Texas Mile FD

#76

RE: Linear potentiometers, AimSports 'new' EVO4 datalogging and sensor package has really blown me away with their quality, ease of installation/adaption, and affordability. I'm half tempted to run one of these:AiM GT Steering Wheel instead of my MXL.

#78

Full Member

Join Date: Jan 2013

Location: Gun Barrel City, Texas

Posts: 53

Likes: 0

Received 0 Likes

on

0 Posts

For comparison, my fc made 159 mph with 389 rwhp and 172.7 with 455 rwhp

#79

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

It seems the more important thing to do regarding aerodynamics is to reduce lift without adding downforce. Downforce adds drag, taking proper measures to reduce lift is more important.

#80

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"It seems the more important thing to do regarding aerodynamics is to reduce lift without adding downforce. Downforce adds drag, taking proper measures to reduce lift is more important."

absolutely, and that is why i want to log ride height... it is a simple deal, around $100 for the sensor. ideally, i want my ride height to not change.

"my fc made 159 mph with 389 rwhp and 172.7 with 455 rwhp"

172.7/159 = 1.0861 MPH increase

it should take a power increase equal to (8.61%) cubed to do 172.7 V 159. that would be 28.1% more hp to go 8.6% faster.

since you have 16.9% more power (455/389) there is some slippage somewhere...

if things had stayed constant w the slower less hp run it should take 498 to run 172.7.

items that might effect:

we all know that dynos provide differing measures of hp... for example your 389 run might have been overstated and your 455 run could have been understated.

changes in the horsepower under the curve... you might, in addition to having a higher hp peak, have more horsepower under the curve. maybe a different power-train/setup?

since you ran 172.7 V 159 you were also running 8.6% more RPM.... different RPM, diff hp. the 172 run probably was around 7250 thru the lights V the 159 run around 6650. what RPM is peak hp for you?

since your car was running 8.6% more MPH and the body may have been effected as to attitude/drag/lift etc.

condition during your runs, wind, track temp, air temp, humidity all could play a role.

were there any aero differences as to car prep?

nice going BTW and thanks for sharing your results.

howard

absolutely, and that is why i want to log ride height... it is a simple deal, around $100 for the sensor. ideally, i want my ride height to not change.

"my fc made 159 mph with 389 rwhp and 172.7 with 455 rwhp"

172.7/159 = 1.0861 MPH increase

it should take a power increase equal to (8.61%) cubed to do 172.7 V 159. that would be 28.1% more hp to go 8.6% faster.

since you have 16.9% more power (455/389) there is some slippage somewhere...

if things had stayed constant w the slower less hp run it should take 498 to run 172.7.

items that might effect:

we all know that dynos provide differing measures of hp... for example your 389 run might have been overstated and your 455 run could have been understated.

changes in the horsepower under the curve... you might, in addition to having a higher hp peak, have more horsepower under the curve. maybe a different power-train/setup?

since you ran 172.7 V 159 you were also running 8.6% more RPM.... different RPM, diff hp. the 172 run probably was around 7250 thru the lights V the 159 run around 6650. what RPM is peak hp for you?

since your car was running 8.6% more MPH and the body may have been effected as to attitude/drag/lift etc.

condition during your runs, wind, track temp, air temp, humidity all could play a role.

were there any aero differences as to car prep?

nice going BTW and thanks for sharing your results.

howard

Last edited by Howard Coleman; 11-17-13 at 10:08 AM.

#81

Senior Member

Since the line of action of the drag acting on the car is ~22" above the line of action of the thrust at the rear wheel contact patches, it winds up that if you truly have a zero-lift/zero-downforce (should be minimum drag) body configuration, you will get induced lift at the front and induced "downforce" at the rear from the thrust/drag offset.

This by itself will give an apparent ~140 lb. of lift at the front of the car and ~140 lb. download at the back of the car at 200mph, even if the shape of the car isn't really giving any lift or downforce.

Basically, at 200mph the drag force is ~610 lb. If the center of aerodynamic pressure is 22" above the ground, then the moment acting to lift the front and lower the rear is 610 lb * 22" = 13420 in-lb. Dividing by the wheelbase we get 13420 in-lb/95.5" = 140.5 lb upload at the front, download at the rear.

If you try to have zero ride height change at the front and back of the car, you will really have to have some downforce at the front and some *lift* at the back of the car. Although the front and rear coefficients of lift would both technically be zero, there would actually have to be some front aero download and rear aero upload required to counteract the vertical forces induced by the offset of the thrust (at ground level) and drag (somewhere just below half the car's height).

