Half BridgePort on stock twins

#26

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,778

Received 2,563 Likes

on

1,823 Posts

With the plan to swap in a small single later on , For quick spool , and good VE at higher RPM ( due to ports ) since that is where Smaller turbos kind of hurt on quic kspool , But lose power at higher RPM, I was wondeirng if I went with something like a half bridge would hte improved VE from the half bridge make up for the downfall of a smaller turbo .

#27

I wrote a lot, but deleted it as most people want an answer and not to learn how something works- pm me if you want the explanation.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

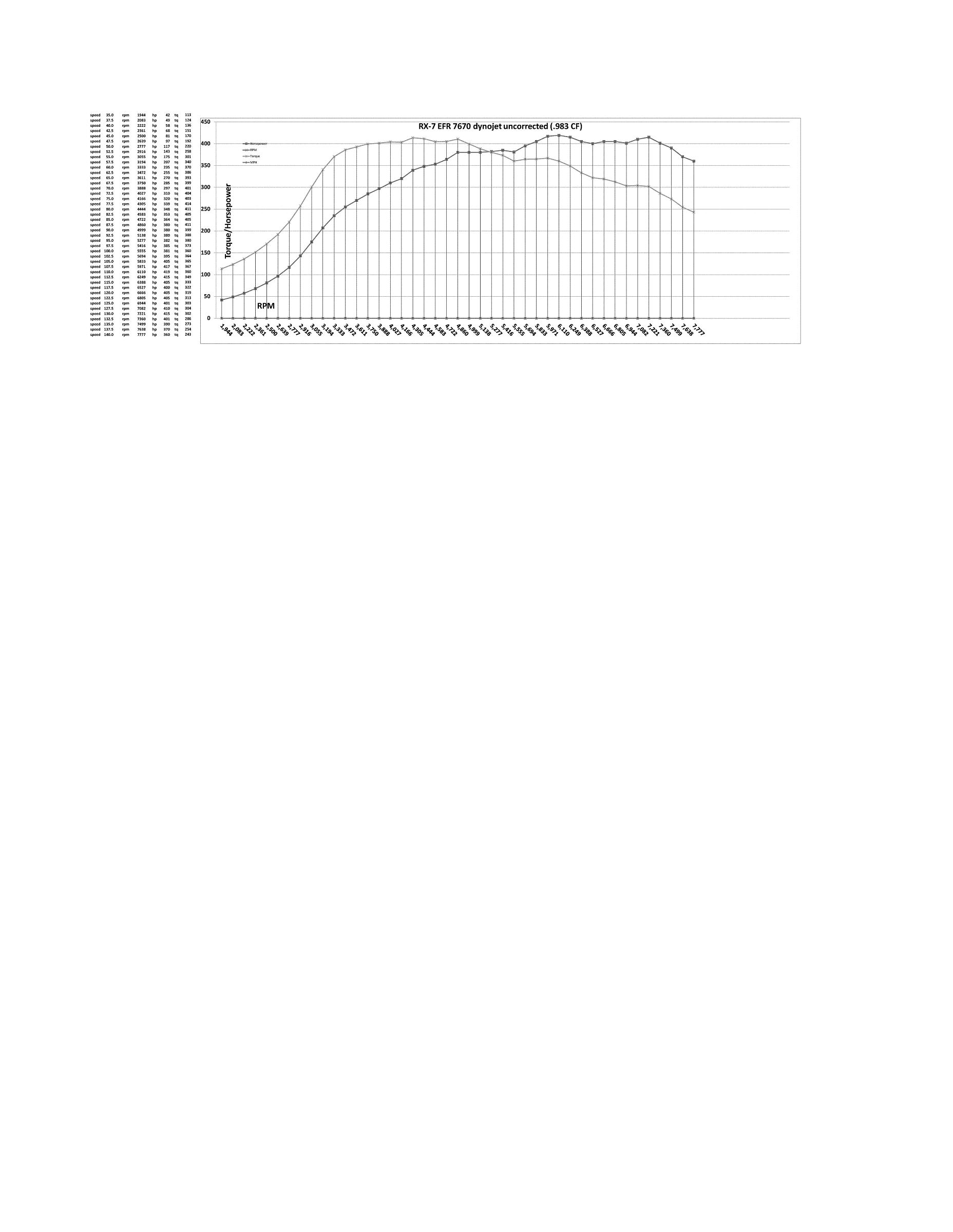

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

#28

PM'd you as i dont wanna go to off topic from the original thread

I wrote a lot, but deleted it as most people want an answer and not to learn how something works- pm me if you want the explanation.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

#29

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

I wrote a lot, but deleted it as most people want an answer and not to learn how something works- pm me if you want the explanation.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

Long story short- you can't try to gain the benefits of high overlap Volumetric Efficiency though bridge porting while putting a small restrictive (exhaust and intake) turbo on the rotary.

