How hot is too hot when at the track?

#126

i had a stock thermostat on my red car that i tracked several times in very hot ambient temp... honestly i'm surprised people waste time drilling their thermostats. it seems like it would do nothing but make the engine take longer to warm up. i'd put a stock thermostat back in it and just make sure you have clean/fresh antifreeze.

i had aftermarket oil coolers, custom VMIC (with koyo radiator) with ducting, and custom air conditioning, and i had zero issues with oil temp or coolant temp in 95+ *F weather in alabama (barber motorsports park) last summer.

i had aftermarket oil coolers, custom VMIC (with koyo radiator) with ducting, and custom air conditioning, and i had zero issues with oil temp or coolant temp in 95+ *F weather in alabama (barber motorsports park) last summer.

#127

The TT's are a problem... It's the main reason I'm going single turbo.

My oil and water temps are fine with well ducted radiator and 19-row coolers, but AITs are just too high. I've traditionally taken July/August off because it's just too hot in southern VA, but even at Watkins Glen in the fall I was pushing into the 70's C IATs. Its simply a matter of getting faster, incrementally more throttle time, etc. I'm only running 12 psi.

I expect the water/oil temps will come down too, with less overall heat in the system.

My oil and water temps are fine with well ducted radiator and 19-row coolers, but AITs are just too high. I've traditionally taken July/August off because it's just too hot in southern VA, but even at Watkins Glen in the fall I was pushing into the 70's C IATs. Its simply a matter of getting faster, incrementally more throttle time, etc. I'm only running 12 psi.

I expect the water/oil temps will come down too, with less overall heat in the system.

#130

#131

All out Track Freak!

iTrader: (263)

Join Date: Jul 2001

Location: Charlottesville VA 22901

Posts: 10,672

Received 412 Likes

on

250 Posts

Probably not ...Car runs on Ethanol as well. Just wanted to be driving when everyone else's cars are getting hot. And in the 100+degree desert heat out here...I really do think it's necessary. Water temps were my main concern...they'll keep the Oil in check!! I might end up re-doing the oil cooler ducts as well. Just to make it look nice again...but something says competition might destroy the ductwork in a hurry.

...Car runs on Ethanol as well. Just wanted to be driving when everyone else's cars are getting hot. And in the 100+degree desert heat out here...I really do think it's necessary. Water temps were my main concern...they'll keep the Oil in check!! I might end up re-doing the oil cooler ducts as well. Just to make it look nice again...but something says competition might destroy the ductwork in a hurry.

my water is never above 180f and oil is always 200f plus. I have dual ducted 25 row coolers however again in your case I'm not worried

#132

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

be careful on the ducting design. you want a pressure differential between the heat exchanger and front/back of ducts.

ideally you want high pressure zones in front of the heat exchanger, low pressure zones exiting the duct behind the heat exchanger, and in front of the duct for the heat exchanger. this sucks air into the duct and pulls it through the exchanger, if designed well at a no drag loss.

General rule is to create a cone diffuser on the rear, bell mouth, and the front of the exchanger you want a large area before the heat exchanger and a smaller duct opening, typically between 1/6 to 3/4 the size of the heat exchanger core. you want to slowly ramp the duct open smoothly.

ideally you want high pressure zones in front of the heat exchanger, low pressure zones exiting the duct behind the heat exchanger, and in front of the duct for the heat exchanger. this sucks air into the duct and pulls it through the exchanger, if designed well at a no drag loss.

General rule is to create a cone diffuser on the rear, bell mouth, and the front of the exchanger you want a large area before the heat exchanger and a smaller duct opening, typically between 1/6 to 3/4 the size of the heat exchanger core. you want to slowly ramp the duct open smoothly.

#133

be careful on the ducting design. you want a pressure differential between the heat exchanger and front/back of ducts.

ideally you want high pressure zones in front of the heat exchanger, low pressure zones exiting the duct behind the heat exchanger, and in front of the duct for the heat exchanger. this sucks air into the duct and pulls it through the exchanger, if designed well at a no drag loss.

