anyone whos done a simplified sequential conversion need input on my project

#1

Senior Member

Thread Starter

iTrader: (5)

Join Date: Dec 2011

Location: iowa city

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

anyone whos done a simplified sequential conversion need input on my project

so i will be doing the perfect patter conversion that damian wrote. and as i was looking at the simplified sequential diagram i was wondering if the 2 turbo controls could be deleted and replaced by manual boost controller? the same concept could be applied to those solenoids like damians write up. i am not sure when i will get to actually starting the research lol but as soon as i have the perfect pattern i would like to put a vacuum/pressure gauge on the feed of those solenoids and see what the reading are when they open/close and with that i could potentially replace the electronic solenoids with manual boost controllers. it could be one less thing to worry about.

here is the diagram

the two solenoids i am referring to are labeled turbo control solenoid with purple and red lines and E with blue and yellow lines

here is the diagram

the two solenoids i am referring to are labeled turbo control solenoid with purple and red lines and E with blue and yellow lines

#2

If it were that easy, Mazda wouldn't have put them in. Then they could have saved a bunch of money.

Manual boost controllers use a simple mechanical valve to limit the amount of pressure on a diaphragm controlling the precontrol and wastegate valve. Their purpose is different from the turbo control solenoids.

The turbo control valve is spring loaded closed with high tension to keep prevent leakage. The design of the actuator requires vacuum and pressure to open it quickly, hence two separate solenoids. Both solenoids engage at the same time.

Manual boost controllers use a simple mechanical valve to limit the amount of pressure on a diaphragm controlling the precontrol and wastegate valve. Their purpose is different from the turbo control solenoids.

The turbo control valve is spring loaded closed with high tension to keep prevent leakage. The design of the actuator requires vacuum and pressure to open it quickly, hence two separate solenoids. Both solenoids engage at the same time.

#4

Senior Member

Thread Starter

iTrader: (5)

Join Date: Dec 2011

Location: iowa city

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

yep so the ones i am replacing for the perfect pattern are I and J.

arghx- i know what you are saying and im not arguing but those valves open during certain rpms so if you can determin the pressure/vacuum at that range you could replace them with mbc's. so a boost controller can work both ways since its in a way a one way valve. the mbc can work and open at the determined boost or vacuum. if you reverse a mbc you can apply vacuum and it will open at the determined load. as to mazdas cost, they went the opposite direction from what ive seen on the solenoids while you could replace a inop one in our systems they decided to put all the solenoids in on huge black box which doesnt make since as a consumer now as a manufacture its a profit since a consumer has to buy the whole thing if one stops working. we can say that their engineers are not very good since they could of gone the simplified vacuum direction but they did not think of it. i doubt that they ever even consider a mbc since they were too focused on when they wanted the transition to occur at least thats the way i see it.

we as the techs know more about what can be fixed but from what i have seen from the engineers that i have met a large portion of engineers have never or have very little knowledge on how to improve things. i work for the university in my area i have talked to some engineers at kia and 95% could not work on a car or improve something i can tell you they are very good a designing something since the know the theory but they lack the experience and the logic. that why manufactures rely on the techs to help them with recalls. i can say i have met maybe a hand full of engineers that knew how to work on things. funny story there was a small carnival at my sons school and they had a robotics showcase from rockwell collins. their showcase was operated by 2 people who were electrical engineers the robot they had would pick up a ball and throw it. it took them about an hour to get it working. these are the people who are building aircraft systems. from what i could tell they would run diagnostics and it would tell them that there was no communication to the robot. one of the guys was checking the wires and batteries the other was running the software diagnostics. these two talked a big game about robotics and yet they couldnt figure out why it wasnt working. it turned out that the controller which was a pc joystick was not plugged in they were 10 seconds away from calling off the robot demonstration till a 7 year old saw that it was unplugged. they even had a guy on the phone. alot of engineers are just interested in the field and have never build anything worth naming. following instructions does not count as building something which alot of people said that they had like kinects or mecanics sets (i think thats what they are called). im not claiming to be a better engineer but i do have alot more qualifications than most of the engineering students.