The restrictions of the turbo negate the benefits of overlap.

If you want a small turbo for low rpm power (as I did) the best bet is a street port that ports for earlier opening, but not later closing.

Yes, I know it sounds like that is adding overlap (which it is to a small degree) - but it is actually decreasing the affects of stock exhaust ports long duration- ok, I'm going to stop there- PM for explanation.

My FC's EFR 7670 turbo set-up was for race gas and auto-x/sprints- I wouldn't recommend the EFR 7670 for low boost or prolonged tracking.

For longevity while tracking I would recommend a larger turbo with less low rpm power/response. EFR 8374 would be more appropriate.

Post it here, some people want to learn.

#30

First a disclaimer-

I am not trying to be some rotary guru, I don't advise ANYONE to do as I say- but rather do as I DID and put the motor together and rotate it with a port drawn on a plexiglass plate and figure out the nuances of the rotary motor for themselves. Take motors apart and analyze the wear.

If you try to blindly follow my porting philosophy instead of reasoning it out yourself you may misunderstand something and end up with a port that hurts your power and or reliability.

----------------

Porting for small single, ie best low rpm torque-

I personally went with as early opening and near stock closing street port as possible with my small single (EFR 7670). What this does is actually decrease the exhaust pollution of the intake and promote intake chamber filling.

Early intake port opening-

The reason I went with early opening is because stock intake ports open 32 deg After Top Dead Center and the exhaust ports long duration has it closing even later 48 deg After Top Dead Center- meaning the intake chamber is expanding sucking up exhaust from the open exhaust port before the intake port opens to allow intake air in.

Mazda has documented this effect and even used the resulting trapped high pressure exhaust blowing back into the intake manifold as the intake port opens as part of their Dynamic Effect Intake pressure wave tuning.

That is, they took a negative limitation (late intake port opening) and used some of it's counter productive energy to negate the negative limitation's own effects- don't think of this part of DEI as a net positive that you will destroy with earlier opening intake.

Stock intake port timing is 32 deg After Top Dead Center (on all ports of motors up to '89* with EGR and on the 2ndary ports of all motors) which is as early as Mazda could go and protect the side seals using a normal end mill to cut the openings of the ports.

*On '89 and later motors Mazda used even later 45 deg ATDC opening primary ports to promote EGR without an EGR valve and have physically smaller higher velocity primary ports.

Back in the late '60s when Mazda hand ported (Cosmo Sport) they used 24 deg ATDC intake port opening which is about as early opening as you can get and protect the side seals with a smaller cutting tool for more precise port shaping.

This early Mazda hand ported port is like a Racing Beat or Pineapple style port- you can actually gain side seal life with the Judge Ito, Lynn Hannover or BLUE TII style port.

*I describe side seal friendly street porting in following post*

To get even closer to 0 deg ATDC intake timing you can bevel the rotor edge that uncovers the intake. This does make the side seal groove more susceptible to foreign object damage and you should balance the rotating assembly.

If you use stock beveled RX-8 rotors (or rotating assembly so you don't have to balance) that also have the big corner seal heads and side seal slots moved out to the edge of the rotor you can get to 0 deg ATDC- but you are stuck with 10:1 CR rotors.

Near stock closing intake port-

The reason I went with as close to stock closing as possible is two fold.

1st, keeping the port volume low keeps the intake velocity up for improved chamber filling at low rpm which will lead to more low rpm torque.

2nd, the stock ports close at 50 degrees After Bottom Dead Center, so the compression chamber has been decreasing in volume for 50 degrees raising the compression charge pressure. At low rpm this means flow will revert from the compression chamber back into the intake port as intake velocity is not high enough to counter this reversion. This leads to poor chamber filling (and thus torque) at low rpm.

So, the later you port the intake closing the higher the rpm this reversion takes place- thus decreasing low rpm torque.

