Cracked front iron anyone know why this happens

#1

Registered User

Thread Starter

iTrader: (2)

Join Date: May 2010

Location: Midwest

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

Ok guys have a rebuilt engine in my car with about 1,200 miles or so on it.

tuned on e85 not a lot of horsepower in the 500's. was driving home went to pass someone and hit about 15psi and next thing you know windshield is covered in oil car started losing power and shut off. i popped open the hood and found a cracked front iron right where the oil feed line is for the turbo.

Has anyone had this happen or know what caused this?

tuned on e85 not a lot of horsepower in the 500's. was driving home went to pass someone and hit about 15psi and next thing you know windshield is covered in oil car started losing power and shut off. i popped open the hood and found a cracked front iron right where the oil feed line is for the turbo.

Has anyone had this happen or know what caused this?

#3

not a lot of horsepower..in the 500's. Really? 500hp isn't a lot

Either way, it seems like it could have been a combination of things.

Really high oil pressure.

Did you drill and tap the front iron to accept that fitting? If you did it incorrectly it should have weakened or developed a hairline crack causing what you have now.

Either way, it seems like it could have been a combination of things.

Really high oil pressure.

Did you drill and tap the front iron to accept that fitting? If you did it incorrectly it should have weakened or developed a hairline crack causing what you have now.

#4

Registered User

Thread Starter

iTrader: (2)

Join Date: May 2010

Location: Midwest

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

not a lot of horsepower..in the 500's. Really? 500hp isn't a lot

Either way, it seems like it could have been a combination of things.

Really high oil pressure.

Did you drill and tap the front iron to accept that fitting? If you did it incorrectly it should have weakened or developed a hairline crack causing what you have now.

Either way, it seems like it could have been a combination of things.

Really high oil pressure.

Did you drill and tap the front iron to accept that fitting? If you did it incorrectly it should have weakened or developed a hairline crack causing what you have now.

#5

Likely spun bearings and destroyed e-shaft. Hopefully the irons and housings survived.

Cause, likely an issue with how the feed line fitting was installed. Or iron could have been dropped on that spot while disassembled, or if it was shipped it is very common for them to get damaged. The high oil pressure alone did not cause the failure.

Cause, likely an issue with how the feed line fitting was installed. Or iron could have been dropped on that spot while disassembled, or if it was shipped it is very common for them to get damaged. The high oil pressure alone did not cause the failure.

#7

Racing Rotary Since 1983

iTrader: (6)

"Cracked irons is caused by detonation my book.."

unfortunately i am going to have to agree. i do not think it is a coincidence that the crack is exactly where the front dowel pin rests, it is no coincidence that the pin was pushed outward which would probably be motivated by knock combustion pressures pushing the rotor housing outward.

it will be important to determine the cause so as to not have it happen again.

one possible contributing factor is that the turbine is close to the front intake runners. since the AFR tune is derived from both front and rear rotors, if the front was running a bit lean due to the temp diff a tune where the rear balanced the overall AFR would leave the front lean. the front apparently was the problem.

i would be very interested to see the two leading plugs. my bet is the front will look lean.

while i didn't build the engine i was there for the gas part of the tune at Beyond Redline and i did talk to Luke the next day (prior to the engine problem) and he said he never heard the slightest knock from the motor which was tuned conservatively... Luke uses the Link Knock headphones tuned to 3500 cps. with this setup you can easily hear the very start of any knock and can make adjustments. the motor was tuned to just a bit over 20 PSI. i believe timing w E85 was 9 w 11 split and a conservative AFR.

i am really sorry to see this as Sal's FD is beautifully built and was very well prepared for the session. of course something was a dealbreaker and job one is to find the cause.

howard

unfortunately i am going to have to agree. i do not think it is a coincidence that the crack is exactly where the front dowel pin rests, it is no coincidence that the pin was pushed outward which would probably be motivated by knock combustion pressures pushing the rotor housing outward.

it will be important to determine the cause so as to not have it happen again.

