will do nothing other than induce another set of problems more likely to cause knock.

The J&S Safeguard is probably one of the best stand alone knock detection devices in the world presently. When applied properly to a rotary application it can work wonders.

Anyway this in not the time and place.

No more thread jacking.

The J&S Safeguard is probably one of the best stand alone knock detection devices in the world presently. When applied properly to a rotary application it can work wonders.

Anyway this in not the time and place.

No more thread jacking.

So Chris , are you saying that knock control that retards the ignition timing by a predetermined amount (typically 3-10 deg) is a useless feature ? One of the main features / attractions of the new V88 is the fact that it has knock control , would I be wasting my money ?

#64

So Chris , are you saying that knock control that retards the ignition timing by a predetermined amount (typically 3-10 deg) is a useless feature ? One of the main features / attractions of the new V88 is the fact that it has knock control , would I be wasting my money ?

The Bosch knock sensor when coupled to the right electronics that's been tuned to the actual combination is one way to measure actual knock and not noise.

This datalog shows the difference between a factory noise sensor and a well respected knock monitor/control system.

On a rotary retarding the ignition event is not going to stop actual knock. Depending on the type of knock you can remove the ignition complety and it will still keep on knocking. Also from my experience excessive retard on a rotary also leads to other problems that result in knock. Ask yourself this question, what is your first reaction when knock occurs? That's the only way you can try and save a rotary motor when it knocks.

The trick is to remove the human reaction part of the equation and apply it to electronics.

I have!

The last time I check micro processors are much quicker than human reaction.

The sad part is that most are under the impression that knock is mainly responsible for broken apex seals when it's not. On most high powered and 100% methanol fueled applications it never knocks most of the times when the motor goes.

The only way to prevent broken apex seals is to make all the pre-cautions to avoid it.

#66

Rotary Freak

Join Date: Nov 2001

Location: trinidad and tobago

Posts: 2,715

Likes: 0

Received 0 Likes

on

0 Posts

This is the information given on the knock control for this particular ECU.

Knock Control

Knock Control is a feature designed for reducing engine damage caused by detonation. Detonation occurs due to sharp increases in cylinder pressure usually caused by the ignition event happening too early (too much advance), or excessive compression pressures (eg too much boost).. Other factors can cause detonation including excessive engine temperatures, low octane fuels and lean mixtures.

Detonation can cause irreparable damage to an engine, including burnt pistons and broken ring lands. In almost all cases detonation can be avoided by reducing the amount of ignition advance for a given load. The Knock Control function allows the ECU to detect detonation and automatically reduce ignition advance until detonation no longer occurs.

Timing removed by the Knock Control function remains removed until next time the ECU is shut down. For safety reasons, the ECU will not attempt to put the timing back into the engine. Timing removed will be reset when power is cycled to the ECU therefore timing changes are not permanently stored.

Warning: Knock Control should be used as a safety feature only. It is not design as a tuning aid to helpdetermine optimum ignition timing!

Knock Mode

Knock Mode selects the operating mode of the Knock Control function. The following modes are available:

· OFF - Knock Control is disabled.

· ON - Knock Control is active.

Knock Target Table

The 2D/3D Knock Target Table will become visible when Knock Control is activated. This table sets the allowable engine noise for a given RPM/Load. Each engine will have different noise characteristics. Engine noise is generated by mechanical clearances, valve train noise and even valves closing against the seat! Knock control will reduce ignition advance when the actual measured level of engine noise is above the value in the Knock Target Table. This table must be manually filled out for a particular engine. Knock Target values can range from 0 (minimum noise) to 1020 (maximum noise). See the Knock Control setup procedure below for more info on entering values into this table.

The Load axis used for this table can be set under the Load Axis option. Set Load Axis to None to use only a 2D table. The RPM and Load centres of the tables rows and columns can be adjusted by setting the appropriate Table Start and Table Increment values.

Knock Retard Table

Note: This is read only table (only the ECU can change its values).

The Knock Retard Table shows the amount of ignition retard caused by the Knock Control system. Each time the actual engine noise level exceeds the Knock Target value for that particular RPM/Load 0.5 degrees of retard will be added to a cell in this table. The Knock Retard Table can be used to determine where excessive engine noise has been detected as each cell that has its retard value changed will turn blue.

The Knock Retard Table is cleared when the ECU is turned off. Ignition changes made by the Knock Control function are NOT stored permanently. The Knock Retard Table can also be cleared by setting Knock Mode to OFF, then back to ON.

