Feedback on my SMIC and retaining the stock air box

#1

Senior Member

Thread Starter

Feedback on my SMIC and retaining the stock air box

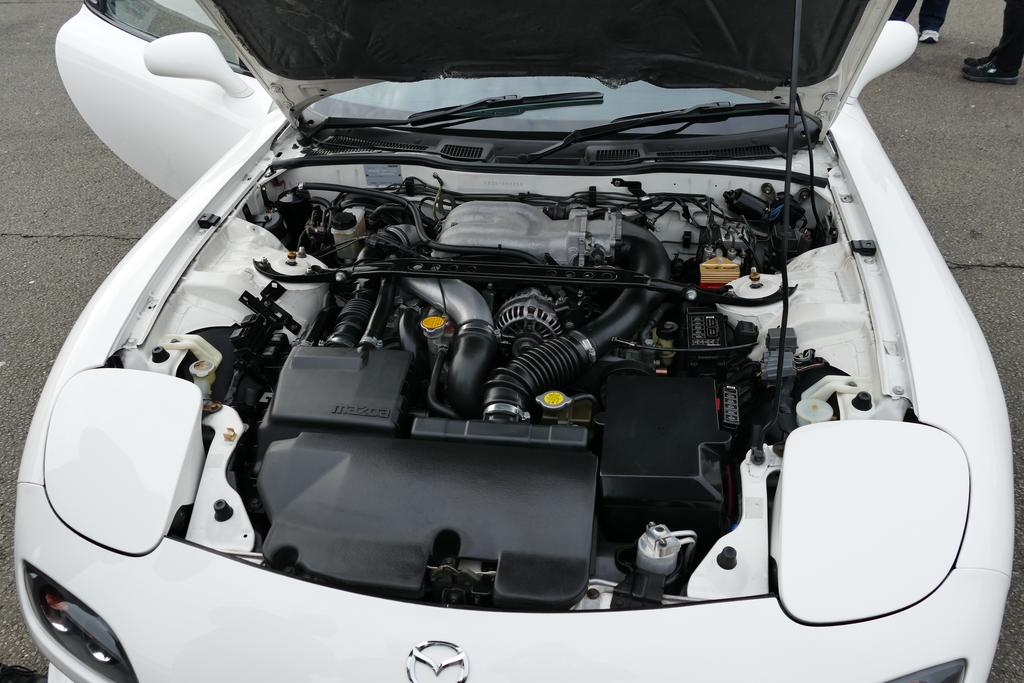

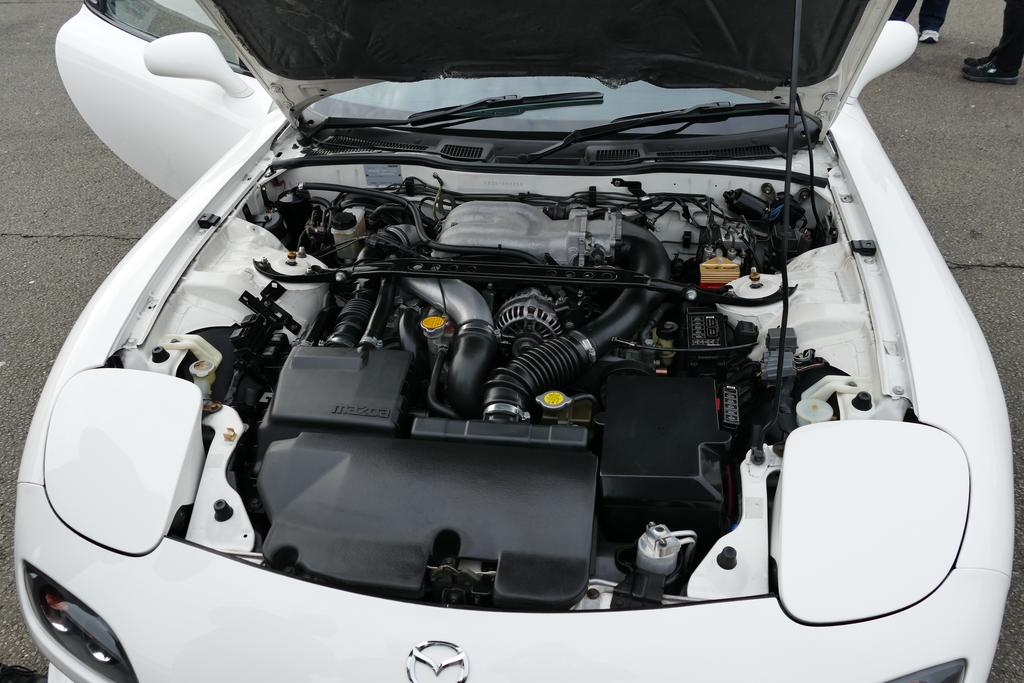

I bought a Greddy SMIC a while back and I finally got around to having it fitted. Stubbornly, the idea all along was to keep the battery and stock air box and intake system in place as the Greddy unit should technically fit.

Well, after a lot of measuring I'm proud to say we go it to fit by only slightly modifying the air box bracket closest to the intercooler so that the intercooler could drop into place.

In order to keep the stock air guide that accesses air in the void behind the license plate (99 spec car) and feeds the air into the air box, it had to be modified, so some fiberglass work was done to allow it all to sit in place.

I haven't been able to dyno it or track it yet to see if I created a new restriction because the car is in the body shop at the moment getting resprayed to refresh the exterior. But I have road tested it for about 400 miles an no issues so far.

But I thought I would share some of the photos and was curious to see what you guys think about the approach.

The goal is to be able to run 0.9-1.0 bar reliably on track (300-330 hp) with an OEM look.

Stock

Greddy SMIC

Painted

Stock SMIC duct modified with fiberglass

Duct painted

Greddy SMIC fits but air guide doesn't

Well, after a lot of measuring I'm proud to say we go it to fit by only slightly modifying the air box bracket closest to the intercooler so that the intercooler could drop into place.

In order to keep the stock air guide that accesses air in the void behind the license plate (99 spec car) and feeds the air into the air box, it had to be modified, so some fiberglass work was done to allow it all to sit in place.

I haven't been able to dyno it or track it yet to see if I created a new restriction because the car is in the body shop at the moment getting resprayed to refresh the exterior. But I have road tested it for about 400 miles an no issues so far.