General rule is to create a cone diffuser on the rear, bell mouth, and the front of the exchanger you want a large area before the heat exchanger and a smaller duct opening, typically between 1/6 to 3/4 the size of the heat exchanger core. you want to slowly ramp the duct open smoothly.

ideally you want high pressure zones in front of the heat exchanger, low pressure zones exiting the duct behind the heat exchanger, and in front of the duct for the heat exchanger. this sucks air into the duct and pulls it through the exchanger, if designed well at a no drag loss.

General rule is to create a cone diffuser on the rear, bell mouth, and the front of the exchanger you want a large area before the heat exchanger and a smaller duct opening, typically between 1/6 to 3/4 the size of the heat exchanger core. you want to slowly ramp the duct open smoothly.

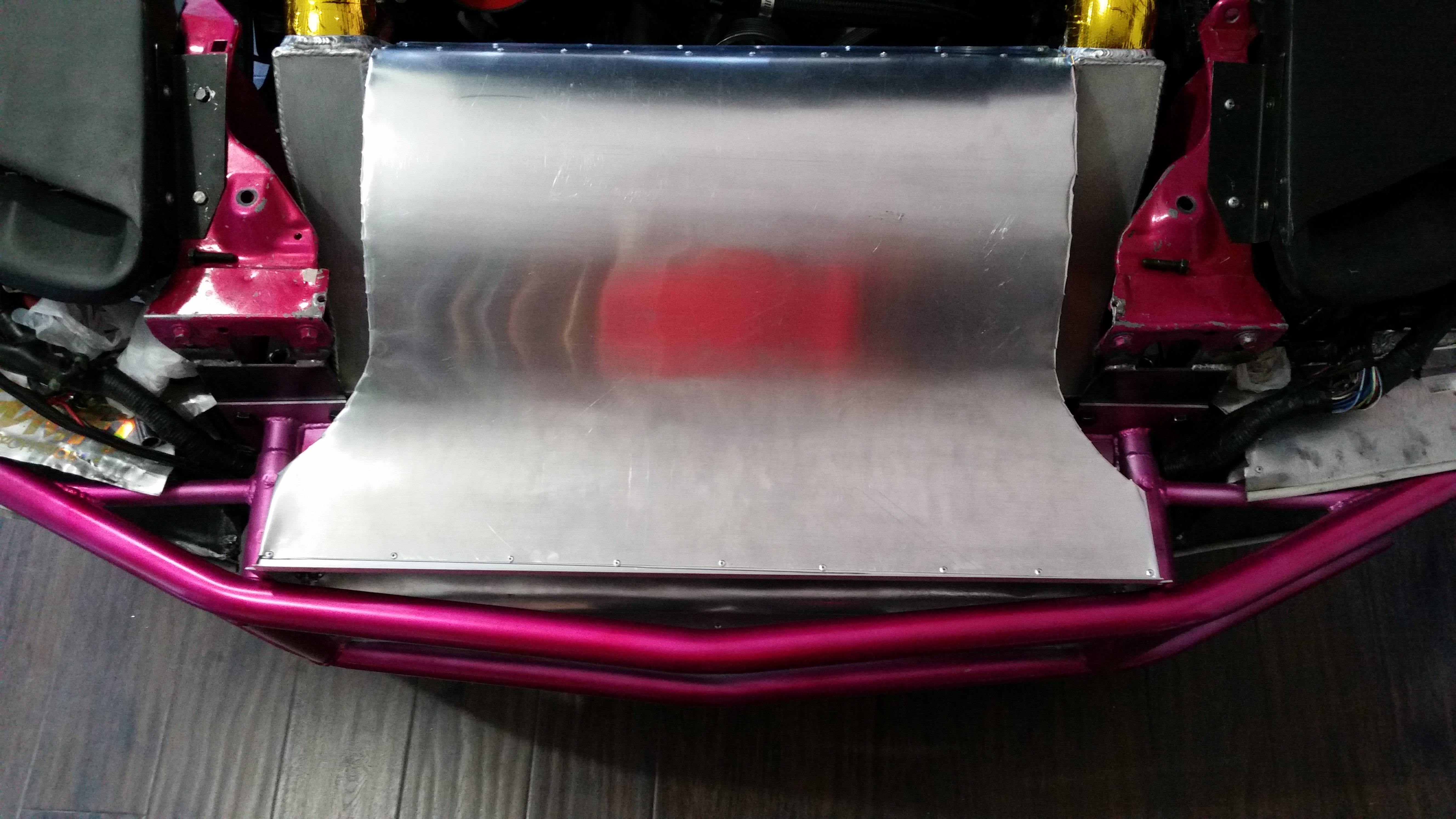

But again... I'm not making tons of power... Nor am I necessarily worried about mega high speeds. This is a drift car with the occasional grip day. I made the duct work so that when guys had to pull of the track due to their cars "getting Hot" I could still drive without worries. The old set up worked just fine... I'm thinking this one will due as well.

#134

True.. But I figure....at the very least... the water temp being controlled will at least eliminate it affecting rising oil temps at all.

Thanks for the input. I really havn't gone into that much detail with the design of the duct work... I simply copied some really high end cars with duct work and made my work based off the old set up I did. The plenum on the Radiator is much larger than the opening... and the only thing I don't have is a low pressure area behind the radiator. That might be hard to make... The IC has a nice low pressure area behind it.

But again... I'm not making tons of power... Nor am I necessarily worried about mega high speeds. This is a drift car with the occasional grip day. I made the duct work so that when guys had to pull of the track due to their cars "getting Hot" I could still drive without worries. The old set up worked just fine... I'm thinking this one will due as well.

Thanks for the input. I really havn't gone into that much detail with the design of the duct work... I simply copied some really high end cars with duct work and made my work based off the old set up I did. The plenum on the Radiator is much larger than the opening... and the only thing I don't have is a low pressure area behind the radiator. That might be hard to make... The IC has a nice low pressure area behind it.