Knock Retard Limit

The Knock Retard Limit sets the maximum amount of ignition timing in degrees that will be removed (or maximum amount of ignition retard). This limit avoids the ECU removing too much timing if the value in the Knock Target Table is set too low.

Filtering

On ECU's equipped with Knock Control, signal filtering is configurable. The following adjustments are available to configure knock signal filtering:

· Freq Channel - This setting sets the sensitivity of the ECU to a particular knock signal frequency range. The following options are available:

· LP Only - Knock input is sensitive to all frequencies below 7 kHz

· 5.5 kHz - Knock input is most sensitive to frequencies near 5.5 kHz

· 7.0 kHz - Knock input is most sensitive to frequencies near 7.0 kHz

· 9.0 kHz - Knock input is most sensitive to frequencies near 9.0 kHz

· Gain Channel - This setting adjusts the overall gain of the knock circuitry amplifier. A higher gain number will result in larger Knock Level numbers for a particular signal input. Use this adjustment to getter a better range of Knock Level numbers. If Knock Level numbers are reaching full scale then reducing Gain Channel will bring them back into range.

The required Gain Channel and Freq Channel numbers will depend on the engine type, engine capacity, knock sensor type and knock sensor location. A Freq Channel setting of LP Only is not often used and exists for compatibility with older ECU's. As a general rule engines with a larger capacity require a lower Freq Channel setting.

Runtime Values

The following Runtime values can be observed under the Ignition Runtime Values tab to monitor the state of the Knock Control function:

· Knock Level - The current measured engine noise level.

· Knock Target - The current value as interpolated from the Knock Target Table.

· Knock Ign Trim - The current value as taken from the Knock Retard Table. This shows the amount of retard caused by the Knock Control function at the current RPM/Load.

Knock Control Setup Procedure:

The following procedure is a guide to setting up Knock Control. Unfortunately the amount of engine noise measured before and during detonation varies significantly from engine to engine, with sensor type and sensor location. Experience is required to determine the best Knock Control setup.

At all times during setup, make sure that an audible knock detection device is used (such as a KnockBlock with headphones). Avoid unnecessarily causing detonation as engine damage may result!

1. Ensure the engine is tuned to its final optimum state, particularly ignition values. Remember that Knock Control is used as a safety feature should engine operating conditions change, not to determine the final ignition values.

2. Set Knock Mode to ON. This will activate the Knock Target Table and clear the Knock Retard Table.

3. Select the desired Load Axis. This will typically be the same load axis as used for the ignition table. Set Load Axis to OFF if only a 2D table is to be used (ie engine noise level vs RPM).

4. Set up the Knock Target Table. The following hints may be useful:

· Use the Knock Level Runtime Value (under the ignition runtime values tab) to monitor the current engine noise level.

· The engine must be run at various RPM and load values to determine the engines 'non-detonating' noise characteristics.

· The value entered in the Knock Target Table will be the amount of engine noise that must be exceeded before ignition timing is decreased. Therefore, this value should be the 'non-detonating' noise level plus some headroom. Typically the value entered in the Knock Target Table will be about 10-20% higher than the 'non-detonating' noise level.

· Enter high Knock Target Values in areas where Knock Control is not required such as idle, cruise and free revving.

5. Set the Ignition Retard Limit to the maximum amount of ignition timing allowed to be removed by the Knock Control function. This will typically be between 3 and 10 degrees.

6. Perform power runs and operate the engine in all load/RPM areas where knock control is to be used. Check the values in the Knock Retard Table. If these values are not zero (or have turned blue) then the Knock Control function became active in those areas. It is up to the tuner to decide if this was due to the occurrence of detonation or if the Knock Target Table values are too low. Remember the Knock Retard Table is cleared each time the ECU loses power.

Knock Control

Knock Control is a feature designed for reducing engine damage caused by detonation. Detonation occurs due to sharp increases in cylinder pressure usually caused by the ignition event happening too early (too much advance), or excessive compression pressures (eg too much boost).. Other factors can cause detonation including excessive engine temperatures, low octane fuels and lean mixtures.

Detonation can cause irreparable damage to an engine, including burnt pistons and broken ring lands. In almost all cases detonation can be avoided by reducing the amount of ignition advance for a given load. The Knock Control function allows the ECU to detect detonation and automatically reduce ignition advance until detonation no longer occurs.

Timing removed by the Knock Control function remains removed until next time the ECU is shut down. For safety reasons, the ECU will not attempt to put the timing back into the engine. Timing removed will be reset when power is cycled to the ECU therefore timing changes are not permanently stored.

Warning: Knock Control should be used as a safety feature only. It is not design as a tuning aid to helpdetermine optimum ignition timing!