But I thought I would share some of the photos and was curious to see what you guys think about the approach.

The goal is to be able to run 0.9-1.0 bar reliably on track (300-330 hp) with an OEM look.

Stock

Greddy SMIC

Painted

Stock SMIC duct modified with fiberglass

Duct painted

Greddy SMIC fits but air guide doesn't

Last edited by cib24; 05-17-17 at 02:47 AM.

#6

Really fantastic work.

My only question is on the AST relocation? My understanding is the AST needs to be the highest point in the cooling system. Although that appears to be above the radiator - it seems to be below the water pump. I'm not sure that's ok.

Everything else though, really top notch.

Edit: Yeah - what Narfle said!

My only question is on the AST relocation? My understanding is the AST needs to be the highest point in the cooling system. Although that appears to be above the radiator - it seems to be below the water pump. I'm not sure that's ok.

Everything else though, really top notch.

Edit: Yeah - what Narfle said!

#7

If you ever want a finish rcloser to a factory plastic look you can use Duplicolor Truck Bed Liner (the Blue label). It gives it a textured satin Black plastic finish. You can vary the amount of texture with how you apply it.

It can take some heat, but not extreme heat. Probably work fine on the air guides/ducts and IC top.

I can appreciate all the work you did for the stock like look, turned out great.

It can take some heat, but not extreme heat. Probably work fine on the air guides/ducts and IC top.

I can appreciate all the work you did for the stock like look, turned out great.

Trending Topics

#9

Senior Member

Thread Starter

Thanks guys.

BLUE TII, I completely agree on the finish. I didn't want a glossy style finish but it's all we had available to use at the time. I would have preferred to use engine paint or something that would leave a matte finish and be able to take higher temps. I have noticed in the 400 miles I have driven that the clearcoat on the air guide has already started to crack from the heat in the engine bay, so I will have a chance to paint it again when time allows me to.

