Powdercoating Question

#1

Powdercoating Question

I know powder coating is bad for certain applications unless handled in a specific manner (causing loss of structural integrity when down to rims for instance).

What I would like to know is if there is any reason why powder coating would be bad on brake calipers? Yes I could just spray them but I am owed some free powder coating so thought, "why not?".

Thanks all!

What I would like to know is if there is any reason why powder coating would be bad on brake calipers? Yes I could just spray them but I am owed some free powder coating so thought, "why not?".

Thanks all!

#2

I know powder coating is bad for certain applications unless handled in a specific manner (causing loss of structural integrity when down to rims for instance).

What I would like to know is if there is any reason why powder coating would be bad on brake calipers? Yes I could just spray them but I am owed some free powder coating so thought, "why not?".

Thanks all!

What I would like to know is if there is any reason why powder coating would be bad on brake calipers? Yes I could just spray them but I am owed some free powder coating so thought, "why not?".

Thanks all!

Powdercoating is not bad for wheels at all. It is not bad for springs either. The low temperatures used in powdercoating are not a major factor at all for metal.

There is rubber gaskets that would melt in the calipers.

Paint is WAY easier anyways.

P.S.

My best friends family owns the largest, available for public use, powdercoating bussiness in the US.

#3

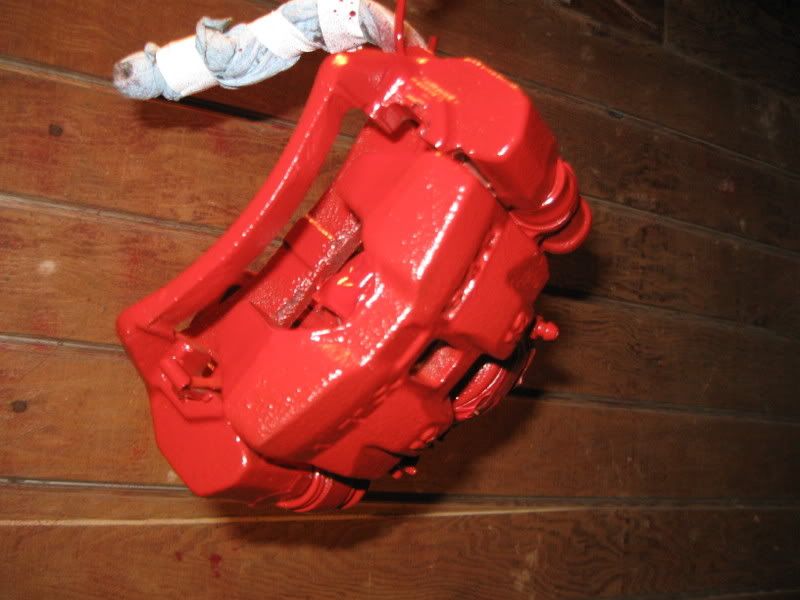

I powdercoated my calipers gold, I haven't driven on them much, but I do know that it holds up against brake fluid fairly well. I'm sure if you had a darker color they would be pretty damn tough.

#5

Powdercoating is not bad for wheels at all. It is not bad for springs either. The low temperatures used in powdercoating are not a major factor at all for metal.

There is rubber gaskets that would melt in the calipers.

Paint is WAY easier anyways.

P.S.

My best friends family owns the largest, available for public use, powdercoating bussiness in the US.

There is rubber gaskets that would melt in the calipers.

Paint is WAY easier anyways.

P.S.

My best friends family owns the largest, available for public use, powdercoating bussiness in the US.

As for the seal burning, I disassembled my calipers, sent them out, and rebuilt them when i got them back. And rebuilding isn't that hard. All you really need is a pick, an air source w/ nozzle, and internal snap ring pliers.

#6

Banned. I got OWNED!!!

You have to electrify the metal to get the powder to stick.... then you have to bake the powder for 20-45 minutes in a 225-325 degree oven so it turns into a gel type material. Then you take the items out of the oven and let them cool at room temp for an hour and the gel turns into a hard coating.

Yeah, too bad there's a lot of other **** to consider.

To the OP - go out and get some VHT Caliper paint and be done with it. The first time I painted my calipers with that it lasted and looked GREAT for about 7 years before I repainted the entire car. Much EASIER than powdercoating too.

Trending Topics

#8

Senior Member

iTrader: (3)

Join Date: Sep 2004

Location: San Luis Obispo, CA

Posts: 548

Likes: 0

Received 0 Likes

on

0 Posts

What company did you say you were familiar with the workings with?

Aluminum alloys are not all the same. Even heating some alloys to that meager 400deg can cause a change in the crystalline structure. If not cooled properly, the atoms can "jam" transitioning from one type structure to another. The points where it jams can make the metal extremely brittle. I don't have to have a friend in the metal industry to tell me that's a bad thing to have in a wheel. Also, just because one person doesn't have a problem, doesn't mean someone else won't.

#9

Banned. I got OWNED!!!

#10

It seems you have little understanding of the curing processes of Powder coating. Every place and process description I've ever seen has gone above 400deg for curing.

There are low cure powders that will cure below 300F as well that should be used on aluminum structural pieces (with an appropriately set oven of course).

Sounds like the shop Paginizondadude hangs out at just isn't a hack shop like most places...

#11

The ovens are usually run hotter than they need to be to get the metal parts up to the required 325-375F as quickly as possible to maximize production.

There are low cure powders that will cure below 300F as well that should be used on aluminum structural pieces (with an appropriately set oven of course).

Sounds like the shop Paginizondadude hangs out at just isn't a hack shop like most places...

There are low cure powders that will cure below 300F as well that should be used on aluminum structural pieces (with an appropriately set oven of course).

Sounds like the shop Paginizondadude hangs out at just isn't a hack shop like most places...

Thanks for understanding.

Like a said... my best friends dad OWNS the largest available to the public powdercoating buisiness in the US. He also has the largest ovens in the US. They are 4 of them total and one of them is two, 40 foot shipping containers welded together side by side. They are quite the awesome shop.... VERY high tech and up to date.

It is called Powder Coating Inc.

They are out of Mukilteo Wa.

#12

I Dislike Everything

iTrader: (1)

Join Date: Apr 2002

Location: St. Louis/Southern Illinois

Posts: 3,701

Likes: 0

Received 7 Likes

on

7 Posts

This has been a major problem with this forum, is members spreading false information to other members, making things more frustrating for contributing members to give input when some guy on the forum says something wrong.

If you are going to post about something in a thread, make sure you're 100% correct in your information. The fact that you said you are 50% sure/correct, makes you look like a newbie and somebody who should NOT be giving out information.

You have also been warned about your language towards TitaniumTT. He said NOTHING disrespectful to you in any way, he was being very constructive, but you took it as an attack.

#13

Senior Member

iTrader: (1)

Join Date: Sep 2008

Location: WA

Posts: 327

Likes: 0

Received 0 Likes

on

0 Posts

This has been a major problem with this forum, is members spreading false information to other members, making things more frustrating for contributing members to give input when some guy on the forum says something wrong.

If you are going to post about something in a thread, make sure you're 100% correct in your information. The fact that you said you are 50% sure/correct, makes you look like a newbie and somebody who should NOT be giving out information.

You have also been warned about your language towards TitaniumTT. He said NOTHING disrespectful to you in any way, he was being very constructive, but you took it as an attack.

If you are going to post about something in a thread, make sure you're 100% correct in your information. The fact that you said you are 50% sure/correct, makes you look like a newbie and somebody who should NOT be giving out information.

You have also been warned about your language towards TitaniumTT. He said NOTHING disrespectful to you in any way, he was being very constructive, but you took it as an attack.

More specifically, not wrong in the method he described, but is wrong about Pagon being wrong?

There's some rather harsh language being directed at him in this thread - even from you yourself - with respect to that, and as Blue TII mentioned, there are low temp cure powders available.

/Just my 2c - so far the primary thing that Pagon seems to be getting attacked over is the temperature specified, and low temp cure powders actually are specified to bake at that temp.

#14

Did you not see his writing? It had big huge bold RED letters that say...

DO NOT POST ANYTHING!!!!!!

And look at the rest of this.... you tell me that he is not being a complete jerk to me.

All you did was perpetuate bad, innacurate information and that accomplishes absolutely nothing positive. We are trying to share usefull information in an attempt to help people here. How is giving someone wrong information helping them?

I feel like you all think i am an idiot because i am 15... I may be young... I may not know everything... but i really and not dumb. I am fairly smart for my age.

Thank you for the people that are actually being nice. Why do people have to be such jerks... I was seriously just trying to help.

I just called my powdercoater and he said some of the powder he uses bakes at 250... and some of it bakes at 395. He said the average was 375 degrees! Now really... was i that far off? I said 225-325.

#15

Part-time Sancho

Join Date: Mar 2004

Location: South Austin

Posts: 359

Likes: 0

Received 0 Likes

on

0 Posts

Not that my opinion counts toward anything but seriously... you are taking TTTs comment about 'do not post anything' way to far. He clearly states that if you are not 100% sure then do no post. I for one have a lot to learn still about the FC among other technical things. I would not someone to make comments in my thread that could possible harm my car or my well being. Even Rowtarded nearly made the same comment.

Oh and celbii comments toward you were pretty pathetic.

Oh and celbii comments toward you were pretty pathetic.

#16

Junior Member

Join Date: Sep 2008

Location: South West Oregon

Posts: 37

Likes: 0

Received 0 Likes

on

0 Posts

Well it seems as though the only real danger would be inadvertently annealing the piece.

I'm not certain of all alloys of aluminum, but I know steel doesn't anneal until quite a high temp (over 500 degrees Celsius), and common aluminum alloys don't anneal until similar temps (according to a very brief internet search 300 degrees Celsius seems to pretty common).

So I dunno. I'd say powder coat away! (although I do agree that painting your calipers is much much easier)

I'm not certain of all alloys of aluminum, but I know steel doesn't anneal until quite a high temp (over 500 degrees Celsius), and common aluminum alloys don't anneal until similar temps (according to a very brief internet search 300 degrees Celsius seems to pretty common).

So I dunno. I'd say powder coat away! (although I do agree that painting your calipers is much much easier)

#17

Banned. I got OWNED!!!

Pagon said.... powdercoating is done @ 225-whatever. One can only assume that he is referring to ALL powdercoating. He then goes on to reference his best friends father owning the largest blah blah blah. So, someone who doesn't know anything about powdercoating would therefore deduce that this 15 yo must be right. In fact he is wrong. Not all powders cure at that temp. Most of the ones that I have ever used flash @ 450, bake @ 400. Period. The way he worded his post was WRONG. End of discussion.

Pagon said.... powdercoating is done @ 225-whatever. One can only assume that he is referring to ALL powdercoating. He then goes on to reference his best friends father owning the largest blah blah blah. So, someone who doesn't know anything about powdercoating would therefore deduce that this 15 yo must be right. In fact he is wrong. Not all powders cure at that temp. Most of the ones that I have ever used flash @ 450, bake @ 400. Period. The way he worded his post was WRONG. End of discussion. He further dug his grave by posting up about being only 1/2 sure. Instant and permanent discreditation in my eyes. Personally, I'll never believe another thing he ever posts up.

There's some rather harsh language being directed at him in this thread - even from you yourself - with respect to that, and as Blue TII mentioned, there are low temp cure powders available.

/Just my 2c - so far the primary thing that Pagon seems to be getting attacked over is the temperature specified, and low temp cure powders actually are specified to bake at that temp.

/Just my 2c - so far the primary thing that Pagon seems to be getting attacked over is the temperature specified, and low temp cure powders actually are specified to bake at that temp.

HELLO!!!!

Did you not see his writing? It had big huge bold RED letters that say...

DO NOT POST ANYTHING!!!!!!

And look at the rest of this.... you tell me that he is not being a complete jerk to me.

All you did was perpetuate bad, innacurate information and that accomplishes absolutely nothing positive. We are trying to share usefull information in an attempt to help people here. How is giving someone wrong information helping them?

Did you not see his writing? It had big huge bold RED letters that say...

DO NOT POST ANYTHING!!!!!!

And look at the rest of this.... you tell me that he is not being a complete jerk to me.

All you did was perpetuate bad, innacurate information and that accomplishes absolutely nothing positive. We are trying to share usefull information in an attempt to help people here. How is giving someone wrong information helping them?

Given my history.....

Given my history..... I feel like you all think i am an idiot because i am 15... I may be young... I may not know everything... but i really and not dumb. I am fairly smart for my age.

Thank you for the people that are actually being nice. Why do people have to be such jerks... I was seriously just trying to help.

I just called my powdercoater and he said some of the powder he uses bakes at 250... and some of it bakes at 395. He said the average was 375 degrees! Now really... was i that far off? I said 225-325.

Thank you for the people that are actually being nice. Why do people have to be such jerks... I was seriously just trying to help.

I just called my powdercoater and he said some of the powder he uses bakes at 250... and some of it bakes at 395. He said the average was 375 degrees! Now really... was i that far off? I said 225-325.

Look, you're going to take this as being disrespectful and there's no avoiding it, yet I'm going to say it anyways becuase it's good advice.... & that's what we're here for. If you don't listen, maybe someone else will. I'm literally twice as old as you. I would dare say that I'm a bit more mature than you. When you do grow up, and you do mature, you'll realize that the adult and mature thing to do is admit when you're wrong, then apologize. You have yet to do that. There's few things more childish than someone that pisses and moans when they're wrong. There's a term - Manning up to something. Think about it.

Not that my opinion counts toward anything but seriously... you are taking TTTs comment about 'do not post anything' way to far. He clearly states that if you are not 100% sure then do no post. I for one have a lot to learn still about the FC among other technical things. I would not someone to make comments in my thread that could possible harm my car or my well being. Even Rowtarded nearly made the same comment.

Oh and celbii comments toward you were pretty pathetic.

Oh and celbii comments toward you were pretty pathetic.

What size spacers do I need to fit FD rims on an FC?

someone answered

I dunno, just stack them until they fit

If you don't know - STFU and let someone who does answer. Like you said, horrible and DANGEROUS advice gets spread around that way.

If you don't know - STFU and let someone who does answer. Like you said, horrible and DANGEROUS advice gets spread around that way./

#18

I Dislike Everything

iTrader: (1)

Join Date: Apr 2002

Location: St. Louis/Southern Illinois

Posts: 3,701

Likes: 0

Received 7 Likes

on

7 Posts

HELLO!!!!

Did you not see his writing? It had big huge bold RED letters that say...

DO NOT POST ANYTHING!!!!!!

And look at the rest of this.... you tell me that he is not being a complete jerk to me.

All you did was perpetuate bad, innacurate information and that accomplishes absolutely nothing positive. We are trying to share usefull information in an attempt to help people here. How is giving someone wrong information helping them?

I feel like you all think i am an idiot because i am 15... I may be young... I may not know everything... but i really and not dumb. I am fairly smart for my age.

Thank you for the people that are actually being nice. Why do people have to be such jerks... I was seriously just trying to help.

I just called my powdercoater and he said some of the powder he uses bakes at 250... and some of it bakes at 395. He said the average was 375 degrees! Now really... was i that far off? I said 225-325.

Did you not see his writing? It had big huge bold RED letters that say...

DO NOT POST ANYTHING!!!!!!

And look at the rest of this.... you tell me that he is not being a complete jerk to me.

All you did was perpetuate bad, innacurate information and that accomplishes absolutely nothing positive. We are trying to share usefull information in an attempt to help people here. How is giving someone wrong information helping them?

I feel like you all think i am an idiot because i am 15... I may be young... I may not know everything... but i really and not dumb. I am fairly smart for my age.

Thank you for the people that are actually being nice. Why do people have to be such jerks... I was seriously just trying to help.

I just called my powdercoater and he said some of the powder he uses bakes at 250... and some of it bakes at 395. He said the average was 375 degrees! Now really... was i that far off? I said 225-325.

And I quote, you called him a "******* *******" for his comments above towards you. TitaniumTT could not have been MORE respectful to you. He, along with the thousands upon thousands of other members of this forum despise people giving out wrong information.

#19

anyone seen my head

Join Date: Nov 2006

Location: albuquerque nm

Posts: 108

Likes: 0

Received 0 Likes

on

0 Posts

so to answer the op's question yes but make sure they are using the technique and proper powder/coating for your free job and on a side note what temp are glowing calipers at wouldn't that be similar temp to an oven just not for extended periods

#20

I coated mine with 2 layers of primer and 2 layers of base and 3 layers of clearcoat, all the layers are based up on "heat-resistant" spraypaint, the pic is taken before i put on any clearcoat layers..Paint is baked at 160 Celcius for 10 minutes. Left one got a rough finish since i screwed up and started using a metalbrush on the calipers with a rondell wich pretty much screwed up the surface on that caliper, right one is much smoother as u can see.

#21

Banned. I got OWNED!!!

I am done with this tread. I can stick to my beliefs (which i know are correct) and you can stick to yours. I know for a FACT that i am right. I talked to the damn owner of the powder coating shop.

Dude. I honestly dont care how old i am. That is the NUMBER ONE thing that pisses me off. That is a very very poor come back. It really doesnt matter how old i am or you are. And one other thing... I am not immature... that is also a poor comeback.

Dude. You disrespected me. I really dont apprieciate it.

I am done posting on this thread.

Dude. I honestly dont care how old i am. That is the NUMBER ONE thing that pisses me off. That is a very very poor come back. It really doesnt matter how old i am or you are. And one other thing... I am not immature... that is also a poor comeback.

Dude. You disrespected me. I really dont apprieciate it.

I am done posting on this thread.

Outcold - that looks really good. I'd be curious to see how it hold up to the heat especially with the clear. I've been told that clear bronzes when it heats. Did you use a specific high heat clear?

I've always had good luck with VHT products. I consider them to be a baby 3M. If they say it'll work, I'll believe them.

The key is the prep though, as it often is. Brakekleen is a great way to get the grease, grime and dust off the calipers prior to painting or coating. My powdercoating system actually suggests that you bake your part @ 400 for 20 minutes to cook off some of the grease and grime that may have made it's way into the pores of material. I powdercoated an A/C / PS bracket. I spent a great deal of time mechanically and chemically cleaning it till it was clean enough to eat off of. Then I popped it in the over for 20 minutes, being cast AL and all.... the **** that was on it when I took it out was unbelievable. I spent half as much time the second time cleaning it again. The end result was worth it though. Only a few spots actually came though the powder.

#23

Banned. I got OWNED!!!

Aluminum alloys are not all the same. Even heating some alloys to that meager 400deg can cause a change in the crystalline structure. If not cooled properly, the atoms can "jam" transitioning from one type structure to another. The points where it jams can make the metal extremely brittle. I don't have to have a friend in the metal industry to tell me that's a bad thing to have in a wheel. Also, just because one person doesn't have a problem, doesn't mean someone else won't.

I started this thread because I already KNEW that certain powder coating processes were bad for the structural integrity of rims for instance...I know at least once racing organization bans powder coated rims unless they come with some type of sticker or affidavit that they were done in a manner that could not cause failure of the rim.

Last edited by TitaniumTT; 01-09-09 at 01:14 AM.

#24

My wheels on both my RX7's are powdercoated.

I have seen Porsche 24 hour endurance racing wheels in their shop (he is an avid Porsche fan).

My brothers racecar wheels are powdercoated.

Dude. I think he would have figured it out by now. Its not bad for wheels.

50%... hint hint... i wasnt 100%... so i could be 50% right or 50% wrong. I was partially wrong on the temps.... yes. I will admit that. But there is low powdercoating temps such as 295 degrees. There is also high ones such as 425. Which i was also wrong. I didnt know that they could bake at over 400. But i was pretty damn close to the average powedercoating temperature so you have to give me something here.

Can we please, PLEASE just come to an agreement. We are both wrong and right in some things. Apperently i was more wrong. I really want to be done argueing.

I have seen Porsche 24 hour endurance racing wheels in their shop (he is an avid Porsche fan).

My brothers racecar wheels are powdercoated.

Dude. I think he would have figured it out by now. Its not bad for wheels.

50%... hint hint... i wasnt 100%... so i could be 50% right or 50% wrong. I was partially wrong on the temps.... yes. I will admit that. But there is low powdercoating temps such as 295 degrees. There is also high ones such as 425. Which i was also wrong. I didnt know that they could bake at over 400. But i was pretty damn close to the average powedercoating temperature so you have to give me something here.

Can we please, PLEASE just come to an agreement. We are both wrong and right in some things. Apperently i was more wrong. I really want to be done argueing.