Heater Core Restoration w/Photos

#1

Heater Core Restoration w/Photos

I recently restored my blower, evaporator, and heater core. The heater core was the trickiest by far.

Link to blower restoration: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/c-blower-rebuild-w-photos-993190/

Link to evaporator restoration: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/c-evaporator-rebuild-w-photos-993467/

Note: Take photos and pay attention how stuff goes together. This thing has a lot of little pieces so reassembly can be tricky.

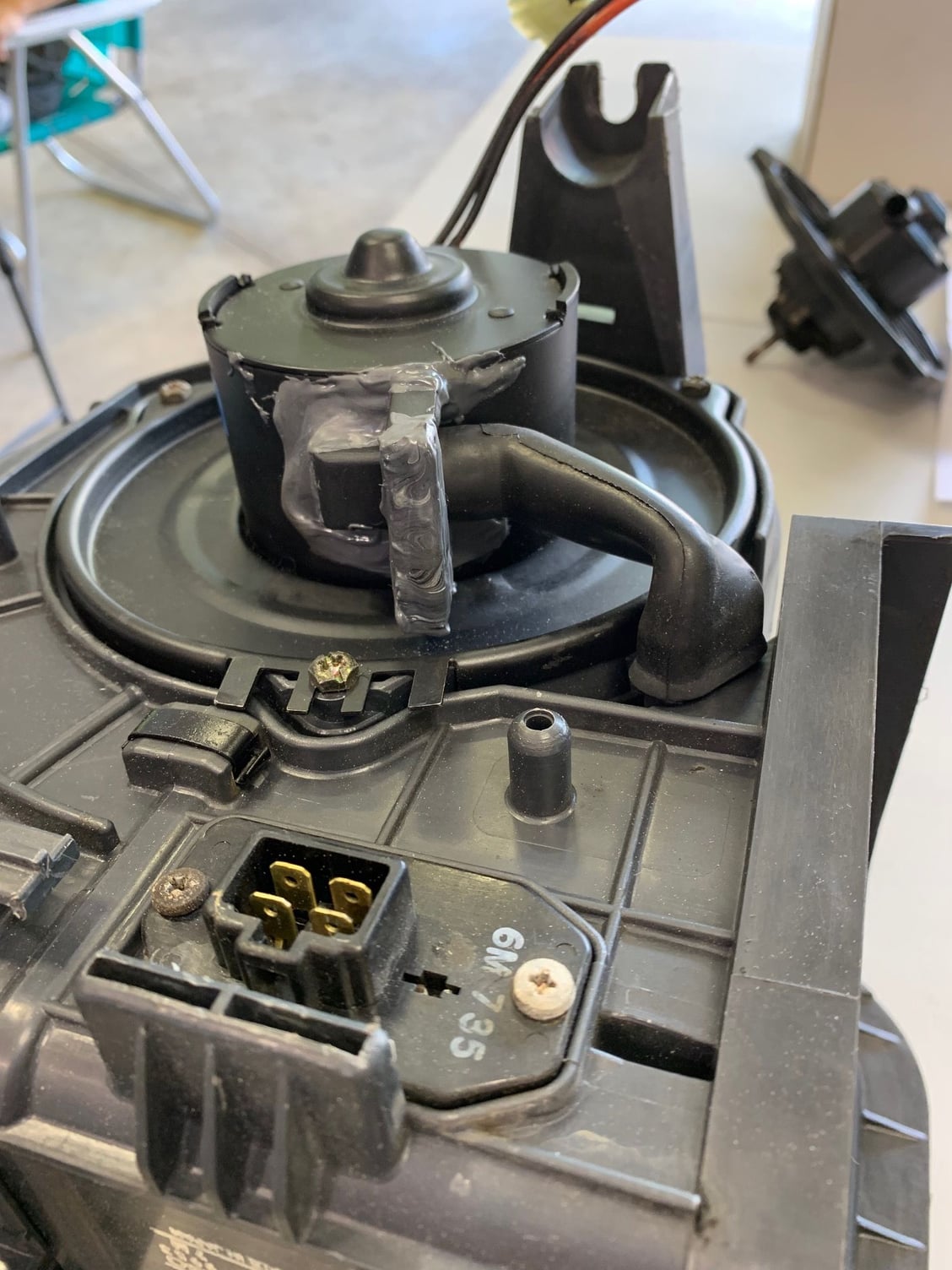

Here's what we start off with. Note all of the rotting foam pieces.

