Aluminum Flywheel WTF?

#28

still 1.3 liter v8 eater

Join Date: Sep 2006

Location: San Diego, CA

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by 1.3 liter V8 eater

James...

SR Motorsports flywheel...

its obviously advertised as machined. the image above clearly has a machined friction surface.

SR Motorsports flywheel...

its obviously advertised as machined. the image above clearly has a machined friction surface.

#30

Magnet Boy

Thread Starter

No Smearing Required

I spoke at length with the vendor. He explained to me the evolution of the flywheel manufacturing details over the years. There is still some difference of opinion about the suitability of the surface on the as shipped plate. He offered to take the whole thing back, no questions or to ship me a new contact plate that is not pitted like the depicted one. I chose the later and agreed not to smear his good name!

Since I started this thread, I have received numerous opinions including several from respectable and knowledgable sources that suggest that as long as the plate is flat, the texture shown makes no difference. I was told of an "experiment" in which an unmachined plate like mine was installed, broken in, and driven for 100 miles. When pulled apart, the contact plate "looked machined." I guess clutch disks are pretty abrasive and bedding in the contact surface is part of the break-in process. So a rough (but flat) surface actually helps with this process.

The bottom line for other would-be aluminum flywheel purchasers, is that if a machined or smoother surface on the contact plate is important to you (based on you and your mechanic's opinions or personal preference), discuss it with your vendor prior to ordering. The vendor can choose an appropriate contact surface to send with your flywheel, or advise you to shop elsewhere!

Since I started this thread, I have received numerous opinions including several from respectable and knowledgable sources that suggest that as long as the plate is flat, the texture shown makes no difference. I was told of an "experiment" in which an unmachined plate like mine was installed, broken in, and driven for 100 miles. When pulled apart, the contact plate "looked machined." I guess clutch disks are pretty abrasive and bedding in the contact surface is part of the break-in process. So a rough (but flat) surface actually helps with this process.

The bottom line for other would-be aluminum flywheel purchasers, is that if a machined or smoother surface on the contact plate is important to you (based on you and your mechanic's opinions or personal preference), discuss it with your vendor prior to ordering. The vendor can choose an appropriate contact surface to send with your flywheel, or advise you to shop elsewhere!

#31

Originally Posted by rxcited2

I was told of an "experiment" in which an unmachined plate like mine was installed, broken in, and driven for 100 miles. When pulled apart, the contact plate "looked machined." I guess clutch disks are pretty abrasive and bedding in the contact surface is part of the break-in process. So a rough (but flat) surface actually helps with this process.

The break-in is in respect to the clutch disc, not the firction surfaces. The disc, as do new brake pads, needs some time to lose it's high spots so that it can make full contact with the flywheel and pressure plate.

#32

Magnet Boy

Thread Starter

OK. I had previously decided to cut the vendor Ray "Greg" Lochhead of SR Motorsports some slack. Why? Because he made some barely passable excuses, rebated some money on an unrelated issue, and agreed to furnish me with a new smoother friction surface. He did furnish another plate (to his credit), but it was essentially the same as the original - an un-machined hot-rolled surface that he attempted to polish slightly and ineffectively with an orbital sander. gRayG lied to me and said "we've always made them this way [with an un-machined friction surface]." Clearly this was a lie because I have multiple reports from other SR Motorsports aluminum flywheel owners who bought them a few years ago and the friction surface was NOT un-machined like they are now. It seems that gRayG has made a choice to save manufacturing costs without passing on any savings to the customer and lying about it. I decided at the time that I would go ahead and try the rough plate and "test" the theory that an un-machined surface is fine.

Now it is 3500 miles later and my tranny was going out - it was partially already going out and made worse by increased HP! I got a used JDM tranny, some diff bushings, trailing arms and toe links, and while it was all apart, also pulled the clutch. See attached photos below. Needless to say I was very disappointed in the results. I had the spare friction surface machined and replaced that and the clutch disc while I had the chance.

Based on the line of baloney from gRayG (my nickname for Ray who also calls himself Greg now), and many other shady things he said, did and lied about, I have to tell you all that this guy is not to be trusted. I don't really care if I burn this bridge with him because I will never EVER buy anything from Ray "Greg" Lochhead" at SR Motorsports again, EVER!

In summary, my advice is:

1) DO NOT ACCEPT AN UN-MACHINED FRICTION SURFACE FROM ANY VENDOR.

2) DO NOT TRUST RAY "GREG" LOCHHEAD FARTHER THAN YOU CAN THROW HIM.

3) DO NOT BUY FROM SR MOTORSPORTS.

These are my opinions and I stand by them. Make up your own opinions with respect to the SR Motorsports Aluminum flywheel and gRayG's lies, examine the photos below...

