BDC motor teardown

#1

Wanker Club

Thread Starter

iTrader: (3)

Join Date: Sep 2002

Location: Dallas

Posts: 293

Likes: 0

Received 0 Likes

on

0 Posts

BDC motor teardown

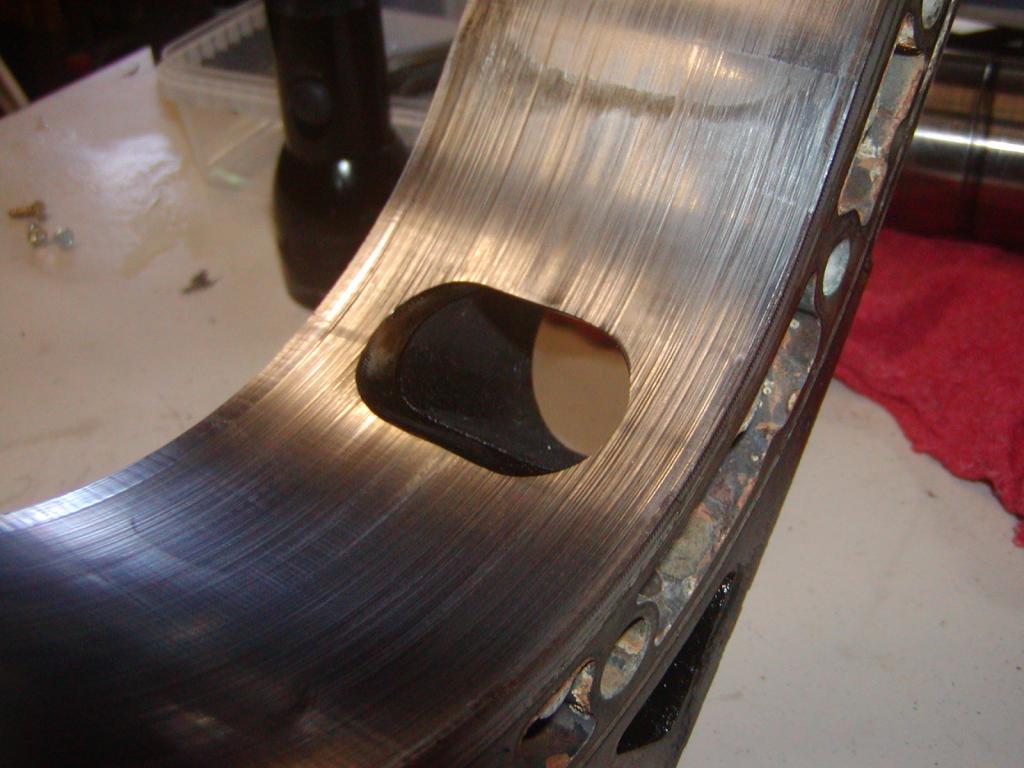

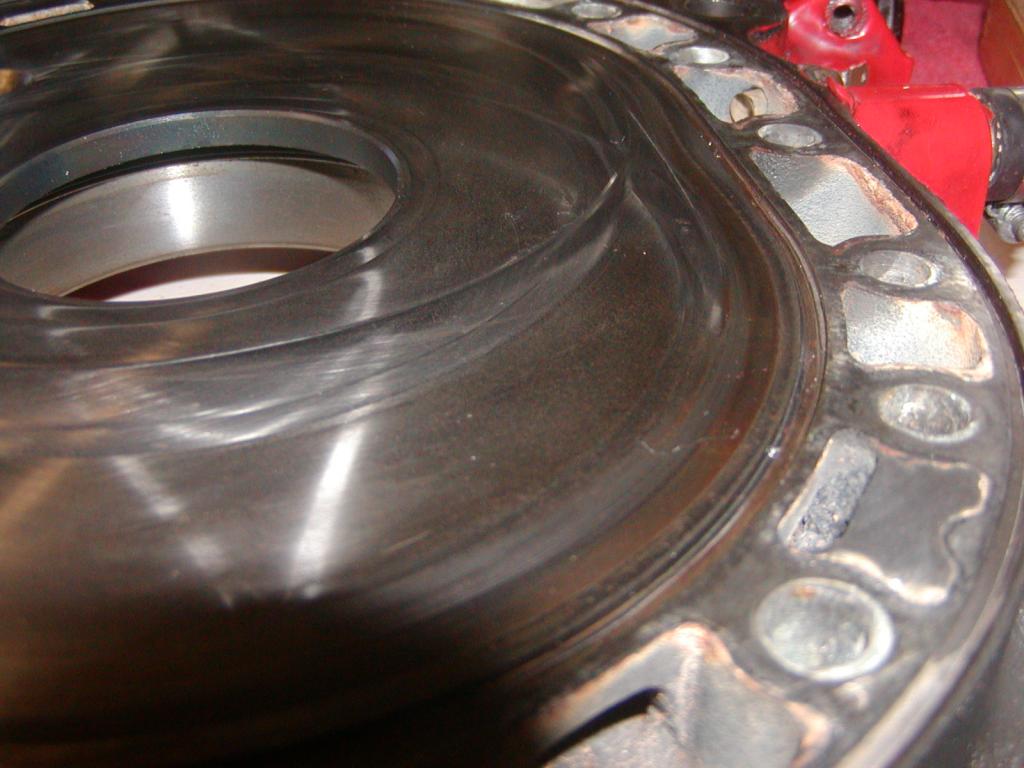

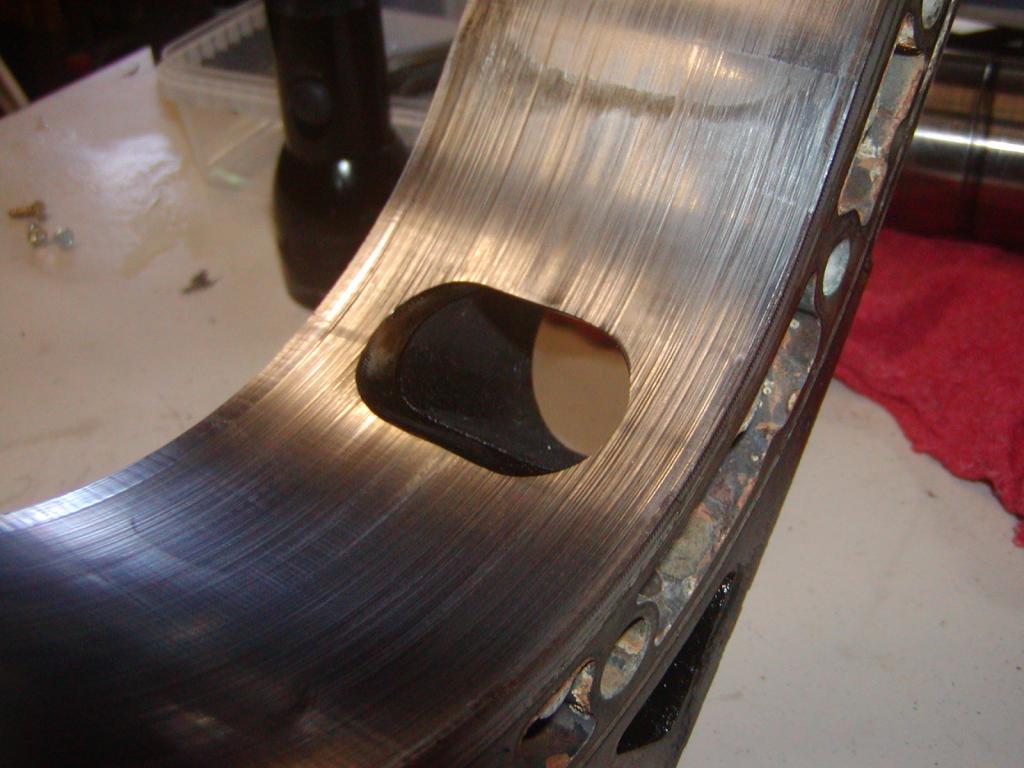

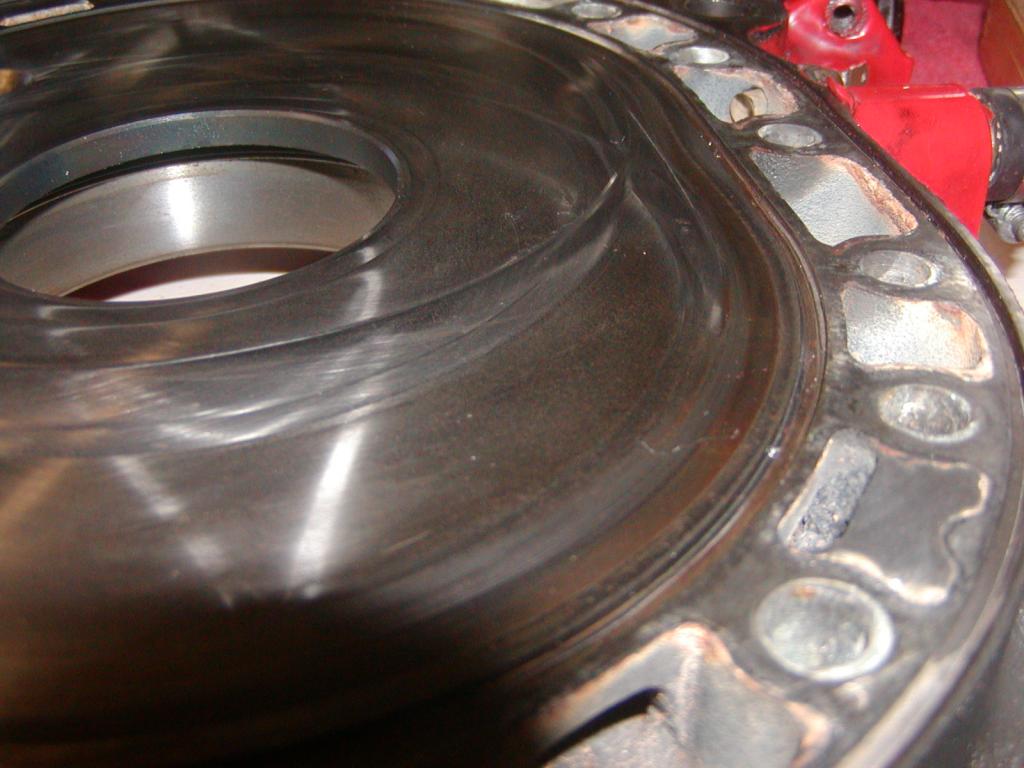

Posting this for a pal. They are trying to figure out what caused the scars on everything. Bearings are within spec. All seals were intact.

Motor is a BDC build from maybe 2005. Bridgeport and running 15-18psi, about 450rwhp conservative tune from Rotary Performance. Vac hose came off the wastegate at one time and it may have overboosted. Motor still ran but over time got hard to start and rear rotor was low on compression.

Motor was not studded or doweled.

Any ideas what happened to this motor? Pics are rear rotor and housing, front is similar but not as bad.

Motor is a BDC build from maybe 2005. Bridgeport and running 15-18psi, about 450rwhp conservative tune from Rotary Performance. Vac hose came off the wastegate at one time and it may have overboosted. Motor still ran but over time got hard to start and rear rotor was low on compression.

Motor was not studded or doweled.

Any ideas what happened to this motor? Pics are rear rotor and housing, front is similar but not as bad.

#5

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

what kind of apex seals are in it?

#7

The rough surface on the rotor face is due to shaft flex, the rotor has been physically contacting the rotor housing at very high rpm...the rotors are too heavy for the rpm it's been spinning to.

Normally you only see this (in streetcars) in engines with one or more bad bearings, allowing enough play in the eshaft for the rotor to touch. However it can also happen in an engine with good bearings that's being spun too fast for the rotor weight.

