save the whales... save your MOTOR chapter two

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

save the whales... save your MOTOR chapter two

here's a pretty common site under the hood of a typical FD in the year 2010...

a non factory turbo. done right it is a win win of course. done wrong it is a succession of blown motors.

how many times have we heard the story of a broken apex seal in the rear rotor housing. and there's lots of theories. some may even be true.

here's my theory and a fix.

note how close the turbine housing is to the front rotor's intake runners.

note how far away the turbine housing is to the rear rotors intake runners.

note that the turbine housing gets cherry red on the dyno where you get tuned.

note aluminum is very close to the top materials as to absorbing heat quickly and efficiently.

so you are on the dyno and you are progressively leaning the motor out. you are reading the number of O2 molecules zipping by the sensor in the downpipe. what you are reading is the average of both rotors.

your front LIM is very very hot from the radiance from the cherry red turbine housing. hot runners, hot air/fuel mix... not much O2 per volume as the molecules have expanded. rich.

the rear is considerably colder. relatively dense mixture w lots of O2. lean.

one rotor rich, one rotor lean... lets tune the motor up to 11.5 overall. what do you suppose the AFRs are in the front and rear at 11.5?

simple fix of course is a heat barrier and of course they are becoming more common.

do make sure you are, uh, covered.

oh, don't cinch it too tight. you want a half inch or so of air between the blanket and housing so you don't cook your turbo bearings at shutdown.

hc

.

a non factory turbo. done right it is a win win of course. done wrong it is a succession of blown motors.

how many times have we heard the story of a broken apex seal in the rear rotor housing. and there's lots of theories. some may even be true.

here's my theory and a fix.

note how close the turbine housing is to the front rotor's intake runners.

note how far away the turbine housing is to the rear rotors intake runners.

note that the turbine housing gets cherry red on the dyno where you get tuned.

note aluminum is very close to the top materials as to absorbing heat quickly and efficiently.

so you are on the dyno and you are progressively leaning the motor out. you are reading the number of O2 molecules zipping by the sensor in the downpipe. what you are reading is the average of both rotors.

your front LIM is very very hot from the radiance from the cherry red turbine housing. hot runners, hot air/fuel mix... not much O2 per volume as the molecules have expanded. rich.

the rear is considerably colder. relatively dense mixture w lots of O2. lean.

one rotor rich, one rotor lean... lets tune the motor up to 11.5 overall. what do you suppose the AFRs are in the front and rear at 11.5?

simple fix of course is a heat barrier and of course they are becoming more common.

do make sure you are, uh, covered.

oh, don't cinch it too tight. you want a half inch or so of air between the blanket and housing so you don't cook your turbo bearings at shutdown.

hc

.

#2

Original Gangster/Rotary!

iTrader: (213)

Well said Howard. Here's a plug for a quality solution, pictured is my engine bay:

http://www.turblown.net/store/index.php?productID=56

Also one of the reasons I've always liked the A-Spec long runner manifold is the placement of the turbine housing away from the block, relatively speaking

http://www.turblown.net/store/index.php?productID=56

Also one of the reasons I've always liked the A-Spec long runner manifold is the placement of the turbine housing away from the block, relatively speaking

#3

Turd Ferguson

iTrader: (1)

Join Date: Jul 2006

Location: Sherman Oaks, California

Posts: 2,047

Likes: 0

Received 1 Like

on

1 Post

Is it better to have the barrier on the turbo (ala turbo blanket) or on the LIM? I can never seem to talk myself into the LIM blanket with a turbo blanket already in place.

Wanna help change some minds? I'm sure I'm not alone in this situation.

.

Wanna help change some minds? I'm sure I'm not alone in this situation.

.

#4

RAWR!!!!!!!!

iTrader: (1)

Join Date: Oct 2003

Location: RR, NC

Posts: 440

Likes: 0

Received 0 Likes

on

0 Posts

This is one of the things I plan to "borrow" from Rich's car. I like "some" of the lengths he went to in order to protect everything from heat. Some I will copy, others I may not. It's up to you bc it's your car. But protect as much as you can. It will help your parts, and your wallet.

#6

Also, I've been wondering if ceramic coating the intake manifolds would help or make it worse by slowing heat transfer out of a heatsoaked manifold.