But again... I'm not making tons of power... Nor am I necessarily worried about mega high speeds. This is a drift car with the occasional grip day. I made the duct work so that when guys had to pull of the track due to their cars "getting Hot" I could still drive without worries. The old set up worked just fine... I'm thinking this one will due as well.

#135

More testimonial for a good V-Mount.

My FD has been autox'd in 95f weather, and the water temps never go above 215f. That is after the run and the car is not moving.

Starting 6th year of autox on the motor with vmount.

On the track? Can't run flat out in the morning on a cool fall day, engine never gets warm enough.

My FD has been autox'd in 95f weather, and the water temps never go above 215f. That is after the run and the car is not moving.

Starting 6th year of autox on the motor with vmount.

On the track? Can't run flat out in the morning on a cool fall day, engine never gets warm enough.

#136

We've got a couple tricks up our sleeve cooling wise. Efficient dual oil coolers are a must (we use 25 row Setrabs in our track-use dual oil cooler kits and haven't found anything better to date). Keeping Oil temps in check is a high priority on the FD and takes a load off the water cooling system as a bonus. The stock coolers from mazda (dual r1 coolers or not) are just old/cheap inefficient technology and have a small oil volume as well, not to mention bend fins with age. If you look at the cooler setup on the R3 RX8 (which makes no power by the way  ) the coolers are massive and a much more efficient fin design. You better believe mazda learned a lesson with the FD

) the coolers are massive and a much more efficient fin design. You better believe mazda learned a lesson with the FD

FD3S: Dual Oil Cooler Upgrade Kit - SakeBomb Garage LLC

) the coolers are massive and a much more efficient fin design. You better believe mazda learned a lesson with the FD

) the coolers are massive and a much more efficient fin design. You better believe mazda learned a lesson with the FD

FD3S: Dual Oil Cooler Upgrade Kit - SakeBomb Garage LLC

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

Last edited by SakeBomb Garage; 03-03-15 at 11:33 AM.