The rough surface on the rotor housings is most likely due to a hard aftermarket apex seal being run, such as the rotary aviation or similar. It's well and fine to produce an apex seal made of a harder blend of steel and call them "unbreakable" but guess what? They're now a lot harder than the rotor housing surface and will chew into it.

Mazda spent a LOT of time and money back in the 60s and 70s R&D'ing this issue to find the right set of materials to work together, so that neither would prematurely wear out or wear the other out. The apex seal is obviously a wear item. Believe it or not the rotor housing is also a wear item. If they had made the housing of a harder material that would not wear so much, the apex seals would have taken more abuse and would have worn prematurely. It works vice versa as well. Mazda has built the rotary with a balance in material hardness between the apex seals and rotor housing surface...if you alter one of those materials' hardness properties significantly you'll change the way that the other wears.

I have seen numerous similar engines with aftermarket apex seals that wear housings in this way. This is why I try to be a little more picky about what I use, either atkins or oem mazda.

Back a few years ago when I was trying out the cermet coated rotor housings I also noticed that they were EATING the steel apex seals because the ceramic surface was harder than the steel apex seal. I tore down one engine that supposedly had about 8-10k miles on it and the apex seals were worn down to 1/3 their original size. The engine had no compression because there was zero spring tension left to keep the seal in contact with the housing...all of the seal had worn away. This was wear that far exceeds what I'd normally see in a stock 200k mile engine.