Knock Mode

Knock Mode selects the operating mode of the Knock Control function. The following modes are available:

· OFF - Knock Control is disabled.

· ON - Knock Control is active.

Knock Target Table

The 2D/3D Knock Target Table will become visible when Knock Control is activated. This table sets the allowable engine noise for a given RPM/Load. Each engine will have different noise characteristics. Engine noise is generated by mechanical clearances, valve train noise and even valves closing against the seat! Knock control will reduce ignition advance when the actual measured level of engine noise is above the value in the Knock Target Table. This table must be manually filled out for a particular engine. Knock Target values can range from 0 (minimum noise) to 1020 (maximum noise). See the Knock Control setup procedure below for more info on entering values into this table.

The Load axis used for this table can be set under the Load Axis option. Set Load Axis to None to use only a 2D table. The RPM and Load centres of the tables rows and columns can be adjusted by setting the appropriate Table Start and Table Increment values.

Knock Retard Table

Note: This is read only table (only the ECU can change its values).

The Knock Retard Table shows the amount of ignition retard caused by the Knock Control system. Each time the actual engine noise level exceeds the Knock Target value for that particular RPM/Load 0.5 degrees of retard will be added to a cell in this table. The Knock Retard Table can be used to determine where excessive engine noise has been detected as each cell that has its retard value changed will turn blue.

The Knock Retard Table is cleared when the ECU is turned off. Ignition changes made by the Knock Control function are NOT stored permanently. The Knock Retard Table can also be cleared by setting Knock Mode to OFF, then back to ON.

Knock Retard Limit

The Knock Retard Limit sets the maximum amount of ignition timing in degrees that will be removed (or maximum amount of ignition retard). This limit avoids the ECU removing too much timing if the value in the Knock Target Table is set too low.

Filtering

On ECU's equipped with Knock Control, signal filtering is configurable. The following adjustments are available to configure knock signal filtering:

· Freq Channel - This setting sets the sensitivity of the ECU to a particular knock signal frequency range. The following options are available:

· LP Only - Knock input is sensitive to all frequencies below 7 kHz

· 5.5 kHz - Knock input is most sensitive to frequencies near 5.5 kHz

· 7.0 kHz - Knock input is most sensitive to frequencies near 7.0 kHz

· 9.0 kHz - Knock input is most sensitive to frequencies near 9.0 kHz

· Gain Channel - This setting adjusts the overall gain of the knock circuitry amplifier. A higher gain number will result in larger Knock Level numbers for a particular signal input. Use this adjustment to getter a better range of Knock Level numbers. If Knock Level numbers are reaching full scale then reducing Gain Channel will bring them back into range.

The required Gain Channel and Freq Channel numbers will depend on the engine type, engine capacity, knock sensor type and knock sensor location. A Freq Channel setting of LP Only is not often used and exists for compatibility with older ECU's. As a general rule engines with a larger capacity require a lower Freq Channel setting.

Runtime Values

The following Runtime values can be observed under the Ignition Runtime Values tab to monitor the state of the Knock Control function:

· Knock Level - The current measured engine noise level.

· Knock Target - The current value as interpolated from the Knock Target Table.

· Knock Ign Trim - The current value as taken from the Knock Retard Table. This shows the amount of retard caused by the Knock Control function at the current RPM/Load.

Knock Control Setup Procedure:

The following procedure is a guide to setting up Knock Control. Unfortunately the amount of engine noise measured before and during detonation varies significantly from engine to engine, with sensor type and sensor location. Experience is required to determine the best Knock Control setup.

At all times during setup, make sure that an audible knock detection device is used (such as a KnockBlock with headphones). Avoid unnecessarily causing detonation as engine damage may result!

1. Ensure the engine is tuned to its final optimum state, particularly ignition values. Remember that Knock Control is used as a safety feature should engine operating conditions change, not to determine the final ignition values.

2. Set Knock Mode to ON. This will activate the Knock Target Table and clear the Knock Retard Table.

3. Select the desired Load Axis. This will typically be the same load axis as used for the ignition table. Set Load Axis to OFF if only a 2D table is to be used (ie engine noise level vs RPM).

4. Set up the Knock Target Table. The following hints may be useful:

· Use the Knock Level Runtime Value (under the ignition runtime values tab) to monitor the current engine noise level.

· The engine must be run at various RPM and load values to determine the engines 'non-detonating' noise characteristics.

· The value entered in the Knock Target Table will be the amount of engine noise that must be exceeded before ignition timing is decreased. Therefore, this value should be the 'non-detonating' noise level plus some headroom. Typically the value entered in the Knock Target Table will be about 10-20% higher than the 'non-detonating' noise level.