I think it's a better idea to simply have some static rake to give the desired attitude at speed. With stiffish springs (say, 16kg), the static rake required would only be about 3/8". So just set the front ride height 3/8" lower than the attitude you want.

This by itself will give an apparent ~140 lb. of lift at the front of the car and ~140 lb. download at the back of the car at 200mph, even if the shape of the car isn't really giving any lift or downforce.

Basically, at 200mph the drag force is ~610 lb. If the center of aerodynamic pressure is 22" above the ground, then the moment acting to lift the front and lower the rear is 610 lb * 22" = 13420 in-lb. Dividing by the wheelbase we get 13420 in-lb/95.5" = 140.5 lb upload at the front, download at the rear.

If you try to have zero ride height change at the front and back of the car, you will really have to have some downforce at the front and some *lift* at the back of the car. Although the front and rear coefficients of lift would both technically be zero, there would actually have to be some front aero download and rear aero upload required to counteract the vertical forces induced by the offset of the thrust (at ground level) and drag (somewhere just below half the car's height).

I think it's a better idea to simply have some static rake to give the desired attitude at speed. With stiffish springs (say, 16kg), the static rake required would only be about 3/8". So just set the front ride height 3/8" lower than the attitude you want.

#82

Brap..

iTrader: (2)

"It seems the more important thing to do regarding aerodynamics is to reduce lift without adding downforce. Downforce adds drag, taking proper measures to reduce lift is more important."

absolutely, and that is why i want to log ride height... it is a simple deal, around $100 for the sensor. ideally, i want my ride height to not change.

"my fc made 159 mph with 389 rwhp and 172.7 with 455 rwhp"

172.7/159 = 1.0861 MPH increase

it should take a power increase equal to (8.61%) cubed to do 172.7 V 159. that would be 28.1% more hp to go 8.6% faster.

since you have 16.9% more power (455/389) there is some slippage somewhere...

if things had stayed constant w the slower less hp run it should take 498 to run 172.7.

items that might effect:

we all know that dynos provide differing measures of hp... for example your 389 run might have been overstated and your 455 run could have been understated.

changes in the horsepower under the curve... you might, in addition to having a higher hp peak, have more horsepower under the curve. maybe a different power-train/setup?

since you ran 172.7 V 159 you were also running 8.6% more RPM.... different RPM, diff hp. the 172 run probably was around 7250 thru the lights V the 159 run around 6650. what RPM is peak hp for you?

since your car was running 8.6% more MPH and the body may have been effected as to attitude/drag/lift etc.

condition during your runs, wind, track temp, air temp, humidity all could play a role.

were there any aero differences as to car prep?

nice going BTW and thanks for sharing your results.

howard

absolutely, and that is why i want to log ride height... it is a simple deal, around $100 for the sensor. ideally, i want my ride height to not change.

"my fc made 159 mph with 389 rwhp and 172.7 with 455 rwhp"

172.7/159 = 1.0861 MPH increase

it should take a power increase equal to (8.61%) cubed to do 172.7 V 159. that would be 28.1% more hp to go 8.6% faster.

since you have 16.9% more power (455/389) there is some slippage somewhere...

if things had stayed constant w the slower less hp run it should take 498 to run 172.7.

items that might effect:

we all know that dynos provide differing measures of hp... for example your 389 run might have been overstated and your 455 run could have been understated.

changes in the horsepower under the curve... you might, in addition to having a higher hp peak, have more horsepower under the curve. maybe a different power-train/setup?

since you ran 172.7 V 159 you were also running 8.6% more RPM.... different RPM, diff hp. the 172 run probably was around 7250 thru the lights V the 159 run around 6650. what RPM is peak hp for you?

since your car was running 8.6% more MPH and the body may have been effected as to attitude/drag/lift etc.

condition during your runs, wind, track temp, air temp, humidity all could play a role.

were there any aero differences as to car prep?

nice going BTW and thanks for sharing your results.