The flaps that direct air flow are also covered in rotting foam. This stuff falls apart and flows out the vents in the car and it makes a mess.

There are several clips and screws holding the two halves together. First, remove all of the clips where the two halves meet. Then remove this screw:

Then remove the servo motor, and remove the screw in this hole underneath it:

Unlatch this little actuator arm:

Now you can pull the two halves apart to gain access to the air flow guides.

Link to blower restoration: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/c-blower-rebuild-w-photos-993190/

Link to evaporator restoration: https://www.rx7club.com/3rd-generation-specific-1993-2002-16/c-evaporator-rebuild-w-photos-993467/

Note: Take photos and pay attention how stuff goes together. This thing has a lot of little pieces so reassembly can be tricky.

Here's what we start off with. Note all of the rotting foam pieces.

The flaps that direct air flow are also covered in rotting foam. This stuff falls apart and flows out the vents in the car and it makes a mess.

There are several clips and screws holding the two halves together. First, remove all of the clips where the two halves meet. Then remove this screw:

Then remove the servo motor, and remove the screw in this hole underneath it:

Unlatch this little actuator arm:

Now you can pull the two halves apart to gain access to the air flow guides.

The following 2 users liked this post by RaceDriver7:

gsxrjjordan (01-19-22),

nicad2 (06-06-21)

#2

To remove the flaps, use a flat head screw driver to pull the little lock tab on the end of the shaft, then slide the flap out. For some reason I didn't realize you could do this when I did the A/C blower. It definitely makes it easier to take the flap out completely.

Scrub off all of the old foam. Originally I tried just sticking some adhesive-backed rubber on there, but it didn't stick at all. So I tried a plastic glue, which didn't work at all. I ended up using JB Weld, believe it or not. That stuff held it better than anything else.

Some of the flaps are made from metal, however, and on those the adhesive-backed foam works fine.

The foam I used is Part # 93625K294 from McMaster.com. It's a little harder than I would have liked, so I might have tried something softer if I were to do it again.

Here are the plastic ones after replacing the foam. There are also a couple of metal ones.

I also pulled the little copper radiator and cleaned it up:

Reassembled the whole thing and added new rubber gasket around the outer seals. I used McMaster.com part # 93725K72 which worked perfectly.

Scrub off all of the old foam. Originally I tried just sticking some adhesive-backed rubber on there, but it didn't stick at all. So I tried a plastic glue, which didn't work at all. I ended up using JB Weld, believe it or not. That stuff held it better than anything else.

Some of the flaps are made from metal, however, and on those the adhesive-backed foam works fine.

The foam I used is Part # 93625K294 from McMaster.com. It's a little harder than I would have liked, so I might have tried something softer if I were to do it again.

Here are the plastic ones after replacing the foam. There are also a couple of metal ones.

I also pulled the little copper radiator and cleaned it up:

Reassembled the whole thing and added new rubber gasket around the outer seals. I used McMaster.com part # 93725K72 which worked perfectly.

The following users liked this post:

gracer7-rx7 (01-12-20)

#3

On a side note, I also replaced all the foam rubber and anti-rattle foam on my dash.

Also, JB weld works very well for fixing any cracks and broken plastic pieces. In some places I used plastic "weld" glue, and then covered it in JB weld later. JB weld gets very hard so it works great for reinforcing the repair.

Also, JB weld works very well for fixing any cracks and broken plastic pieces. In some places I used plastic "weld" glue, and then covered it in JB weld later. JB weld gets very hard so it works great for reinforcing the repair.

#5

You can buy a whole new heater core assembly. It's $452.10, if they're still even available. Mazda has been discontinuing a lot of parts lately.

Trending Topics

The following users liked this post:

Project88Turbo (01-12-20)

#11

Basically, I just took it apart, and tried to figure out what the original thickness of the foam was. You can measure the width of it easily, but the thickness is a little difficult to figure out when the foam is flattened out and disintegrating. That 1/4" thickness worked well though. Then you kind of have to guess on the correct firmness based on the descriptions on McMaster.com. Also look at the different types of foam and get something that has a good temperature range, resiliency, etc for a reasonable price. You want something that will hopefully last longer than the OEM stuff. Closed-cell foam is also typically better than open cell.