#7

RX-7 Bad Ass

iTrader: (55)

Good point, but engines with the stock twins always seem to blow the rear rotor more often than the front, and the heat load with the twins is concentrated closer to the rear rotor than the front.

The one I've always heard is the intake manifold gives an unequal distribution of airflow where one rotor gets more than the other. I've also heard the rear rotor is hotter since the coolant flow through the engine is front to back and the rear rotor sees coolant that has already loaded with heat from the front rotor.

Regardless, heat shielding is always a good idea. Like the McDLT, keep the hot side hot and the cold side cold.

Dale

The one I've always heard is the intake manifold gives an unequal distribution of airflow where one rotor gets more than the other. I've also heard the rear rotor is hotter since the coolant flow through the engine is front to back and the rear rotor sees coolant that has already loaded with heat from the front rotor.

Regardless, heat shielding is always a good idea. Like the McDLT, keep the hot side hot and the cold side cold.

Dale

Trending Topics

#9

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

ceramics, glass (fiber or otherwise) and mica come to mind as heat barriers.

my new manifold positions the hotside close to the the LIM purposely to gain advantage in other areas.

given the effectiveness of various heat shields i have zero problem as long as i can position what i want between the runner and turbine housing.

i was planning to use a secret weapon:

MICA.

i am told that zero heat can penetrate an 1/8 inch sheet of Mica. i had been using a shield of Stainless Steel which works to a point but MICA is in a whole 'nuther world.

maybe someone w a materials background would care to weigh in.

fiberglass wrap is quite effective and has been used primarily to wrap downpipes/exhaust. i have a suspicion it is related to MICA. the space shuttle of course uses some sort of ceramic bricks which, again, appear related.

my friend and co-conspirator on a number of items on my 2010 FD build, Cam Worth/Pettit, is sending me his Cool Power system. (http://www.pettitracing.com/rx7/a_coolpower.htm). Cam is pretty understated on a number of items on his site. while his single Cool Power setup look similar to others, (turbine cover, exhaust wrap and LIM shield panel) the actual material in the items is not a match. the material's family tree is firmly rooted in an extremely high tech operation based in Fl.

an uptick from the usual fiberglass wrap... (which i am not knocking, it works very well.)

it was Cam, BTW, observing an outside tuner dialing in a single turbo, observing the setup and concluding bad things were developing that sparked my premise for this thread. noting no heat shielding between the turbo and the front part of the LIM he found a piece of sheet metal and stuck it in between the turbo and LIM.

the motor immediately leaned out!

case closed.

there are many ways, besides sheet metal to get it done.

as i mentioned, i have a piece of MICA. probably 1/8 thick. position it between your manifold and turbine and you have fixed the heat radiation issue as far as the LIM.

there is a balance between completely encapsulating your turbine housing and cooking the bearings and not using any shielding. ideally you need a bit of airspace in the blanket.

another source of interesting heat shielding is Elliot White at Turblown. he has a high dollar spiffy inconel setup and also a nice blanket and shield.

here's the LIM heat shield.. http://www.turblown.net/store/index.php?productID=90

of course you can build it yourself. here's what i did in 2004 for my twin TO4 setup. it worked excellently. there is plenty of airspace but there is also a stainless steel shield around the turbine and a LIM shield.

let's see what you have built/bought.

howard

my new manifold positions the hotside close to the the LIM purposely to gain advantage in other areas.

given the effectiveness of various heat shields i have zero problem as long as i can position what i want between the runner and turbine housing.

i was planning to use a secret weapon:

MICA.

i am told that zero heat can penetrate an 1/8 inch sheet of Mica. i had been using a shield of Stainless Steel which works to a point but MICA is in a whole 'nuther world.

maybe someone w a materials background would care to weigh in.

fiberglass wrap is quite effective and has been used primarily to wrap downpipes/exhaust. i have a suspicion it is related to MICA. the space shuttle of course uses some sort of ceramic bricks which, again, appear related.