one possible contributing factor is that the turbine is close to the front intake runners. since the AFR tune is derived from both front and rear rotors, if the front was running a bit lean due to the temp diff a tune where the rear balanced the overall AFR would leave the front lean. the front apparently was the problem.

i would be very interested to see the two leading plugs. my bet is the front will look lean.

while i didn't build the engine i was there for the gas part of the tune at Beyond Redline and i did talk to Luke the next day (prior to the engine problem) and he said he never heard the slightest knock from the motor which was tuned conservatively... Luke uses the Link Knock headphones tuned to 3500 cps. with this setup you can easily hear the very start of any knock and can make adjustments. the motor was tuned to just a bit over 20 PSI. i believe timing w E85 was 9 w 11 split and a conservative AFR.

i am really sorry to see this as Sal's FD is beautifully built and was very well prepared for the session. of course something was a dealbreaker and job one is to find the cause.

howard

Trending Topics

#8

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,832

Received 2,599 Likes

on

1,846 Posts

it could also be some kind of cross fire between the spark plug(s), same effect as the detonation, 10X normal combustion pressure... its going to break things

#10

Registered User

Thread Starter

iTrader: (2)

Join Date: May 2010

Location: Midwest

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

unfortunately if it more than a front plate and "IF" I need to buy new housing again. i will be doing a different engine swap and selling all the great parts i have been collecting for the past year. Or sell the car as a whole, thats how i'm feeling right now.

#14

Racing Rotary Since 1983

iTrader: (6)

this from Luke...

"Doubt it was detonation. Afr collectively was in the low 11 range with 50c different between rotor egt. So at worst it would have been probably high 11 in front rotor. Also I mounted the knock sensor on the front rotor. Also I didn't let him go at the timing we dyno d with, I pulled out just a bit more when we were all done. "

let's hope that it was some sort of defect int the front iron.

howard

"Doubt it was detonation. Afr collectively was in the low 11 range with 50c different between rotor egt. So at worst it would have been probably high 11 in front rotor. Also I mounted the knock sensor on the front rotor. Also I didn't let him go at the timing we dyno d with, I pulled out just a bit more when we were all done. "

let's hope that it was some sort of defect int the front iron.

howard

#15

Registered User

Thread Starter

iTrader: (2)

Join Date: May 2010

Location: Midwest

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

this from Luke...

"Doubt it was detonation. Afr collectively was in the low 11 range with 50c different between rotor egt. So at worst it would have been probably high 11 in front rotor. Also I mounted the knock sensor on the front rotor. Also I didn't let him go at the timing we dyno d with, I pulled out just a bit more when we were all done. "

let's hope that it was some sort of defect int the front iron.

howard

"Doubt it was detonation. Afr collectively was in the low 11 range with 50c different between rotor egt. So at worst it would have been probably high 11 in front rotor. Also I mounted the knock sensor on the front rotor. Also I didn't let him go at the timing we dyno d with, I pulled out just a bit more when we were all done. "

let's hope that it was some sort of defect int the front iron.

howard

Im hoping so to, but why would the car just shut down? is it due to crank position sensor getting covered in oil.

#16

#17

What is the spark plug heat range?

So there are three things to think about when you run high output on E85.

1) normal spark knock: This happens when you fire the plug, and gases at the edge of the combustion chamber ignite unintentionally. E85 is good for preventing that, even under high intake temperatures. The fact that the ethanol blend may have only been like E60 isn't such a big deal, as the knock benefits start to taper off at that part (i've got some more info on this if anyone's curious).

2) preignition: Ethanol needs really cold plugs--there have been a number of studies on the fact that it can be more prone to preignition compared to gasoline, especially with non-copper plugs. I would run at least 11 heat range with that kind of goal.

3) too much combustion chamber pressure- Short answer: even if you're not knocking, enough spark on race gas/ethanol causes high peak combustion pressure which stresses the hell out of the engine and could break something.