#137

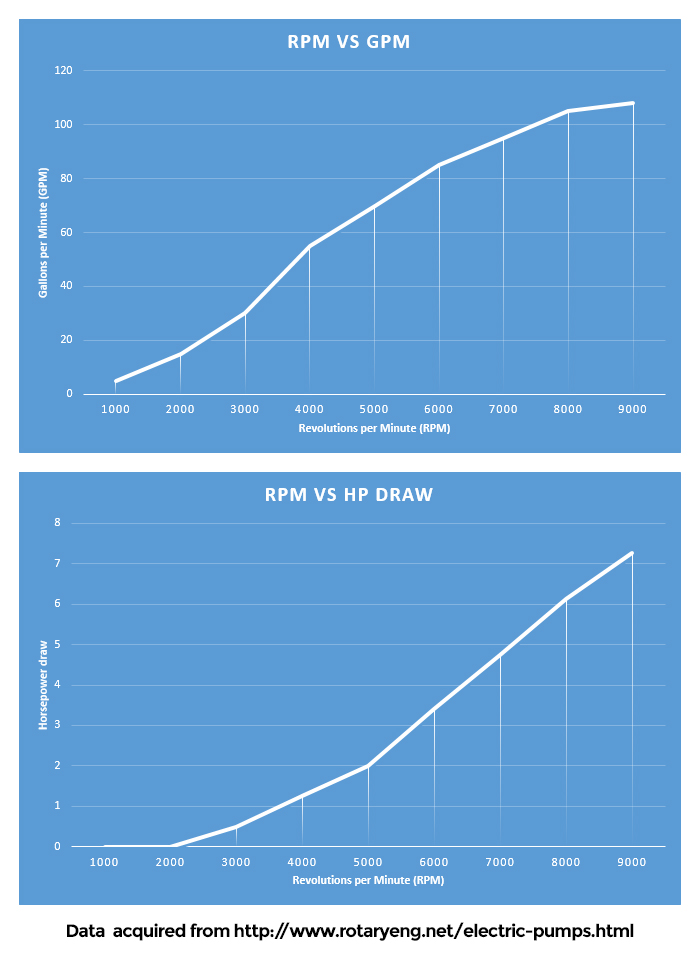

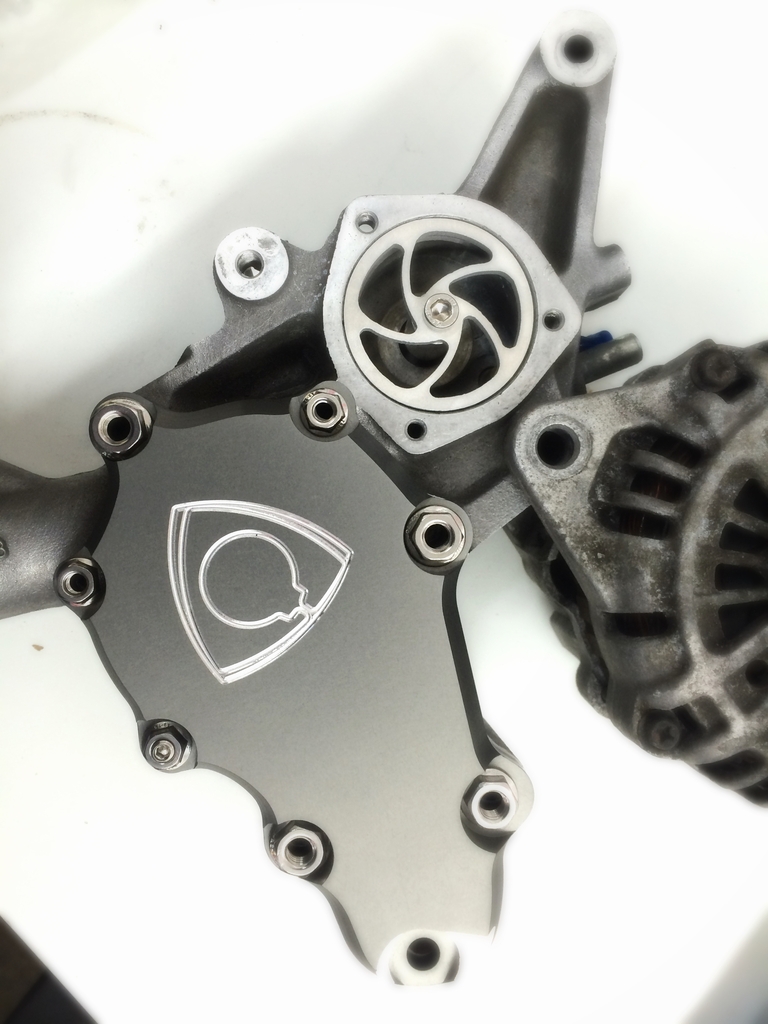

Then comes the water cooling system. The OEM pumps are (for lack of a better term) garbage with the impeller made from folded sheet metal. Up until this year we've been using the ‘remedy’ machined mechanical pumps, however no impeller can be designed for optimal flow at all RPMs... you either under flow at low RPM's or cavitate at high RPM's. The issue is that the pump being mechanically connected to the motor operates regardless of temperature and is forced to spin outside of its optimal range.

So, if you’re overheating but your motor speed drops, you’re now moving less coolant when you need it most. Temp, load, and RPM all become irrelevant factors with a mechanical pump tied to the crank pulley, it’s just along for the ride. The mechanical pump just does whatever the motor is doing and robs power to do it regardless of how much or little that pump really needs to be working. If we look at optimum pump speed, the mechanical waterpump is either under or overcooling, under or over spinning, or not spinning at all when you need it most (shutdown) . New OEM applications tend to favor electric waterpumps for a number of reasons, one being efficiency (no drag on the motor) and low power consumption (this one takes 8 amps max at full speed, and less as needed), but allows for other possibilities such as continuing to circulate coolant through the motor, radiator, and turbos after shutdown. The controller module we use also has the ability to trigger the fans if the temperature set point is exceeded after ramping the pump speed up. It’s a pretty nice piece of kit and may end up rendering the mechanical waterpump system a thing of the past. We spent a considerable amount of time refining the "coolant flow plate" and after multiple iterations ended up with a 3d (4 axis) machined surface to optimize flow through the waterpump housing with the missing mechanical pump.