I am not trying to be some rotary guru, I don't advise ANYONE to do as I say- but rather do as I DID and put the motor together and rotate it with a port drawn on a plexiglass plate and figure out the nuances of the rotary motor for themselves. Take motors apart and analyze the wear.

If you try to blindly follow my porting philosophy instead of reasoning it out yourself you may misunderstand something and end up with a port that hurts your power and or reliability.

----------------

Porting for small single, ie best low rpm torque-

I personally went with as early opening and near stock closing street port as possible with my small single (EFR 7670). What this does is actually decrease the exhaust pollution of the intake and promote intake chamber filling.

Early intake port opening-

The reason I went with early opening is because stock intake ports open 32 deg After Top Dead Center and the exhaust ports long duration has it closing even later 48 deg After Top Dead Center- meaning the intake chamber is expanding sucking up exhaust from the open exhaust port before the intake port opens to allow intake air in.

Mazda has documented this effect and even used the resulting trapped high pressure exhaust blowing back into the intake manifold as the intake port opens as part of their Dynamic Effect Intake pressure wave tuning.

That is, they took a negative limitation (late intake port opening) and used some of it's counter productive energy to negate the negative limitation's own effects- don't think of this part of DEI as a net positive that you will destroy with earlier opening intake.

Stock intake port timing is 32 deg After Top Dead Center (on all ports of motors up to '89* with EGR and on the 2ndary ports of all motors) which is as early as Mazda could go and protect the side seals using a normal end mill to cut the openings of the ports.

*On '89 and later motors Mazda used even later 45 deg ATDC opening primary ports to promote EGR without an EGR valve and have physically smaller higher velocity primary ports.

Back in the late '60s when Mazda hand ported (Cosmo Sport) they used 24 deg ATDC intake port opening which is about as early opening as you can get and protect the side seals with a smaller cutting tool for more precise port shaping.

This early Mazda hand ported port is like a Racing Beat or Pineapple style port- you can actually gain side seal life with the Judge Ito, Lynn Hannover or BLUE TII style port.

*I describe side seal friendly street porting in following post*

To get even closer to 0 deg ATDC intake timing you can bevel the rotor edge that uncovers the intake. This does make the side seal groove more susceptible to foreign object damage and you should balance the rotating assembly.

If you use stock beveled RX-8 rotors (or rotating assembly so you don't have to balance) that also have the big corner seal heads and side seal slots moved out to the edge of the rotor you can get to 0 deg ATDC- but you are stuck with 10:1 CR rotors.

Near stock closing intake port-

The reason I went with as close to stock closing as possible is two fold.

1st, keeping the port volume low keeps the intake velocity up for improved chamber filling at low rpm which will lead to more low rpm torque.

2nd, the stock ports close at 50 degrees After Bottom Dead Center, so the compression chamber has been decreasing in volume for 50 degrees raising the compression charge pressure. At low rpm this means flow will revert from the compression chamber back into the intake port as intake velocity is not high enough to counter this reversion. This leads to poor chamber filling (and thus torque) at low rpm.

So, the later you port the intake closing the higher the rpm this reversion takes place- thus decreasing low rpm torque.

#31

Street ports-

Yes, RB and Pineapple ports are early opening- but they do wear the side seals and housings more than they need to which will lead to lower power numbers over time.

Basically, you can improve their port templates by putting a tighter radius curve at the upper outer side to top so the tip of the horizontal side seal that has dropped into the port does not hit the housing first. Then it won't wear the outer tip of the side seal off at an angle and won't wear a line in the plate there at the closing line.

You can also put a slight bevel or angled ramp on the closing line to pick up the side seal that has dropped into the port or change the scissor line of the port closing. You have to consider the rotor edge to end of bevled ramp (where you can still see any light between the rotor and the port) as your final port timing- ie, it is easy to add more port timing and low rpm reversion than you want with beveling the port closing line.

You can improve over the low end power/spool of the RB and Pineapple ports by keeping the closing timing closer to stock- but you must be careful to keep the closing line scissored to the side seals. You end up with a port that closes ~3- 5mm later than stock instead of ~10-15mm later like their templates.

It takes some experience to figure out how little scissor and or bevel you need to keep from wearing the side seals.

Its best to put the front housing, rotor housing, rotor and e-shaft together with a plexiglass sheet over the rotor housing with a port drawn on so you can see the exact side seal path as you turn the e-shaft. This is how I made my port template following the advice of Lynn Hannover.

