Creative and mechanical minds wanted - Differential Puzzel

#1

Boosted 7

Thread Starter

Hey guys,

Here a quick background, I have a turbo engine, with a custom made aluminum driveshaft, I recently blew the N/A Open Differential, and replaced it with the S4 TII LSD. Installation was a breeze untill i realized that the bolt circle on the LSD Companion flange was larger than the N/A flange, and thus my expensive and pretty driveshaft wont mate up!

I called the drive shaft shop, they can order me a new T2 driveshaft flange along with a larger yoke & U-joint for around $200. This is pretty pricey!

Then i threw around the idea of just redrilling the smaller bolt circle onto the TII Flange, but i'm concerned about vibration and resulting balance issues.

So then i got to thinking, maybe i can just use the N/A companion flange on the T2 LSD and be able to use my current driveshaft. And when i did some dissassembling heres what i found...

The Companion flanges are different lengths. While they are both the same diameter, and oil seal sizes are the same, the turbo flange is .3 of an inch longer. So I took apart the N/A differential, to see if i could get away with just using the shorter flange and calling it a day.

heres what i found...

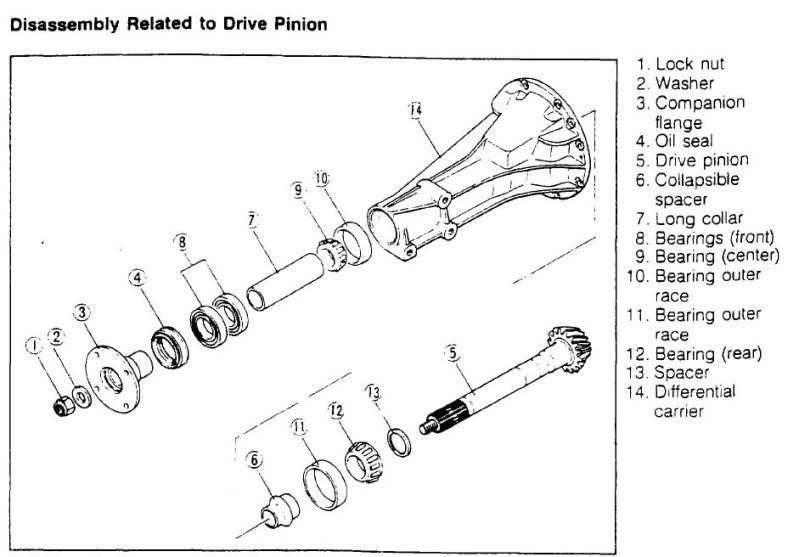

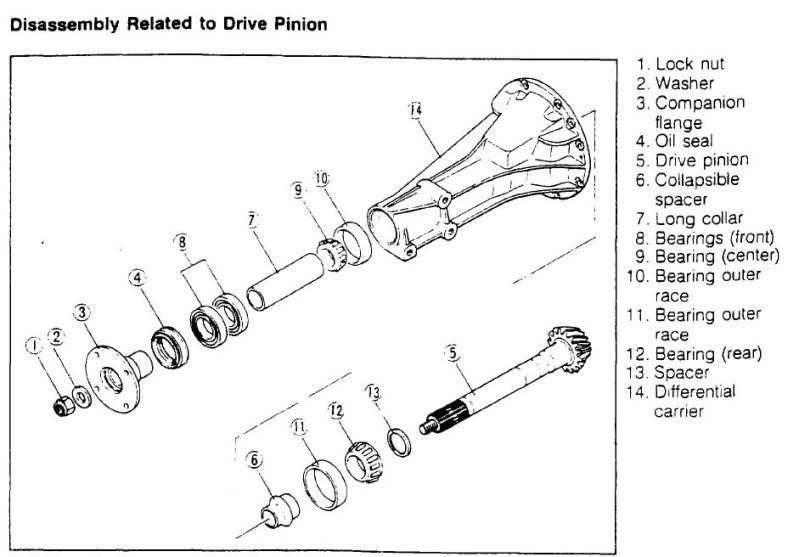

So the companion flange pushes against the "long Collar", and the long colar pushes against the center bearing. As shown in this diagram...

So my puzzel is this: Can i simply remove the assumeably shorter long collar from the LSD, and replace it with the Longer one from the N/A in order to use the N/A Companion flange?

Can anyone think of why these parts would be of different lengths in both applications, and if it could cause me problems down the line?

Should I give it a shot, or should i just shell out $200 to do it the right way? or is redrilling the flange an option also?

Thanks Guys!

Here a quick background, I have a turbo engine, with a custom made aluminum driveshaft, I recently blew the N/A Open Differential, and replaced it with the S4 TII LSD. Installation was a breeze untill i realized that the bolt circle on the LSD Companion flange was larger than the N/A flange, and thus my expensive and pretty driveshaft wont mate up!

