Crack in rear iron when installing oil press reg... need advice

#1

Crack in rear iron when installing oil press reg... need advice

I just finished rebuilding the block with one of my friends a few weeks ago. I was reinstalling the oil pressure regulator last night when I realized I cracked the iron (yes, im pissed at myself). I attached a few pics and circled the crack. I'm not sure how detrimental this could be and I'm hoping its somewhat fixable. I was thinking about jb welding the crack to keep it stable without further damaging anything but really im unsure where to go from here. Any advice/help would be greatly appreciated!

Tony

Tony

#3

RX-7 Bad Ass

iTrader: (55)

JB Weld isn't going to cut it. That's a pressurized oil galley, you're going to have 120psi oil in there, some goo won't hold up to that.

You're going to have to do it the hard way - pull the motor and pull the rear iron. If you can find a shop that can reliably weld cast iron, that may be an option, but you may just be money and time ahead just getting another good rear iron.

At least you caught it before you dumped 4 quarts of oil all over your nice clean engine bay .

.

Dale

You're going to have to do it the hard way - pull the motor and pull the rear iron. If you can find a shop that can reliably weld cast iron, that may be an option, but you may just be money and time ahead just getting another good rear iron.

At least you caught it before you dumped 4 quarts of oil all over your nice clean engine bay

.

.Dale

#7

Sponsor

iTrader: (41)

We had an engine come in with a crack in the same area some time ago. I had to look very carefully to catch it as it was not as pronounced as in your case. It looked like someone applied excessive teflon tape to the sender and over-tightened it, cracking the iron. You are going to have to pull the motor and replace the iron. There is a chance to weld it, but cast iron is difficult to weld because it is porous, and you risk it cracking again. If the rest of the motor is good, you can brace the other irons and housings together and just pop the rear plate off. You can use the oil pan, turbo manifold, and coil bracket to hold the motor together as you remove the tension bolts. Just take out the oil pan bolts in the rear iron. Once you have the replacement iron on and the tension bolts re-torqued, remove the oil pan completely and re-seal it. DO NOT re-use any coolant seals or the tension bolt o-rings. Hope this helps.

Trending Topics

#8

Exhaust Manifold Leak

some time ago I also had to swap rear plate on fresh built motor (crack the plate due to too much boost and too little fuel) and I just replaced the orange inner oring, the black outer and tension bolt seals still looked fine. engine is running now fine for 6 months or so, no leaks =)

#9

I'm about to replace my oil pressure sender, the new one has a coating already on the threads (blue loctite??), should I add any type of sealant or teflon tape or just use as is?

also, is there a torque spec or a recommendation on how much to tighten it so it doesn't leak and the iron doesn't crack?? Thanks

also, is there a torque spec or a recommendation on how much to tighten it so it doesn't leak and the iron doesn't crack?? Thanks

#10

Exhaust Manifold Leak

Nope, just install it like it is, I cant saw how much i number nut just not so tight, be gentle, if it leaks you can always turn half a turn more instead of killing the iron when overdoing it..

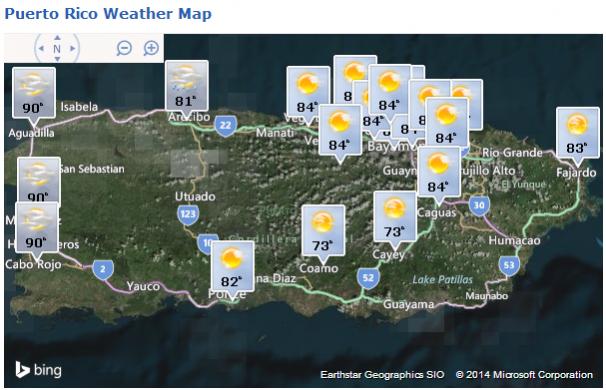

Hows the wheater in puerto rico? I'll be flying there in about 2 weeks =)

Hows the wheater in puerto rico? I'll be flying there in about 2 weeks =)

#13

Exhaust Manifold Leak

Thread

Thread Starter

Forum

Replies

Last Post

stickmantijuana

20B Forum

8

08-18-15 02:46 PM