my friend and co-conspirator on a number of items on my 2010 FD build, Cam Worth/Pettit, is sending me his Cool Power system. (http://www.pettitracing.com/rx7/a_coolpower.htm). Cam is pretty understated on a number of items on his site. while his single Cool Power setup look similar to others, (turbine cover, exhaust wrap and LIM shield panel) the actual material in the items is not a match. the material's family tree is firmly rooted in an extremely high tech operation based in Fl.

an uptick from the usual fiberglass wrap... (which i am not knocking, it works very well.)

it was Cam, BTW, observing an outside tuner dialing in a single turbo, observing the setup and concluding bad things were developing that sparked my premise for this thread. noting no heat shielding between the turbo and the front part of the LIM he found a piece of sheet metal and stuck it in between the turbo and LIM.

the motor immediately leaned out!

case closed.

there are many ways, besides sheet metal to get it done.

as i mentioned, i have a piece of MICA. probably 1/8 thick. position it between your manifold and turbine and you have fixed the heat radiation issue as far as the LIM.

there is a balance between completely encapsulating your turbine housing and cooking the bearings and not using any shielding. ideally you need a bit of airspace in the blanket.

another source of interesting heat shielding is Elliot White at Turblown. he has a high dollar spiffy inconel setup and also a nice blanket and shield.

here's the LIM heat shield.. http://www.turblown.net/store/index.php?productID=90

of course you can build it yourself. here's what i did in 2004 for my twin TO4 setup. it worked excellently. there is plenty of airspace but there is also a stainless steel shield around the turbine and a LIM shield.

let's see what you have built/bought.

howard

Last edited by Howard Coleman; 05-31-10 at 11:04 AM.

#11

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Well said Howard. Here's a plug for a quality solution, pictured is my engine bay:

http://www.turblown.net/store/index.php?productID=56

Also one of the reasons I've always liked the A-Spec long runner manifold is the placement of the turbine housing away from the block, relatively speaking

http://www.turblown.net/store/index.php?productID=56

Also one of the reasons I've always liked the A-Spec long runner manifold is the placement of the turbine housing away from the block, relatively speaking

#14

The water pump cools the front combustion chamber first, and then coolant flows to the rear. So the rear combustion chamber is not going to be cooled as effectively.

As for the LIM design, well the turbo 2nd gen cars don't have the LIM flow imbalance of the FD. They still blow rear rotors and the rear rotor still runs hotter. I have EGT logs which show this.

As for the LIM design, well the turbo 2nd gen cars don't have the LIM flow imbalance of the FD. They still blow rear rotors and the rear rotor still runs hotter. I have EGT logs which show this.

#15

Ceramic coating $400

Turbo blanket $150

LIM blanket $250

Total $800

+ alky/water injection + vented hood + this + that...................

Besides power benefits due to cooler temps is there a study on how many miles the engine life is extended as a result of all these precautionary measures and $$$ spent? And how much is a reman engine instead? Just food for thought.............

Just food for thought.............

Turbo blanket $150

LIM blanket $250

Total $800

+ alky/water injection + vented hood + this + that...................

Besides power benefits due to cooler temps is there a study on how many miles the engine life is extended as a result of all these precautionary measures and $$$ spent? And how much is a reman engine instead?

Just food for thought.............

Just food for thought.............

#16

I used to work in pcb manufacturing and one great material to use for thermal insulation was ceramic fiber paper. It is one of the key component in our thermal barrier design to prevent heat transfer of the hot load to the hugh alumimun presses. The ceramic fiber paper is flexible, easy to cut and shaped for used as insulation sheilding. It can be doubled up to whatever thickness you want and it is fire retardant. One of the thing to do is to sandwich the material in between two sheets of single sided reflective material, the reflective side facing towards the hot source (in this case the turbo) The reflective material used in pcb manufacturing was a high temp polyimide material with gold plated on top of a layer of copper. In the case of using it as a turbo sheild, we can't use polyimide because of the turbo temps but maybe just a sheet of metal with a super thin layer of gold plating on one side. Plating thickness does not matter, all you need is enough gold to provide a reflective surface.

#18

I lost all my contacts when the company I've worked shut down and the IS department went around wiping out all sensitive data on the computers before I had a chance to backup my data.