Detailed answer: try to follow me on this one. If you've never worked with combustion pressure sensors (and only myself and Barry Bordes have any experience with this as far as I know) it's a little hard to understand. When you have race gas or E85, you can have more advanced combustion. The location of peak pressure can be earlier.

The location of peak pressure directly relates to the amount of peak combustion pressure. If I have fast combustion and/or early spark timing, you can get really high diesel-like peak pressure. That's why turbo gasoline engines can basically never run at MBT at high loads, MBT being defined by the location of peak pressure rather than some knock limit or dyno experimentation. 9 degrees of spark doesn't sound like a lot, but if you have fast enough combustion the peak pressure will hit early enough that it could break something without knock and without pre ignition. This kind of stuff often mostly happens in the strange world of race fuels and ethanol. When you make high output on pump gas or pump gas with water/meth injection the combustion is actually pretty crappy and you don't make the same kind of peak pressures.

This image is from a piston engine (actually at idle) but it shows what I'm talking about. Look at the Y axis scale. See how much higher it goes with spark at MBT and advanced past MBT.

Rotary pressure traces are funnier looking, and I'd have to dig through some data I got from Barry to see if I can find anything somewhat representative of what I'm talking about here. All I'm saying is, this damage was probably caused by excessive peak combustion pressure. Excessive pressure doesn't always come about from regular old spark knock.

So there are three things to think about when you run high output on E85.

1) normal spark knock: This happens when you fire the plug, and gases at the edge of the combustion chamber ignite unintentionally. E85 is good for preventing that, even under high intake temperatures. The fact that the ethanol blend may have only been like E60 isn't such a big deal, as the knock benefits start to taper off at that part (i've got some more info on this if anyone's curious).

2) preignition: Ethanol needs really cold plugs--there have been a number of studies on the fact that it can be more prone to preignition compared to gasoline, especially with non-copper plugs. I would run at least 11 heat range with that kind of goal.

3) too much combustion chamber pressure- Short answer: even if you're not knocking, enough spark on race gas/ethanol causes high peak combustion pressure which stresses the hell out of the engine and could break something.

Detailed answer: try to follow me on this one. If you've never worked with combustion pressure sensors (and only myself and Barry Bordes have any experience with this as far as I know) it's a little hard to understand. When you have race gas or E85, you can have more advanced combustion. The location of peak pressure can be earlier.

The location of peak pressure directly relates to the amount of peak combustion pressure. If I have fast combustion and/or early spark timing, you can get really high diesel-like peak pressure. That's why turbo gasoline engines can basically never run at MBT at high loads, MBT being defined by the location of peak pressure rather than some knock limit or dyno experimentation. 9 degrees of spark doesn't sound like a lot, but if you have fast enough combustion the peak pressure will hit early enough that it could break something without knock and without pre ignition. This kind of stuff often mostly happens in the strange world of race fuels and ethanol. When you make high output on pump gas or pump gas with water/meth injection the combustion is actually pretty crappy and you don't make the same kind of peak pressures.

This image is from a piston engine (actually at idle) but it shows what I'm talking about. Look at the Y axis scale. See how much higher it goes with spark at MBT and advanced past MBT.

Rotary pressure traces are funnier looking, and I'd have to dig through some data I got from Barry to see if I can find anything somewhat representative of what I'm talking about here. All I'm saying is, this damage was probably caused by excessive peak combustion pressure. Excessive pressure doesn't always come about from regular old spark knock.

#18

Racing Rotary Since 1983

iTrader: (6)

"63% ethanol content? Thats way too low. The timing is also very retarded for e85. Any missfires?"

the car has a FFS onboard and was tuned both for gas and E85. the computer interpolates so E content is not an issue and certainly not at 15 PSI.

further, the E benefit diminishes in relation to content above 50%.

"The fact that the ethanol blend may have only been like E60 isn't such a big deal, as the knock benefits start to taper off at that part (i've got some more info on this if anyone's curious)."

yes on that.

"can be more prone to pre-ignition compared to gasoline, especially with non-copper plugs"

copper plugs onboard. 10 heat range.

