Why won't the axles go in?

#1

YOUR TRIANGLE NIGHTMARE

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: automotive purgatory

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

Okay so I had a good friend of mine(Dan from LT motorsports) install a kaaz 1.5 way differential. You may know him as the driver of the Jigsaw rx7. I installed the differential casing with differential, and I can't seem to get the axles back into the the new differential. They go in a short way but then they just stop. Is there some trick to this?

#4

YOUR TRIANGLE NIGHTMARE

Thread Starter

iTrader: (6)

Join Date: Mar 2006

Location: automotive purgatory

Posts: 807

Likes: 0

Received 0 Likes

on

0 Posts

okay im not going to beat on them lol i ve tried rotating them ive tried backing them out and reinserting them they go in except for about the last inch or so.

Trending Topics

#10

Just rotating the assembly and use a mallet slowly tapping it. Works everytime =).

Tip: Usually before you install it, I tent to put some grease and hold the clip in the center so it is not lob-sided towards any directly (must be as center as possible) and with little force or a mallet. Goes in like a charm =).

-AzEKnightz

Tip: Usually before you install it, I tent to put some grease and hold the clip in the center so it is not lob-sided towards any directly (must be as center as possible) and with little force or a mallet. Goes in like a charm =).

-AzEKnightz

#13

For any future search, I removed mine for seal replacement a few years ago. I was careful NOT to rotate or move the differential while the axles were out and they both slipped right back in w/o issues. Maybe just lucky, but there you go.

Can't remember for sure, but I thought there was an acceptable tolerance/gap measurement on the clips.

And don't forget to paint the inner "hubs" green again. If you do that you'll be able to use synthetic oil and a KOYO radiator will "drop right in". Then you can also then delete the OMP, AST and it's worth 10 whp....per axle.

Can't remember for sure, but I thought there was an acceptable tolerance/gap measurement on the clips.

And don't forget to paint the inner "hubs" green again. If you do that you'll be able to use synthetic oil and a KOYO radiator will "drop right in". Then you can also then delete the OMP, AST and it's worth 10 whp....per axle.

#15

Just rotating the assembly and use a mallet slowly tapping it. Works everytime =).

Tip: Usually before you install it, I tent to put some grease and hold the clip in the center so it is not lob-sided towards any directly (must be as center as possible) and with little force or a mallet. Goes in like a charm =).

-AzEKnightz

Tip: Usually before you install it, I tent to put some grease and hold the clip in the center so it is not lob-sided towards any directly (must be as center as possible) and with little force or a mallet. Goes in like a charm =).

-AzEKnightz

Last edited by RotaryEvolution; 01-11-11 at 04:42 PM.

#16

This works for me:

Push the axle as far as it will go in easily.

Pull it back out a half inch or so, you need to make sure you don't pull it out too far.

You'll understand why the first time you do it.

Then give the axle a good hard shove - it will pop right it.

Make sure the clips are oriented as per the manual, open side up IIRC

Push the axle as far as it will go in easily.

Pull it back out a half inch or so, you need to make sure you don't pull it out too far.

You'll understand why the first time you do it.

Then give the axle a good hard shove - it will pop right it.

Make sure the clips are oriented as per the manual, open side up IIRC

#18

Junior Member

Alright squad, it's been 12 years and this thread was super helpful for me to get this job done, and I'm gonna add some details below that helped me, for posterity.

- Putting a little cold grease on the retention spring/clip to hold it in place is super, super helpful. If it's not pretty much perfectly upright (i.e. the opening in the spring/clip straight up), it just won't go in. that grease helps keep it lined up beautifully.

- I saw some tips on this thread and others to take a mallet and tap the axle in. This doesn't work if your hub / rotor end is still attached as well (I don't know, but maybe it could damage the bearings too?)

- pushing the threads in on the halfshaft will get you most of the way there, but you'll probably jam about an inch away from it being totally flush, which is the point where your spring clip starts to "bite"