But just did a quick google search and here are some info/specs on ceramic fiber paper in general.....super low thermal conductivity and extremely easy to work with.

http://www.ceramicfiber.net/ceramicfiberpaper.htm

http://www.infraredheaters.com/550-k.htm

But just did a quick google search and here are some info/specs on ceramic fiber paper in general.....super low thermal conductivity and extremely easy to work with.

http://www.ceramicfiber.net/ceramicfiberpaper.htm

http://www.infraredheaters.com/550-k.htm

#19

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

here's what i am going to be testing. the pic (not my car) shows part of Pettit's Cool Power package. the heat shield, which is designed primarily as a barrier to the manifold has their trick material on the backside as does the turbo cover and panels for the tunnel above the exhaust

more info on it here:

http://www.pettitracing.com/rx7/a_coolpower.htm

if i have room for the MICA it will also be on board.

as far as spending $s on all this stuff... i made my own (post 9) for low dollars and it worked great. there's lots of ways to skin the cat. further, i think that viewed on the basis of heat reduction per dollar ceramic coating is a ripXXX. save your money. hey, it looks nice though.

let's see what you run.

as to post 14, i agree with it completely but it doesn't, in any way, rule out the turbine torching the front runners situation.

thanks to fd3rew for the ceramic fiber paper... i will, however, pass on the gold plating.... doesn't gold melt at low temps? at 1000 plus per ounce i will pass on it today.

more info on it here:

http://www.pettitracing.com/rx7/a_coolpower.htm

if i have room for the MICA it will also be on board.

as far as spending $s on all this stuff... i made my own (post 9) for low dollars and it worked great. there's lots of ways to skin the cat. further, i think that viewed on the basis of heat reduction per dollar ceramic coating is a ripXXX. save your money. hey, it looks nice though.

let's see what you run.

as to post 14, i agree with it completely but it doesn't, in any way, rule out the turbine torching the front runners situation.

thanks to fd3rew for the ceramic fiber paper... i will, however, pass on the gold plating.... doesn't gold melt at low temps? at 1000 plus per ounce i will pass on it today.

Last edited by Howard Coleman; 06-01-10 at 07:16 AM.

#20

The gold can withstand the temperature, I remember having alumimun brackets melt in press fires before any damages were done on the gold plated sheets. You only need a couple of microns of gold but yeah at like @$1100 or 1200 and ounce, it's hard to justify the cost benefit for this application and especially if you just want to test it out. The ceramic paper on the other hand is definitely feasible. It cost only a tiny fraction and you can make your own heat sheilding.

Now if you really want to go crazy, you want to be able to touch the sheilding when the turbo is glowing, you will need a steel honeycomb structure as an air gap (reduce conductive heat transfer) followed by the reflective material, a couple of sheets of ceramic paper, and then more reflective material and you can send this thing out to space and back...haha

Now if you really want to go crazy, you want to be able to touch the sheilding when the turbo is glowing, you will need a steel honeycomb structure as an air gap (reduce conductive heat transfer) followed by the reflective material, a couple of sheets of ceramic paper, and then more reflective material and you can send this thing out to space and back...haha

#21

Remember kids: heat is as much of a friend, as it is a foe...

Heat isolation is the key to turbocharged engines.

Keeping the heat in the turbine housing & reducing radiant heat into the intake is key here.

I'm interested in the statement that 1/8" mica is impervious to heat... I do not see how that is possible.

But before I cry wolf & say that is false, I will investigate.

I was thinking of adapting a semi-trucks turbo oil filter to the FD's turbo's oiling system (placed above the turbo's oil inlet, inverted & on the fire wall)

they are around .2 - .5 liters & when the engine shuts down, they drain oil through the turbo (cooling the bearings)

Also, wondering if the mica material can be tooled into a gasket for the LIM (to reduce heatsoak from the block)

if money is tight, I suggest grabbing the heat wrap from any reputable race supply store. I wonder if double wrapping has any advantages.

The blankets are very nice, but don't show oil leeks...

Oily turbo blankets can cause engine fires (along with neglect)

remember to remove the blankets & extensive heatshielding every now & then to inspect for oil leaks.

If money is no object, then swing for the fences (coatings, wraps, shields & blankets)

Keeping the heat in the turbine housing & reducing radiant heat into the intake is key here.