#12

Built not bought.

iTrader: (8)

Join Date: Aug 2006

Location: Sacramento, CA

Posts: 302

Likes: 0

Received 0 Likes

on

0 Posts

Page G33? Where is this page G33 at? In the service manual G is the section for engine electrical components... Which manual is this? Because I have no clue how the heating system works and I want to know what all goes into it.

#14

DRFTRX7

Replacement Copper Pipes / Tubes

You mean replacing just the copper radiator? It's not available separately, and at least on my car it was in good condition and wasn't leaking or anything. The only thing that can really go wrong with it is a leak. I did replace one of the pipes though, because it was damaged when I pulled the whole assembly.

You can buy a whole new heater core assembly. It's $452.10, if they're still even available. Mazda has been discontinuing a lot of parts lately.

You can buy a whole new heater core assembly. It's $452.10, if they're still even available. Mazda has been discontinuing a lot of parts lately.

#17

RX-7 Bad Ass

iTrader: (55)

First off, again, THANK YOU so much for pioneering this procedure.

We're TOTALLY rebuilding an FD here in Pensacola, going damn near down to the shell and back up. Of course I'm going to spend the time to do the heater core and everything!

JUST got done putting the heater core back together. Here's a few tricks and tips I figured out -

- For the foam on the doors, I used McMaster-Carr part number 86025K56. It's a 1/4" thick soft foam with excellent rebound and it's closed cell. I'm hoping it will hold up well. The adhesive is very strong on it and you get a BIG roll, enough to do more than one car.

- For the plastic doors, I cleaned the hell out of them and got all the old foam off. I then masked up the pivot points and sprayed 3M high strength contact adhesive on the panel. Let it set up then applied the foam. So far so good.

- For the "bumps" on the plastic panels, after adhering the new foam, I used an XActo knife to trim around the little bumps and cut the foam out. Then, I used a small Dynamat roller to roll the foam down and insure that it was well stuck on and pushed down around the foam bumps.

- On the other side, there's a raised square in the middle of the panel. Again, foam down then used the XActo knife to trim around both sides of the raised square then used the roller to press down. Some of the foam stuck up so I trimmed it off.

- This thread is VERY useful for pictures to re-assemble. It's a real maze of parts, the big one is make sure you have the flapper doors in the right position and orientation. I had one that was 180 out, I had to pull it apart again to re-orient. Make sure everything is where it should be first before putting the motors and linkage back on.

- I got a small tube of white lithium grease to grease all the moving parts, that's what the factory did and most of it has broken down over time. May not make a huge difference but it's worth doing.

I've also done the blower motor using RaceDriver7's guide, I recommend starting small and getting comfortable before doing the heater core. The heater core is NO JOKE of a job. Get a big, clean area to work on as well, I put towels down and used the dining room table (the wife loved it ).

).

Dale

We're TOTALLY rebuilding an FD here in Pensacola, going damn near down to the shell and back up. Of course I'm going to spend the time to do the heater core and everything!

JUST got done putting the heater core back together. Here's a few tricks and tips I figured out -

- For the foam on the doors, I used McMaster-Carr part number 86025K56. It's a 1/4" thick soft foam with excellent rebound and it's closed cell. I'm hoping it will hold up well. The adhesive is very strong on it and you get a BIG roll, enough to do more than one car.

- For the plastic doors, I cleaned the hell out of them and got all the old foam off. I then masked up the pivot points and sprayed 3M high strength contact adhesive on the panel. Let it set up then applied the foam. So far so good.

- For the "bumps" on the plastic panels, after adhering the new foam, I used an XActo knife to trim around the little bumps and cut the foam out. Then, I used a small Dynamat roller to roll the foam down and insure that it was well stuck on and pushed down around the foam bumps.

- On the other side, there's a raised square in the middle of the panel. Again, foam down then used the XActo knife to trim around both sides of the raised square then used the roller to press down. Some of the foam stuck up so I trimmed it off.

- This thread is VERY useful for pictures to re-assemble. It's a real maze of parts, the big one is make sure you have the flapper doors in the right position and orientation. I had one that was 180 out, I had to pull it apart again to re-orient. Make sure everything is where it should be first before putting the motors and linkage back on.

- I got a small tube of white lithium grease to grease all the moving parts, that's what the factory did and most of it has broken down over time. May not make a huge difference but it's worth doing.