You have a little more leeway on not scissoring the primary port as much because it is so much shorter top to bottom, so the side seal doesn't drop into the port as deep. Therefore, I raise the inner closing line a little bit more than the outer closing line (less scissor) to get the flow while keeping the port volume down. If you port the whole port to the closing line you have to port the transition in the port runner to the port face.

I port the primary port a tiny bit later closing as a whole (~1mm) as I reason the smaller intake manifold runners and ports may lead to higher velocity than the secondaries (thus countering reversion at a slightly later closing timing).

On the secondary port I keep the scissor with a bevel on the closing line instead of porting the whole port to the taller scissored closing line. Again, this keeps the port volume down by not having to port the transition from runner to port face.

You can bend up some side seal springs and put them in the rotor so the tips scribe the path of the side seal tips onto the plexi glass.

If I was at the mercy of someone else porting the motor I might just go with stock or cleaned up stock FD ports.

The porting I am recommending is only going to be a little bit better than stock FD ports for low rpm torque and it would be easy to mess them up so your motor is less reliable than stock.

I mean, the experts who have been doing this 40 years have ports templates I would never run again.

From what I understand my friend talked porting with world renowned rotary builder Darryl Drummond (builds all the Formula Mazda engines) about porting and he cautioned him NOT to go early opening because of the problems with side seal wear. Even he had identified the problem with common street port templates, but hadn't figured out the solution (or hadn't figured out a way to explain the solution in a reasonable amount of time to my friend).

If you keep stock FD ports and instead use the effort and money to go with a larger diameter exhaust and intake with V-stack and largest filter you can fit you will probably realize more improvement than if you had the perfect ports and the usual 3" exhaust and 3" or 4" intake straight to filter like everyone else runs.

Of course, you probably want to do it all as I also did.

However, now I am at the point where it sure is nice to use the best stock/MazdaComp parts so you can just buy them and put the engine back together instead of taking all the time to do the machine work and cleaning before you can put it back together.

Yes, you give up a little power- but you do gain seat time racing; which will probably make you faster in the end.

Yes, RB and Pineapple ports are early opening- but they do wear the side seals and housings more than they need to which will lead to lower power numbers over time.

Basically, you can improve their port templates by putting a tighter radius curve at the upper outer side to top so the tip of the horizontal side seal that has dropped into the port does not hit the housing first. Then it won't wear the outer tip of the side seal off at an angle and won't wear a line in the plate there at the closing line.

You can also put a slight bevel or angled ramp on the closing line to pick up the side seal that has dropped into the port or change the scissor line of the port closing. You have to consider the rotor edge to end of bevled ramp (where you can still see any light between the rotor and the port) as your final port timing- ie, it is easy to add more port timing and low rpm reversion than you want with beveling the port closing line.

You can improve over the low end power/spool of the RB and Pineapple ports by keeping the closing timing closer to stock- but you must be careful to keep the closing line scissored to the side seals. You end up with a port that closes ~3- 5mm later than stock instead of ~10-15mm later like their templates.

It takes some experience to figure out how little scissor and or bevel you need to keep from wearing the side seals.

Its best to put the front housing, rotor housing, rotor and e-shaft together with a plexiglass sheet over the rotor housing with a port drawn on so you can see the exact side seal path as you turn the e-shaft. This is how I made my port template following the advice of Lynn Hannover.

You have a little more leeway on not scissoring the primary port as much because it is so much shorter top to bottom, so the side seal doesn't drop into the port as deep. Therefore, I raise the inner closing line a little bit more than the outer closing line (less scissor) to get the flow while keeping the port volume down. If you port the whole port to the closing line you have to port the transition in the port runner to the port face.

I port the primary port a tiny bit later closing as a whole (~1mm) as I reason the smaller intake manifold runners and ports may lead to higher velocity than the secondaries (thus countering reversion at a slightly later closing timing).

On the secondary port I keep the scissor with a bevel on the closing line instead of porting the whole port to the taller scissored closing line. Again, this keeps the port volume down by not having to port the transition from runner to port face.

You can bend up some side seal springs and put them in the rotor so the tips scribe the path of the side seal tips onto the plexi glass.

If I was at the mercy of someone else porting the motor I might just go with stock or cleaned up stock FD ports.

