FC3S Rear Suspension Explained/Demystified

#1

Senior Member

Thread Starter

Rear FC suspension explained/demystified

This is a result of rebuilding and working with FC rear suspensions for the past 8 years. I'm seeing a lot of new drifting and other enthusiasts (even some old) having no idea what they are talking about and rely on the large range of info found all over the internet. Here is everything you need to know (There is other crazier stuff you can do like changing suspension points and total redesign but this is the average stuff anyone can do/have done)

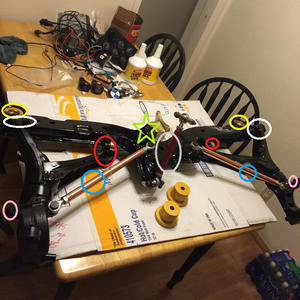

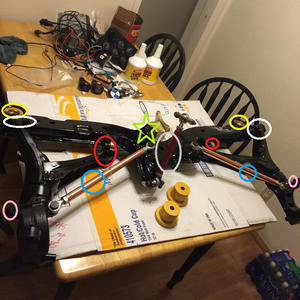

Pink : DTSS Bushings. Fancy Mazda rear steering bushings that where designed to help with the limitations of semi trailing arm suspension. Works great when NEW and when running factory tire widths. Terrible in drifting as it will make the rear end dance all over during transitioning and when gripping hard with wider/stickier tires and 20 year old bushings car will be rear steer heavy and be awkward and unpredictable. I prefer the racing beat version over other delrin ones due to the metal insert. Solid aluminium is fine aswell. Be careful during install/removal as the knuckle can split. Mazdatrix has some, RacingBeat, PBM. Common part.

Blue : Lateral Rods. Holds the control arm in place as far as toe is concerned. Would recommend newer/aftermarket ones as the older ones can have slot in the balljoints and allow for the rear toe to wander. I had one get all sloppy and allow for 5-10deg in toe change. You can use them to adjust tow aswell but its moreso meant to adjust the dynamic tow with your ride height change. When you lower/slam your car the dynamic tow can change and this can help even it out. (OEM at mazdatrix or aftermarket at AWR or PBM)

Red: Control arm Links? / Jangle Rods. Determines the camber of the car at the specified ride height. Unless your running 14s and your frame is on the ground you can usually have these shortened enough to have 0 camber. Mazdatrix has adjustable ones and PBM has shorter ones. I usually opt for sorter ones to keep it simple. If you need/want adjust-ability then go all out. (NOTE: Changing the length of these links changes the axis of rotation of the control arm bushing and will cause binding/damage to solid/polyurethane bushings. If modifying these links it is highly recommended to get spherical control arm bushings or stay with the stock rubber ones.)

White: Control arm Bushing. This is where toe is traditionally set. There is an eccentric bolt that allows for toe to be adjusted. most people set to zero, some like a bit of toe out as the FC rear suspension toes in under accel or they like the back end to be "happier" for when drifting. You can use stock bushing and still be able to adjust camber with the jangle rods as the rubber bushings have lots of play but i wouldn't recommend it as it makes them rotate way out of axis. Spherical bushing is the way to go if you want to adjust camber. (Via the jangle rods) I don't know if anyone else makes them anymore. (I have old MMR ones, but they are discontinued, and I have energy ones for the stock jangle rods) I know PBM makes spherical ones now.

Grey: Subframe stay/mount. Factory subframe bushings have lots of compliance so this is here to have a physical limit to the subframe deflection. Some people use this to adjust camber by pulling on the entire subframe. When doing it this way with stock subframe bushings you'll have uneven camber due to the offset location. In reality it is a terrible way to adjust camber and just a cheap way. Can be removed all together if you have solid subframe mounts or left in place for peace of mind. You can find these all over the internet. Dont waste your money. But hey, its your money.

Yellow: Subframe mounts. PMB makes weird moving ones. Its a feature that adds unnecessary play/another degree of freedom in your subframe. You can get the PBM diff mounts and just drill them to 20mm to fit the subframe studs. Or get any other solid subframe mount. Adjusting camber by cranking on the subframe is terrible way to do it. Not saying you cant, just saying you prolly shouldn't. Hard to find these anymore in solid form.

Green star!! : Front subframe mount. Bane of all FC owners. Break all the time or are broken and you just can't tell anymore/ignore it. The one in my turbo car wasn't broken but had so much compliance that the diff would actually move enough to hit things. Unless you have solid rear mounts dont waste your time and solidly mount this. I have seen some hokey "fixes" to this mount over the years from pinion snubs to complete mount redesigns. Honestly easiest way is to have the stock mount boxed in and welded. Reinforce the mounting tab on the subframe because that is the next thing to go. Pinion snubbers "work" sortof. The floor above is thin and not reinforced by anything so I doubt it will do anything other then delay the inevitable. If you use a solid front mount and still have stock rears then the diff will pop out of the subframe no matter how tight you put it. Its slotted so nothing is really holding it down. I had to cut an "access hole" in my floor to put it back into place after every run at an event. (Drifting an n/a car but the clutch kicks alone where enough) Solid mounting the diff seems to be the only way to help alleviate the front mount problems. Would recommend solid mounting diff to everyone regardless of driving style. Solid mounted it on my street car, I don't hear anything with my quiet exhaust. If you do then change your diff oil. (You may still hear some diff noise at a certain RPM/gear but its the nature of the beast. Drive your corolla/civic if your sensitive to these noises)

(People have argued that you can change camber with the rear camber adjuster. I'm not saying you cant, just recommending you don't.

People have also argued that the PBM subframe bushings are "solid as hell". Thats fine, but I'd rather not have an extra point that can potentially/is moving when I setup my suspension. I want it solid, with as little moving parts/adjustment areas as possible. Keeping it simple is key to eliminate as many variables as possible. Even "solid" bushings/mounts deflect to a certain degree.

Please feel free to add suppliers

86-92 Suspension Parts

Suspension Components - 1986-92 Mazda RX-7 Performance Parts

Multilink and Steering Angle for FC - Parts Shop MAX

AWR's E-Production parts for RX-7

This is a result of rebuilding and working with FC rear suspensions for the past 8 years. I'm seeing a lot of new drifting and other enthusiasts (even some old) having no idea what they are talking about and rely on the large range of info found all over the internet. Here is everything you need to know (There is other crazier stuff you can do like changing suspension points and total redesign but this is the average stuff anyone can do/have done)

Pink : DTSS Bushings. Fancy Mazda rear steering bushings that where designed to help with the limitations of semi trailing arm suspension. Works great when NEW and when running factory tire widths. Terrible in drifting as it will make the rear end dance all over during transitioning and when gripping hard with wider/stickier tires and 20 year old bushings car will be rear steer heavy and be awkward and unpredictable. I prefer the racing beat version over other delrin ones due to the metal insert. Solid aluminium is fine aswell. Be careful during install/removal as the knuckle can split. Mazdatrix has some, RacingBeat, PBM. Common part.

Blue : Lateral Rods. Holds the control arm in place as far as toe is concerned. Would recommend newer/aftermarket ones as the older ones can have slot in the balljoints and allow for the rear toe to wander. I had one get all sloppy and allow for 5-10deg in toe change. You can use them to adjust tow aswell but its moreso meant to adjust the dynamic tow with your ride height change. When you lower/slam your car the dynamic tow can change and this can help even it out. (OEM at mazdatrix or aftermarket at AWR or PBM)

Red: Control arm Links? / Jangle Rods. Determines the camber of the car at the specified ride height. Unless your running 14s and your frame is on the ground you can usually have these shortened enough to have 0 camber. Mazdatrix has adjustable ones and PBM has shorter ones. I usually opt for sorter ones to keep it simple. If you need/want adjust-ability then go all out. (NOTE: Changing the length of these links changes the axis of rotation of the control arm bushing and will cause binding/damage to solid/polyurethane bushings. If modifying these links it is highly recommended to get spherical control arm bushings or stay with the stock rubber ones.)

White: Control arm Bushing. This is where toe is traditionally set. There is an eccentric bolt that allows for toe to be adjusted. most people set to zero, some like a bit of toe out as the FC rear suspension toes in under accel or they like the back end to be "happier" for when drifting. You can use stock bushing and still be able to adjust camber with the jangle rods as the rubber bushings have lots of play but i wouldn't recommend it as it makes them rotate way out of axis. Spherical bushing is the way to go if you want to adjust camber. (Via the jangle rods) I don't know if anyone else makes them anymore. (I have old MMR ones, but they are discontinued, and I have energy ones for the stock jangle rods) I know PBM makes spherical ones now.

Grey: Subframe stay/mount. Factory subframe bushings have lots of compliance so this is here to have a physical limit to the subframe deflection. Some people use this to adjust camber by pulling on the entire subframe. When doing it this way with stock subframe bushings you'll have uneven camber due to the offset location. In reality it is a terrible way to adjust camber and just a cheap way. Can be removed all together if you have solid subframe mounts or left in place for peace of mind. You can find these all over the internet. Dont waste your money. But hey, its your money.

Yellow: Subframe mounts. PMB makes weird moving ones. Its a feature that adds unnecessary play/another degree of freedom in your subframe. You can get the PBM diff mounts and just drill them to 20mm to fit the subframe studs. Or get any other solid subframe mount. Adjusting camber by cranking on the subframe is terrible way to do it. Not saying you cant, just saying you prolly shouldn't. Hard to find these anymore in solid form.

Green star!! : Front subframe mount. Bane of all FC owners. Break all the time or are broken and you just can't tell anymore/ignore it. The one in my turbo car wasn't broken but had so much compliance that the diff would actually move enough to hit things. Unless you have solid rear mounts dont waste your time and solidly mount this. I have seen some hokey "fixes" to this mount over the years from pinion snubs to complete mount redesigns. Honestly easiest way is to have the stock mount boxed in and welded. Reinforce the mounting tab on the subframe because that is the next thing to go. Pinion snubbers "work" sortof. The floor above is thin and not reinforced by anything so I doubt it will do anything other then delay the inevitable. If you use a solid front mount and still have stock rears then the diff will pop out of the subframe no matter how tight you put it. Its slotted so nothing is really holding it down. I had to cut an "access hole" in my floor to put it back into place after every run at an event. (Drifting an n/a car but the clutch kicks alone where enough) Solid mounting the diff seems to be the only way to help alleviate the front mount problems. Would recommend solid mounting diff to everyone regardless of driving style. Solid mounted it on my street car, I don't hear anything with my quiet exhaust. If you do then change your diff oil. (You may still hear some diff noise at a certain RPM/gear but its the nature of the beast. Drive your corolla/civic if your sensitive to these noises)

(People have argued that you can change camber with the rear camber adjuster. I'm not saying you cant, just recommending you don't.

People have also argued that the PBM subframe bushings are "solid as hell". Thats fine, but I'd rather not have an extra point that can potentially/is moving when I setup my suspension. I want it solid, with as little moving parts/adjustment areas as possible. Keeping it simple is key to eliminate as many variables as possible. Even "solid" bushings/mounts deflect to a certain degree.

Please feel free to add suppliers

86-92 Suspension Parts

Suspension Components - 1986-92 Mazda RX-7 Performance Parts

Multilink and Steering Angle for FC - Parts Shop MAX

AWR's E-Production parts for RX-7

The following users liked this post:

mr_vaughn (06-04-20)

#4

Nice Fleemer, generally good info except for this.

Sounds like you're missing the dual-hole oval washer that catches the lip of the subframe tab and prevents the diff mount from popping out of the slots.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

#6

Nice Fleemer, generally good info except for this.

Sounds like you're missing the dual-hole oval washer that catches the lip of the subframe tab and prevents the diff mount from popping out of the slots.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

Sounds like you're missing the dual-hole oval washer that catches the lip of the subframe tab and prevents the diff mount from popping out of the slots.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

#7

Pinion snubbers work very well actually. I have used then on multiple cars. If they are set up correctly they really don't take a lot of load they just reduce the strain on the stock mount. I have never seen any significant deflection of the body. I have however seen broken brackets from solid mounted solutions, but this vehicle was heavily road driven as well as drifted and did not have any other solid mounts. Point being is the snubber is not a bad solution for a street driven vehicle.

Trending Topics

#8

Senior Member

Thread Starter

Nice Fleemer, generally good info except for this.

Sounds like you're missing the dual-hole oval washer that catches the lip of the subframe tab and prevents the diff mount from popping out of the slots.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

Sounds like you're missing the dual-hole oval washer that catches the lip of the subframe tab and prevents the diff mount from popping out of the slots.

As you said though, a solid front mount is probably the way to go if you're running >200 RWHP.

And its a PITA to put it back in place without dropping the subframe unless you cut a hole/inspection panel in the floor. Even then it needs some coaxing.

#9

Senior Member

Thread Starter

Pinion snubbers work very well actually. I have used then on multiple cars. If they are set up correctly they really don't take a lot of load they just reduce the strain on the stock mount. I have never seen any significant deflection of the body. I have however seen broken brackets from solid mounted solutions, but this vehicle was heavily road driven as well as drifted and did not have any other solid mounts. Point being is the snubber is not a bad solution for a street driven vehicle.

After seeing my diff popout of the front mount a whole bunch I doubt it could hold the diff in its entirety.

#10

What's the point??

iTrader: (6)

Join Date: Oct 2005

Location: Omaha, NE

Posts: 995

Likes: 0

Received 0 Likes

on

0 Posts

Never had an issue with my pinion snubber, and I launch on 255 drag radials constantly.

That lip is just bent metal for the double washer, so I ran a quick bead to make it thick enough so the diff cant jump out. If you don't like a snubber, then I'd suggest the Bikedad brace, (ironically enough, that's his picture you used)

That lip is just bent metal for the double washer, so I ran a quick bead to make it thick enough so the diff cant jump out. If you don't like a snubber, then I'd suggest the Bikedad brace, (ironically enough, that's his picture you used)

#13

Your subframe is screwed up, that is why your diff is sliding out. There is a small tab on the subframe that will prevent the diff from sliding out of the subframe if you use the OEM hardware to mount the diff. That is why people rip the mount off the subframe, with a solid front diff mount while you are just pulling the diff away from the subframe. See picture below.

I will add that if you use a solid front diff mount you MUST use solid subframe and rear diff mounts to keep from damaging the subframe long term.

I will add that if you use a solid front diff mount you MUST use solid subframe and rear diff mounts to keep from damaging the subframe long term.

#14

White: Control arm Bushing. This is where toe is traditionally set. There is an eccentric bolt that allows for toe to be adjusted. most people set to zero, some like a bit of toe out as the FC rear suspension toes in under accel or they like the back end to be "happier" for when drifting.

#15

Rotary Shack

Join Date: May 2005

Location: Los Angeles, California

Posts: 1,788

Received 0 Likes

on

0 Posts

I don't think he's talking about bump and/or travel, only that the rear wheels will tend to pull in or rather towards each other to the front under hard acceleration. Maybe he can clarify this.

#16

Senior Member

iTrader: (3)

Join Date: Oct 2008

Location: Glenwood, Iowa

Posts: 447

Likes: 0

Received 0 Likes

on

0 Posts

I've got delrin in the yellow spot, diff mount I know, with Mazda comp "crowns" on the bottom of them and a Mazda comp up front in the grey. Good or bad? Your post confused me a bit on which way you don't want solids and non-solids.

#18

Rotary Enthusiast

iTrader: (1)

Join Date: Nov 2012

Location: bloomington, mn

Posts: 1,100

Likes: 0

Received 0 Likes

on

0 Posts

dammit largeorange! Now I need to double check, I think I put the crowns on upside down. The crown "tongs" are facing down on mine. Easy quick fix, but I can not remember.

#22

Brap Brap Brap

iTrader: (1)

Join Date: Mar 2010

Location: Greensboro, NC

Posts: 115

Likes: 0

Received 0 Likes

on

0 Posts

Question for you. So can you really buy the PBM rear solid diff mounts and drill then to 20mm and use them for solid subframe mounts? I have bought everything from PBM but the subframe risers because I have been trying to find solid subframe mounts and can't find any. I just want to be sure before I buy them. Has anyone done this before? Maybe a picture of it?

Thanks in advance!!

Thanks in advance!!

#23

Senior Member

Thread Starter

Question for you. So can you really buy the PBM rear solid diff mounts and drill then to 20mm and use them for solid subframe mounts? I have bought everything from PBM but the subframe risers because I have been trying to find solid subframe mounts and can't find any. I just want to be sure before I buy them. Has anyone done this before? Maybe a picture of it?

Thanks in advance!!

Thanks in advance!!

. (Some local machine shop should be able to put it in a lsth and sort it out for you for next to nothing. )

. (Some local machine shop should be able to put it in a lsth and sort it out for you for next to nothing. )

#24

Rear FC suspension explained/demystified

This is a result of rebuilding and working with FC rear suspensions for the past 8 years. I'm seeing a lot of new drifting and other enthusiasts (even some old) having no idea what they are talking about and rely on the large range of info found all over the internet. Here is everything you need to know (There is other crazier stuff you can do like changing suspension points and total redesign but this is the average stuff anyone can do/have done)

Pink : DTSS Bushings. Fancy Mazda rear steering bushings that where designed to help with the limitations of semi trailing arm suspension. Works great when NEW and when running factory tire widths. Terrible in drifting as it will make the rear end dance all over during transitioning and when gripping hard with wider/stickier tires and 20 year old bushings car will be rear steer heavy and be awkward and unpredictable. I prefer the racing beat version over other delrin ones due to the metal insert. Solid aluminium is fine aswell. Be careful during install/removal as the knuckle can split. Mazdatrix has some, RacingBeat, PBM. Common part.

Blue : Lateral Rods. Holds the control arm in place as far as toe is concerned. Would recommend newer/aftermarket ones as the older ones can have slot in the balljoints and allow for the rear toe to wander. I had one get all sloppy and allow for 5-10deg in toe change. You can use them to adjust tow aswell but its moreso meant to adjust the dynamic tow with your ride height change. When you lower/slam your car the dynamic tow can change and this can help even it out. (OEM at mazdatrix or aftermarket at AWR or PBM)

Red: Control arm Links? / Jangle Rods. Determines the camber of the car at the specified ride height. Unless your running 14s and your frame is on the ground you can usually have these shortened enough to have 0 camber. Mazdatrix has adjustable ones and PBM has shorter ones. I usually opt for sorter ones to keep it simple. If you need/want adjust-ability then go all out. (NOTE: Changing the length of these links changes the axis of rotation of the control arm bushing and will cause binding/damage to solid/polyurethane bushings. If modifying these links it is highly recommended to get spherical control arm bushings or stay with the stock rubber ones.)

White: Control arm Bushing. This is where toe is traditionally set. There is an eccentric bolt that allows for toe to be adjusted. most people set to zero, some like a bit of toe out as the FC rear suspension toes in under accel or they like the back end to be "happier" for when drifting. You can use stock bushing and still be able to adjust camber with the jangle rods as the rubber bushings have lots of play but i wouldn't recommend it as it makes them rotate way out of axis. Spherical bushing is the way to go if you want to adjust camber. (Via the jangle rods) I don't know if anyone else makes them anymore. (I have old MMR ones, but they are discontinued, and I have energy ones for the stock jangle rods) I know PBM makes spherical ones now.

Grey: Subframe stay/mount. Factory subframe bushings have lots of compliance so this is here to have a physical limit to the subframe deflection. Some people use this to adjust camber by pulling on the entire subframe. When doing it this way with stock subframe bushings you'll have uneven camber due to the offset location. In reality it is a terrible way to adjust camber and just a cheap way. Can be removed all together if you have solid subframe mounts or left in place for peace of mind. You can find these all over the internet. Dont waste your money. But hey, its your money.

Yellow: Subframe mounts. PMB makes weird moving ones. Its a feature that adds unnecessary play/another degree of freedom in your subframe. You can get the PBM diff mounts and just drill them to 20mm to fit the subframe studs. Or get any other solid subframe mount. Adjusting camber by cranking on the subframe is terrible way to do it. Not saying you cant, just saying you prolly shouldn't. Hard to find these anymore in solid form.

Green star!! : Front subframe mount. Bane of all FC owners. Break all the time or are broken and you just can't tell anymore/ignore it. The one in my turbo car wasn't broken but had so much compliance that the diff would actually move enough to hit things. Unless you have solid rear mounts dont waste your time and solidly mount this. I have seen some hokey "fixes" to this mount over the years from pinion snubs to complete mount redesigns. Honestly easiest way is to have the stock mount boxed in and welded. Reinforce the mounting tab on the subframe because that is the next thing to go. Pinion snubbers "work" sortof. The floor above is thin and not reinforced by anything so I doubt it will do anything other then delay the inevitable. If you use a solid front mount and still have stock rears then the diff will pop out of the subframe no matter how tight you put it. Its slotted so nothing is really holding it down. I had to cut an "access hole" in my floor to put it back into place after every run at an event. (Drifting an n/a car but the clutch kicks alone where enough) Solid mounting the diff seems to be the only way to help alleviate the front mount problems. Would recommend solid mounting diff to everyone regardless of driving style. Solid mounted it on my street car, I don't hear anything with my quiet exhaust. If you do then change your diff oil. (You may still hear some diff noise at a certain RPM/gear but its the nature of the beast. Drive your corolla/civic if your sensitive to these noises)

(People have argued that you can change camber with the rear camber adjuster. I'm not saying you cant, just recommending you don't.

People have also argued that the PBM subframe bushings are "solid as hell". Thats fine, but I'd rather not have an extra point that can potentially/is moving when I setup my suspension. I want it solid, with as little moving parts/adjustment areas as possible. Keeping it simple is key to eliminate as many variables as possible. Even "solid" bushings/mounts deflect to a certain degree.

Please feel free to add suppliers

86-92 Suspension Parts

Suspension Components - 1986-92 Mazda RX-7 Performance Parts

Multilink and Steering Angle for FC - Parts Shop MAX

AWR's E-Production parts for RX-7

This is a result of rebuilding and working with FC rear suspensions for the past 8 years. I'm seeing a lot of new drifting and other enthusiasts (even some old) having no idea what they are talking about and rely on the large range of info found all over the internet. Here is everything you need to know (There is other crazier stuff you can do like changing suspension points and total redesign but this is the average stuff anyone can do/have done)

Pink : DTSS Bushings. Fancy Mazda rear steering bushings that where designed to help with the limitations of semi trailing arm suspension. Works great when NEW and when running factory tire widths. Terrible in drifting as it will make the rear end dance all over during transitioning and when gripping hard with wider/stickier tires and 20 year old bushings car will be rear steer heavy and be awkward and unpredictable. I prefer the racing beat version over other delrin ones due to the metal insert. Solid aluminium is fine aswell. Be careful during install/removal as the knuckle can split. Mazdatrix has some, RacingBeat, PBM. Common part.

Blue : Lateral Rods. Holds the control arm in place as far as toe is concerned. Would recommend newer/aftermarket ones as the older ones can have slot in the balljoints and allow for the rear toe to wander. I had one get all sloppy and allow for 5-10deg in toe change. You can use them to adjust tow aswell but its moreso meant to adjust the dynamic tow with your ride height change. When you lower/slam your car the dynamic tow can change and this can help even it out. (OEM at mazdatrix or aftermarket at AWR or PBM)

Red: Control arm Links? / Jangle Rods. Determines the camber of the car at the specified ride height. Unless your running 14s and your frame is on the ground you can usually have these shortened enough to have 0 camber. Mazdatrix has adjustable ones and PBM has shorter ones. I usually opt for sorter ones to keep it simple. If you need/want adjust-ability then go all out. (NOTE: Changing the length of these links changes the axis of rotation of the control arm bushing and will cause binding/damage to solid/polyurethane bushings. If modifying these links it is highly recommended to get spherical control arm bushings or stay with the stock rubber ones.)

White: Control arm Bushing. This is where toe is traditionally set. There is an eccentric bolt that allows for toe to be adjusted. most people set to zero, some like a bit of toe out as the FC rear suspension toes in under accel or they like the back end to be "happier" for when drifting. You can use stock bushing and still be able to adjust camber with the jangle rods as the rubber bushings have lots of play but i wouldn't recommend it as it makes them rotate way out of axis. Spherical bushing is the way to go if you want to adjust camber. (Via the jangle rods) I don't know if anyone else makes them anymore. (I have old MMR ones, but they are discontinued, and I have energy ones for the stock jangle rods) I know PBM makes spherical ones now.

Grey: Subframe stay/mount. Factory subframe bushings have lots of compliance so this is here to have a physical limit to the subframe deflection. Some people use this to adjust camber by pulling on the entire subframe. When doing it this way with stock subframe bushings you'll have uneven camber due to the offset location. In reality it is a terrible way to adjust camber and just a cheap way. Can be removed all together if you have solid subframe mounts or left in place for peace of mind. You can find these all over the internet. Dont waste your money. But hey, its your money.

Yellow: Subframe mounts. PMB makes weird moving ones. Its a feature that adds unnecessary play/another degree of freedom in your subframe. You can get the PBM diff mounts and just drill them to 20mm to fit the subframe studs. Or get any other solid subframe mount. Adjusting camber by cranking on the subframe is terrible way to do it. Not saying you cant, just saying you prolly shouldn't. Hard to find these anymore in solid form.

Green star!! : Front subframe mount. Bane of all FC owners. Break all the time or are broken and you just can't tell anymore/ignore it. The one in my turbo car wasn't broken but had so much compliance that the diff would actually move enough to hit things. Unless you have solid rear mounts dont waste your time and solidly mount this. I have seen some hokey "fixes" to this mount over the years from pinion snubs to complete mount redesigns. Honestly easiest way is to have the stock mount boxed in and welded. Reinforce the mounting tab on the subframe because that is the next thing to go. Pinion snubbers "work" sortof. The floor above is thin and not reinforced by anything so I doubt it will do anything other then delay the inevitable. If you use a solid front mount and still have stock rears then the diff will pop out of the subframe no matter how tight you put it. Its slotted so nothing is really holding it down. I had to cut an "access hole" in my floor to put it back into place after every run at an event. (Drifting an n/a car but the clutch kicks alone where enough) Solid mounting the diff seems to be the only way to help alleviate the front mount problems. Would recommend solid mounting diff to everyone regardless of driving style. Solid mounted it on my street car, I don't hear anything with my quiet exhaust. If you do then change your diff oil. (You may still hear some diff noise at a certain RPM/gear but its the nature of the beast. Drive your corolla/civic if your sensitive to these noises)

(People have argued that you can change camber with the rear camber adjuster. I'm not saying you cant, just recommending you don't.

People have also argued that the PBM subframe bushings are "solid as hell". Thats fine, but I'd rather not have an extra point that can potentially/is moving when I setup my suspension. I want it solid, with as little moving parts/adjustment areas as possible. Keeping it simple is key to eliminate as many variables as possible. Even "solid" bushings/mounts deflect to a certain degree.

Please feel free to add suppliers

86-92 Suspension Parts

Suspension Components - 1986-92 Mazda RX-7 Performance Parts

Multilink and Steering Angle for FC - Parts Shop MAX

AWR's E-Production parts for RX-7

#25

Engine, Not Motor

iTrader: (1)

Join Date: Feb 2001

Location: London, Ontario, Canada

Posts: 29,789

Likes: 0

Received 108 Likes

on

91 Posts

Recommend solid mounting the diff and/or subframe to everyone?!

Any solid mounted diff or subframe car I have driven or has sounded like a bag of spanners being dragged down a gravel road. Solid bushings transmit every little noise the drivetrain makes right to the big resonating chamber at the rear of the car. In my opinion it's possibly the worst mod one can make on a street car. Right up there with removing the sound deadening, removing the cold start cam and/or BAC, or running a straight pipe from the header to a dump in front of the rear drivers tire.

Now I'm sure there are people out there with higher tolerances for driving a tin can than I, in fact I know it, because some of these people with the aforementioned mods seem to have no issue with them.

However I'd wager that most would get very tired of driving around with solid mounts after a short while.

There are owners of 100% track cars (trailered to the track) who have complained to me that their solid diff/subframe cars are too tiring to drive for extended periods on the track and have subsequently switched to competition rubber mounts. They are faster because they are happier.

I just want to keep people reading this topic from making a very annoying mistake.

In my opinion, solid suspension mounts are not suitable for street car use.

Any solid mounted diff or subframe car I have driven or has sounded like a bag of spanners being dragged down a gravel road. Solid bushings transmit every little noise the drivetrain makes right to the big resonating chamber at the rear of the car. In my opinion it's possibly the worst mod one can make on a street car. Right up there with removing the sound deadening, removing the cold start cam and/or BAC, or running a straight pipe from the header to a dump in front of the rear drivers tire.

Now I'm sure there are people out there with higher tolerances for driving a tin can than I, in fact I know it, because some of these people with the aforementioned mods seem to have no issue with them.

However I'd wager that most would get very tired of driving around with solid mounts after a short while.

There are owners of 100% track cars (trailered to the track) who have complained to me that their solid diff/subframe cars are too tiring to drive for extended periods on the track and have subsequently switched to competition rubber mounts. They are faster because they are happier.

I just want to keep people reading this topic from making a very annoying mistake.

In my opinion, solid suspension mounts are not suitable for street car use.

The following users liked this post:

CrispyRX7 (11-16-19)