As for the final install, I'm proud to say everything fits. The Greddy does not touch the Koyo and is well clear of the pulleys, and fits according to Greddys original mounting points. However, it does nudge against the battery cover so taking the battery cover off is a royal pain now but when it's on, it's on way tighter than it was before! The other issue is that it's very tall and thus I noticed it was hitting the hood when closed as after a short drive a chip started to form on the top of the SMIC and on the hood where they were coming into contact. I have put a piece of foam adhesive there for now but will have to touch in the SMIC with some touch up paint and perhaps have the body shop sand away a tiny piece of metal on the underside of the hood as part of the respray to make clearance (it hits one of the reinforced areas so there is plenty of material to play with). I will get a photo at some point to show you guys what I mean.

To demonstrate how much taller the Greddy is than the stock intercooler have a look at the SMIC dimensions below:

Type ..........................L (left-to-right) x H (bottom-to-top) x W (front-to-back) (mm) = Total Surface Area Compared to Stock

----------------------------------------------------------------------------------------------

Stock ........................295 x 115 x 65 = 1.0x

ARC M103...................310 x 150 x 105 = 2.21x

KNIGHTSPORTS...........300 x 160 x (75x2) = 3.27x

GREDDY.....................295 x 190 x 100 = 2.54x

BLITZ.........................280 x 140 x 102 = 1.81x

Old RE-Amemiya................Apparently same core as Greddy = 2.54x

As for the duct, I'm very impressed with the final result barring the fact that the fiberglass started to bend a bit at the widest opening at the top before it hardened as you can see in one of the fiberglass photos above. It's not going to affect anything and you can't see it because the air guide is over it, but once the fiberglass starts to set you are kind of left with what you have, so I'm glad there were no other issues as that job was quite tricky. Also, to get the duct off we had to disconnect the A/C lines and drain the system and then refill the system with R-134A when we were done. Not a huge deal but still an extra step.

I chose not to extend the duct further into the front bumper because it already extends pretty far and is visible and with the amount of high pressure air that goes through the bumper it should pick up plenty of air flow anyway. So, an extension of the duct would have been for marginal benefit and would have looked funny with a huge duct sticking out in the void of the bumper opening.

Fiberglass for the air guide was a lot easier and we were worried that cutting so much away was going to compromise the design. However, we managed to keep the inside of the air guide completely functional and leave as much internal surface area as we could fit which was awesome.

The Greddy hard pipe from the crossover pipe was untouched but the Greddy hard pipe from the intercooler to throttle body elbow had to be trimmed about 1/4"-1/2" at the join to the throttle body elbow because it was too long. The silicone couplers cover the modification.

The AST is fitted in the location provided by Greddy on the back of the SMIC. I agree with everyone that I'm not a fan of how it sits a bit lower than the water pump now. I haven't had any issues yet because I didn't have to unplug the AST or anything when installing the SMIC, and my system was well bled when I changed my coolant last year. Of course, when it comes time to change the coolant again it could be more difficult to bleed the system.

As for relocating the AST, where to? There is literally no room anywhere as my engine bay is now extremely crowded, haha. I have a catch can the size of a wine bottle stuffed into the space near the fender and the brake master cylinder and pipes, and a HKS twin power as you can see in the photo on the right side. I also have my water injection pump hidden and secured on the frame next to the spark plugs so you can't see it and so it sits lower or at least level with the windshield washer tank that is my reservoir. All you see is the nozzle going into the elbow.

BLUE TII, I completely agree on the finish. I didn't want a glossy style finish but it's all we had available to use at the time. I would have preferred to use engine paint or something that would leave a matte finish and be able to take higher temps. I have noticed in the 400 miles I have driven that the clearcoat on the air guide has already started to crack from the heat in the engine bay, so I will have a chance to paint it again when time allows me to.

As for the final install, I'm proud to say everything fits. The Greddy does not touch the Koyo and is well clear of the pulleys, and fits according to Greddys original mounting points. However, it does nudge against the battery cover so taking the battery cover off is a royal pain now but when it's on, it's on way tighter than it was before! The other issue is that it's very tall and thus I noticed it was hitting the hood when closed as after a short drive a chip started to form on the top of the SMIC and on the hood where they were coming into contact. I have put a piece of foam adhesive there for now but will have to touch in the SMIC with some touch up paint and perhaps have the body shop sand away a tiny piece of metal on the underside of the hood as part of the respray to make clearance (it hits one of the reinforced areas so there is plenty of material to play with). I will get a photo at some point to show you guys what I mean.

