E85 Experience

#203

klotz techniplate is castor based, works with E85 and is less stinky for those who don't want to smell like a nitro RC car.

i personally love the smell of castor oil but not everyone does.

it also doesn't make a lot of sense to me why someone would build a car so extensively and then say premixing is too bothersome. it is more a racecar than anything mazda ever had in mind when you make the switch to almost pure ethanol.

i personally love the smell of castor oil but not everyone does.

it also doesn't make a lot of sense to me why someone would build a car so extensively and then say premixing is too bothersome. it is more a racecar than anything mazda ever had in mind when you make the switch to almost pure ethanol.

Last edited by RotaryEvolution; 05-08-13 at 12:57 PM.

#205

keep the same trims as you would with the stock system. ethanol may evaporate more readily but it won't dry out any lubricants. the only issue it presents is that it does not mix with conventional 2 stroke oils, they will separate(which in theory if you inject it through the oil metering system you could run conventional 2 stroke oil but if you premix you must use a castor based lubricant).

#206

My point of concern is that standard 2 cycle will get washed away when using E85. From my understanding that's why most 2 cycle oils out there say not for use with alcohol. Knowing the OMP's main purpose is for cooling Apex seals and lubrication, not sure if standard 2 cycle would be a good idea at stock flow levels. I'm thinking if going regular 2 cycle will have to increase flow to combat the washing effect. At least this is what I've gathered researching across the internet. Everyone I've talked to has always recommended caster oil for use with E85.

#207

My point of concern is that standard 2 cycle will get washed away when using E85. From my understanding that's why most 2 cycle oils out there say not for use with alcohol. Knowing the OMP's main purpose is for cooling Apex seals and lubrication, not sure if standard 2 cycle would be a good idea at stock flow levels. I'm thinking if going regular 2 cycle will have to increase flow to combat the washing effect. At least this is what I've gathered researching across the internet. Everyone I've talked to has always recommended caster oil for use with E85.

I on the other hand completed removed OMP on my 3 rotor and going E85 high HP and pump gas while it sit around. Hope I put enough mixture for decent lubrication.

#208

Full Member

On my setup which consist of Haltech E6K(I know i need to upgrade) 4x 1600cc injectors, s5 half bridgeport dowell pinned, Bosch 044, T76 Turbonetics, & modded ls throttle body.. i made 404hp on 16psi my question here is can i throw some e85 in the tank retune it & maybe run 22psi - 23psi & still be ok? ]

#209

Rotary Enthusiast

Join Date: Aug 2006

Location: Melbourne FL/San Antonio TX/Okinawa Japan

Posts: 1,216

Likes: 0

Received 10 Likes

on

10 Posts

Biggest benefit is your motor is ingesting 30% more fuel and the end result is more exhaust to help turn the turbo faster/sooner witch results in peak boost happening sooner in the power band. The sooner you reach peak boost the faster the car will be with out sacrificing exhaust flow.

#210

It allows you to run more timing and a bit leaner afr. Both add HP.

Biggest benefit is your motor is ingesting 30% more fuel and the end result is more exhaust to help turn the turbo faster/sooner witch results in peak boost happening sooner in the power band. The sooner you reach peak boost the faster the car will be with out sacrificing exhaust flow.

Biggest benefit is your motor is ingesting 30% more fuel and the end result is more exhaust to help turn the turbo faster/sooner witch results in peak boost happening sooner in the power band. The sooner you reach peak boost the faster the car will be with out sacrificing exhaust flow.

#211

It allows you to run more timing and a bit leaner afr. Both add HP.

Biggest benefit is your motor is ingesting 30% more fuel and the end result is more exhaust to help turn the turbo faster/sooner witch results in peak boost happening sooner in the power band. The sooner you reach peak boost the faster the car will be with out sacrificing exhaust flow.