I've also done the blower motor using RaceDriver7's guide, I recommend starting small and getting comfortable before doing the heater core. The heater core is NO JOKE of a job. Get a big, clean area to work on as well, I put towels down and used the dining room table (the wife loved it

).

).Dale

#18

Senior Member

iTrader: (2)

First off, again, THANK YOU so much for pioneering this procedure.

We're TOTALLY rebuilding an FD here in Pensacola, going damn near down to the shell and back up. Of course I'm going to spend the time to do the heater core and everything!

JUST got done putting the heater core back together. Here's a few tricks and tips I figured out -

- For the foam on the doors, I used McMaster-Carr part number 86025K56. It's a 1/4" thick soft foam with excellent rebound and it's closed cell. I'm hoping it will hold up well. The adhesive is very strong on it and you get a BIG roll, enough to do more than one car.

- For the plastic doors, I cleaned the hell out of them and got all the old foam off. I then masked up the pivot points and sprayed 3M high strength contact adhesive on the panel. Let it set up then applied the foam. So far so good.

- For the "bumps" on the plastic panels, after adhering the new foam, I used an XActo knife to trim around the little bumps and cut the foam out. Then, I used a small Dynamat roller to roll the foam down and insure that it was well stuck on and pushed down around the foam bumps.

- On the other side, there's a raised square in the middle of the panel. Again, foam down then used the XActo knife to trim around both sides of the raised square then used the roller to press down. Some of the foam stuck up so I trimmed it off.

- This thread is VERY useful for pictures to re-assemble. It's a real maze of parts, the big one is make sure you have the flapper doors in the right position and orientation. I had one that was 180 out, I had to pull it apart again to re-orient. Make sure everything is where it should be first before putting the motors and linkage back on.

- I got a small tube of white lithium grease to grease all the moving parts, that's what the factory did and most of it has broken down over time. May not make a huge difference but it's worth doing.

I've also done the blower motor using RaceDriver7's guide, I recommend starting small and getting comfortable before doing the heater core. The heater core is NO JOKE of a job. Get a big, clean area to work on as well, I put towels down and used the dining room table (the wife loved it ).

).

Dale

We're TOTALLY rebuilding an FD here in Pensacola, going damn near down to the shell and back up. Of course I'm going to spend the time to do the heater core and everything!

JUST got done putting the heater core back together. Here's a few tricks and tips I figured out -

- For the foam on the doors, I used McMaster-Carr part number 86025K56. It's a 1/4" thick soft foam with excellent rebound and it's closed cell. I'm hoping it will hold up well. The adhesive is very strong on it and you get a BIG roll, enough to do more than one car.

- For the plastic doors, I cleaned the hell out of them and got all the old foam off. I then masked up the pivot points and sprayed 3M high strength contact adhesive on the panel. Let it set up then applied the foam. So far so good.

- For the "bumps" on the plastic panels, after adhering the new foam, I used an XActo knife to trim around the little bumps and cut the foam out. Then, I used a small Dynamat roller to roll the foam down and insure that it was well stuck on and pushed down around the foam bumps.

- On the other side, there's a raised square in the middle of the panel. Again, foam down then used the XActo knife to trim around both sides of the raised square then used the roller to press down. Some of the foam stuck up so I trimmed it off.

- This thread is VERY useful for pictures to re-assemble. It's a real maze of parts, the big one is make sure you have the flapper doors in the right position and orientation. I had one that was 180 out, I had to pull it apart again to re-orient. Make sure everything is where it should be first before putting the motors and linkage back on.

- I got a small tube of white lithium grease to grease all the moving parts, that's what the factory did and most of it has broken down over time. May not make a huge difference but it's worth doing.

I've also done the blower motor using RaceDriver7's guide, I recommend starting small and getting comfortable before doing the heater core. The heater core is NO JOKE of a job. Get a big, clean area to work on as well, I put towels down and used the dining room table (the wife loved it

).