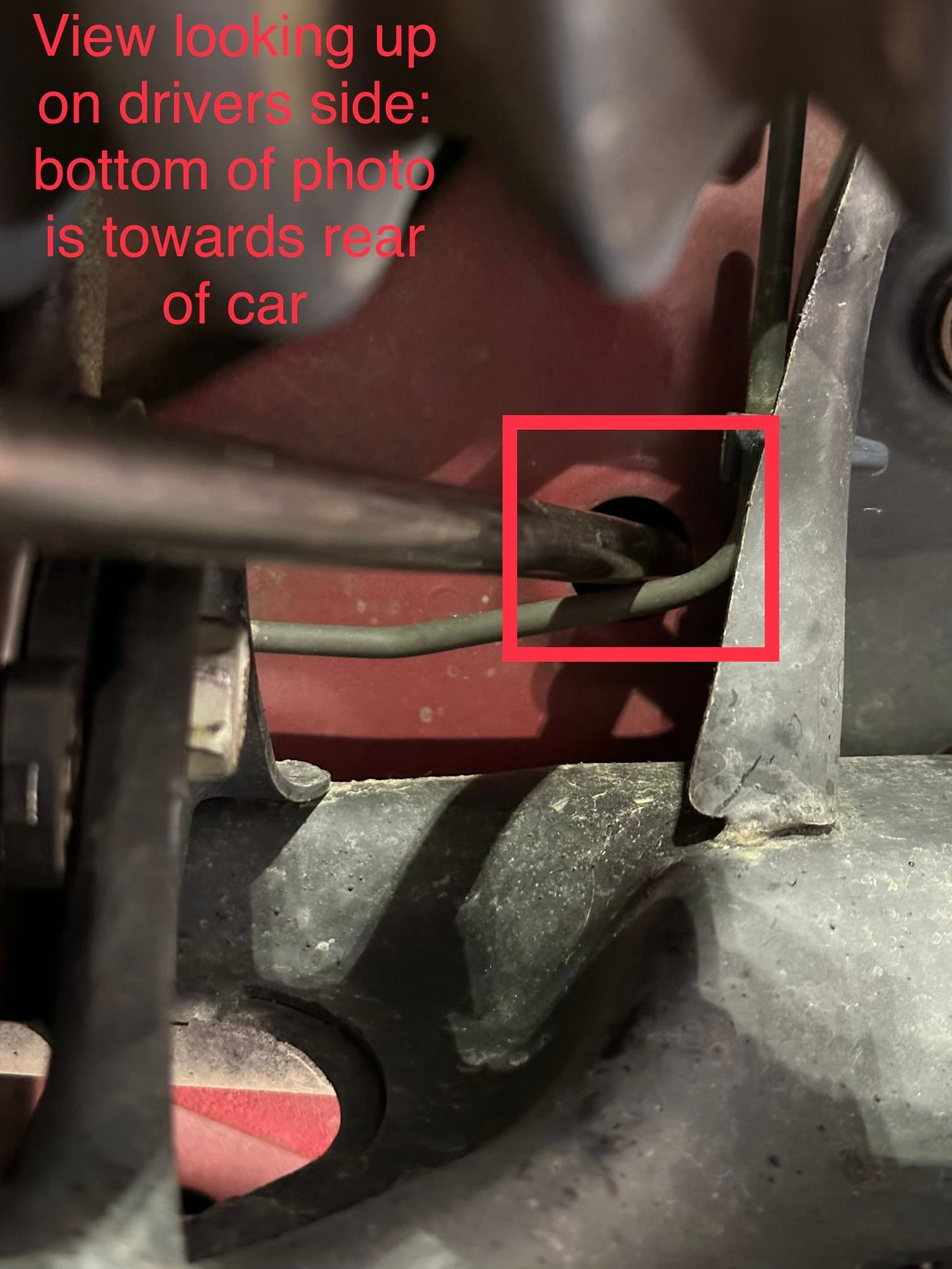

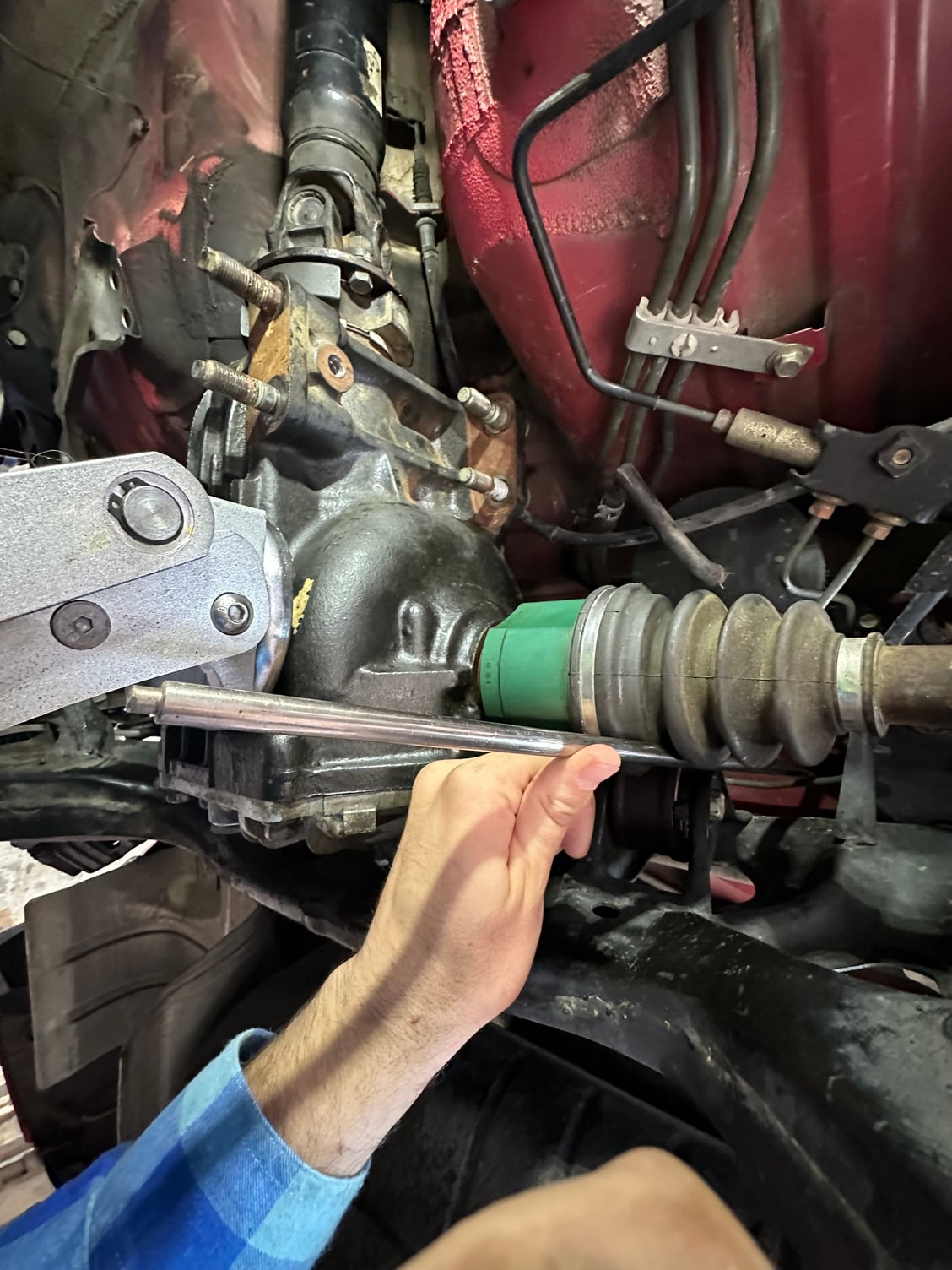

- To get past this, I took a 3/8" rod about 18" long, and hooked the back end against the subframe, and nudged it against the outer edge of the CV cover (see photo 1)