Biggest benefit is your motor is ingesting 30% more fuel and the end result is more exhaust to help turn the turbo faster/sooner witch results in peak boost happening sooner in the power band. The sooner you reach peak boost the faster the car will be with out sacrificing exhaust flow.

the amount of air entering the engine is the same but ethanol burns at a slower/cooler rate than gasoline does. as far as i see it the combustion event is continuing even after it exits the engine, expanding the gases in the manifold to aid in spooling the turbo earlier/quicker.

but the amount of exhaust is still equal. the small amount of additional fuel really means nothing in the big picture about the amount of exhaust gases that come through the turbo.

if you were to examine an engine idling on gasoline versus alcohol you would likely see the flames still burning as it comes out the exhaust on alcohol, in gasoline the fuel is almost completely burned in the combustion process.

as far as injecting 2 stroke oil via an OMP, the oil injection should not be affected by the type of fuel. it has no time to be affected by the type of fuel being used, if it were actually being mixed with the fuel and injected that is a different scenario.

Last edited by RotaryEvolution; 05-09-13 at 12:35 PM.

#213

Full Member

On my setup which consist of Haltech E6K(I know i need to upgrade) 4x 1600cc injectors, s5 half bridgeport dowell pinned, Bosch 044, T76 Turbonetics, & modded ls throttle body.. i made 404hp on 16psi my question here is can i throw some e85 in the tank retune it & maybe run 22psi - 23psi & still be ok? ]

#214

Hi Guys,

We are looking to run E85 in the FD circuit (track) car, 13B REW, full BP, custom BW362, 4x 2200ID injectors (xcessive LIM). Looking for 520RWHP +/- @ 18-20psi.

Will run custom Alloy 85litre fuel cell, 2x 044 bosch main pumps from 4ltr surge (alloy), -8 feed to engine. Undesided on haltech PS1000 (4x2200) PS2000 (4x2200 & 2x1000)

Or would we be able to run a single SX18203 -10 pump & SX s/steel filter???

Questions:

What pre -pumps are typically used in this application & filters, ie stainless steel - what micron is best & ideal location please, for example: 100 micron s/steel filter post 044???

Is there any merit in running an additional pair of ID1000 in the factory primary location??? Using PS2000, or will the 4xID2200 inj be sufficient???

What is the accepted oil form pre-mixing & amount per Litre. Klotz etc??

Many Thanks.

BatmanNZ3

We are looking to run E85 in the FD circuit (track) car, 13B REW, full BP, custom BW362, 4x 2200ID injectors (xcessive LIM). Looking for 520RWHP +/- @ 18-20psi.

Will run custom Alloy 85litre fuel cell, 2x 044 bosch main pumps from 4ltr surge (alloy), -8 feed to engine. Undesided on haltech PS1000 (4x2200) PS2000 (4x2200 & 2x1000)

Or would we be able to run a single SX18203 -10 pump & SX s/steel filter???

Questions:

What pre -pumps are typically used in this application & filters, ie stainless steel - what micron is best & ideal location please, for example: 100 micron s/steel filter post 044???

Is there any merit in running an additional pair of ID1000 in the factory primary location??? Using PS2000, or will the 4xID2200 inj be sufficient???

What is the accepted oil form pre-mixing & amount per Litre. Klotz etc??

Many Thanks.

BatmanNZ3

#215

Hi Guys,

We are looking to run E85 in the FD circuit (track) car, 13B REW, full BP, custom BW362, 4x 2200ID injectors (xcessive LIM). Looking for 520RWHP +/- @ 18-20psi.

Will run custom Alloy 85litre fuel cell, 2x 044 bosch main pumps from 4ltr surge (alloy), -8 feed to engine. Undesided on haltech PS1000 (4x2200) PS2000 (4x2200 & 2x1000)

Or would we be able to run a single SX18203 -10 pump & SX s/steel filter???

Questions:

What pre -pumps are typically used in this application & filters, ie stainless steel - what micron is best & ideal location please, for example: 100 micron s/steel filter post 044???

Is there any merit in running an additional pair of ID1000 in the factory primary location??? Using PS2000, or will the 4xID2200 inj be sufficient???

What is the accepted oil form pre-mixing & amount per Litre. Klotz etc??

Many Thanks.

BatmanNZ3

We are looking to run E85 in the FD circuit (track) car, 13B REW, full BP, custom BW362, 4x 2200ID injectors (xcessive LIM). Looking for 520RWHP +/- @ 18-20psi.

Will run custom Alloy 85litre fuel cell, 2x 044 bosch main pumps from 4ltr surge (alloy), -8 feed to engine. Undesided on haltech PS1000 (4x2200) PS2000 (4x2200 & 2x1000)

Or would we be able to run a single SX18203 -10 pump & SX s/steel filter???