).Dale

#19

Finished the evaporator and blower motor and in process of doing the heater core.some things that helped me and things I've replaced along the way:

-replaced blower motor with 4 seasons unit PN 35011 (no wheel) from Amazon for around $57. in the other rebuild thread of the evap or blower motor,someone did a test with the rx8 wheel and can confirm that the fd rx7 blower motor was plug and plug with intake tube.slight wiring needed to be done,as the 4 seasons unit only has bare wires going to it.taking the wheel off stock blower was a pain.combo of prying while trying to hold clip to free the wheel from shaft.good to have an extra set of hands here

-ac expansion valve.denso unit PN 475-0107 from Amazon for around $30 bucks. Came with 4 new prints

things that helped me:

- for metal flaps,I used a plastic scraping tool to get most of foam off,then an angle grinder with cup brush (copper) to get the rest of the adhesive off. Tried lacquer thinner and utility knife blades,but you're subjected to getting layers and layers off slowly

-plastic flaps,I used plastic scraping tool,then a wire hand brush with lacquer thinner.

-while the clips that hold pieces together and some of the metal swing arms,brackets,I cleaned them with clr and a brush,then hit it with some black engine paint that I had. Good thing I had done this,as I discovered a group of 8 or so wires going into a servo motor that was cut/gnawed off? That I needed to re-connect

-white lithium grease moving parts

-lysoled the evap,and ducts and boxes yo disinfect. Figured the boxes weren't ever coming apart again

I did blower motor,evap,then heater core. Everyone is right,take lots of pictures while disassembling heater core

-replaced blower motor with 4 seasons unit PN 35011 (no wheel) from Amazon for around $57. in the other rebuild thread of the evap or blower motor,someone did a test with the rx8 wheel and can confirm that the fd rx7 blower motor was plug and plug with intake tube.slight wiring needed to be done,as the 4 seasons unit only has bare wires going to it.taking the wheel off stock blower was a pain.combo of prying while trying to hold clip to free the wheel from shaft.good to have an extra set of hands here

-ac expansion valve.denso unit PN 475-0107 from Amazon for around $30 bucks. Came with 4 new prints

things that helped me:

- for metal flaps,I used a plastic scraping tool to get most of foam off,then an angle grinder with cup brush (copper) to get the rest of the adhesive off. Tried lacquer thinner and utility knife blades,but you're subjected to getting layers and layers off slowly

-plastic flaps,I used plastic scraping tool,then a wire hand brush with lacquer thinner.

-while the clips that hold pieces together and some of the metal swing arms,brackets,I cleaned them with clr and a brush,then hit it with some black engine paint that I had. Good thing I had done this,as I discovered a group of 8 or so wires going into a servo motor that was cut/gnawed off? That I needed to re-connect

-white lithium grease moving parts

-lysoled the evap,and ducts and boxes yo disinfect. Figured the boxes weren't ever coming apart again

I did blower motor,evap,then heater core. Everyone is right,take lots of pictures while disassembling heater core

#21

Junior Member

iTrader: (1)

Used RX8 Blower Motor

I did wind up replacing the stock RX7 blower motor with a RX8 spec blower motor (Four Seasons part # 35364). I had to modify the plastic piece that came with it designed to direct cooling air into the motor assembly in order to accept the RX7 rubber hose but a Dremel tool and some JB Weld did the trick (see pictures). The motor accepted the RX7 wheel without issue. Also had the same sort of electrical connector so should be plug and play with the factory FD wiring harness. Hope this is helpful to folks who may be contemplating the same.

Last edited by OneQwickTwo; 05-16-21 at 09:37 AM.

The following users liked this post:

DaleClark (05-17-21)

#23

Junior Member

iTrader: (4)

Join Date: Apr 2003

Location: Cleveland

Posts: 23

Likes: 0

Received 0 Likes

on

0 Posts

Replacing the Heater Core

I need to remove my heater core due to a leak. I suspect the orings connecting the coolant pipes have failed. I'm trying to avoid removing the dash. Has anyone successfully done an R and R of the core and pipes with the dash in place?

Regards,

Alan

Regards,

Alan

#24

RX-7 Bad Ass

iTrader: (55)

Absolutely no way to do it without removing the dash, period.

All things considered pulling the dash isn't the worst thing. Just take your time with it. Also get the seats out of there so you have more room to work with.

Dale

All things considered pulling the dash isn't the worst thing. Just take your time with it. Also get the seats out of there so you have more room to work with.

Dale

Thread

Thread Starter

Forum

Replies

Last Post

nonameuser

2nd Generation Specific (1986-1992)

12

02-08-17 09:11 AM

RaceDriver7

3rd Generation Specific (1993-2002)

13

09-11-13 11:52 PM