To demonstrate how much taller the Greddy is than the stock intercooler have a look at the SMIC dimensions below:

Type ..........................L (left-to-right) x H (bottom-to-top) x W (front-to-back) (mm) = Total Surface Area Compared to Stock

----------------------------------------------------------------------------------------------

Stock ........................295 x 115 x 65 = 1.0x

ARC M103...................310 x 150 x 105 = 2.21x

KNIGHTSPORTS...........300 x 160 x (75x2) = 3.27x

GREDDY.....................295 x 190 x 100 = 2.54x

BLITZ.........................280 x 140 x 102 = 1.81x

Old RE-Amemiya................Apparently same core as Greddy = 2.54x

As for the duct, I'm very impressed with the final result barring the fact that the fiberglass started to bend a bit at the widest opening at the top before it hardened as you can see in one of the fiberglass photos above. It's not going to affect anything and you can't see it because the air guide is over it, but once the fiberglass starts to set you are kind of left with what you have, so I'm glad there were no other issues as that job was quite tricky. Also, to get the duct off we had to disconnect the A/C lines and drain the system and then refill the system with R-134A when we were done. Not a huge deal but still an extra step.

I chose not to extend the duct further into the front bumper because it already extends pretty far and is visible and with the amount of high pressure air that goes through the bumper it should pick up plenty of air flow anyway. So, an extension of the duct would have been for marginal benefit and would have looked funny with a huge duct sticking out in the void of the bumper opening.

Fiberglass for the air guide was a lot easier and we were worried that cutting so much away was going to compromise the design. However, we managed to keep the inside of the air guide completely functional and leave as much internal surface area as we could fit which was awesome.

The Greddy hard pipe from the crossover pipe was untouched but the Greddy hard pipe from the intercooler to throttle body elbow had to be trimmed about 1/4"-1/2" at the join to the throttle body elbow because it was too long. The silicone couplers cover the modification.

The AST is fitted in the location provided by Greddy on the back of the SMIC. I agree with everyone that I'm not a fan of how it sits a bit lower than the water pump now. I haven't had any issues yet because I didn't have to unplug the AST or anything when installing the SMIC, and my system was well bled when I changed my coolant last year. Of course, when it comes time to change the coolant again it could be more difficult to bleed the system.

As for relocating the AST, where to? There is literally no room anywhere as my engine bay is now extremely crowded, haha. I have a catch can the size of a wine bottle stuffed into the space near the fender and the brake master cylinder and pipes, and a HKS twin power as you can see in the photo on the right side. I also have my water injection pump hidden and secured on the frame next to the spark plugs so you can't see it and so it sits lower or at least level with the windshield washer tank that is my reservoir. All you see is the nozzle going into the elbow.

Last edited by cib24; 05-17-17 at 04:05 AM.

#11

Senior Member

Thread Starter

Nah, we would have done it if there was space. There isn't enough space between the intercooler-TB elbow pipe and the battery for the AST to fit any higher and there isn't any space on the left side of the intercooler-TB elbow pipe because the other crossover-intercooler pipe is in the way.

Any other ideas?

Any other ideas?

#14

Senior Member

Thread Starter

Eliminating the AST is not something I will consider as I think there is too much risk running without one and I'm not willing to try to spend ages and ages bleeding the system and hoping I got all of the bubbles out. Perhaps there isn't a reasonable place to relocate it but I'll have another think.

As for how it will hold up, well the clearcoat on the air guide is already cracking so that will need to be repainted with something that can withstand higher temperatures. The fiberglass itself should be able to withstand quite high temperatures and given the only fiberglass is the air guide and the duct at the front of the engine, with the duct not even really a very hot source except the intercooler which will occassionally heatsoak, I think it will be fine. If I were to place something made of fiberglass down near the twins then I would have worries.