I'm interested in the statement that 1/8" mica is impervious to heat... I do not see how that is possible.

But before I cry wolf & say that is false, I will investigate.

I was thinking of adapting a semi-trucks turbo oil filter to the FD's turbo's oiling system (placed above the turbo's oil inlet, inverted & on the fire wall)

they are around .2 - .5 liters & when the engine shuts down, they drain oil through the turbo (cooling the bearings)

Also, wondering if the mica material can be tooled into a gasket for the LIM (to reduce heatsoak from the block)

if money is tight, I suggest grabbing the heat wrap from any reputable race supply store. I wonder if double wrapping has any advantages.

The blankets are very nice, but don't show oil leeks...

Oily turbo blankets can cause engine fires (along with neglect)

remember to remove the blankets & extensive heatshielding every now & then to inspect for oil leaks.

If money is no object, then swing for the fences (coatings, wraps, shields & blankets)

#22

Turd Ferguson

iTrader: (1)

Join Date: Jul 2006

Location: Sherman Oaks, California

Posts: 2,047

Likes: 0

Received 1 Like

on

1 Post

A VERY good point. Mine caught fire. I knew there was some leaking oil from the turbo (wasn't exactly sure where - thought it was an internal leak somewhere) but I never expected to see the blanket on fire when I popped the hood.

I'd definitely keep an eye on the blanket. I learned my lesson.

#23

Speed Mach Go Go Go

iTrader: (2)

Join Date: Oct 2001

Location: My 350Z Roadster kicks my RX7's butt

Posts: 4,772

Likes: 0

Received 2 Likes

on

2 Posts

Both the version above and below have the same exact description but above looks different like is sewn to mold better and the one below looks like it's made with the reflective material and not the one above. I'm confused on which to choose, fit or reflective material. What are those studs for stocking on top of the one below?