Questions:

What pre -pumps are typically used in this application & filters, ie stainless steel - what micron is best & ideal location please, for example: 100 micron s/steel filter post 044???

Is there any merit in running an additional pair of ID1000 in the factory primary location??? Using PS2000, or will the 4xID2200 inj be sufficient???

What is the accepted oil form pre-mixing & amount per Litre. Klotz etc??

Many Thanks.

BatmanNZ3

Use Klotz Benol or any type of Castor oil.

I have 3 filters. The main sock, then a 100 micron after that, then a 40 micron.

Good luck! Sounds like you are well on yer way!

#216

Hi Rxtasy57,

Thanks for the reply - just to clarify the pre pump type & filters.

With running a surge tank we obviously require pre pumps & filters from the main tank to the surge - what is the accepted solution with E85.

The 100 micron before the 044's, then the 40 micron between pumps & fuel rail ??

What could we expect to set fuel pressure to - 60psi ??? + Boost

Many Thanks

Thanks for the reply - just to clarify the pre pump type & filters.

With running a surge tank we obviously require pre pumps & filters from the main tank to the surge - what is the accepted solution with E85.

The 100 micron before the 044's, then the 40 micron between pumps & fuel rail ??

What could we expect to set fuel pressure to - 60psi ??? + Boost

Many Thanks

#217

Hi Rxtasy57,

Thanks for the reply - just to clarify the pre pump type & filters.

With running a surge tank we obviously require pre pumps & filters from the main tank to the surge - what is the accepted solution with E85.

The 100 micron before the 044's, then the 40 micron between pumps & fuel rail ??

What could we expect to set fuel pressure to - 60psi ??? + Boost

Many Thanks

Thanks for the reply - just to clarify the pre pump type & filters.

With running a surge tank we obviously require pre pumps & filters from the main tank to the surge - what is the accepted solution with E85.

The 100 micron before the 044's, then the 40 micron between pumps & fuel rail ??

What could we expect to set fuel pressure to - 60psi ??? + Boost

Many Thanks

As far as filtration after the surge tank you would want to go as low as you can go while meeting your fuel needs. I believe the ID injectors have a built in 7 micron filter. Best case is to have filtration lower then this to ensure you do not get clogged injectors. I have been using the bigger Fuel labs E85 safe 6 micro fuel filter with out any flow related issues. I am near 600 WHP and will hopefully be over on my next tuning session on the 19th.

#218

how do you figure this?

the amount of air entering the engine is the same but ethanol burns at a slower/cooler rate than gasoline does. as far as i see it the combustion event is continuing even after it exits the engine, expanding the gases in the manifold to aid in spooling the turbo earlier/quicker.

but the amount of exhaust is still equal. the small amount of additional fuel really means nothing in the big picture about the amount of exhaust gases that come through the turbo.

if you were to examine an engine idling on gasoline versus alcohol you would likely see the flames still burning as it comes out the exhaust on alcohol, in gasoline the fuel is almost completely burned in the combustion process.

as far as injecting 2 stroke oil via an OMP, the oil injection should not be affected by the type of fuel. it has no time to be affected by the type of fuel being used, if it were actually being mixed with the fuel and injected that is a different scenario.

the amount of air entering the engine is the same but ethanol burns at a slower/cooler rate than gasoline does. as far as i see it the combustion event is continuing even after it exits the engine, expanding the gases in the manifold to aid in spooling the turbo earlier/quicker.

but the amount of exhaust is still equal. the small amount of additional fuel really means nothing in the big picture about the amount of exhaust gases that come through the turbo.

if you were to examine an engine idling on gasoline versus alcohol you would likely see the flames still burning as it comes out the exhaust on alcohol, in gasoline the fuel is almost completely burned in the combustion process.

as far as injecting 2 stroke oil via an OMP, the oil injection should not be affected by the type of fuel. it has no time to be affected by the type of fuel being used, if it were actually being mixed with the fuel and injected that is a different scenario.

With normal gasoline / pump petrol 98RON best rich torque is 0.85 lambda, nobody is going to keep a rotary alive at 0.85 lambda (which is 12.5:1 air fuel) with 1.7bar and lots of timing.