The porting I am recommending is only going to be a little bit better than stock FD ports for low rpm torque and it would be easy to mess them up so your motor is less reliable than stock.

I mean, the experts who have been doing this 40 years have ports templates I would never run again.

From what I understand my friend talked porting with world renowned rotary builder Darryl Drummond (builds all the Formula Mazda engines) about porting and he cautioned him NOT to go early opening because of the problems with side seal wear. Even he had identified the problem with common street port templates, but hadn't figured out the solution (or hadn't figured out a way to explain the solution in a reasonable amount of time to my friend).

If you keep stock FD ports and instead use the effort and money to go with a larger diameter exhaust and intake with V-stack and largest filter you can fit you will probably realize more improvement than if you had the perfect ports and the usual 3" exhaust and 3" or 4" intake straight to filter like everyone else runs.

Of course, you probably want to do it all as I also did.

However, now I am at the point where it sure is nice to use the best stock/MazdaComp parts so you can just buy them and put the engine back together instead of taking all the time to do the machine work and cleaning before you can put it back together.

Yes, you give up a little power- but you do gain seat time racing; which will probably make you faster in the end.

#34

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

Street ports-

Yes, RB and Pineapple ports are early opening- but they do wear the side seals and housings more than they need to which will lead to lower power numbers over time.

Basically, you can improve their port templates by putting a tighter radius curve at the upper outer side to top so the tip of the horizontal side seal that has dropped into the port does not hit the housing first. Then it won't wear the outer tip of the side seal off at an angle and won't wear a line in the plate there at the closing line.

You can also put a slight bevel or angled ramp on the closing line to pick up the side seal that has dropped into the port or change the scissor line of the port closing. You have to consider the rotor edge to end of bevled ramp (where you can still see any light between the rotor and the port) as your final port timing- ie, it is easy to add more port timing and low rpm reversion than you want with beveling the port closing line.

You can improve over the low end power/spool of the RB and Pineapple ports by keeping the closing timing closer to stock- but you must be careful to keep the closing line scissored to the side seals. You end up with a port that closes ~3- 5mm later than stock instead of ~10-15mm later like their templates.

It takes some experience to figure out how little scissor and or bevel you need to keep from wearing the side seals.

Its best to put the front housing, rotor housing, rotor and e-shaft together with a plexiglass sheet over the rotor housing with a port drawn on so you can see the exact side seal path as you turn the e-shaft. This is how I made my port template following the advice of Lynn Hannover.

You have a little more leeway on not scissoring the primary port as much because it is so much shorter top to bottom, so the side seal doesn't drop into the port as deep. Therefore, I raise the inner closing line a little bit more than the outer closing line (less scissor) to get the flow while keeping the port volume down. If you port the whole port to the closing line you have to port the transition in the port runner to the port face.

I port the primary port a tiny bit later closing as a whole (~1mm) as I reason the smaller intake manifold runners and ports may lead to higher velocity than the secondaries (thus countering reversion at a slightly later closing timing).

On the secondary port I keep the scissor with a bevel on the closing line instead of porting the whole port to the taller scissored closing line. Again, this keeps the port volume down by not having to port the transition from runner to port face.

You can bend up some side seal springs and put them in the rotor so the tips scribe the path of the side seal tips onto the plexi glass.

If I was at the mercy of someone else porting the motor I might just go with stock or cleaned up stock FD ports.

The porting I am recommending is only going to be a little bit better than stock FD ports for low rpm torque and it would be easy to mess them up so your motor is less reliable than stock.

I mean, the experts who have been doing this 40 years have ports templates I would never run again.

From what I understand my friend talked porting with world renowned rotary builder Darryl Drummond (builds all the Formula Mazda engines) about porting and he cautioned him NOT to go early opening because of the problems with side seal wear. Even he had identified the problem with common street port templates, but hadn't figured out the solution (or hadn't figured out a way to explain the solution in a reasonable amount of time to my friend).

If you keep stock FD ports and instead use the effort and money to go with a larger diameter exhaust and intake with V-stack and largest filter you can fit you will probably realize more improvement than if you had the perfect ports and the usual 3" exhaust and 3" or 4" intake straight to filter like everyone else runs.

Of course, you probably want to do it all as I also did.

However, now I am at the point where it sure is nice to use the best stock/MazdaComp parts so you can just buy them and put the engine back together instead of taking all the time to do the machine work and cleaning before you can put it back together.

