Idler to replace Air Pump

#1

What's your point ?

Thread Starter

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Idler to replace Air Pump

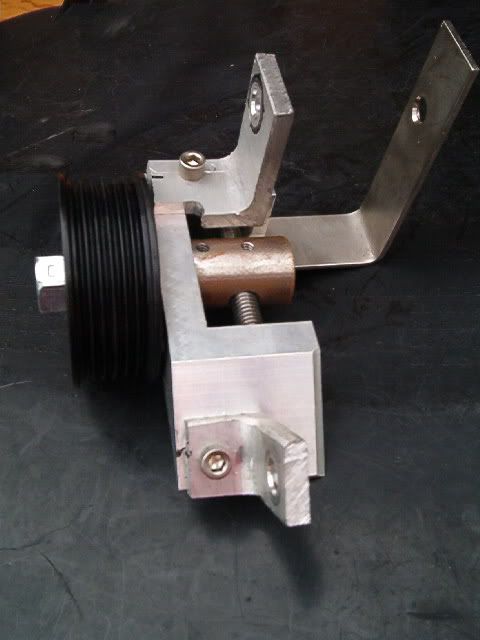

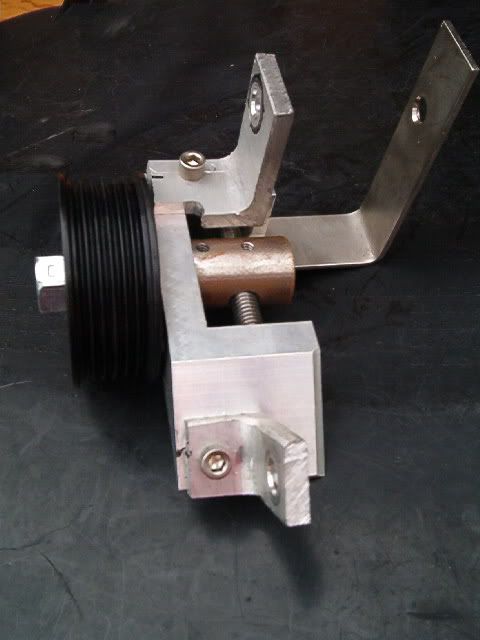

Here's my latest shadetree project. I eliminated my air pump (hasn't been hooked up for a while any way) but wasn't ready to go with the water pump under drive pulley and belt (very little contact area) as I didn't want to lessen the flow at lower RPM since I'm not turning it any higher than stock on the top end. I dug an idler bracket out of the scrap bin at work (discarded of an old mechanical aptitude machine) to see if there was a way I could put it to use. Sorry so long.