. New OEM applications tend to favor electric waterpumps for a number of reasons, one being efficiency (no drag on the motor) and low power consumption (this one takes 8 amps max at full speed, and less as needed), but allows for other possibilities such as continuing to circulate coolant through the motor, radiator, and turbos after shutdown. The controller module we use also has the ability to trigger the fans if the temperature set point is exceeded after ramping the pump speed up. It’s a pretty nice piece of kit and may end up rendering the mechanical waterpump system a thing of the past. We spent a considerable amount of time refining the "coolant flow plate" and after multiple iterations ended up with a 3d (4 axis) machined surface to optimize flow through the waterpump housing with the missing mechanical pump.

And now for the barrage of questions…

-Heath

So, if you’re overheating but your motor speed drops, you’re now moving less coolant when you need it most. Temp, load, and RPM all become irrelevant factors with a mechanical pump tied to the crank pulley, it’s just along for the ride. The mechanical pump just does whatever the motor is doing and robs power to do it regardless of how much or little that pump really needs to be working. If we look at optimum pump speed, the mechanical waterpump is either under or overcooling, under or over spinning, or not spinning at all when you need it most (shutdown)

. New OEM applications tend to favor electric waterpumps for a number of reasons, one being efficiency (no drag on the motor) and low power consumption (this one takes 8 amps max at full speed, and less as needed), but allows for other possibilities such as continuing to circulate coolant through the motor, radiator, and turbos after shutdown. The controller module we use also has the ability to trigger the fans if the temperature set point is exceeded after ramping the pump speed up. It’s a pretty nice piece of kit and may end up rendering the mechanical waterpump system a thing of the past. We spent a considerable amount of time refining the "coolant flow plate" and after multiple iterations ended up with a 3d (4 axis) machined surface to optimize flow through the waterpump housing with the missing mechanical pump.