Yes, you give up a little power- but you do gain seat time racing; which will probably make you faster in the end.

Yes, RB and Pineapple ports are early opening- but they do wear the side seals and housings more than they need to which will lead to lower power numbers over time.

Basically, you can improve their port templates by putting a tighter radius curve at the upper outer side to top so the tip of the horizontal side seal that has dropped into the port does not hit the housing first. Then it won't wear the outer tip of the side seal off at an angle and won't wear a line in the plate there at the closing line.

You can also put a slight bevel or angled ramp on the closing line to pick up the side seal that has dropped into the port or change the scissor line of the port closing. You have to consider the rotor edge to end of bevled ramp (where you can still see any light between the rotor and the port) as your final port timing- ie, it is easy to add more port timing and low rpm reversion than you want with beveling the port closing line.

You can improve over the low end power/spool of the RB and Pineapple ports by keeping the closing timing closer to stock- but you must be careful to keep the closing line scissored to the side seals. You end up with a port that closes ~3- 5mm later than stock instead of ~10-15mm later like their templates.

It takes some experience to figure out how little scissor and or bevel you need to keep from wearing the side seals.

Its best to put the front housing, rotor housing, rotor and e-shaft together with a plexiglass sheet over the rotor housing with a port drawn on so you can see the exact side seal path as you turn the e-shaft. This is how I made my port template following the advice of Lynn Hannover.

You have a little more leeway on not scissoring the primary port as much because it is so much shorter top to bottom, so the side seal doesn't drop into the port as deep. Therefore, I raise the inner closing line a little bit more than the outer closing line (less scissor) to get the flow while keeping the port volume down. If you port the whole port to the closing line you have to port the transition in the port runner to the port face.

I port the primary port a tiny bit later closing as a whole (~1mm) as I reason the smaller intake manifold runners and ports may lead to higher velocity than the secondaries (thus countering reversion at a slightly later closing timing).

On the secondary port I keep the scissor with a bevel on the closing line instead of porting the whole port to the taller scissored closing line. Again, this keeps the port volume down by not having to port the transition from runner to port face.

You can bend up some side seal springs and put them in the rotor so the tips scribe the path of the side seal tips onto the plexi glass.

If I was at the mercy of someone else porting the motor I might just go with stock or cleaned up stock FD ports.

The porting I am recommending is only going to be a little bit better than stock FD ports for low rpm torque and it would be easy to mess them up so your motor is less reliable than stock.

I mean, the experts who have been doing this 40 years have ports templates I would never run again.

From what I understand my friend talked porting with world renowned rotary builder Darryl Drummond (builds all the Formula Mazda engines) about porting and he cautioned him NOT to go early opening because of the problems with side seal wear. Even he had identified the problem with common street port templates, but hadn't figured out the solution (or hadn't figured out a way to explain the solution in a reasonable amount of time to my friend).

If you keep stock FD ports and instead use the effort and money to go with a larger diameter exhaust and intake with V-stack and largest filter you can fit you will probably realize more improvement than if you had the perfect ports and the usual 3" exhaust and 3" or 4" intake straight to filter like everyone else runs.

Of course, you probably want to do it all as I also did.

However, now I am at the point where it sure is nice to use the best stock/MazdaComp parts so you can just buy them and put the engine back together instead of taking all the time to do the machine work and cleaning before you can put it back together.

Yes, you give up a little power- but you do gain seat time racing; which will probably make you faster in the end.

There is some valuable information in what he wrote here that I also maximized on my car. look at everything in the system. I see a lot of people running large intercoolers which don't need to. You have backpressure in the exhaust and turbine, but very little is talked about the pressure drop from the intake and filter side of things. Also about grabbing cold air in the front of the car/bumper where you can place an intake with a smaller V-mount intercooler and ducting it all up. You also have airflow all through the system of the intercooler, intake, and exhaust. It not what fits, its more about the design of everything fitting together and smoothing out the bends, having endtanks which use the entire intercooler area, ducting to cool everything in the intercooler, etc, etc, etc. so endtank design, piping diameters, piping reducers/expanders with smooth non-tight radiuses, think about the system. Also think about ducting after the heat exchangers for reduced drag and more downforce. look at ducting design, etc, etc to maximize everything.