Picture of the semi finished prototype

This is a 76mm generic pulley from Advance auto parts

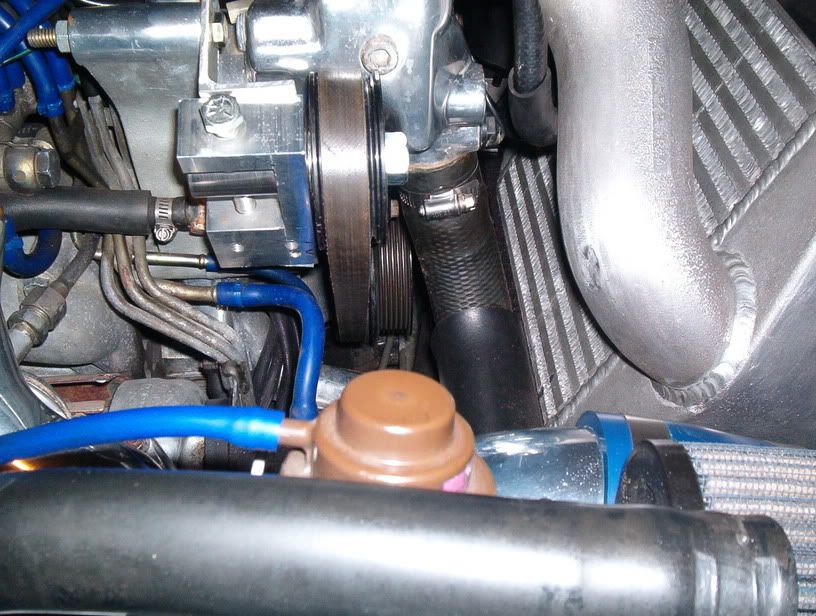

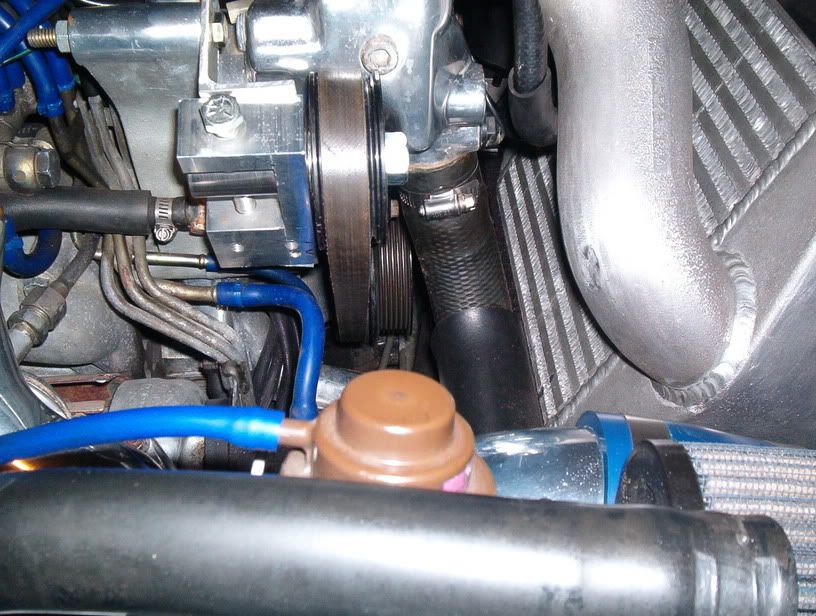

installed on the car

some of the fitment trials

Picture of the semi finished prototype

This is a 76mm generic pulley from Advance auto parts

installed on the car

some of the fitment trials

#2

Banned. I got OWNED!!!

Join Date: Jul 2004

Location: next to the polishing wheel!!!

Posts: 1,179

Likes: 0

Received 1 Like

on

1 Post

I made an idler for mine that sits where the air pump was . Brackets ,a tube that holds two bearings ,a shaft and pulley .It has been on there for over 60 k miles ,several years . It looks factory made .I have under drive pullies and as you ,I did not like the small amount of contact area .It adjust as the air pump did . Your adjuster is ,good thinking . I think if I had your design the 90 degree bracket needs to be thicker and the corners would be rounded off for a finished look .Good job ,good skill for you .

#3

What's your point ?

Thread Starter

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the positive note . So far I've changed the brackets to 1/4" rounded the corners for a finished look and trimmed/rounded the corner on the stainless bracket. I upped the generic pulley from 70mm to 76mm as I couldn't get the right length belt I needed 550 vs 500 and hve all most the same contact area I had with the air pump. Right now the milling machine at work is in need of an overhaul so I can't swap out the stainless L-brackets with the machined one. I retained my stock pulley (will machine one out of aluminium (same size as stock) later, and try and make an idler that matches the Pettit rotor pulley like I have on the alternator.

#4

nice job.

I am trying to accomplish the same thing except with the A/C and P/S idler pulley.

I can get a ribbed pulley from the parts store...no problem. I have not been able to find some sort of spacer for the middle of the pulley to keep it centered on the stock idler pulley bolt. it is getting quite warm here and I about died yesterday driving with no A/C.

any suggestions on where to find/make a spacer (or whatever they are called) for a new ribbed idler pulley? I dont even know where to begin as everyone I asked had no idea and couldnt point me in any direction.

I am trying to accomplish the same thing except with the A/C and P/S idler pulley.

I can get a ribbed pulley from the parts store...no problem. I have not been able to find some sort of spacer for the middle of the pulley to keep it centered on the stock idler pulley bolt. it is getting quite warm here and I about died yesterday driving with no A/C.

any suggestions on where to find/make a spacer (or whatever they are called) for a new ribbed idler pulley? I dont even know where to begin as everyone I asked had no idea and couldnt point me in any direction.

#6

Eats, Sleeps, Dreams Rotary

iTrader: (4)

Join Date: Apr 2003

Location: Denver, NC

Posts: 3,531

Likes: 0

Received 0 Likes

on

0 Posts

why don't you just get a shorter belt and run the stock pullies. You are out thinking yourself here and the idler is not needed, offers no water flow advantage to the stock WP and main pulley.contact area is nice but more doesn't improve the flow..., It still spins the same speed as a shorter belt would spin it. As the belts can only spin as fast as the engine spins them. I have NO problems with the WP flow or cooling abilities with a shorter belt.

