To those of you considering sequential FD twin turbos...

#1

To those of you considering sequential FD twin turbos...

I've been bored lately, and when I'm bored (especially at work) I do Rx-7 writeups. It's a break from the mindless Office Space style monotony.

So lately I've been figuring out how to run sequential twins as simply as possible (assuming you can get them to fit in there) to help this guy with a 12A: https://www.rx7club.com/newthread.php?do=newthread&f=17 . Some of you who may want to do sequential twins just for the complete and utter hell of it may be interested in this info. Let's assume you figured out how to fit them in there (might need a spacer for exhaust manifold) and you've run the oil and coolant lines.

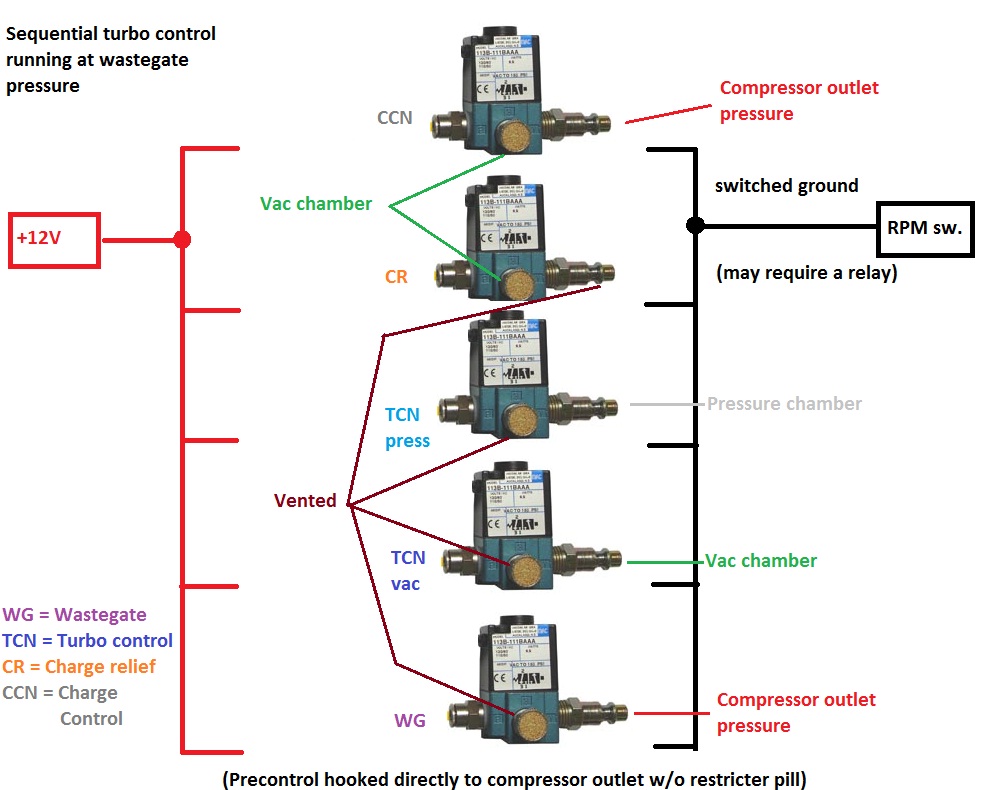

In this case let's assume you are running at the spring pressure of 7-8psi. The OEM FD solenoids are known to be problematic, but you should be able to use aftermarket 3 port solenoids, same as the Haltech/AEM boost control soleniod, to control the twins (viton check valves are an upgrade as well).

available here for about $26 each: http://www.frightprops.com/FrightPro...ID=A-0013-0082

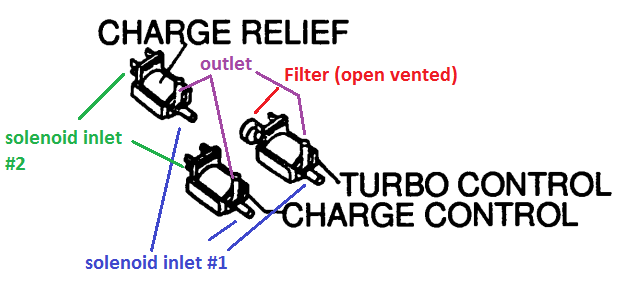

the factory solenoids look like this:

You will need 4 or preferably 5 of the MAC solenoids if you want to keep the wastegate shut just like Mazda does from the factory. Then you will need an rpm switch (or you can use an Rtek) such as this cheapo one: http://www.racerpartswholesale.com/p...ue_Shift_Light

If you have the stock ECU/Rtek you will need a custom TID that splits from the AFM to the two turbos. You can also use dual MBC's or a single external EBC. There's more than one way to do it.

So lately I've been figuring out how to run sequential twins as simply as possible (assuming you can get them to fit in there) to help this guy with a 12A: https://www.rx7club.com/newthread.php?do=newthread&f=17 . Some of you who may want to do sequential twins just for the complete and utter hell of it may be interested in this info. Let's assume you figured out how to fit them in there (might need a spacer for exhaust manifold) and you've run the oil and coolant lines.