As for how it will hold up, well the clearcoat on the air guide is already cracking so that will need to be repainted with something that can withstand higher temperatures. The fiberglass itself should be able to withstand quite high temperatures and given the only fiberglass is the air guide and the duct at the front of the engine, with the duct not even really a very hot source except the intercooler which will occassionally heatsoak, I think it will be fine. If I were to place something made of fiberglass down near the twins then I would have worries.

Last edited by cib24; 05-17-17 at 11:36 AM.

#15

I chose not to extend the duct further into the front bumper because it already extends pretty far and is visible and with the amount of high pressure air that goes through the bumper it should pick up plenty of air flow anyway. So, an extension of the duct would have been for marginal benefit and would have looked funny with a huge duct sticking out in the void of the bumper opening.

https://www.rx7club.com/3rd-generati...temps-1070765/

Can you currently uncap the AST and see air space in it? Or, does it overflow? If there's no airspace in it, it's not functioning. I know the coolant level comes up pretty high on my filler neck. The only good AST relocations I've seen are by the brake booster(rhd) or in space evacuated by a smaller-than-stock intake setup.

#16

Senior Member

Thread Starter

Thanks. I have seen that thread and that is originally where the idea came from to extend the stock duct while it was out, but aside from the fact that mine is already well visible in the bumper opening (perhaps 99 spec cars have a slightly longer intercooler duct or it's just the revised shape of the bumper that makes it more visible), I am running 250cc of water injection with an AEM water injection kit, so even if the intercooler starts to heatsoak the water is there to save the day and act as a cooling agent for the intake charge.

Now, originally I wasn't going to even bother with an upgraded SMIC because I was already running water injection last year with the stock intercooler and 0.8-0.85 bar (11.6-12.3 PSI) with no issues (factory boost level on my 280ps Type RS was 0.74 bar (10.7 PSI)) on track. If it was just a street car I wouldn't have bothered. However, I wanted to increase my boost levels to around 1.0 bar (14.5 PSI), maybe a touch more, for a bit more power and I didn't like the fact that the stock intercooler has a real issue with pressure drop, something like 3-4 PSI equivalent if running 1.0 bar (14.5 PSI). So, that would mean the turbos could be running as much as 1.25 bar (18 PSI) in order to get 1.0 bar into the engine and that would mean extra heat and more importantly a really short life for my twins.

I don't know how much pressure drop the Greddy SMIC has but surely it's more like 1-2 PSI at most rather than 3-4 PSI like the OEM intercooler. And it will make the whole system more efficient.

But hey, it's nearly a 20 year old car so something could go kaput on the track at any point and it's rebuild time, haha. My 99 spec twins were already leaking tons of oil so the twins on my car are a good used set of older ones which I will run until they blow, and I'll have my rebuilt 99 specs to put back on the car at lower boost levels.

Now, originally I wasn't going to even bother with an upgraded SMIC because I was already running water injection last year with the stock intercooler and 0.8-0.85 bar (11.6-12.3 PSI) with no issues (factory boost level on my 280ps Type RS was 0.74 bar (10.7 PSI)) on track. If it was just a street car I wouldn't have bothered. However, I wanted to increase my boost levels to around 1.0 bar (14.5 PSI), maybe a touch more, for a bit more power and I didn't like the fact that the stock intercooler has a real issue with pressure drop, something like 3-4 PSI equivalent if running 1.0 bar (14.5 PSI). So, that would mean the turbos could be running as much as 1.25 bar (18 PSI) in order to get 1.0 bar into the engine and that would mean extra heat and more importantly a really short life for my twins.

I don't know how much pressure drop the Greddy SMIC has but surely it's more like 1-2 PSI at most rather than 3-4 PSI like the OEM intercooler. And it will make the whole system more efficient.

But hey, it's nearly a 20 year old car so something could go kaput on the track at any point and it's rebuild time, haha. My 99 spec twins were already leaking tons of oil so the twins on my car are a good used set of older ones which I will run until they blow, and I'll have my rebuilt 99 specs to put back on the car at lower boost levels.

Last edited by cib24; 05-17-17 at 12:03 PM.

#17

Eliminating the AST is not something I will consider as I think there is too much risk running without one and I'm not willing to try to spend ages and ages bleeding the system and hoping I got all of the bubbles out. Perhaps there isn't a reasonable place to relocate it but I'll have another think.

