Breaking S5 intermediate housings at the pass side motor mount bolt holes

#1

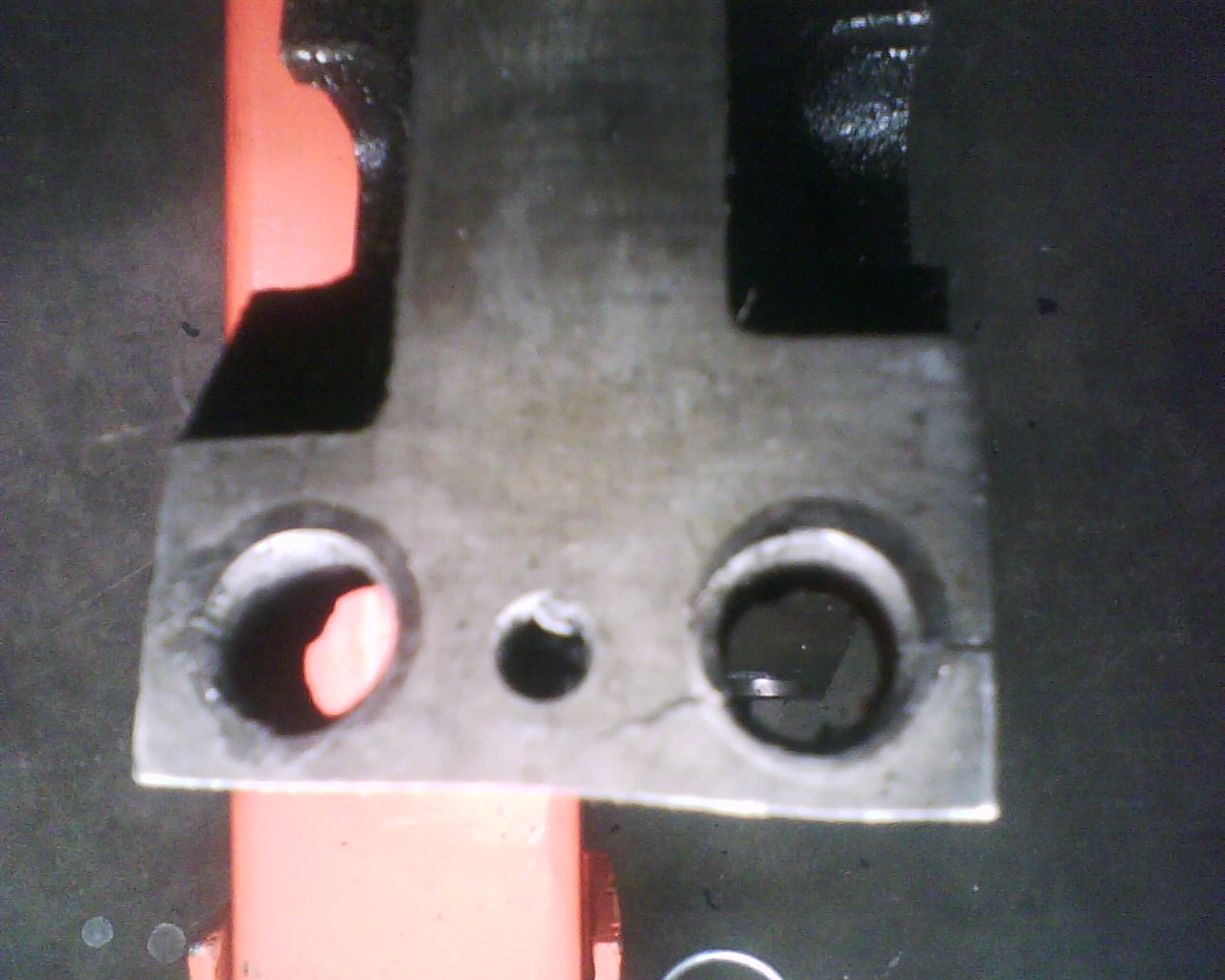

Breaking S5 intermediate housings at the pass side motor mount bolt holes

When my first S5 TII intermediate housing cracked at the passenger side motor mount holes I figured that I must not have cleaned out the threads well enough and it cracked torquing the motor mount bolts down.

I just found I have broken my second S5 intermediate housing at the passenger side motor mount holes.

I have Mazda Comp motor mounts, trans mounts, diff/subframe mounts, pinion snubber and a torque arm from the alternator mount on the waterpump housing to the passenger strut mount.

I am only making a little over 300ft/lbs of torque- nothing monstrous.

I have never used real drag slicks- just 275 Nitto NT01.

I am wondering if the torque arm is somehow concentrating forces onto the passenger motor mount?

You can see the torque arm has a 45deg bend and mounts off a long bolt with spacer to the strut bar. I would think this gives it some give, but perhaps I need more give.

Has anyone else encountered this problem?

I just found I have broken my second S5 intermediate housing at the passenger side motor mount holes.

I have Mazda Comp motor mounts, trans mounts, diff/subframe mounts, pinion snubber and a torque arm from the alternator mount on the waterpump housing to the passenger strut mount.

I am only making a little over 300ft/lbs of torque- nothing monstrous.

I have never used real drag slicks- just 275 Nitto NT01.

I am wondering if the torque arm is somehow concentrating forces onto the passenger motor mount?

You can see the torque arm has a 45deg bend and mounts off a long bolt with spacer to the strut bar. I would think this gives it some give, but perhaps I need more give.

Has anyone else encountered this problem?

#3

you're probably right about it being the torque arm, i have never seen a similar failure yet.

ditch it and let the motor do what it wants/needs to.

if worried about the mounts ripping something i have done in the past and plan to make still are stainless steel straps that go over the mounts, similar to how the REW mounts are to keep the mounts from deflecting too much and ripping the rubber on these POS 2nd gen mounts. haven't pulled my mounts off to inspect and see how they have been doing over the past several years yet before i consider making them.

in all honesty i hate torque braces, they seem good on paper but in reality they are more harmful than beneficial unless it has give like a hydraulic version.

ditch it and let the motor do what it wants/needs to.

if worried about the mounts ripping something i have done in the past and plan to make still are stainless steel straps that go over the mounts, similar to how the REW mounts are to keep the mounts from deflecting too much and ripping the rubber on these POS 2nd gen mounts. haven't pulled my mounts off to inspect and see how they have been doing over the past several years yet before i consider making them.

in all honesty i hate torque braces, they seem good on paper but in reality they are more harmful than beneficial unless it has give like a hydraulic version.

Last edited by RotaryEvolution; 02-02-12 at 10:15 AM.

Thread

Thread Starter

Forum

Replies

Last Post

rx8volks

Canadian Forum

0

08-11-15 10:30 PM