howard

#84

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

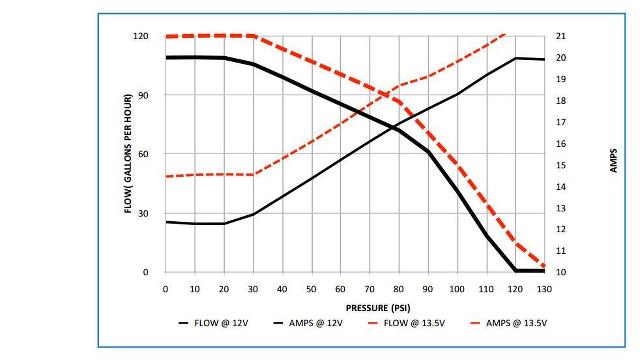

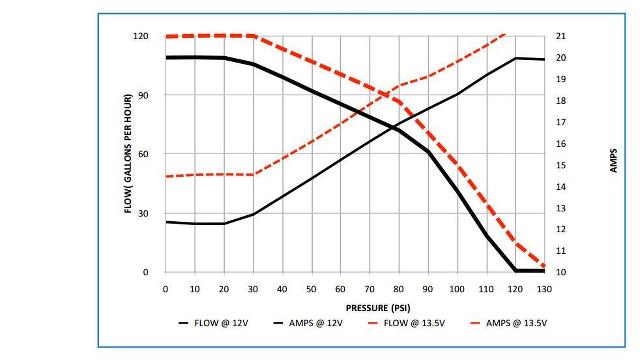

here's the chart that tells the tale as to my fuse. i can't plead ignorance because i posted the chart in my thread "Fuel pumps 2013." note the required amps around 73 psi (43 rail plus 30 boost)...

16.4 amps at 12 V

18.3 amps at 13.5 V

running the pump as i was at 16 V would require 21.6 amps.

the above is calculated at 30 psi which is the top boost contemplated w my 4094r.

we didn't have enough time to get to 30 on the dyno so i was running a max of 26. further, my rail pressure was 39.

so 39 plus 26 = 65 PSI.

15.6 amps at 12 V

17.5 amps at 13.5 V

20.7 amps at 16 V

the fuse worked fine for a couple of months and over 40 dyno pulls including 3 runs thru 5 gears on the dyno. it also worked fine on my first Texas run thru 4 gears and a bit of fifth.

it was 3 hours between my first and second run so it certainly had time to cool. the fuse failed on the second run as i shifted into 4th.

i do feel the fuel filter blockage was a contributing factor but the fuse would have probably failed at some point at the 16 V level.

i will upgrade any wiring as well as the fuse and may see if the pump is adequate without the BAP.

it is worth noting that the OE fuel pump fuse in the FD is 20 Amps.

"Where did you get your background in fluid dynamics?"

"Tune to Win" by Carroll Smith published 1978, acquired by me in 1981. Chapter 8 "External Aerodynamics"... along w engineering data supplied to me from Mazda allowed me to calculate the top speed (143) of my GT3 RX3 at Road Atlanta to within 2 mph. i either set the fastest top speed or tied at the Runoffs every year i participated. i still use much of the content in Carroll's classic book.

Howard

16.4 amps at 12 V

18.3 amps at 13.5 V

running the pump as i was at 16 V would require 21.6 amps.

the above is calculated at 30 psi which is the top boost contemplated w my 4094r.

we didn't have enough time to get to 30 on the dyno so i was running a max of 26. further, my rail pressure was 39.

so 39 plus 26 = 65 PSI.

15.6 amps at 12 V

17.5 amps at 13.5 V

20.7 amps at 16 V

the fuse worked fine for a couple of months and over 40 dyno pulls including 3 runs thru 5 gears on the dyno. it also worked fine on my first Texas run thru 4 gears and a bit of fifth.

it was 3 hours between my first and second run so it certainly had time to cool. the fuse failed on the second run as i shifted into 4th.

i do feel the fuel filter blockage was a contributing factor but the fuse would have probably failed at some point at the 16 V level.

i will upgrade any wiring as well as the fuse and may see if the pump is adequate without the BAP.

it is worth noting that the OE fuel pump fuse in the FD is 20 Amps.

"Where did you get your background in fluid dynamics?"

"Tune to Win" by Carroll Smith published 1978, acquired by me in 1981. Chapter 8 "External Aerodynamics"... along w engineering data supplied to me from Mazda allowed me to calculate the top speed (143) of my GT3 RX3 at Road Atlanta to within 2 mph. i either set the fastest top speed or tied at the Runoffs every year i participated. i still use much of the content in Carroll's classic book.

Howard

#85

Eye In The Sky

iTrader: (2)

Join Date: Feb 2001

Location: In A Disfunctional World

Posts: 7,892

Likes: 0

Received 114 Likes

on

66 Posts

Here is why I ask.

A few years ago I completely rewired most of the fuel pump wiring. Included was a separate fuse for the pump. It was located just off of the positive terminal of the battery for quick access.