Now it is 3500 miles later and my tranny was going out - it was partially already going out and made worse by increased HP! I got a used JDM tranny, some diff bushings, trailing arms and toe links, and while it was all apart, also pulled the clutch. See attached photos below. Needless to say I was very disappointed in the results. I had the spare friction surface machined and replaced that and the clutch disc while I had the chance.

Based on the line of baloney from gRayG (my nickname for Ray who also calls himself Greg now), and many other shady things he said, did and lied about, I have to tell you all that this guy is not to be trusted. I don't really care if I burn this bridge with him because I will never EVER buy anything from Ray "Greg" Lochhead" at SR Motorsports again, EVER!

In summary, my advice is:

1) DO NOT ACCEPT AN UN-MACHINED FRICTION SURFACE FROM ANY VENDOR.

2) DO NOT TRUST RAY "GREG" LOCHHEAD FARTHER THAN YOU CAN THROW HIM.

3) DO NOT BUY FROM SR MOTORSPORTS.

These are my opinions and I stand by them. Make up your own opinions with respect to the SR Motorsports Aluminum flywheel and gRayG's lies, examine the photos below...

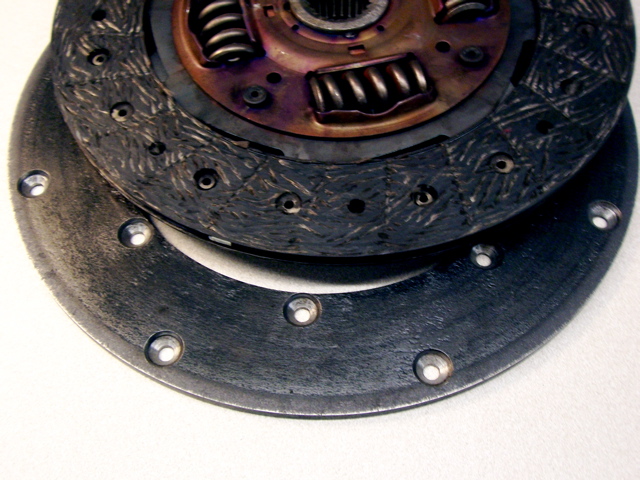

- Un-Machined friction surface, with clutch disc, upside down to show wear on the surface that was in contact with the friction surface.

- Close up of same. Note that the friction surface is still quite pitted, despite 3500 miles of use. More importantly note that my formerly brand new clutch disc is very worn. It is down to the bottom of the grooves in the friction material. While not completely worn out, it is more than half-way through its service life after only 3500 miles.

- The backside of the clutch disk that was against a brand new ACT XT pressure plate. This looks nearly new. If there ever was any question about whether a clutch friction surface ought to be machined or not, there isn't any question now. A RAW UN-MACHINED FRICTION SURFACE WILL EAT YOUR CLUTCH DISC!!

Last edited by rxcited2; 08-14-07 at 06:08 PM.

#33

still 1.3 liter v8 eater

Join Date: Sep 2006

Location: San Diego, CA

Posts: 546

Likes: 0

Received 0 Likes

on

0 Posts

All of that damage after just 3500 miles?? Its totally pitted. That is total BS, I remember when we were at Jeremy's shop, you were talking to him about the flywheel and he said all of them came like that. What a liar, I will never buy from them again...

#34

Senior Member

iTrader: (5)

Join Date: Dec 2005

Location: SF Bay Area, CA

Posts: 694

Likes: 0

Received 0 Likes

on

0 Posts

So I guess gRayG ***khead no longer makes any good parts, I wouldn't trust the pulleys after this either! Hopefully he gets what's coming to him, and soon! I believe my flywheel is one of the machined ones but we'll see next time it comes out, I currently have 8k on it.

#37

Original Gangster/Rotary!

iTrader: (213)

More interesting reading about what a scumbag Ray Lochhead of SR Motorsports/Shane Racing is:

https://www.rx7club.com/questions-about-members-102/thinking-about-ordering-sr-motorsports-shane-racing-ray-lochhead-read-1st-628636/

https://www.rx7club.com/questions-about-members-102/thinking-about-ordering-sr-motorsports-shane-racing-ray-lochhead-read-1st-628636/

#38

Passenger

Posts: n/a

ALSO PLEASE READ THIS THREAD:

http://forums.rotarytuner.com/showth...newpost&t=7018

it is a thread i made with all my research about SR and my findings, it also includes links to ANY other thread on this fourm where SR is mentioned negatively.

good reading

Thread

Thread Starter

Forum

Replies

Last Post

LongDuck

1st Generation Specific (1979-1985)

12

10-07-15 08:12 PM