· Enter high Knock Target Values in areas where Knock Control is not required such as idle, cruise and free revving.

5. Set the Ignition Retard Limit to the maximum amount of ignition timing allowed to be removed by the Knock Control function. This will typically be between 3 and 10 degrees.

6. Perform power runs and operate the engine in all load/RPM areas where knock control is to be used. Check the values in the Knock Retard Table. If these values are not zero (or have turned blue) then the Knock Control function became active in those areas. It is up to the tuner to decide if this was due to the occurrence of detonation or if the Knock Target Table values are too low. Remember the Knock Retard Table is cleared each time the ECU loses power.

#68

E85 Addict

Thread Starter

#69

God forbid a dyno sheet doesn't have hp and tq crossing at 5252 it must be fake...

#70

Rotary Enthusiast

but i have a biiiig problem. the car worked like a charm on the dyno giving me good afr's but i was maxing out my injectors. just running 4 1680cc still but cranked up the base fuel pressure to 3 bar, but noticed it would not go over 4 bar. have the aeromotive eliminator pump and A1000 FPR. running on BUR9EQP.

it was jumping between 11.5-12 afr under full boost wich is ok, and a 17 degreece ignition at 1 bar and 13 at 1.5 bar.

So now to the problem, when i got on the track on friday the car started shooting when giving it gas, first few laps it was ok, then started after 3-4 laps. then it got worse and worse. sometimes it would go ok, and just shoot/backfire at lower rps and go ok up in the rews and then the oppesit. and the afr's kept quite ok when this happend. might go 0.5afr leaner but that's not so bad. running brand new BUR9EQP plugs now. tried 2 sets and same problem. Tried running without the hood and same problem. It idles fine at 1750 rpm and has about -280mm/hg of vacume so it's quite good. Has 60+psi of compression on all 6 sides. has dropped down from 80 psi. and i have a manual boost meeter so its kinda sensitive. and the boost needle will jump up and down alot when this happens. it jumps like a bunny. im gonna pull the engine this week, open it and im guessing il find a broken side seal or corner seal.

and im gonna go trough my entire engine harness and check it for bad wires/connectors, and the same with the ignition harness. might change out the coils as well, and also uppgrade my fuel system as well. gonna go with a AN 10 fuel line from the new Aeromotive Pro pump and also gonna get the Pro FPR to regulate the fuel correctly.

But it's gettin anoying. Anyone ever had problems with heat soaking of the fuel rail/injectors before?

JT

#71

E85 Addict

Thread Starter

It's already been done. we had nice results, no dyno sheets tho since it was slipping on the dyno. but estimated hp was 530rwhp at 1.3 bar of boost.

but i have a biiiig problem. the car worked like a charm on the dyno giving me good afr's but i was maxing out my injectors. just running 4 1680cc still but cranked up the base fuel pressure to 3 bar, but noticed it would not go over 4 bar. have the aeromotive eliminator pump and A1000 FPR. running on BUR9EQP.

it was jumping between 11.5-12 afr under full boost wich is ok, and a 17 degreece ignition at 1 bar and 13 at 1.5 bar.

So now to the problem, when i got on the track on friday the car started shooting when giving it gas, first few laps it was ok, then started after 3-4 laps. then it got worse and worse. sometimes it would go ok, and just shoot/backfire at lower rps and go ok up in the rews and then the oppesit. and the afr's kept quite ok when this happend. might go 0.5afr leaner but that's not so bad. running brand new BUR9EQP plugs now. tried 2 sets and same problem. Tried running without the hood and same problem. It idles fine at 1750 rpm and has about -280mm/hg of vacume so it's quite good. Has 60+psi of compression on all 6 sides. has dropped down from 80 psi. and i have a manual boost meeter so its kinda sensitive. and the boost needle will jump up and down alot when this happens. it jumps like a bunny. im gonna pull the engine this week, open it and im guessing il find a broken side seal or corner seal.

and im gonna go trough my entire engine harness and check it for bad wires/connectors, and the same with the ignition harness. might change out the coils as well, and also uppgrade my fuel system as well. gonna go with a AN 10 fuel line from the new Aeromotive Pro pump and also gonna get the Pro FPR to regulate the fuel correctly.

But it's gettin anoying. Anyone ever had problems with heat soaking of the fuel rail/injectors before?