Ask any real tech they will tell you the same thing what were they thinking when they made this LOL

wow this was long!!!!!

arghx- i know what you are saying and im not arguing but those valves open during certain rpms so if you can determin the pressure/vacuum at that range you could replace them with mbc's. so a boost controller can work both ways since its in a way a one way valve. the mbc can work and open at the determined boost or vacuum. if you reverse a mbc you can apply vacuum and it will open at the determined load. as to mazdas cost, they went the opposite direction from what ive seen on the solenoids while you could replace a inop one in our systems they decided to put all the solenoids in on huge black box which doesnt make since as a consumer now as a manufacture its a profit since a consumer has to buy the whole thing if one stops working. we can say that their engineers are not very good since they could of gone the simplified vacuum direction but they did not think of it. i doubt that they ever even consider a mbc since they were too focused on when they wanted the transition to occur at least thats the way i see it.

we as the techs know more about what can be fixed but from what i have seen from the engineers that i have met a large portion of engineers have never or have very little knowledge on how to improve things. i work for the university in my area i have talked to some engineers at kia and 95% could not work on a car or improve something i can tell you they are very good a designing something since the know the theory but they lack the experience and the logic. that why manufactures rely on the techs to help them with recalls. i can say i have met maybe a hand full of engineers that knew how to work on things. funny story there was a small carnival at my sons school and they had a robotics showcase from rockwell collins. their showcase was operated by 2 people who were electrical engineers the robot they had would pick up a ball and throw it. it took them about an hour to get it working. these are the people who are building aircraft systems. from what i could tell they would run diagnostics and it would tell them that there was no communication to the robot. one of the guys was checking the wires and batteries the other was running the software diagnostics. these two talked a big game about robotics and yet they couldnt figure out why it wasnt working. it turned out that the controller which was a pc joystick was not plugged in they were 10 seconds away from calling off the robot demonstration till a 7 year old saw that it was unplugged. they even had a guy on the phone. alot of engineers are just interested in the field and have never build anything worth naming. following instructions does not count as building something which alot of people said that they had like kinects or mecanics sets (i think thats what they are called). im not claiming to be a better engineer but i do have alot more qualifications than most of the engineering students.

Ask any real tech they will tell you the same thing what were they thinking when they made this LOL

wow this was long!!!!!

#6

Sounds like you have encountered some second-rate engineers. I'm sure there are plenty of second-rate techs out there also.

I'm not saying Mazda's engineers did everything right on the FD, but I predict you will find it difficult, if not impossible, to replace the turbo control solenoids with a purely mechanical control system like a manual boost controller. I'd be happy to see you prove me wrong, so please post results when you're done.

I'm not saying Mazda's engineers did everything right on the FD, but I predict you will find it difficult, if not impossible, to replace the turbo control solenoids with a purely mechanical control system like a manual boost controller. I'd be happy to see you prove me wrong, so please post results when you're done.

#7

You're welcome to try an MBC or some other strictly mechanical solution to controlling the turbo transition. Keep the following things in mind:

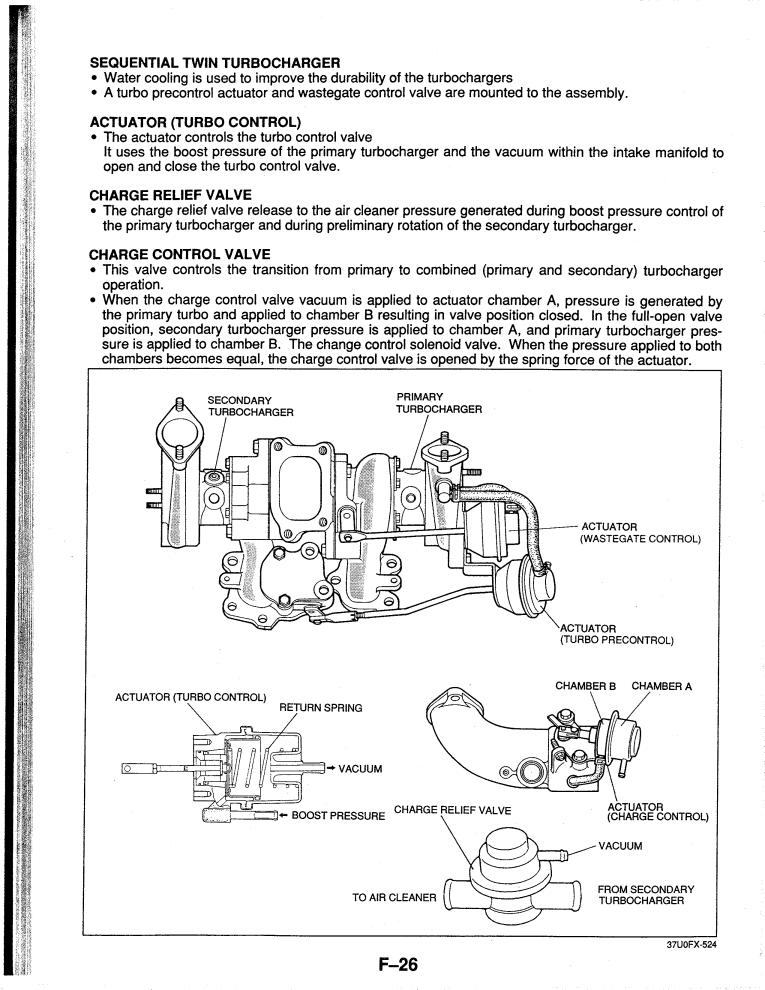

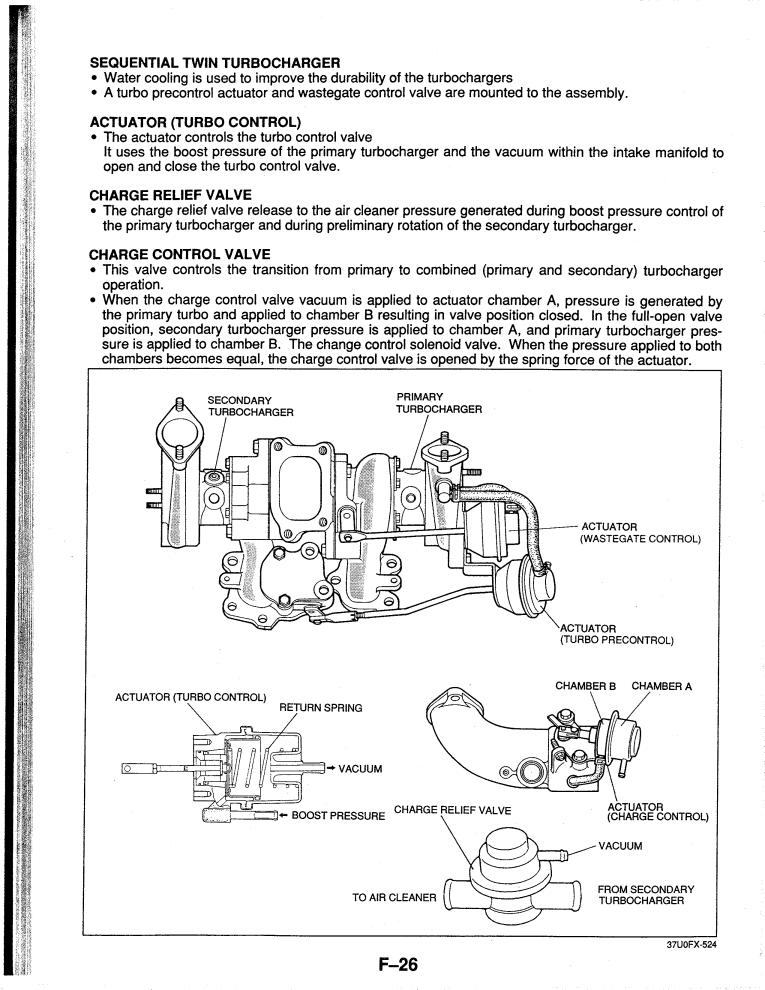

In the lower left you can see a diagram of the inside of the turbo control valve. You'll see that there is a spring, a diaphragm (unlabeled), a vacuum port, and a pressure port. The basic design of this actuator has the opening rate determined by the vacuum, pressure, and spring tension forces.