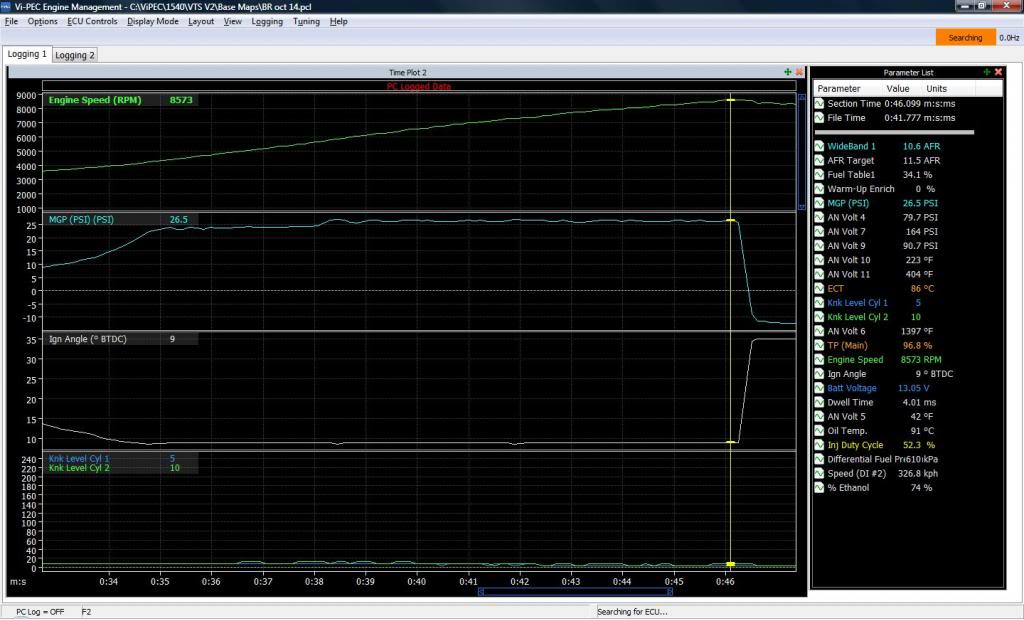

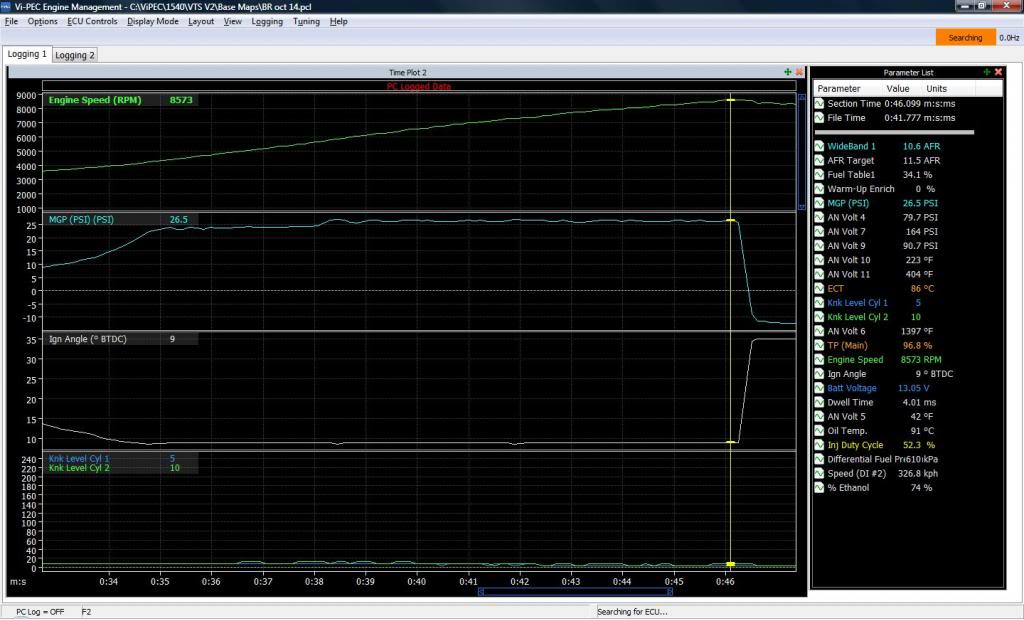

as to 9 degrees timing, here's a run i did last year in fifth gear to 202 mph on the dyno at 9 degrees...

fifth can clearly provide stress to the motor.