colder air could gain a good chunk of power, velocity stack and low pressure drop air filter can gain some spool and more power, the turbo can run at a lower pressure ratio from the lower pressure drop from the exhaust and intake system, smaller intercooler v-mount reduces volume and pressure drop across core, fin density in the core (lower) have lower pressure drop, but is a high fin density needed if you are sucking in ambient air? less intercooler piping and smaller diameter decreases volume and increases velocity and efficiency + spool. its about making a single turbo more efficient and spool quicker. also look at not peak power but ease of driveability, is it faster to have a peaky turbo or a broad powerband? Stock ports aren't a bad set up but you might choose a different turbo or different A/R on the turbine side of you can spool the turbo earlier but what a little more top end power. or street port an engine and run a smaller turbine A/R for better spool but have good port flow. think about the entire system and making it efficient.

I run a GT3574R, velocity stack on 4" pipe, 6" ID filter 10" filter length in my bumper, 15x10x4 intercooler core, 10" intercooler piping on each side, smooth intercooler bends, short/medium length exhaust manifold runner, 3" back exhaust, water injection.

#35

I would like to add to this.

Exactly!

The point I am at now, I would rather keep as close to a stock engine block as possible and optimize all the peripherals.

The peripherals are more permanent and together make more of difference than anything you can do to the motor.

If you race you will keep rebuilding the engine block and it sure is a lot easier and faster to put it together with stock parts. Likewise, its faster and easier to put the engine bay together with well thought out peripherals.

Exactly!

The point I am at now, I would rather keep as close to a stock engine block as possible and optimize all the peripherals.

The peripherals are more permanent and together make more of difference than anything you can do to the motor.

If you race you will keep rebuilding the engine block and it sure is a lot easier and faster to put it together with stock parts. Likewise, its faster and easier to put the engine bay together with well thought out peripherals.

#36

Rotary Enthusiast

iTrader: (19)

Join Date: Apr 2002

Location: Colorado Springs, CO

Posts: 1,169

Likes: 0

Received 11 Likes

on

10 Posts

I agree. I am an engineer, I like to look at maximizing efficiency of a system. There are parts of the car that Mazda had designed well and designed well to fit together. I think the stock ports, stock OEM seals, etc work well together and do not need upgrading. The only thing needed would be viton seals for the water seals. everything else internally to the engine I would leave stock. Porting an engine is basically just stealing low end and giving it to the top end. A rotary engine needs low end torque, not more high end power/torque? I would leave the ports stock, run a .84-1.0 A/R hot side single turbo with a 62MM compressor wheel. I would try to find a lightweight turbine wheel to increase spool (EFR series turbo). Run all the stuff I said above to maximize the system.

I think what people get hung up on are the wrong things. Peak power only occurs in a small minute spot in the power band. Think about maximizing the entire powerband, its easier to drive. Think about minimizing risk in the system. risk is porting an engine, as it can easily be done poorly. Risk is running any aftermarket seal, as the R&D isn't anywhere near the OEM seals, and what about the manufacturing quality control on the processes making those seals.

anything above 400WHP is going to be rough on the car. drivetrain feels it, fuel system then have to be modified with large pumps or dual pumps, turbo's above this have more lag, tuning becomes more important and riskier, systems become more complex with E85 or water/meth, the list goes on.

I think the easiest most reliable route is a 300-350WHP single turbo, well thought out, stock internal engine. broadest most reliable powerband with lots of margin of safety and the components can still handle the power easily in stock form (diff, tranny, etc).

I think what people get hung up on are the wrong things. Peak power only occurs in a small minute spot in the power band. Think about maximizing the entire powerband, its easier to drive. Think about minimizing risk in the system. risk is porting an engine, as it can easily be done poorly. Risk is running any aftermarket seal, as the R&D isn't anywhere near the OEM seals, and what about the manufacturing quality control on the processes making those seals.

anything above 400WHP is going to be rough on the car. drivetrain feels it, fuel system then have to be modified with large pumps or dual pumps, turbo's above this have more lag, tuning becomes more important and riskier, systems become more complex with E85 or water/meth, the list goes on.

I think the easiest most reliable route is a 300-350WHP single turbo, well thought out, stock internal engine. broadest most reliable powerband with lots of margin of safety and the components can still handle the power easily in stock form (diff, tranny, etc).

Thread

Thread Starter

Forum

Replies

Last Post

msilvia

3rd Generation Specific (1993-2002)

28

04-14-16 12:58 PM