The holder seemed normal albeit a little loose holding the fuse.

Was out one day on a road doing spirited driving which means the pump was pulling maximum current for a long time. Luckily I had slowed down and was off boost when the engine died.

I coasted off the road to check out the problem. No fuel pressure.

The fuse holder was melted. I pulled the fuse and it actually was only slightly melted and looked good. I used my knife to strip the wires and reconnect without a fuse.

The fuel pump then worked and I drove home without any problems.

At home I inspected the fuse and its holder. THE FUSE WAS STILL GOOD! I shorted it across the battery for a test. It blew and did not melt the plastic.

The holder was melted around the terminals where the fuse slides into them.

The only thing that can cause this failure is loose connections between the fuse legs and the sockets.

This causes a high impedance connection thus power/wattage/heat occurs there and the heat builds up until something gives; the plastic melts and the holder comes apart.

I found a better fuse holder but I also made sure it grabs the fuse legs very tightly

to prevent a voltage drop and heat.

Be aware of poor quality fuse holders! If your holder is also melting, you have the same problem I had!

#88

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

i had 3 safety items that were borderline on my car when i did the Oct 2013 Mile. upon return the good news was my motor was fine but i did want to fix the 3 items. given my busy motor business, the upcoming holiday season and short run of time til March 21 i elected to pass on the early Texas Mile and get the car properly prepared for the Oct event.

the car will get a nylon scattershield as the motor should spend about 15 seconds in fifth gear above 8000 rpm

a fuel cell. having raced 22 seasons all with a (required) fuel cell and having watched from the start line what happened to the black Camaro (twin turbo) when it blew a tire above 200... it looked like a bomb went off. the car had a Pro Stock cage and fuel cell but it wasn't pretty. no way would you want a steel gas tank in that mess.

i feel my tire situation is locked down w the Michelin Pilot Cup Sport tires. while the Camaro was probably running the same tire it weighed a lot more and was packing way more than a 1000 additional hp. i am not surprised re the tire failure. i will be running more than 500 pounds lighter and with 600 tops.

finally, i will add a set of axles which may be overkill but overkill is good at 200.

on the non safety mod list will be a ride height sensor. i will log dynamic ride height. ideally it would be nice if i could trim the car to no change.

i will be evaluating an EFR 9180 vs my GT4094 and will switch back to 100% meth as AI. the only reason i ran a W/M combo was to keep it non-flammable. the 4.5 gallon AI Jaz poly fuel cell will gain a steel container box.

Oh, and yes, I will be swapping in a 30 amp fuse for my fuel pump and checking the relays etc.

there is an event in Houston this June in conjunction w Hennessey but it is a half mile.

Howard

the car will get a nylon scattershield as the motor should spend about 15 seconds in fifth gear above 8000 rpm

a fuel cell. having raced 22 seasons all with a (required) fuel cell and having watched from the start line what happened to the black Camaro (twin turbo) when it blew a tire above 200... it looked like a bomb went off. the car had a Pro Stock cage and fuel cell but it wasn't pretty. no way would you want a steel gas tank in that mess.

i feel my tire situation is locked down w the Michelin Pilot Cup Sport tires. while the Camaro was probably running the same tire it weighed a lot more and was packing way more than a 1000 additional hp. i am not surprised re the tire failure. i will be running more than 500 pounds lighter and with 600 tops.

finally, i will add a set of axles which may be overkill but overkill is good at 200.

on the non safety mod list will be a ride height sensor. i will log dynamic ride height. ideally it would be nice if i could trim the car to no change.

i will be evaluating an EFR 9180 vs my GT4094 and will switch back to 100% meth as AI. the only reason i ran a W/M combo was to keep it non-flammable. the 4.5 gallon AI Jaz poly fuel cell will gain a steel container box.

Oh, and yes, I will be swapping in a 30 amp fuse for my fuel pump and checking the relays etc.

there is an event in Houston this June in conjunction w Hennessey but it is a half mile.

Howard

#89

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

Why would you switch back to straight meth again? Didnt you already figure out that is not a good idea?

Are you going to keep running e-85? Or switch that too?

Why dont you just keep e-85 or run e-98 and not run any auxilary injectant? Ditch the stock mount intercooler and run a front mount or v-mount?

Are you going to keep running e-85? Or switch that too?

Why dont you just keep e-85 or run e-98 and not run any auxilary injectant? Ditch the stock mount intercooler and run a front mount or v-mount?

Last edited by RENESISFD; 04-06-14 at 11:49 AM.