Don't get me wrong, good job on the fab work, it is just time that could have been spent in other places of the car that need improvement.( all cars not yours in particular )

)

Don't get me wrong, good job on the fab work, it is just time that could have been spent in other places of the car that need improvement.( all cars not yours in particular

)

)

Last edited by BigIslandSevens; 06-05-05 at 01:51 PM.

#7

Originally Posted by GARCO MOTORWORKS

I can make a spacer , can you measure and draw what you need ? If not I need the parts so I can design the part .

I feel like an idiot. all this time I have been looking for a bushing/spacer piece and just realized that the metal center piece on the pulley doesnt move...DUH. Of course I knew this. But it didnt dawn on me until this morning that as long as the metal center ring stays put, so will the pulley and everything will be fine.

I got it now.

I got it now. FYI: The stock spacer (frisbee looking thing), 76 mm 6 rib idler pulley, M10 washer, M10 x 1.25 nut and a 37 inch 6 rib belt are all that is needed to keep A/C while getting rid of P/S.

sorry for the interruption...now back to your regularly scheduled thread.

Trending Topics

#8

What's your point ?

Thread Starter

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Pulley spacer

Originally Posted by TwinTurbo_SE7EN

nice job.

I am trying to accomplish the same thing except with the A/C and P/S idler pulley.

I can get a ribbed pulley from the parts store...no problem. I have not been able to find some sort of spacer for the middle of the pulley to keep it centered on the stock idler pulley bolt. it is getting quite warm here and I about died yesterday driving with no A/C.

any suggestions on where to find/make a spacer (or whatever they are called) for a new ribbed idler pulley? I dont even know where to begin as everyone I asked had no idea and couldnt point me in any direction.

I am trying to accomplish the same thing except with the A/C and P/S idler pulley.

I can get a ribbed pulley from the parts store...no problem. I have not been able to find some sort of spacer for the middle of the pulley to keep it centered on the stock idler pulley bolt. it is getting quite warm here and I about died yesterday driving with no A/C.

any suggestions on where to find/make a spacer (or whatever they are called) for a new ribbed idler pulley? I dont even know where to begin as everyone I asked had no idea and couldnt point me in any direction.

#9

What's your point ?

Thread Starter

Join Date: Feb 2001

Location: Gainesville, Fla.

Posts: 3,573

Likes: 0

Received 0 Likes

on

0 Posts

Out thinking self ? ? ?

[QUOTE= You are out thinking yourself here and the idler is not needed, offers no water flow advantage to the stock WP and main pulley.contact area is nice but more doesn't improve the flow..., It still spins the same speed as a shorter belt would spin it. As the belts can only spin as fast as the engine spins them. I have NO problems with the WP flow or cooling abilities with a shorter belt.

Don't get me wrong, good job on the fab work, it is just time that could have been spent in other places of the car that need improvement.( all cars not yours in particular )[/QUOTE]

)[/QUOTE]

The reason was due to slippage.....if your running the under drive water/ alternator pulley's and shorter belt you have very little contact area. I didn't want to under drive the water pump, I wanted it stock. If I used the under drive alternator pulley and the stock water pump pulley (smaller than the under drive water pulley) there would have been even less contact. Right now you can tighten you water pump/ alternator belt as tight as possible and you will still be able to turn your water pump. I'm running the ider with minimal tension (less pressure on the water pump pulley) and when I spin my water pump pulley I can turn the motor over (I'd say good contact ! !!) which was my intention any way. I feel the cooling system is one area of the car that doesn't need to be a problem.

Don't get me wrong, good job on the fab work, it is just time that could have been spent in other places of the car that need improvement.( all cars not yours in particular

)[/QUOTE]

)[/QUOTE]The reason was due to slippage.....if your running the under drive water/ alternator pulley's and shorter belt you have very little contact area. I didn't want to under drive the water pump, I wanted it stock. If I used the under drive alternator pulley and the stock water pump pulley (smaller than the under drive water pulley) there would have been even less contact. Right now you can tighten you water pump/ alternator belt as tight as possible and you will still be able to turn your water pump. I'm running the ider with minimal tension (less pressure on the water pump pulley) and when I spin my water pump pulley I can turn the motor over (I'd say good contact ! !!) which was my intention any way. I feel the cooling system is one area of the car that doesn't need to be a problem.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

12abridgeport

1st Generation Specific (1979-1985)

2

08-17-15 06:28 PM