T2 cranking but wont start

#27

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

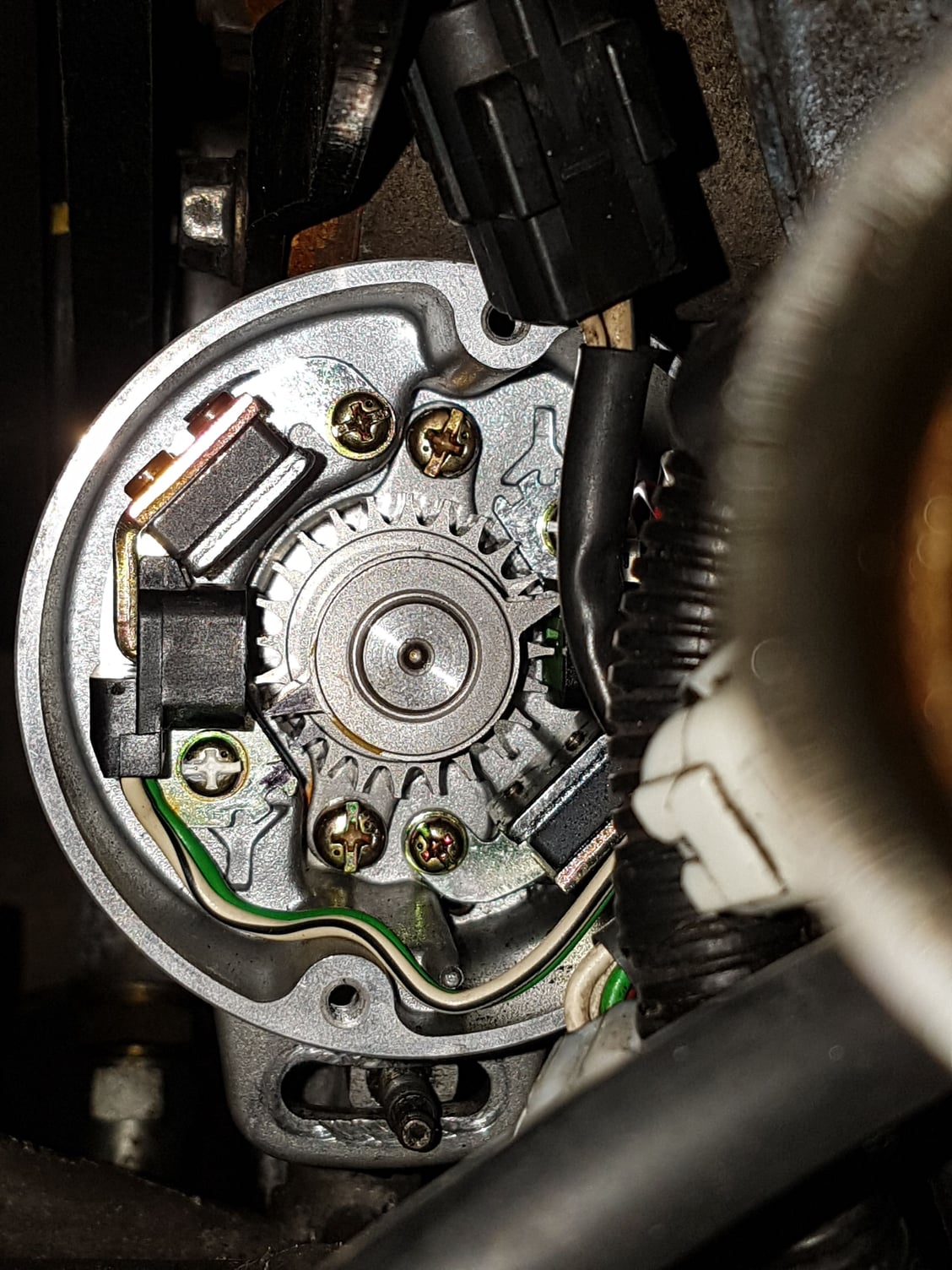

This is with the marks on the bottom of the cas lined up and the pin lined up with the yellow mark (the one on the right). I made reference marks on the teeth so i could see it didnt move when installed.

#30

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

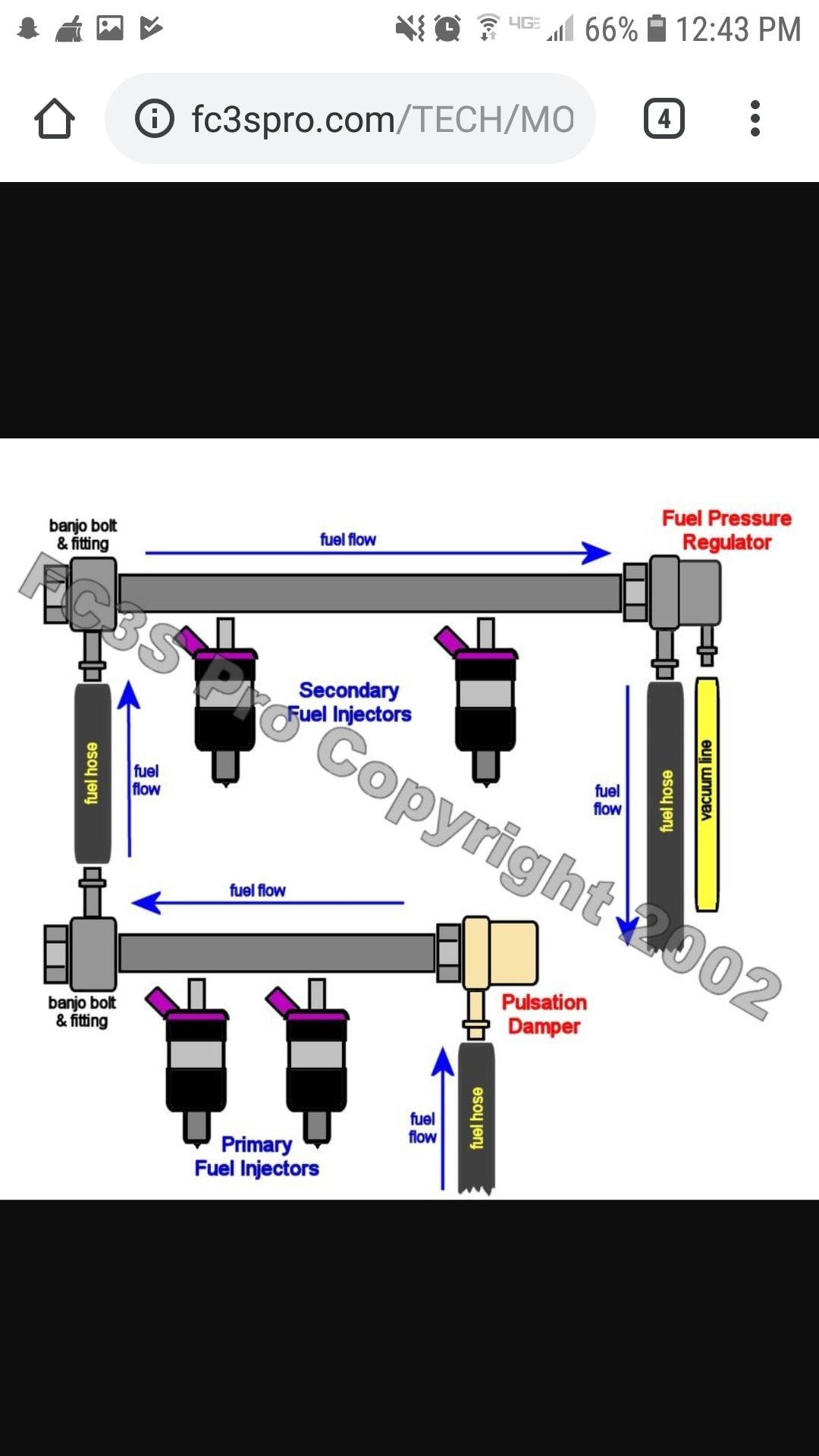

I removed the UIM and the fuel rails and did a ziptie leak test, no leaks. .14 ohms on all injectors and 12v on all plugs. I followed the fuel lines and and it goes from a hard line on the firewall to the fuel pressure regulator -> right size of the secondary fuel rail -> primary fuel rail -> my fuel pressure gauge to a soft line that goes down to what looks like beneath the car. I couldnt see which one attaches to the fuel filter so ill jack the car up and see if i can figure that out tomorrow. And ill grab a picture of how the wires are hooked up to the injectors. If all this is right and the timing is right, what are the next steps to diagnosing why this wont start? I plan on going stand alone ecu later on but i want to get it running and clean it up first

#31

Bankrupt rotary

iTrader: (1)

I recently rebuilt my s4 turbo motor and it gave me a ton of trouble starting. I had fuel and spark, though I didn't check the compression but it sounded good when cranking. After putting two pumps of 90w gear oil in the upper spark plug holes it fired right over. Sometimes rebuilt motors have trouble building compression, but after they run for a couple hours the seals break in and build compression.

#32

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

The fuel pressure regulator should be after the fuel rails right? And the return line comes out of the secondaries if im not mistaken. So it should go from the hardline on the firewall -> right side of secondary fuel rail -> left side of primary -> fuel pressure regulator? Im not sure if changing the direction of fuel flow would effect it or not

#33

Bankrupt rotary

iTrader: (1)

The fuel pressure regulator should be after the fuel rails right? And the return line comes out of the secondaries if im not mistaken. So it should go from the hardline on the firewall -> right side of secondary fuel rail -> left side of primary -> fuel pressure regulator? Im not sure if changing the direction of fuel flow would effect it or not

#34

Sucker for Punishment

The line coming from your "fuel filter" goes to pulsation damper which is the right side of primary/ out of left side of primary/ in to left side of secondary/ through regulator/ to return line. It will not operate in reverse.