. New OEM applications tend to favor electric waterpumps for a number of reasons, one being efficiency (no drag on the motor) and low power consumption (this one takes 8 amps max at full speed, and less as needed), but allows for other possibilities such as continuing to circulate coolant through the motor, radiator, and turbos after shutdown. The controller module we use also has the ability to trigger the fans if the temperature set point is exceeded after ramping the pump speed up. It’s a pretty nice piece of kit and may end up rendering the mechanical waterpump system a thing of the past. We spent a considerable amount of time refining the "coolant flow plate" and after multiple iterations ended up with a 3d (4 axis) machined surface to optimize flow through the waterpump housing with the missing mechanical pump.

And now for the barrage of questions…

-Heath

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

Last edited by SakeBomb Garage; 03-04-15 at 12:05 PM.

#138

Heath, I like the idea of circulating coolant post shutdown. However, for most of us street cruising steady-state with V-mounts, coolant temps are usually well controlled. The thing that scares me most about an EWP solution is "what happens if I'm between Phx and LA on the freeway and my EWP decides to fail"? At least with my stock mechanical solution I can continue on. It seems like the EWP is adding a potential failure mode to the system that currently does not exist with the stock mechanical pump. Again, an inline pump for coolant circulation post shutdown is a great idea, but I'd need more reassurance that these things are bulletproof before I could be persuaded to make the change. How much added HP is to be gained by switching from a mechanical pump to the EWP solution?

#140

Heath, I like the idea of circulating coolant post shutdown. However, for most of us street cruising steady-state with V-mounts, coolant temps are usually well controlled. The thing that scares me most about an EWP solution is "what happens if I'm between Phx and LA on the freeway and my EWP decides to fail"? At least with my stock mechanical solution I can continue on. It seems like the EWP is adding a potential failure mode to the system that currently does not exist with the stock mechanical pump. Again, an inline pump for coolant circulation post shutdown is a great idea, but I'd need more reassurance that these things are bulletproof before I could be persuaded to make the change. How much added HP is to be gained by switching from a mechanical pump to the EWP solution?

If your mechanical pump seal fails you'll lose coolant pressure through the weep hole. Sure it will still spin but will it get you home without a tow truck? Maybe a handful of exits with the heater on, but when I've had the mechanical pump seal go bad I got stuck in a long conversation with a tow truck driver the full hour home, despite my best efforts to limp it back.

Many OEM's run electric waterpumps (for instance the E90 3 series

). The Davies Craig 150 pump we use is rated at 40 gal per minute, 72.5 PSI max pressure rating, recommended operating temp -40-266f. With the variable speed control module in use, the pump is rated for 7000 hours minimum operating life span. If you average 35mph city and highway that translates to 245,000 miles. How long does the OEM one last? (I've had anywhere between 40-90K on mechanical units).

). The Davies Craig 150 pump we use is rated at 40 gal per minute, 72.5 PSI max pressure rating, recommended operating temp -40-266f. With the variable speed control module in use, the pump is rated for 7000 hours minimum operating life span. If you average 35mph city and highway that translates to 245,000 miles. How long does the OEM one last? (I've had anywhere between 40-90K on mechanical units).I knew getting into this it would be an uncomfortable concept to introduce to people, and I was skeptical myself initially. But 8A of power consumption at 40gal/min vs mechanical loss, no drag on the motor, no cavitation, optimum flow at all RPM's and speed adjusted as needed, ability to bleed the system without the car running, ability to kick on the fans at a temp I set, and a cast aluminum pump housing with a 7000 hour rating on the motor... I had to at least consider it (personally). It's uncomfortable because it's new but once the community accepts the new technology I doubt many will look back.

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

Last edited by SakeBomb Garage; 03-04-15 at 02:52 PM.

#141

Think of all the water pump pulley tensioners that could potentially be up for sale  .

.