JT

but i have a biiiig problem. the car worked like a charm on the dyno giving me good afr's but i was maxing out my injectors. just running 4 1680cc still but cranked up the base fuel pressure to 3 bar, but noticed it would not go over 4 bar. have the aeromotive eliminator pump and A1000 FPR. running on BUR9EQP.

it was jumping between 11.5-12 afr under full boost wich is ok, and a 17 degreece ignition at 1 bar and 13 at 1.5 bar.

So now to the problem, when i got on the track on friday the car started shooting when giving it gas, first few laps it was ok, then started after 3-4 laps. then it got worse and worse. sometimes it would go ok, and just shoot/backfire at lower rps and go ok up in the rews and then the oppesit. and the afr's kept quite ok when this happend. might go 0.5afr leaner but that's not so bad. running brand new BUR9EQP plugs now. tried 2 sets and same problem. Tried running without the hood and same problem. It idles fine at 1750 rpm and has about -280mm/hg of vacume so it's quite good. Has 60+psi of compression on all 6 sides. has dropped down from 80 psi. and i have a manual boost meeter so its kinda sensitive. and the boost needle will jump up and down alot when this happens. it jumps like a bunny. im gonna pull the engine this week, open it and im guessing il find a broken side seal or corner seal.

and im gonna go trough my entire engine harness and check it for bad wires/connectors, and the same with the ignition harness. might change out the coils as well, and also uppgrade my fuel system as well. gonna go with a AN 10 fuel line from the new Aeromotive Pro pump and also gonna get the Pro FPR to regulate the fuel correctly.

But it's gettin anoying. Anyone ever had problems with heat soaking of the fuel rail/injectors before?

JT

about the popping exhaust and not being able to hold fuelpressure, have you checked your fuel filters?

The heat soaking sounds strange.. my rails are cold! are you using a catch tank? is the return routed through the catch or is it going directly to the tank?

Btw, what egt's where you seeing running 11.5 and 13dgr (13dgr at 1.3bar?).

Gus.

Last edited by gusfd3s; 07-14-08 at 09:43 AM.

#72

Rotary Enthusiast

it's not just popping the car goes like **** like it's hesetating. and it's like it shooting.

Well my fuel is cold but injectors and fuel rail get's too about 80 degreece celcius. Fuel filter is brand new.

Well one of my EGT's are faulty as it says my idle temp is between 600-700 degreece celcius while the other is around 400.

At boost the one that is working says just bellow 800 degreece and the other around 1100 so it's def not working.

Im also redoing alot of stuff, like setting up a new relay that will draw current straight from the battery to the fuel pump, and not run the relay that comes with the SM4

JT

Well my fuel is cold but injectors and fuel rail get's too about 80 degreece celcius. Fuel filter is brand new.

Well one of my EGT's are faulty as it says my idle temp is between 600-700 degreece celcius while the other is around 400.

At boost the one that is working says just bellow 800 degreece and the other around 1100 so it's def not working.

Im also redoing alot of stuff, like setting up a new relay that will draw current straight from the battery to the fuel pump, and not run the relay that comes with the SM4

JT

#73

Rotary Enthusiast

I think i found the problem. I saw that one of my coils where dirty around the plugg where the plugg wires connect to it. And i also checked the resistance in the coils and they are abit lower then what crane cams lists. I cheked between the HEI plugg and where the signal wires from the ecu comes in. And the lowest i messured was .860 k ohm.

JT

JT

#74

E85 Addict

Thread Starter

i took i ride today, first time in one month.

i did some road tuning and measured downpipe backpressure.

My boost controller is set at 1.3bar/18.8psi.

i advanced the ignition 2dgr's to 13dgr. AFR's jumped up from 10.5 to 12 so added some fuel. max inj.duty is presently at 66% with my 6x1680cc injectors.

Boost pattern is 1.3bar at 5600 going down to 1.14bar at 8000rpm,

seeing max 0.3bar of dp backpressure. knock in single digits.

Will take a look at my bc, see if i can make it hold the pressure, also move the pressure bung pre turbo to measure manifold backpressure.

Will also be doing some more dyno time very soon

i did some road tuning and measured downpipe backpressure.

My boost controller is set at 1.3bar/18.8psi.

i advanced the ignition 2dgr's to 13dgr. AFR's jumped up from 10.5 to 12 so added some fuel. max inj.duty is presently at 66% with my 6x1680cc injectors.

Boost pattern is 1.3bar at 5600 going down to 1.14bar at 8000rpm,

seeing max 0.3bar of dp backpressure. knock in single digits.

Will take a look at my bc, see if i can make it hold the pressure, also move the pressure bung pre turbo to measure manifold backpressure.

Will also be doing some more dyno time very soon