Edit: Cryosignal is right, especially since you aren't running the OMP you aren't getting a ton of lubrication which is important after a rebuild. You also have a 28.6% difference in compression tests. This is high and the book actually calls for a rebuild at that point.

Edit: Cryosignal is right, especially since you aren't running the OMP you aren't getting a ton of lubrication which is important after a rebuild. You also have a 28.6% difference in compression tests. This is high and the book actually calls for a rebuild at that point.

Last edited by Rotary Alkymist; 11-29-18 at 03:05 PM.

#35

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

Once i verify the fuel lines are routed right ill put everything back together and pour oil into the low compression rotor and see if that helps with anything. Would about a lid of oil be enough? And would low compression be a reason for it starting with the timing advanced 5 degrees? With the cas set with the divots lined up it doesnt feel like it wants to start at all. Even when i give it gas

#36

Bankrupt rotary

iTrader: (1)

I bought a hand pump that screws to the top of the bottle, and put two good pumps of 90w gear oil. Probably doesn't have to be that thick, I'm sure the 20-50W oil for the engine would work. Make sure the hose from the pump gets all the way in the spark plug holes or more is going to dribble down the engine than go into the chamber. Just to be safe I'd put oil in both rotors while your at it and start it with FSM timing specs. Once its running you can play with the timing using a light.

#37

Smells like 2 stroke.

Are you sure it's not flooded?

If it's not flooded, are you sure the fuel pump is working when you jumper the test connector? What is the voltage at the pump? Where are you taking fuel pressure readings from?

If it's not flooded, are you sure the fuel pump is working when you jumper the test connector? What is the voltage at the pump? Where are you taking fuel pressure readings from?

#39

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

I have tried the deflooding procedure many times with no luck. And i have a fuel pressure gauge hooked up before the primary fuel rail reading 40 psi.

#40

Sucker for Punishment

You need to pull codes as a process of deduction. Its one of the first things you should for plenty of reasons:

1. No wrenches involved.

2. Pinpoint an issue in seconds instead of hours perhaps days.

3. In the event that you don't have any codes to pull will hint to a mechanical issue.

4. The system was implemented to make a mechanics job much simpler.

It's there as a tool and it should be used. It costs about 10 bucks to fashion a tester.

1. No wrenches involved.

2. Pinpoint an issue in seconds instead of hours perhaps days.

3. In the event that you don't have any codes to pull will hint to a mechanical issue.

4. The system was implemented to make a mechanics job much simpler.

It's there as a tool and it should be used. It costs about 10 bucks to fashion a tester.

#41

Sucker for Punishment

Did you indeed check to see if you AFM is plugged in? I think it'll spit out a code 08 for AFM. I know the car will have a really hard time starting without it plugged in.

#43

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

You need to pull codes as a process of deduction. Its one of the first things you should for plenty of reasons:

1. No wrenches involved.

2. Pinpoint an issue in seconds instead of hours perhaps days.

3. In the event that you don't have any codes to pull will hint to a mechanical issue.

4. The system was implemented to make a mechanics job much simpler.

It's there as a tool and it should be used. It costs about 10 bucks to fashion a tester.

1. No wrenches involved.

2. Pinpoint an issue in seconds instead of hours perhaps days.

3. In the event that you don't have any codes to pull will hint to a mechanical issue.

4. The system was implemented to make a mechanics job much simpler.

It's there as a tool and it should be used. It costs about 10 bucks to fashion a tester.

#44

Sucker for Punishment

FC3S Pro v2.0:  How-To - Zenki FC3S Error Codes

Read this write-up. It's pretty straight forward.

Yes S5 ECU will send codes to the right connector in s4 chassis/wiring. Unless it was omitted in when it was wired up at the ECU.

Read this write-up. It's pretty straight forward.

Yes S5 ECU will send codes to the right connector in s4 chassis/wiring. Unless it was omitted in when it was wired up at the ECU.

Last edited by Rotary Alkymist; 12-03-18 at 05:23 PM.

#45

Full Member

Thread Starter

Join Date: Feb 2017

Location: Comox valley, british columbia

Posts: 81

Likes: 0

Received 0 Likes

on

0 Posts

I didnt ground anything like you would on an s5 chassis, but i did the s4 procedure.

if for whatever reason i did everything right and theres no codes being sent to the check connector, how can i check for ecu trouble codes? Could i get them straight from the ecu somehow?

#48

Sucker for Punishment

Ebay is a click away. You're gonna have a hard time fetching codes with a meter. If anything you would need two analog meters hooked up at the same time, unless the digimeters react fast enough to observe a single pulse.

The error codes are sent to DCC1 and DCC2 at the same time if I'm not mistaken.

The orange wire in the green two pin connector must be grounded to fetch codes. You won't need to do the key thing.

The error codes are sent to DCC1 and DCC2 at the same time if I'm not mistaken.

The orange wire in the green two pin connector must be grounded to fetch codes. You won't need to do the key thing.

Last edited by Rotary Alkymist; 12-14-18 at 03:45 PM. Reason: typo