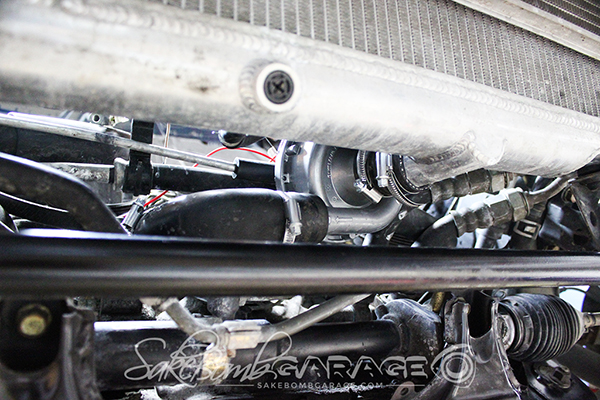

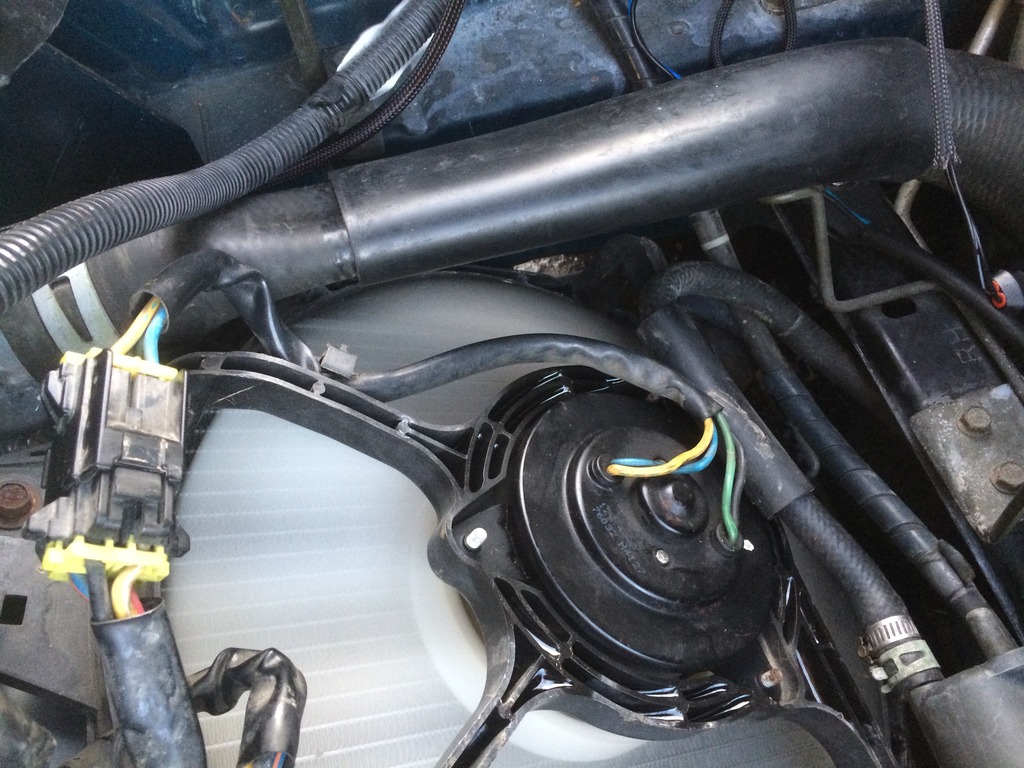

Another concern for me is mounting of the the water pump. I reconfigured my radiator when I went V-mount to have the inlet and outlet on the same side of the rad (closest to the engine). Do you have any images of a pump mounted near the main pulley, or in that general area??

.

. Another concern for me is mounting of the the water pump. I reconfigured my radiator when I went V-mount to have the inlet and outlet on the same side of the rad (closest to the engine). Do you have any images of a pump mounted near the main pulley, or in that general area??

#142

Think of all the water pump pulley tensioners that could potentially be up for sale  .

.