In this case let's assume you are running at the spring pressure of 7-8psi. The OEM FD solenoids are known to be problematic, but you should be able to use aftermarket 3 port solenoids, same as the Haltech/AEM boost control soleniod, to control the twins (viton check valves are an upgrade as well).

available here for about $26 each: http://www.frightprops.com/FrightPro...ID=A-0013-0082

the factory solenoids look like this:

You will need 4 or preferably 5 of the MAC solenoids if you want to keep the wastegate shut just like Mazda does from the factory. Then you will need an rpm switch (or you can use an Rtek) such as this cheapo one: http://www.racerpartswholesale.com/p...ue_Shift_Light

If you have the stock ECU/Rtek you will need a custom TID that splits from the AFM to the two turbos. You can also use dual MBC's or a single external EBC. There's more than one way to do it.

#2

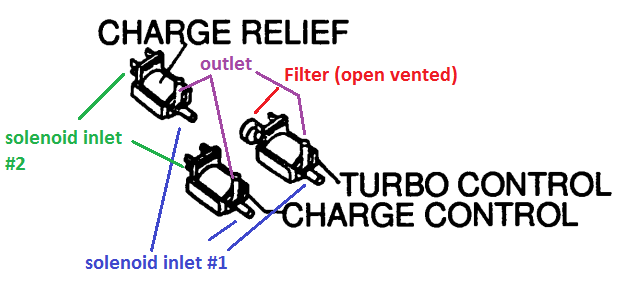

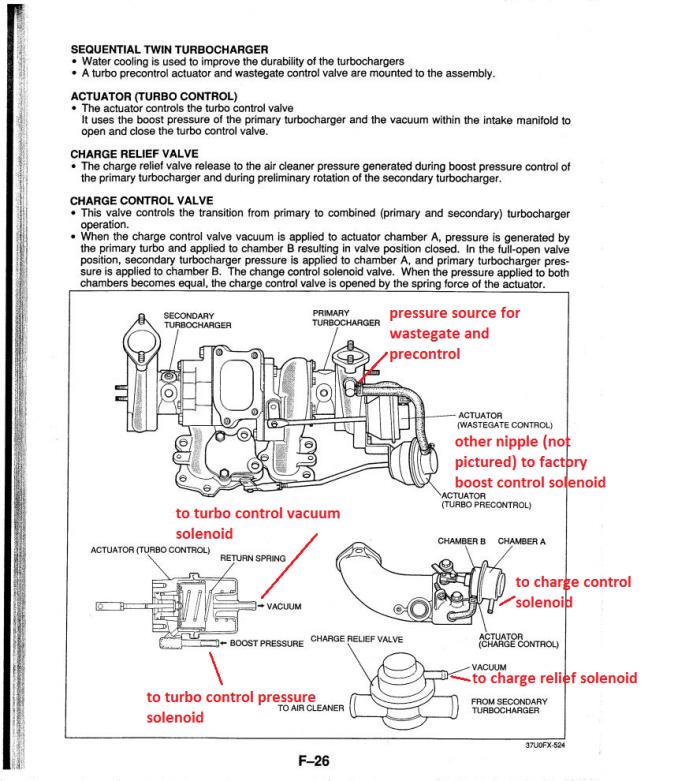

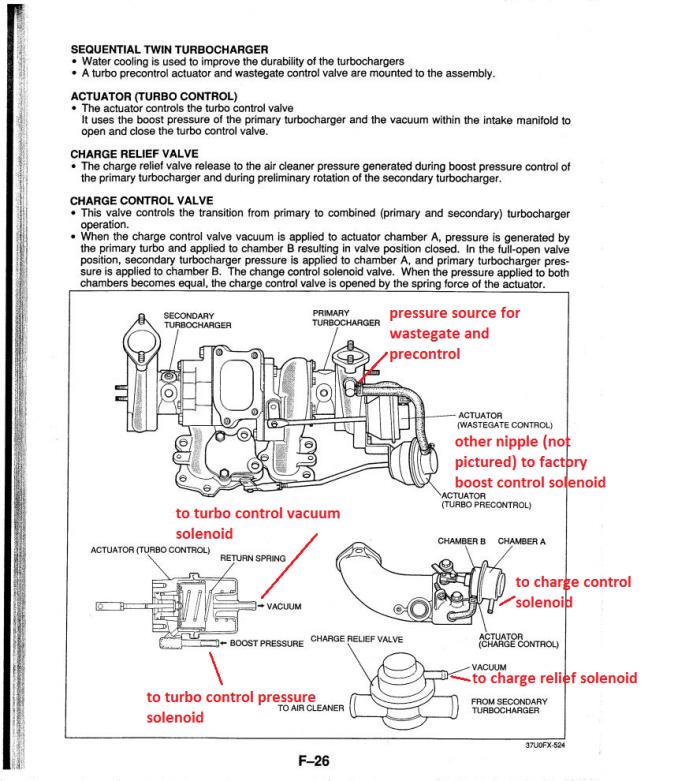

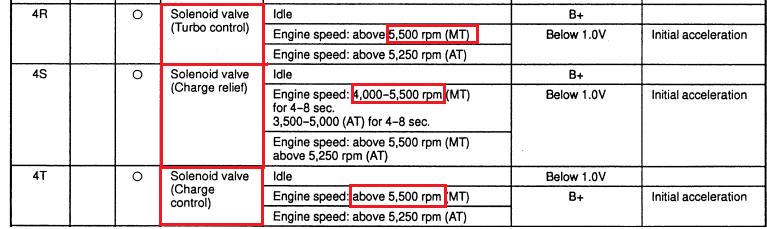

Here's a diagram of the main actuators in the system:

and a bigger thread that explains how it works https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

and a bigger thread that explains how it works https://www.rx7club.com/3rd-generation-specific-1993-2002-16/why-engine-so-damn-complicated-part-1-sequential-turbos-demystified-841821/

#3

That's the factory FD control logic for very low throttle. At high throttle the transition point is 4000rpm. So at 4000rpm (you could still adjust the rpm it later) you will need to switch your charge control, charge relief, the two turbo control solenoids, and you will want to begin opening the wastegate. Technically the charge relief solenoid isn't supposed to come online until at least 2000 rpm (which would require a window switch), but I don't think it matters that much. So here is one idea:

Under 4000rpm:

-- Charge control actuator receives vacuum from vac chamber

-- Charge relief receives vacuum from vac chamber (valve opened)

-- Turbo control actuator (pressure side) is vented

-- Turbo control actuator (vacuum side) is vented

-- Wastegate is vented (held shut to improve spool), 2nd port on actuator capped

-- Pre control valve is connected directly to the compressor outlet to control boost via spring pressure, 2nd port on actuator capped

Over 4000rpm:

-- Charge control actuator receives pressure from compressor outlet

-- Charge relief valve vented (valve closed)

-- Turbo control actuator (pressure side) receives pressure from chamber

-- Turbo control actuator (vacuum side) receives vacuum from chamber

-- Wastegate receives compressor outlet pressure in order to control boost. An MBC or EBC could be installed in-line, but higher boost levels could be dangerous

-- Pre control continues to receive compressor outlet pressure and is thus held in the full open position.

I've never actually tried that exact plumbing personally, but on paper it should work although I'm not sure what the boost pattern would be.

#4

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

the actual info seems to have gotten lost, but a friend of mine figured out that on a stock FD you can use a 3 pole switch and make it non sequential.

https://www.rx7club.com/showthread.p...ghlight=switch

i don't know that anyone actually ever did it, but i think the idea was that if you were on the racetrack, or equivalent, you could turn the sequentials off, to get a more linear power delivery.

https://www.rx7club.com/showthread.p...ghlight=switch

i don't know that anyone actually ever did it, but i think the idea was that if you were on the racetrack, or equivalent, you could turn the sequentials off, to get a more linear power delivery.

#5

you can change the sequential--> non sequential transition point in a Power FC (or Haltech, whatever) if you have the software. In the Power FC for example you could set it to 2000 or 2500 rpm and then you would always be in non sequential for autocross or whatever. If you are wiring it up like I have posted here, you could install a toggle switch along with a 5 pin relay that would work with the rpm switch. You'd wire the relay pins like this:

toggle switch pins: one comes from chassis ground, the other goes to pin 87a of the relay

85: from rpm switch

86 +12V

87a: from toggle switch

87: from chassis ground

30: to solenoids

So with normal sequential operation, the toggle switch would be open and no ground would be supplied to pin 87a. Only the primary turbo would be in operation under the trigger rpm. When the rpm trigger point is reached, ground is supplied to the relay coil pin 85. That will complete the circuit from the solenoids (pin 30) to chassis ground, pin 87.

With the toggle switch closed, ground would always be supplied to the solenoids (pin 30) from pin 87a. When the rpm switch comes online the coil in relay will still engage but it won't affect the operation of the solenoids.

toggle switch pins: one comes from chassis ground, the other goes to pin 87a of the relay

85: from rpm switch

86 +12V

87a: from toggle switch

87: from chassis ground

30: to solenoids

So with normal sequential operation, the toggle switch would be open and no ground would be supplied to pin 87a. Only the primary turbo would be in operation under the trigger rpm. When the rpm trigger point is reached, ground is supplied to the relay coil pin 85. That will complete the circuit from the solenoids (pin 30) to chassis ground, pin 87.

With the toggle switch closed, ground would always be supplied to the solenoids (pin 30) from pin 87a. When the rpm switch comes online the coil in relay will still engage but it won't affect the operation of the solenoids.

Trending Topics

#10

Fair enough; its actually the custom dual TID's that I'd rather not have to deal with. By the time you add that to the cost of a new downpipe and solenoids this ends up being more expensive than a hybrid single that will offer very similar power potential and more simplicity.

#11

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

Fair enough; its actually the custom dual TID's that I'd rather not have to deal with. By the time you add that to the cost of a new downpipe and solenoids this ends up being more expensive than a hybrid single that will offer very similar power potential and more simplicity.

Thread

Thread Starter

Forum

Replies

Last Post

Turblown

Vendor Classifieds

12

10-17-20 03:25 PM