#91

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"Why would you switch back to straight meth again? Didnt you already figure out that is not a good idea?"

it perhaps is not a good idea to run a combo of gas and significantly more than 1500 cc of meth while running platinum fine wire (expensive) plugs. it was just fine at 1500 w that combo.

since i am not running any gas (o k there's a touch in the E85), am not running more than 1500 CC of meth and not running platinum plugs i will gain the benefit of additional IAT reduction versus the water component.

i am primarily running AI to reduce my IAT. since i use an accurate sensor (type K thermocouple) i know what the temp is and don't like the number. i am getting no knock in the motor but i want more oxygen which relates to IAT among other things.

as to intercoolers, my stock location Pettit Coolcharge removes 130 degrees from the charge air. i much prefer it to a front mount which adds to front weight, gets garfed up w road crap and has a ton of tube volume. in addition, it masks the radiator and makes road racing the car almost impossible.

as to a v mount, i don't like what it does to engine compartment room. my car is dual purpose, street, the Mile and road racing.

as to E85, why would i switch it? no knock. happy motor.

"Borg Warner EFR 9180'

i am looking forward to it, especially since the 8374 recently proved a clear mid range advantage on the rotary.

Howard

it perhaps is not a good idea to run a combo of gas and significantly more than 1500 cc of meth while running platinum fine wire (expensive) plugs. it was just fine at 1500 w that combo.

since i am not running any gas (o k there's a touch in the E85), am not running more than 1500 CC of meth and not running platinum plugs i will gain the benefit of additional IAT reduction versus the water component.

i am primarily running AI to reduce my IAT. since i use an accurate sensor (type K thermocouple) i know what the temp is and don't like the number. i am getting no knock in the motor but i want more oxygen which relates to IAT among other things.

as to intercoolers, my stock location Pettit Coolcharge removes 130 degrees from the charge air. i much prefer it to a front mount which adds to front weight, gets garfed up w road crap and has a ton of tube volume. in addition, it masks the radiator and makes road racing the car almost impossible.

as to a v mount, i don't like what it does to engine compartment room. my car is dual purpose, street, the Mile and road racing.

as to E85, why would i switch it? no knock. happy motor.

"Borg Warner EFR 9180'

i am looking forward to it, especially since the 8374 recently proved a clear mid range advantage on the rotary.

Howard

#92

Brap..

iTrader: (2)

Because in case you haven't noticed there has been a common occurrence when people with rotaries try to make power using E85. They blow up.

Just off the top of my head I can think a bunch of high dollar build on this forum that have ended with a rebuild for one reason or another but the one thing they all have in common is.. You ready? E85!!

There's been Mannykiller, Xlr8,BDC, YOU (times like 3 or 4)..

Then let's take a look at gasoline + WI users. Banzai, fendamokey, thewird, countless local builds here that I have seen in person. What do all these builds have in common? They all run and they all run GOOD.

One thing that separates you from an actual engineer is that you are incapable of realizing that just because something works well on paper doesn't mean it will work well in real life. With countless E85 failures, this would be one of those situations.

Rotaries are finicky. E85 might work well for a little while but because of the fuels relatively unstable nature, you can't guarantee that the second tank is the same as the first. And one bad tank = kaboom.

That's why not e85.

Just off the top of my head I can think a bunch of high dollar build on this forum that have ended with a rebuild for one reason or another but the one thing they all have in common is.. You ready? E85!!

There's been Mannykiller, Xlr8,BDC, YOU (times like 3 or 4)..

Then let's take a look at gasoline + WI users. Banzai, fendamokey, thewird, countless local builds here that I have seen in person. What do all these builds have in common? They all run and they all run GOOD.

One thing that separates you from an actual engineer is that you are incapable of realizing that just because something works well on paper doesn't mean it will work well in real life. With countless E85 failures, this would be one of those situations.

Rotaries are finicky. E85 might work well for a little while but because of the fuels relatively unstable nature, you can't guarantee that the second tank is the same as the first. And one bad tank = kaboom.

That's why not e85.

#93

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

^ what are you talking about? Mannykiller was not using e85 xlr8 was not using e85 even howard coleman when using e85 could not blow his motor. Get your facts straight.

High horsepower builds use e-85 and work.

High horsepower builds use e-85 and work.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

NCross

2nd Generation Specific (1986-1992)

9

09-03-15 03:42 PM

fastrx7man

3rd Generation Specific (1993-2002)

33

09-02-15 09:42 PM