I did many kms on pump E85 and I tell you it becomes tiring how often you need to replace your fuel filters. If you actually drive your car (like to work) don't be surprised if they last 2-3 months from brand new to clogged enough the fuel shuts off under high load.

#219

He is correct to a point on the E85 being leaner, its not leaner, it supports a more scientifically ideal lambda ratio. You can tune E85 fueled cars to use best rich torque mixtures at very high loads. You can tune E85 cars leaner than best rich torque at boost levels above 1.7bar / 25psi and I have done it myself and still run lots of timing.

With normal gasoline / pump petrol 98RON best rich torque is 0.85 lambda, nobody is going to keep a rotary alive at 0.85 lambda (which is 12.5:1 air fuel) with 1.7bar and lots of timing.

I did many kms on pump E85 and I tell you it becomes tiring how often you need to replace your fuel filters. If you actually drive your car (like to work) don't be surprised if they last 2-3 months from brand new to clogged enough the fuel shuts off under high load.

With normal gasoline / pump petrol 98RON best rich torque is 0.85 lambda, nobody is going to keep a rotary alive at 0.85 lambda (which is 12.5:1 air fuel) with 1.7bar and lots of timing.

I did many kms on pump E85 and I tell you it becomes tiring how often you need to replace your fuel filters. If you actually drive your car (like to work) don't be surprised if they last 2-3 months from brand new to clogged enough the fuel shuts off under high load.