I called the drive shaft shop, they can order me a new T2 driveshaft flange along with a larger yoke & U-joint for around $200. This is pretty pricey!

Then i threw around the idea of just redrilling the smaller bolt circle onto the TII Flange, but i'm concerned about vibration and resulting balance issues.

So then i got to thinking, maybe i can just use the N/A companion flange on the T2 LSD and be able to use my current driveshaft. And when i did some dissassembling heres what i found...

The Companion flanges are different lengths. While they are both the same diameter, and oil seal sizes are the same, the turbo flange is .3 of an inch longer. So I took apart the N/A differential, to see if i could get away with just using the shorter flange and calling it a day.

heres what i found...

So the companion flange pushes against the "long Collar", and the long colar pushes against the center bearing. As shown in this diagram...

So my puzzel is this: Can i simply remove the assumeably shorter long collar from the LSD, and replace it with the Longer one from the N/A in order to use the N/A Companion flange?

Can anyone think of why these parts would be of different lengths in both applications, and if it could cause me problems down the line?

Should I give it a shot, or should i just shell out $200 to do it the right way? or is redrilling the flange an option also?

Thanks Guys!

#3

Boosted 7

Thread Starter

Just as an update. the Long collar piece is much shorter than expected. the bearing size inside must be larger in the turbo unit. So the Companion flanges are in no way interchangable.

What i've done tho it had the appropriate pilot hole machined into the TII flange and the N/A bolt circle drilled for $40, works for me!

What i've done tho it had the appropriate pilot hole machined into the TII flange and the N/A bolt circle drilled for $40, works for me!

#6

In search of turbo...

Join Date: Jul 2008

Location: Indiana

Posts: 102

Likes: 0

Received 0 Likes

on

0 Posts

it's 2 ltretes taht wree anlcidlcenty rsereved. Taht brleay qlueaifis as a sleilnpg mtskaie. Even tghuoh msot of the lrtetes in tsehe wdors are not orerded crtoercrly you can sltil raed tehm at a filray ispevirmse pcae and ctpelmolpey usadnrtend tiher mnaieng as wlel as the mianeng of the snetcene can you not?

Matty's first 1st Gen was kind enough to put some very valuable info here and you make fun of him for something as simple as that?

-Pat

#7

Senior Member

iTrader: (7)

Join Date: Jul 2008

Location: Seneca, SC

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

Good thought but I think you went the wrong way. Just change the U joint and flange on the drive shaft side. And before you say it's not rebuildable, let me tell you it is. It just takes a good drive shaft shop. I've seen a stock one rebuilt.

I've done this twice, the first time I spent 100 bucks and let the guy cut and weld the whole U joint and flange assemble because I was using a custom length any way. The second time I had it easy because I had a mazdatrix turbo to NA shaft. I called up mazdatrix and kicked out like $60 bucks and got a flange. All I had to do was take apart the u-joint and reassemble.

You will spend more than that if you change all the seals, crush washers, and shims you should change when you pop a diff open.

Just my 2 cents.

I've done this twice, the first time I spent 100 bucks and let the guy cut and weld the whole U joint and flange assemble because I was using a custom length any way. The second time I had it easy because I had a mazdatrix turbo to NA shaft. I called up mazdatrix and kicked out like $60 bucks and got a flange. All I had to do was take apart the u-joint and reassemble.

You will spend more than that if you change all the seals, crush washers, and shims you should change when you pop a diff open.

Just my 2 cents.

Trending Topics

#8

Yeah, some ******** ON HERE have been flooting about saying "you can change out that plate and yada, yada"

You know, for running an n/a driveshaft on a turbo diff, right?

Boy, was i pissed when i had both peices out. The good news is i now have my own 3 jaw puller tool instead of renting the autoparts store **** all the time....

Drilling the plate works every time to make it "universal".

You know, for running an n/a driveshaft on a turbo diff, right?

Boy, was i pissed when i had both peices out. The good news is i now have my own 3 jaw puller tool instead of renting the autoparts store **** all the time....

Drilling the plate works every time to make it "universal".

#9

Senior Member

iTrader: (7)

Join Date: Jul 2008

Location: Seneca, SC

Posts: 352

Likes: 0

Received 0 Likes

on

0 Posts

Yeah, some ******** ON HERE have been flooting about saying "you can change out that plate and yada, yada"

You know, for running an n/a driveshaft on a turbo diff, right?

Boy, was i pissed when i had both peices out. The good news is i now have my own 3 jaw puller tool instead of renting the autoparts store **** all the time....

Drilling the plate works every time to make it "universal".

You know, for running an n/a driveshaft on a turbo diff, right?

Boy, was i pissed when i had both peices out. The good news is i now have my own 3 jaw puller tool instead of renting the autoparts store **** all the time....

Drilling the plate works every time to make it "universal".

Thread

Thread Starter

Forum

Replies

Last Post