On the pneumatic side of the control, there is a vacuum chamber and a pressure chamber with check valves. This basically effectively results in a "fixed" amount of vacuum and pressure force at all times, or at least makes the force always be above a certain threshold in order to work with the actuator. So in the stock system, you have (for our purposes) fixed vacuum and pressure force that is switched on and off with a solenoid.

Now compare that to the wastegate and precontrol actuators:

There is boost pressure working on a diaphragm, which is working on a spring loaded swing valve. Let's ignore exhaust backpressure to make this simpler. The valve position is controlled by regulating the boost pressure acting on the diaphragm. At first glance, this seems similar to the turbo control valve. If an MBC can work well enough on the precontrol and wastegate actuators, even without electronic controls, why not use such a device on the turbo control valve? Why not regulate the flow of vacuum and pressure to each side of the valve, to correspond to some speed and load where you want the turbo transition to occur?

Well, let's dig deeper into the design of the turbo control valve.

It turns out that there's actually two sub-portions of the turbo control valve to help seal the exhaust gasses and then open smoothly. There's a smaller inner valve and a larger outer valve. The opening of the valve occurs in two stages, and works on a balance of forces between the exhaust backpressure, the small inner valve, the large outer valve, and the regulated vacuum and pressure supplied by their respective chambers. It's pretty complicated.

Now, can you make it work "good enough" with say just an MBC on the pressure side, and some other orifice for the vacuum side? Maybe. Will it switch over consistently at your desired engine speed/load, and not get stuck closed sometimes? Maybe. I just wonder how much work it's going to take it make it at least usable/driveable, when you can just use or modify the existing system.

In the lower left you can see a diagram of the inside of the turbo control valve. You'll see that there is a spring, a diaphragm (unlabeled), a vacuum port, and a pressure port. The basic design of this actuator has the opening rate determined by the vacuum, pressure, and spring tension forces.

On the pneumatic side of the control, there is a vacuum chamber and a pressure chamber with check valves. This basically effectively results in a "fixed" amount of vacuum and pressure force at all times, or at least makes the force always be above a certain threshold in order to work with the actuator. So in the stock system, you have (for our purposes) fixed vacuum and pressure force that is switched on and off with a solenoid.

Now compare that to the wastegate and precontrol actuators:

There is boost pressure working on a diaphragm, which is working on a spring loaded swing valve. Let's ignore exhaust backpressure to make this simpler. The valve position is controlled by regulating the boost pressure acting on the diaphragm. At first glance, this seems similar to the turbo control valve. If an MBC can work well enough on the precontrol and wastegate actuators, even without electronic controls, why not use such a device on the turbo control valve? Why not regulate the flow of vacuum and pressure to each side of the valve, to correspond to some speed and load where you want the turbo transition to occur?

Well, let's dig deeper into the design of the turbo control valve.

It turns out that there's actually two sub-portions of the turbo control valve to help seal the exhaust gasses and then open smoothly. There's a smaller inner valve and a larger outer valve. The opening of the valve occurs in two stages, and works on a balance of forces between the exhaust backpressure, the small inner valve, the large outer valve, and the regulated vacuum and pressure supplied by their respective chambers. It's pretty complicated.

Now, can you make it work "good enough" with say just an MBC on the pressure side, and some other orifice for the vacuum side? Maybe. Will it switch over consistently at your desired engine speed/load, and not get stuck closed sometimes? Maybe. I just wonder how much work it's going to take it make it at least usable/driveable, when you can just use or modify the existing system.

Trending Topics

#8

Senior Member

Thread Starter

iTrader: (5)

Join Date: Dec 2011

Location: iowa city

Posts: 312

Likes: 0

Received 0 Likes

on

0 Posts

so what you posted is information that tells "I" and "J". which i am already replacing with mbc the ones i would like to replace and get rid of are "E" and the "turbo control solenoid" both are fed or feed into the vacuum and pressure tanks. ill keep you guy updated on how things are going. my mbc should be in today so im not sure how long it will take for to get the perfect pattern down

#11

Thanks for sharing some useful info in an otherwise silly discussion, by the way. Did all of that come from FD technical docs or was some of it from other sources?

Thread

Thread Starter

Forum

Replies

Last Post