#24

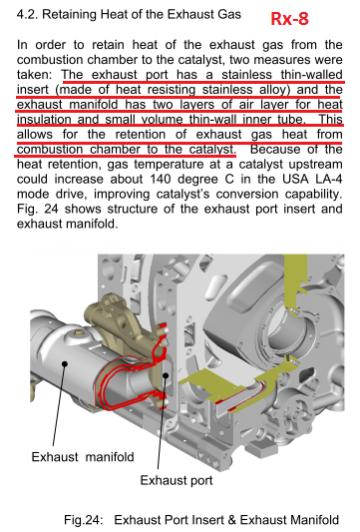

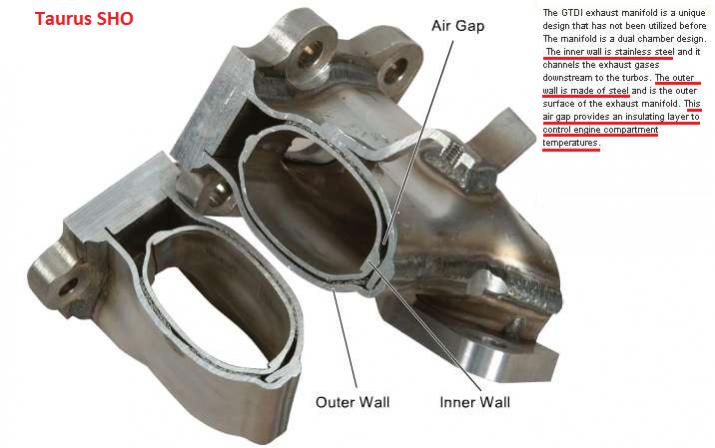

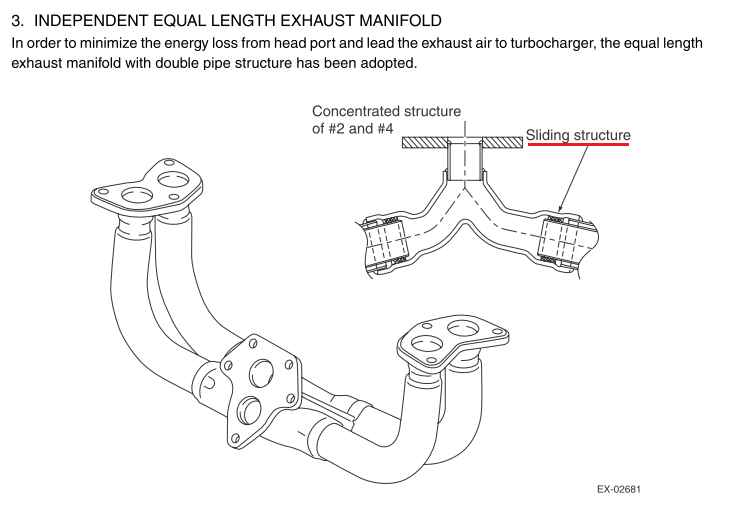

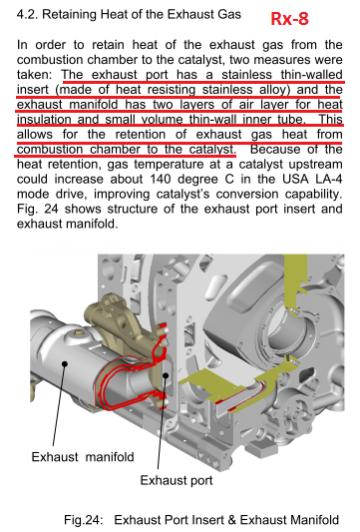

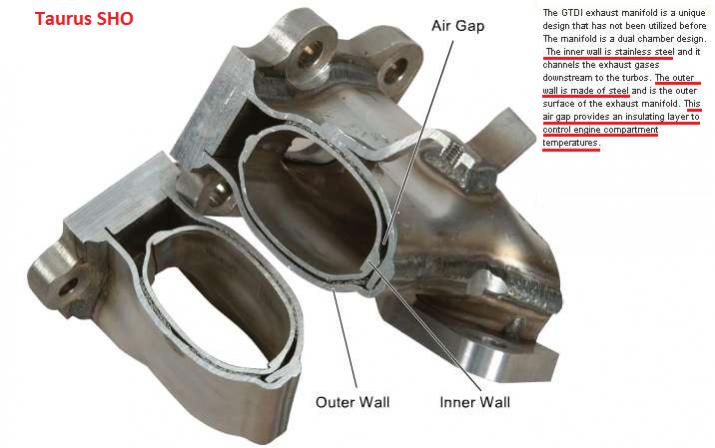

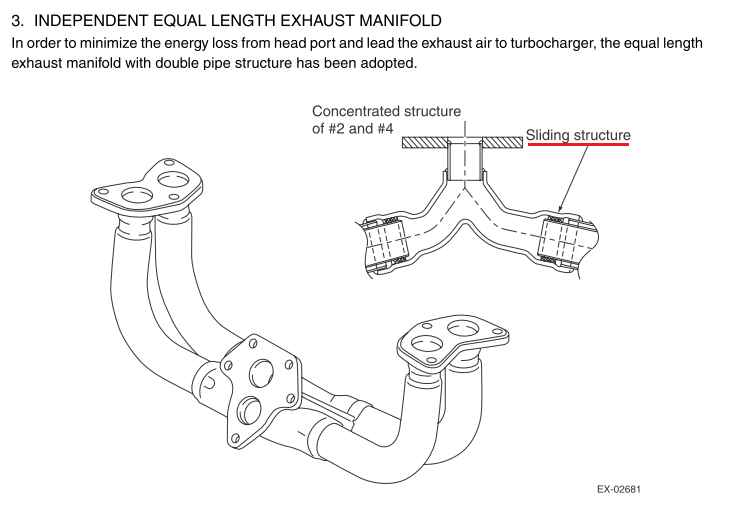

The OEM's have been attacking this heat retention issue. The latest generation of new OEM turbo manifolds and n/a exhaust manifolds are usually some form of stainless steel. They use a dual layer design with an air gap to trap exhaust heat inside the piping in order to reduce engine bay temps and warm up the catalytic converter faster.

Taurus SHO EcoBoost twin turbo engine:

2010 Subaru Legacy EJ255 engine (factory twinscroll equal length turbo manifold):

Rx-8:

Taurus SHO EcoBoost twin turbo engine:

2010 Subaru Legacy EJ255 engine (factory twinscroll equal length turbo manifold):

Rx-8: