Help getting T2 swap/rebuild to run

#1

Help getting T2 swap/rebuild to run

Hey everyone,

I've been working on a t2 swap and build for the last few months and finally got to the point where it was time to start it. It did start, but then promptly died. I've been tweaking things over the last few days with little luck, and I think its time i ask for help.

Its mildly built, but I'm going to list everything that i think could matter.

- Rebuilt S4 T2 swap into S4 NA Chassis using NA harness

- Street ported

- Emissions delete and throttle body mod

- 3 inch TBE

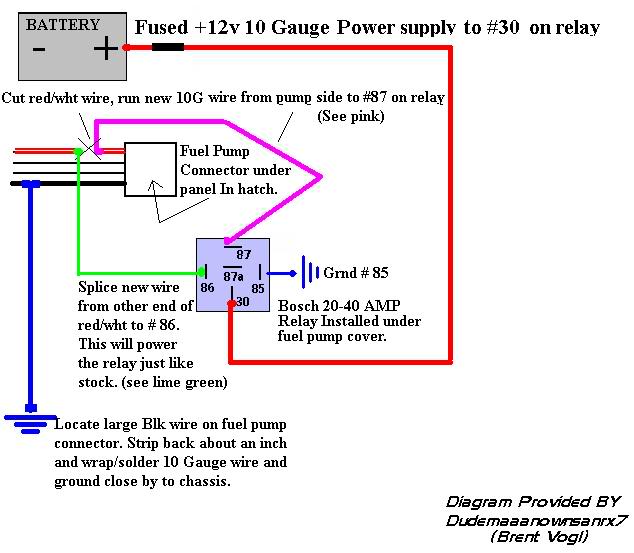

- Rewired Fuel Pump

- FPD delete

- Aeromotive Stealth 340 pump

- SAFC2

Alright i think thats everything that could possibly have a part of my symptoms.

So whats been happening is it will start and then promptly die and then if i try to start it again it will be flooded. I then have to pull power to the pump and then crank it over and then it will start with the fuel thats in the line. At this point if i just let it run with the fuel in the line it revs up to about 4k on its own but smoothly and then dies after it runs out of fuel. If i plug the pump in while its revving up it will then try to die. I can catch it before it dies but it runs terribly and backfires a lot. It also has about 55 psi of fuel pressure during this time according to my fuel pressure gauge. My afr gauge reads about 14.6 as well but i doubt the reading is accurate.

Things I've done:

Quadruple checked timing

Checked all my vacuum hoses for leaks.

Checked TPS and idle scew settings. The TPS was done on a cold engine though so i dont know how accurate that can be.

Tried to tune it a bit with the safc. It seems like its getting too much fuel but pulling fuel didnt do anything.

Thats about it. I feel like its getting too much fuel based on the high fuel pressure when its running but I'm not sure if that would cause it to run so poorly. So i would love any input on 1. Why is it unable to run well or at all really? And to a lesser extent 2. Why is it revving so high on start up when its just running off the fuel in the lines?

I've been working on a t2 swap and build for the last few months and finally got to the point where it was time to start it. It did start, but then promptly died. I've been tweaking things over the last few days with little luck, and I think its time i ask for help.

Its mildly built, but I'm going to list everything that i think could matter.

- Rebuilt S4 T2 swap into S4 NA Chassis using NA harness

- Street ported

- Emissions delete and throttle body mod

- 3 inch TBE

- Rewired Fuel Pump

- FPD delete

- Aeromotive Stealth 340 pump

- SAFC2

Alright i think thats everything that could possibly have a part of my symptoms.

So whats been happening is it will start and then promptly die and then if i try to start it again it will be flooded. I then have to pull power to the pump and then crank it over and then it will start with the fuel thats in the line. At this point if i just let it run with the fuel in the line it revs up to about 4k on its own but smoothly and then dies after it runs out of fuel. If i plug the pump in while its revving up it will then try to die. I can catch it before it dies but it runs terribly and backfires a lot. It also has about 55 psi of fuel pressure during this time according to my fuel pressure gauge. My afr gauge reads about 14.6 as well but i doubt the reading is accurate.

Things I've done:

Quadruple checked timing

Checked all my vacuum hoses for leaks.

Checked TPS and idle scew settings. The TPS was done on a cold engine though so i dont know how accurate that can be.

Tried to tune it a bit with the safc. It seems like its getting too much fuel but pulling fuel didnt do anything.

Thats about it. I feel like its getting too much fuel based on the high fuel pressure when its running but I'm not sure if that would cause it to run so poorly. So i would love any input on 1. Why is it unable to run well or at all really? And to a lesser extent 2. Why is it revving so high on start up when its just running off the fuel in the lines?

#2

Sucker for Punishment

Glad to hear that you're getting somewhere. I would say you're thinking correctly. Your fuel pressure is too high. 55?! Way too high. Stock line pressure is 36-37lbs.

Get an adjustable FPR and set it to 36-37psi.

If you can get it to idle low enough throw a timing light on it and see where you're at.

Get an adjustable FPR and set it to 36-37psi.

If you can get it to idle low enough throw a timing light on it and see where you're at.

Last edited by Rotary Alkymist; 06-15-19 at 08:56 AM.

#4

Sucker for Punishment

I know that the thread specs are hard to match for the s4 rail. It's a strange size and its metric. You might be able to find something if you look hard enough or maybe have an adapter made. I'm running s5 so I had to change the whole rail.

#5

https://www.pegasusautoracing.com/

https://www.summitracing.com/

#6

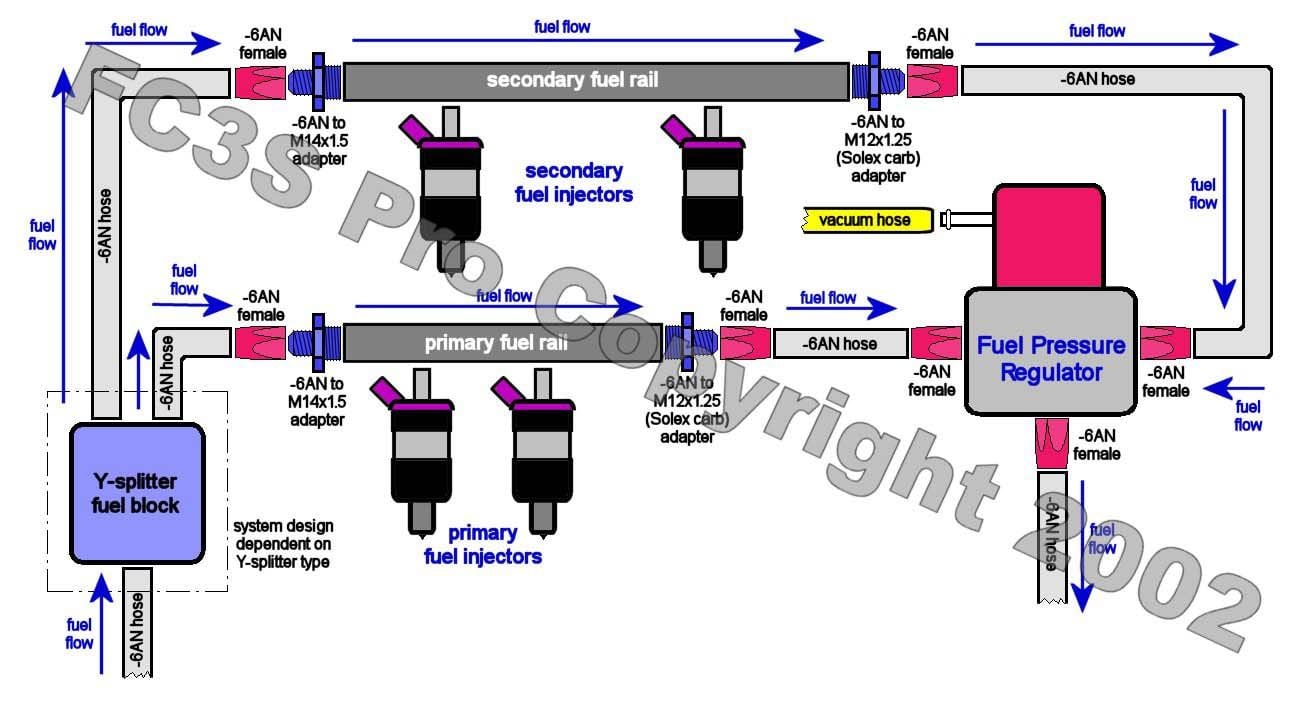

So my options are to tap new common threads or go aftermarket rails. Given a choice between the two I think I'll mod my stock rails. One day when I go to a bigger turbo I may go aftermarket rails and convert to a parallel fuel system, but I think that's pretty overkill for my modest amount of power.

Well I appreciate the response and I'll update this thread once I get the new fpr on.

Well I appreciate the response and I'll update this thread once I get the new fpr on.

#7

you shouldn't need to. there's a diagram of the fuel system around (i think it was RETed's site, if i recall) that said the thread size and pitch you need. i was able to get all the fittings for it shopping between Pegasus Racing and Summit Racing. i don't think it was all that expensive either.

https://www.pegasusautoracing.com/

https://www.summitracing.com/

https://www.pegasusautoracing.com/

https://www.summitracing.com/

Trending Topics

#8

FC3S Pro v2.0: Mods - Fuel System

in the diagram where it shows how to convert to a parallel system, it shows you need:

m12 x 1.25 to -6 an adapters (x2)

m14 x 1.25 to -6 an adapters (x2)

they swap out with your stock fittings - you literally unscrew and replace. no fuss (thread tape and washers aside). you may need to replace one of them with a plug depending on your regulator, but that's about it.

to attach your rails to the regulator and the supply and return lines, you can use -6 an Push-lock or straight adapters. you'll just have figure out what angles you need.

______________________________________

EDIT:

Sorry. your last post was not there when i started typing my response.

yes, that's the diagram.

yes, that's the diagram.

Last edited by diabolical1; 06-15-19 at 05:53 PM.

#9

Any recommendations on the fpr? Was looking at the aeromotive a1000 because it seems like a popular choice. Only goes as low as 40 psi though. Should be good enough right?

EDIT: Actually that would mean 40 psi would be the pressure at idle which is no where good enough.

EDIT: Actually that would mean 40 psi would be the pressure at idle which is no where good enough.

Last edited by tetsu50; 06-15-19 at 06:56 PM.

#10

Update on the car:

I just finished installing a 30-70 psi adjustable aeromotive FPR. My fuel pressure is now in a much better spot, but I'm still getting the same symptoms as i did before. Car still floods with the pump having power but will start and sound fine with the pump off. Still can plug the pump back in before it runs out of fuel but like before it will still try to die immediately unless i catch it and then will run terribly and back fire a lot.

So it doesn't look like the FPR was the problem, though it does sound a little better now with the pressure at a more stock level. I'm still of the believe that it is fuel related because otherwise it wouldn't run smoothly with the pump turned off. It has to be the pump then right? I'm starting to wonder if i should get something more stockish like an FD fuel pump and save the aeromotive 340 for when I'm making bigger power.

Anyone have any thoughts on this?

I just finished installing a 30-70 psi adjustable aeromotive FPR. My fuel pressure is now in a much better spot, but I'm still getting the same symptoms as i did before. Car still floods with the pump having power but will start and sound fine with the pump off. Still can plug the pump back in before it runs out of fuel but like before it will still try to die immediately unless i catch it and then will run terribly and back fire a lot.

So it doesn't look like the FPR was the problem, though it does sound a little better now with the pressure at a more stock level. I'm still of the believe that it is fuel related because otherwise it wouldn't run smoothly with the pump turned off. It has to be the pump then right? I'm starting to wonder if i should get something more stockish like an FD fuel pump and save the aeromotive 340 for when I'm making bigger power.

Anyone have any thoughts on this?

#11

Sucker for Punishment

What is your line pressure? Is it timed correctly? Hard to tell but when I hear backfiring I think timing.

Last edited by Rotary Alkymist; 06-23-19 at 09:21 AM.

#12

I guess whats messing with me is that the car starts, revs to about 4k and sounds good while the pump is turned off. So i feel like it has to be pump related if everything else seems to be running like its supposed to for those few seconds that it runs with the pump off.

#16

I also started going through the electrical system a bit and checking resistances and such. The CAS checked out fine, trailing coil checked out, but the leading coil was under .1 ohm so that is certainly under spec. Tried cleaning the contacts and grounds and that didn't help. I dont think thats the issue main issue here because it still is obviously working fine with the way it runs when it starts with the pump off, but still probably needs to be replaced.

Tomorrow I'm going to move onto checking the MAF. I've read about bad MAFs displaying some of the symptoms that im having.

#17

well, i don't know anything about the S-AFC IIs, so i will be useless there, but maybe there's some kind of adjustment that could be made in there to help??? i don't know. just spit-balling.

also, how did you re-wire the pump? specifically, what's controlling the output? i suppose this may possibly all boil down to pump overkill. the idea you mentioned about trying a more stock pump seems like it might be worth a try. it doesn't sound like you have any really crazy mods (yet), so a more "stock" pump will be fine.

also, how did you re-wire the pump? specifically, what's controlling the output? i suppose this may possibly all boil down to pump overkill. the idea you mentioned about trying a more stock pump seems like it might be worth a try. it doesn't sound like you have any really crazy mods (yet), so a more "stock" pump will be fine.

#19

Sucker for Punishment

It's strange that you're reading higher pressure while running. You should be seeing opposite behaviour. Faulty readings? Return line plugged? Bad regulator?

Last edited by Rotary Alkymist; 06-24-19 at 06:12 PM.

#20

Aside from that im going to switch the primary and secondary injectors. I was testing the primaries a few weeks ago by giving them direct battery voltage and I guess that could have hurt them. Didn't do that to the secondaries though.

Last edited by tetsu50; 06-24-19 at 10:09 AM.

#21

Does the fuel system hold pressure after you cut power to the pump?

What ECU are you running and how confident in your harness modification? You may want to remove the SAFC for troubleshooting.

I've run a walbro on a stock FPR that hit about 50 psi, but it still started and idled fine. A little stinky, but fine.

High revs are a vacuum leak or the throttle butterflies aren't adjusted correctly. Higher revs should help keeping it running while you troubleshoot, so attack that second.

What ECU are you running and how confident in your harness modification? You may want to remove the SAFC for troubleshooting.

I've run a walbro on a stock FPR that hit about 50 psi, but it still started and idled fine. A little stinky, but fine.

High revs are a vacuum leak or the throttle butterflies aren't adjusted correctly. Higher revs should help keeping it running while you troubleshoot, so attack that second.

#22

Does the fuel system hold pressure after you cut power to the pump?

What ECU are you running and how confident in your harness modification? You may want to remove the SAFC for troubleshooting.

I've run a walbro on a stock FPR that hit about 50 psi, but it still started and idled fine. A little stinky, but fine.

High revs are a vacuum leak or the throttle butterflies aren't adjusted correctly. Higher revs should help keeping it running while you troubleshoot, so attack that second.

What ECU are you running and how confident in your harness modification? You may want to remove the SAFC for troubleshooting.

I've run a walbro on a stock FPR that hit about 50 psi, but it still started and idled fine. A little stinky, but fine.

High revs are a vacuum leak or the throttle butterflies aren't adjusted correctly. Higher revs should help keeping it running while you troubleshoot, so attack that second.

Im running an rtek 1.5 s4 t2 ecu.

As far as the harness is concerned I guess im 50/50 on it. The PO of this engine did the harness modifications so I can't be sure it's done well, but he did run the engine himself for awhile until he blew a coolant hose and overheated it.

That's a good point on the safc too. Might be best to start removing unneeded things for simplicity sake if I don't find what's going on soon

#24

Sucker for Punishment

I would keep focusing on your fuel system.

IF you did your fuel pressure test correctly and your readings are indeed correct then you DEFINITELY have a fuel issue. I would also disable the fuel controller as someone mentioned just until you sort this out.

Your fuel pressure while running should be about 8-10 psi lower than when it's not running. I would check return line and line configuration.

Where are you T'ing into for the pressure test? Or do you have a fuel gauge?

IF you did your fuel pressure test correctly and your readings are indeed correct then you DEFINITELY have a fuel issue. I would also disable the fuel controller as someone mentioned just until you sort this out.

Your fuel pressure while running should be about 8-10 psi lower than when it's not running. I would check return line and line configuration.

Where are you T'ing into for the pressure test? Or do you have a fuel gauge?

Last edited by Rotary Alkymist; 06-24-19 at 06:09 PM.

#25

I would keep focusing on your fuel system.

IF you did your fuel pressure test correctly and your readings are indeed correct then you DEFINITELY have a fuel issue. I would also disable the fuel controller as someone mentioned just until you sort this out.

Your fuel pressure while running should be about 8-10 psi lower than when it's not running. I would check return line and line configuration.

Where are you T'ing into for the pressure test? Or do you have a fuel gauge?

IF you did your fuel pressure test correctly and your readings are indeed correct then you DEFINITELY have a fuel issue. I would also disable the fuel controller as someone mentioned just until you sort this out.

Your fuel pressure while running should be about 8-10 psi lower than when it's not running. I would check return line and line configuration.

Where are you T'ing into for the pressure test? Or do you have a fuel gauge?

Also I did check all the hoses and they are hooked up correctly and the return line flows well. Still could try switching the injectors if removing the safc doesn't help.

Last edited by tetsu50; 06-24-19 at 07:02 PM.