photo 1: or lever pry bar against black subframe on right

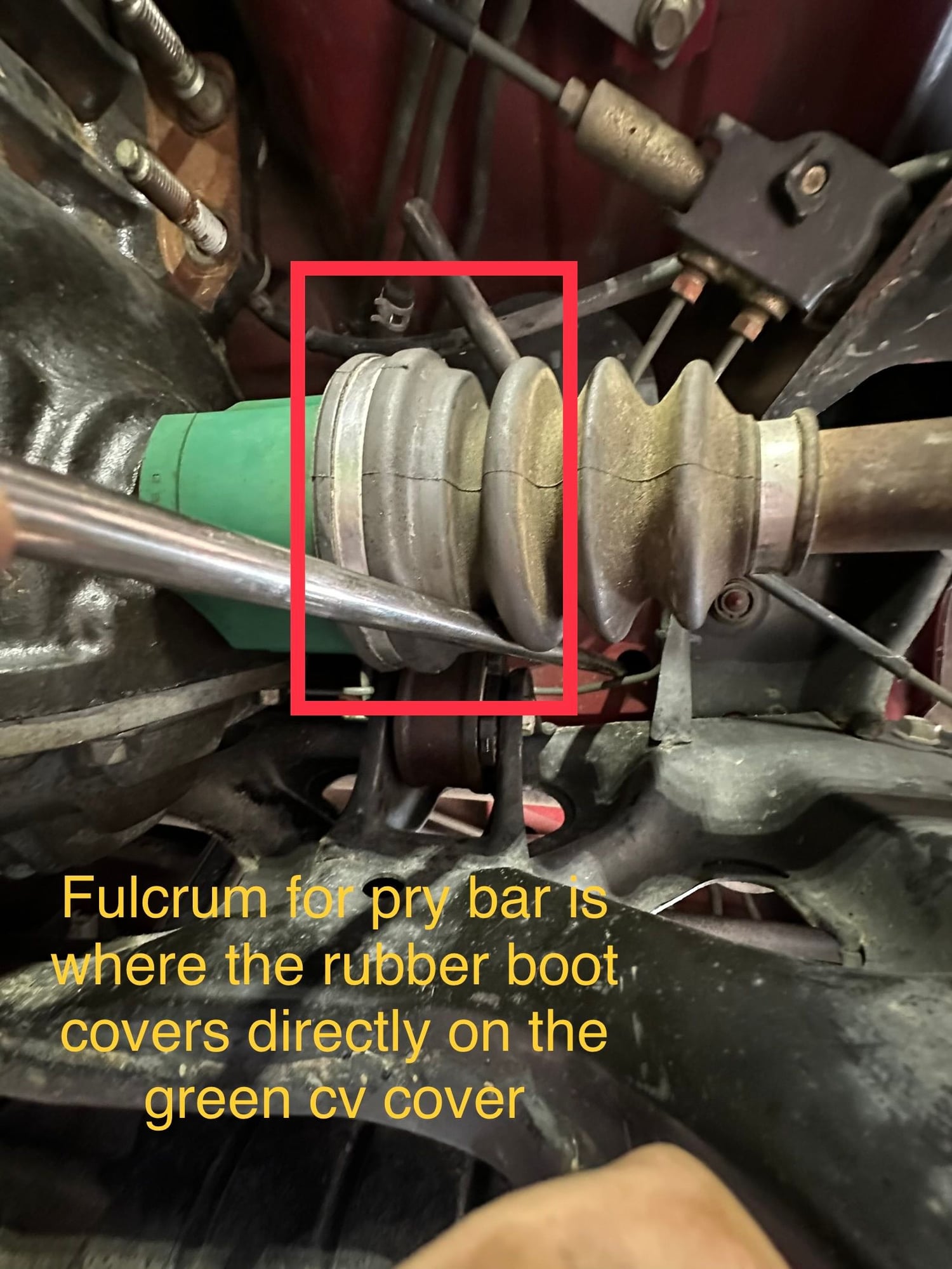

photo 2, showing how pry bar presses against the cover

photo 3, showing the pry bar zoomed out for context

- then tap the end that sticks out furthest towards you with the mallet to gently lever it in to place

- This helps since there isn't much of a lip to hammer on the green cover on it's own

Hope this helps

The following 5 users liked this post by Tomas Jurgensen:

DaleClark (05-19-23),

level7 (05-21-23),

Molotovman (05-19-23),

Pete_89T2 (05-20-23),

Sgtblue (05-20-23)

#19

RX-7 Bad Ass

iTrader: (55)

Thanks for this how-to!

Dale

Dale

#20

Thanks for the how-to write up & pictures Tomas! Wish I had this when I had my axles out to fix my leaky diff/axle seals.

One other relevant tip to add - if your clips are a bit too worn and stay too open to allow the axle to seat, and you don't have new clips from Mazda handy, here's how you can recondition your old clips to close them up a bit and get them to work just like new ones:

1. Stick the clip on the axle in its groove.

2. Take a suitable channel lock plier, vise grips or similar tool to compress around the circumference of the clip so its open end is more closed. Keep the clip compressed on the axle for the next few steps...

3. Take a propane torch and apply heat evenly to the clip for a minute or two. Keep the torch moving; you don't want to give it too much heat, just enough to get the clip a bit more ductile without harming the axle. For that reason, you don't want to use MAPP gas or anything else that would burn hotter than a basic propane torch.

4. Remove the heat, while keeping the clip compressed with the pliers.

5. Wait a good 5~10 minutes for the clip/axle to air cool, then you can release the pliers holding the clip compressed. End result will be the open end of the clip will now be more closed than it was, but it will still retain its springy characteristics.

One other relevant tip to add - if your clips are a bit too worn and stay too open to allow the axle to seat, and you don't have new clips from Mazda handy, here's how you can recondition your old clips to close them up a bit and get them to work just like new ones:

1. Stick the clip on the axle in its groove.

2. Take a suitable channel lock plier, vise grips or similar tool to compress around the circumference of the clip so its open end is more closed. Keep the clip compressed on the axle for the next few steps...

3. Take a propane torch and apply heat evenly to the clip for a minute or two. Keep the torch moving; you don't want to give it too much heat, just enough to get the clip a bit more ductile without harming the axle. For that reason, you don't want to use MAPP gas or anything else that would burn hotter than a basic propane torch.

4. Remove the heat, while keeping the clip compressed with the pliers.

5. Wait a good 5~10 minutes for the clip/axle to air cool, then you can release the pliers holding the clip compressed. End result will be the open end of the clip will now be more closed than it was, but it will still retain its springy characteristics.

The following users liked this post:

Sgtblue (05-20-23)

Thread

Thread Starter

Forum

Replies

Last Post