Another concern for me is mounting of the the water pump. I reconfigured my radiator when I went V-mount to have the inlet and outlet on the same side of the rad (closest to the engine). Do you have any images of a pump mounted near the main pulley, or in that general area??

.

. Another concern for me is mounting of the the water pump. I reconfigured my radiator when I went V-mount to have the inlet and outlet on the same side of the rad (closest to the engine). Do you have any images of a pump mounted near the main pulley, or in that general area??

(don't mind the under-hood grime, this car was not the cleanest for pictures

)

)

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

#143

We've been waiting for these little brass tidbits quite some time which has held up shipping our EWP kits... but they're finally here. These allow the new thermistor (temp sender for the controller) to be inserted in place of the old FD thermosensor. Since the controller has a fan control feature with a user-defined temp set point, the stock thermosensor that triggers one of the fan control relays can be replaced with wire to create essentially a variable or smart "fc-thermoswitch" replacement

If you're on a stock ECU and can not adjust your fan temp turn on point, you can connect this wire to relays 2&3 as well to trigger the main fan relays to activate at your desired set point. The system is redundant in that if you do not cut the wires but only tap in, your stock fan temp control will still work if for some reason the controller fails.

For fun (and to address the skeptics that are afraid this system is not up to the task of cooling the FD) here's is a picture to illustrate how much coolant this pump can flow at max speed. (Max speeds only happens when the pump speed has already ramped up approaching the temp set point, the fans have been triggered, and temps are still climbing). As a last resort the pump goes full BeastMode

with enough coolant flowing through the motor to SUCK THE STRAIGHT SECTION of the upper radiator hose FLAT! :insert innuendo here: I'd love to see a stock pump do this (and without cavitation, as we verified in testing the EWP)... another check in the ‘totally-awesome’ category for this cooling setup

with enough coolant flowing through the motor to SUCK THE STRAIGHT SECTION of the upper radiator hose FLAT! :insert innuendo here: I'd love to see a stock pump do this (and without cavitation, as we verified in testing the EWP)... another check in the ‘totally-awesome’ category for this cooling setup

. (included in our kit is an important provision to prevent a collapsed hose, as an overheating engine is the worst time to flatten your cooling hose

. (included in our kit is an important provision to prevent a collapsed hose, as an overheating engine is the worst time to flatten your cooling hose  )

)

-Heath

p.s. As a bit of a funny anecdote (and to explain why there’s actually a false sense of security with the stock mechanical setup being “fail-safe” ): No less than one week ago, we picked up a Turbo Mazdaspeed Miata (one of the new development platforms for us) which was flawless inside and out - thank you lady owner – but the hood was never opened. It was on original belts and had a very nice little front crank oil leak, so not only were the belts loose, they were oily and squealing as well. Everything under the hood just needed maintenance, as nothing was ever done aside from oil changes that I can tell… but no matter, it was only 20 minutes back to the shop so we’d just sort it out there. 3 miles away I smell a faint burning rubber and snap, charge light is on and we immediately pull over. No less than 3 seconds after the belt snaps the OEM temp gauge needle is pegged FULL hot. AAA the car back, and replaced the belt, everything seems ok, but had we left the motor running longer all bets would have been off… I was amazed how fast the needle hit full hot. Let that be a lesson to everyone out there… you’ve got literally SECONDS to catch a snapped mechanical belt, let alone a slipping waterpump belt in your FD. The Miata motor is somewhat bullet proof, I wouldn’t dare try this in an FD. Suffice to say, the stock mechanical waterpump is NOT fail safe, by any means whatsoever. I had this happen a number of years ago in an FD and lost a coolant seal as a result. Anyway it was ironic that this just happened days before shipping our EWP kits

Keep em cool this summer guys!

Keep em cool this summer guys!

__________________

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

SAKEBOMB GARAGE LLC

www.SAKEBOMBGARAGE.com

Specialty aftermarket parts & service // Fremont, California

Contact: info@sakebombgarage.com

Thread

Thread Starter

Forum

Replies

Last Post

eplusz

General Rotary Tech Support

15

10-07-15 04:04 PM