#18

RX-7 Bad Ass

iTrader: (55)

^Yep, I've been running with no AST for probably 10 years. Coolant temps rock solid at 82-83 deg with a Koyo and a Blitz front mount. Even before the IC upgrade it was just fine.

The Lisle funnel is the trick, it makes filling the system SO much easier.

Going back to the original purpose of this thread, the fiberglass and paint work looks awesome! Really impressed with how it turned out.

Dale

The Lisle funnel is the trick, it makes filling the system SO much easier.

Going back to the original purpose of this thread, the fiberglass and paint work looks awesome! Really impressed with how it turned out.

Dale

#19

Senior Member

Thread Starter

Fair enough. I will ask my rotary guy what he thinks. Perhaps he thinks the same and that it is okay to delete. He has to install IRP engine mounts for me later in the summer anyway so when I stop by his shop we will have a look and see if we can relocate it or if deleting it for now is fine.

#21

Originally Posted by cib24

Now, originally I wasn't going to even bother with an upgraded SMIC because I was already running water injection last year with the stock intercooler and 0.8-0.85 bar (11.6-12.3 PSI) with no issues (factory boost level on my 280ps Type RS was 0.74 bar (10.7 PSI)) on track.

Interested to hear how things go, though. Good luck!

#22

Senior Member

Thread Starter

Temps on my stock SMIC with 250cc/min injection were max around 50-55 C after 15-20 minutes of track time in around 20 C weather. Usually my temps will never go above 45 C and I did 2 track days in winter before water injection and they never went above 45 C, but I attribute it to a few things really. Better OEM design on 99 spec models to help the intercooler be more effective than on earlier cars (larger duct, blocked off completely from the intake box), and I live in the UK so most of my track days are between 7 C (45 F) and 22 C (72 F). I don't know if I will ever be in a situation where I will track when it is above 75 F unless I do a track day in continental Europe at like Imola, Catalunya, Nurburgring, etc.

So, perhaps you are right but if I was tracking in much hotter conditions I would just up the amount of water and tune for it.

The Greddy will help a bit with cooling compared to stock but to me it's mostly about controlling pressure drop.

So, perhaps you are right but if I was tracking in much hotter conditions I would just up the amount of water and tune for it.

The Greddy will help a bit with cooling compared to stock but to me it's mostly about controlling pressure drop.

Last edited by cib24; 06-15-17 at 09:29 AM.

#23

Thanks for that info. I think that makes a lot of sense: you have the benefit of cool ambient temps and better '99 airflow. And maybe slightly shorter stints too: I find that intake temps go up during the session so they're at their highest 15-25min in.

My setup is fine in the low 70sF, but in the mid Atlantic US that's only the case in early spring or late fall. Ambient temps make a huge, huge difference.

I think the Greddy can only help, of course. Let us know how it goes.

My setup is fine in the low 70sF, but in the mid Atlantic US that's only the case in early spring or late fall. Ambient temps make a huge, huge difference.

I think the Greddy can only help, of course. Let us know how it goes.

#24

Could be wrong, but i don't believe water helps too much with IAT. It does help detonation though by increasing the effective fuel octane. Methanol on the other hand does reduce IATs. Since detonation is the danger and is caused by heat (of which IATs are a prime culpret), a mix of water and methanol is a little of the best of both worlds, increasing octane and reducing IATs. (especially if the intercooler is less than optimal)

I believe there are some old threads on replacing the intercooler with pure methanol injection. It's not really practical, but it was an interesting experiment.

I believe there are some old threads on replacing the intercooler with pure methanol injection. It's not really practical, but it was an interesting experiment.

#25

Senior Member

Thread Starter

Well, you're wrong about water not cooling IATs. I've seen it take 15-20 C off my temps when on. Also, just think about the chemistry behind it. Ambient water being injected into a hotter intake tract. The water absorbs the heat in the air and cools the air going into the intake. Methanol does this better but I'm not interested in that because I would then have to tune for it. Injecting 250cc/min like I am isn't enough to affect the air fuel mix at all. It merely cools the intake charge and thus the ECU sees a cooler air charge and injects more fuel and does not retard timing or boost pressure. Keeping the engine operating in the optimal range for power and reliability.