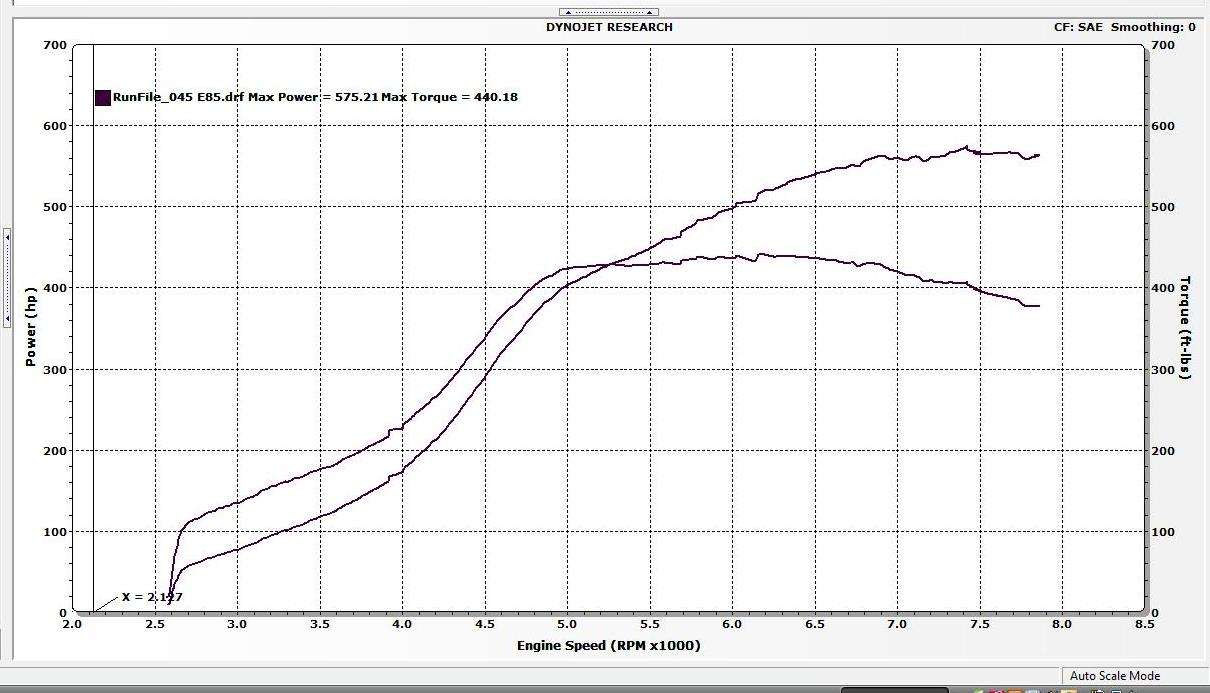

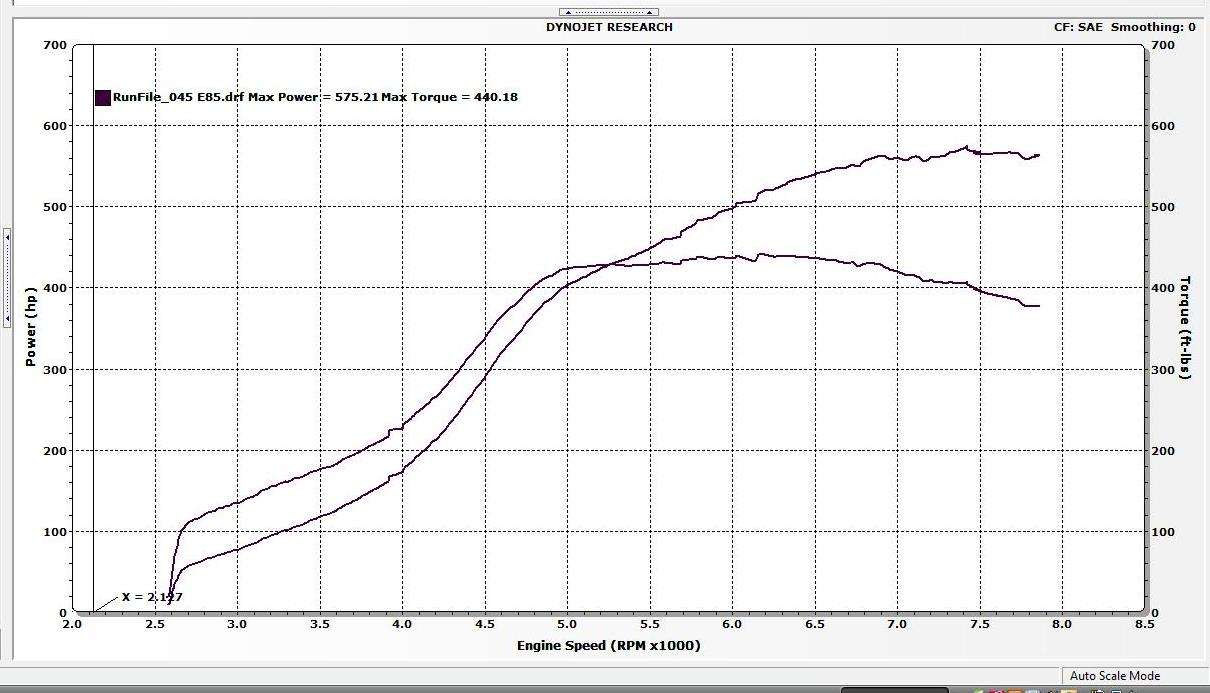

I find my car runs the best at about 12.2:1 AFRS @ 30 PSI.

#220

how do you figure this?

the amount of air entering the engine is the same but ethanol burns at a slower/cooler rate than gasoline does. as far as i see it the combustion event is continuing even after it exits the engine, expanding the gases in the manifold to aid in spooling the turbo earlier/quicker.

the amount of air entering the engine is the same but ethanol burns at a slower/cooler rate than gasoline does. as far as i see it the combustion event is continuing even after it exits the engine, expanding the gases in the manifold to aid in spooling the turbo earlier/quicker.

#221

\\TRASHTALK//

#224

For the flex fuel sensor location discussion...

On a setup running a surge tank, wouldn't it be the best location to integrate the sensor between the lifter pump and the surge tank? wouldn't restrict flow in any way as its a non-pressurized line and wouldn't need a fancy dual Y construction in the fuel rail return line.

On a setup running a surge tank, wouldn't it be the best location to integrate the sensor between the lifter pump and the surge tank? wouldn't restrict flow in any way as its a non-pressurized line and wouldn't need a fancy dual Y construction in the fuel rail return line.