9 degrees advance is set forth on the next to bottom chart.

knock readings, separate front and rear rotors are on the bottom chart...

knock was between 5 and 10 on a scale to 250. no knock at 9 degrees.

AFR in the mid 11s.

same plugs as Sal.

same coils at approx 4 mS dwell.

around 25.5 psi boost and 575 SAE/588 STD hp

Sal's motor was on the rollers for a significant part of two days. it was first tuned on gas and then E.

the Link knock headphones indicated no knock during the two days.

the motor will come apart this sunday... who knows what we will find but my bet is some sort of subsystem failure.

howard

the car has a FFS onboard and was tuned both for gas and E85. the computer interpolates so E content is not an issue and certainly not at 15 PSI.

further, the E benefit diminishes in relation to content above 50%.

"The fact that the ethanol blend may have only been like E60 isn't such a big deal, as the knock benefits start to taper off at that part (i've got some more info on this if anyone's curious)."

yes on that.

"can be more prone to pre-ignition compared to gasoline, especially with non-copper plugs"

copper plugs onboard. 10 heat range.

as to 9 degrees timing, here's a run i did last year in fifth gear to 202 mph on the dyno at 9 degrees...

fifth can clearly provide stress to the motor.

9 degrees advance is set forth on the next to bottom chart.

knock readings, separate front and rear rotors are on the bottom chart...

knock was between 5 and 10 on a scale to 250. no knock at 9 degrees.

AFR in the mid 11s.

same plugs as Sal.

same coils at approx 4 mS dwell.

around 25.5 psi boost and 575 SAE/588 STD hp

Sal's motor was on the rollers for a significant part of two days. it was first tuned on gas and then E.

the Link knock headphones indicated no knock during the two days.

the motor will come apart this sunday... who knows what we will find but my bet is some sort of subsystem failure.

howard

Last edited by Howard Coleman; 05-12-14 at 03:59 PM.

#19

Banned. I got OWNED!!!

iTrader: (11)

my 20b cracked the front iron. we couldnt ever figure out why. replaced it and never had an issue again. best guess is that it just simply had more torque and stress than the old and brittle iron could handle. it was a track car with tons of full throttle/0 throttle and super grippy tires and derlin motor mounts. couple that with weakend areas from machining extra passages for oil etc.. and it could be an issue. just run solid dowel pins and take an external oil line from the filter pedestal to the front iron turbo port for the front bearing oil. my internals were perfect other than the crack.

#21

Registered User

Thread Starter

iTrader: (2)

Join Date: May 2010

Location: Midwest

Posts: 159

Likes: 0

Received 0 Likes

on

0 Posts

I'm hoping that the super aviation apex seals held together, as they claim they have never had any break... we will see on sunday because i have been going crazy trying to figure this out.

#25

Racing Rotary Since 1983

iTrader: (6)

"what fuel was that 5th gear dyno pull?"

E85. if you look at the Parameter Log on the left at the bottom you will see E content was 75%.

i switched primarily for the Texas Mile as it is approx 3/4 of a mile in fifth gear which is about 20 seconds and IMO the engine needs all the help i can give it...

the engine in this thread will come apart Sunday.

HC

E85. if you look at the Parameter Log on the left at the bottom you will see E content was 75%.

i switched primarily for the Texas Mile as it is approx 3/4 of a mile in fifth gear which is about 20 seconds and IMO the engine needs all the help i can give it...

the engine in this thread will come apart Sunday.

HC