#225

Racing Rotary Since 1983

iTrader: (6)

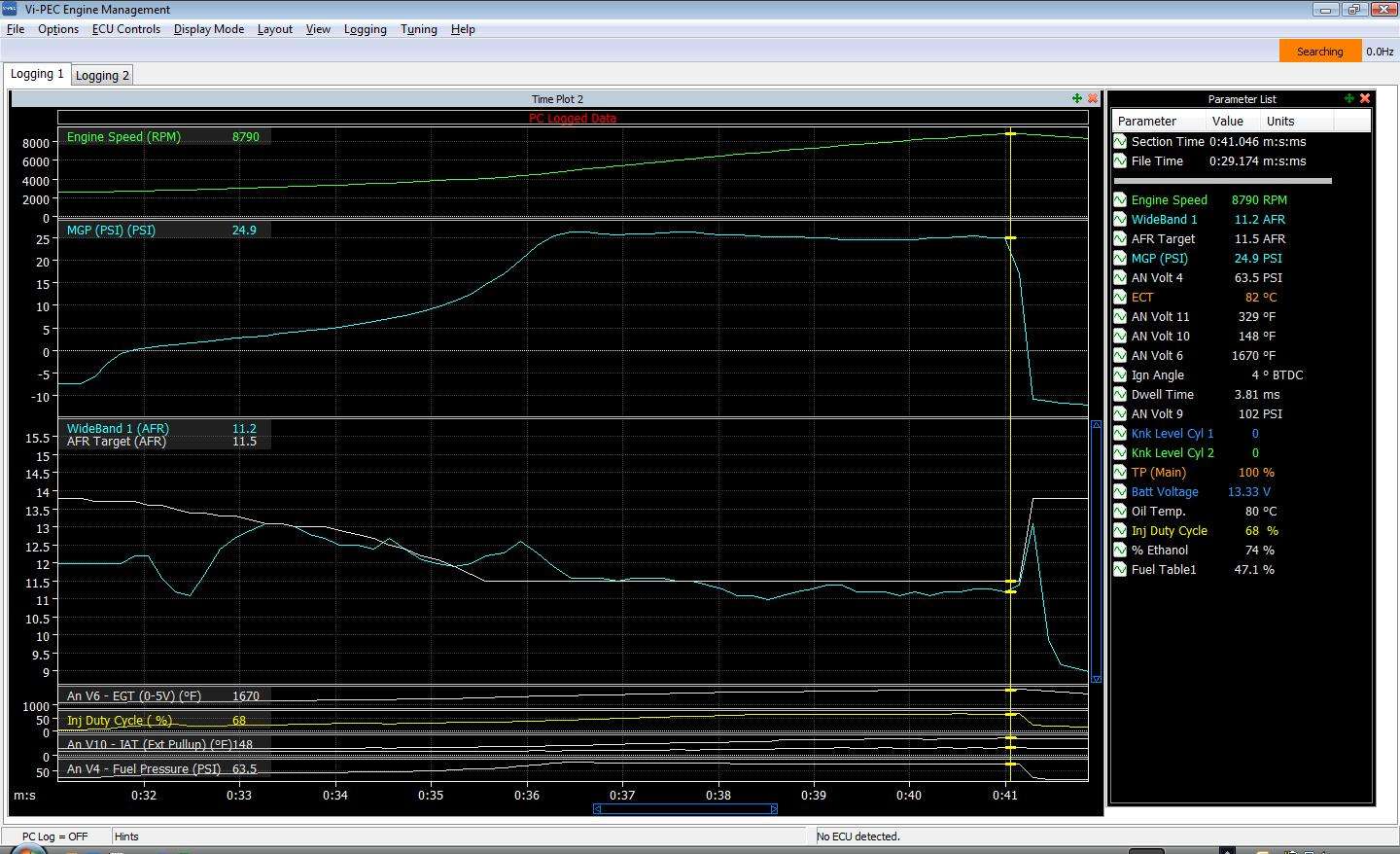

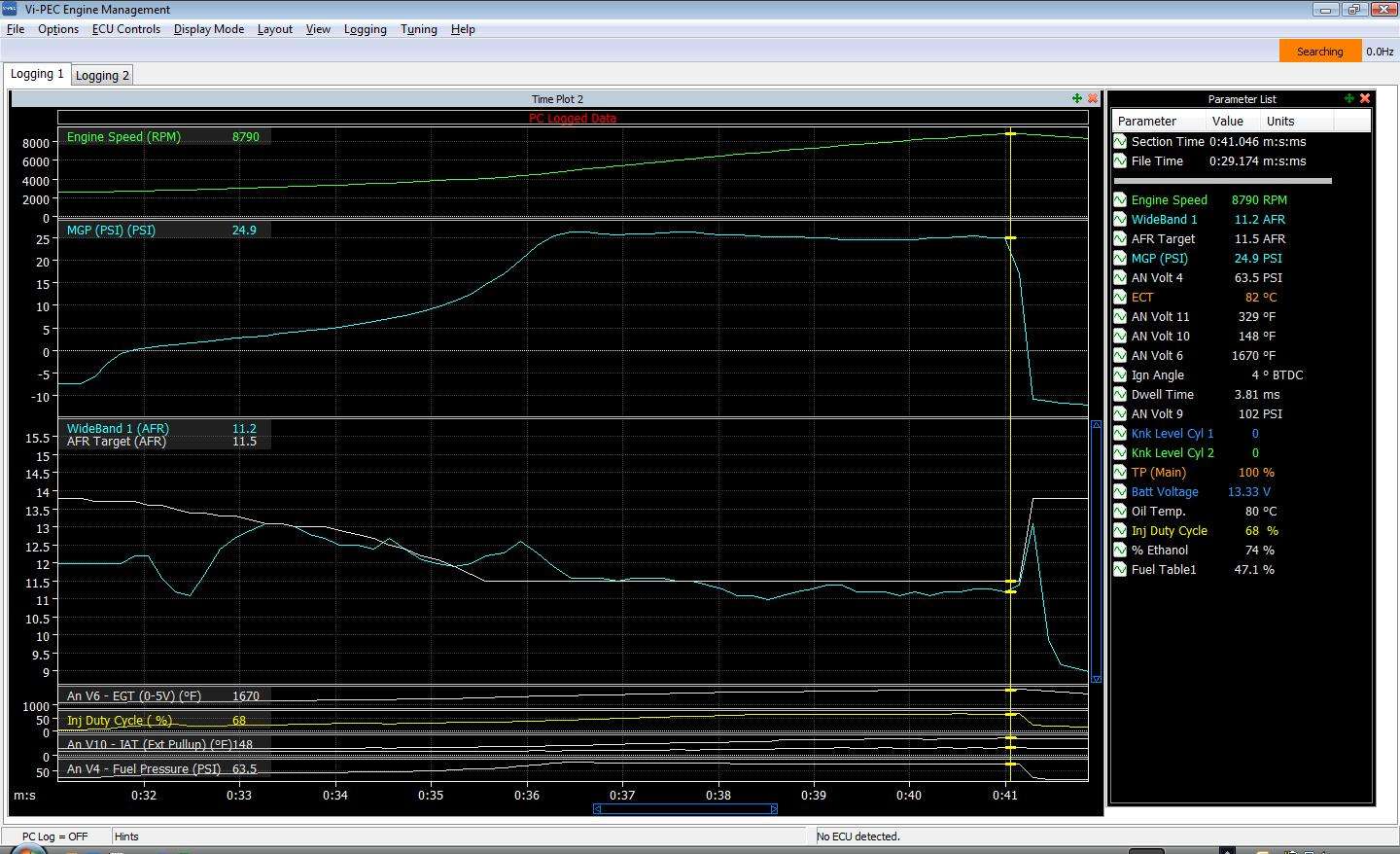

since this is the key E85 thread i thought i would share some of what i did w E85 last saturday. this was the first time on the rollers w E85 and it was a good trip. it looks like according the the FFS that i was at E74.... probably due to residual gasoline in the fuel tank.

we chose to be conservative given it was the first outing so timing was at 9 IGL 0 IGT and AFRs were between 11 and 11.5. (the right hand table shows 4 degrees... i don't know where that came from as all the other numbers on the run were 9).

we will explore the somewhat leaner area above 11.5 probably this saturday along w raising the boost to 29.

so far no hint of detonation.

Thanks RXTASY57 for all your E85 contributuons.

we chose to be conservative given it was the first outing so timing was at 9 IGL 0 IGT and AFRs were between 11 and 11.5. (the right hand table shows 4 degrees... i don't know where that came from as all the other numbers on the run were 9).

we will explore the somewhat leaner area above 11.5 probably this saturday along w raising the boost to 29.

so far no hint of detonation.

Thanks RXTASY57 for all your E85 contributuons.