I also see no bevel on the closing side of that exhaust port...which will eat into the center area of the apex seal over time and cause compression to be lowered as the seal wears in a concave pattern and no longer be flat. The seal flexes into the port hole as it passes over it at high rpm, and you need a 1-2mm bevel to gently bring the seal back out of the port as it passes over the closing edge or you'll get this wear.

I bet if you measure the apex seals they're a bit more worn in the center than on the edges. I'd also like to know what the overall height of the apex seals are (do not measure the end tip where the spring retainers are) as well as the mileage of the engine.

I'm guessing you have some wear/grooving on the iron faces? It's hard to tell in that pic. If you have a channel cut around the outside edge of the iron adjacent to the rotor housing, then that is from the corner seals...odds are you were running aftermarket (hard) corner seals that ate into the softer irons. Another reason why I don't care for aftermarket corner seals unless you just have to run them for some reason.

Normally you only see this (in streetcars) in engines with one or more bad bearings, allowing enough play in the eshaft for the rotor to touch. However it can also happen in an engine with good bearings that's being spun too fast for the rotor weight.

The rough surface on the rotor housings is most likely due to a hard aftermarket apex seal being run, such as the rotary aviation or similar. It's well and fine to produce an apex seal made of a harder blend of steel and call them "unbreakable" but guess what? They're now a lot harder than the rotor housing surface and will chew into it.

Mazda spent a LOT of time and money back in the 60s and 70s R&D'ing this issue to find the right set of materials to work together, so that neither would prematurely wear out or wear the other out. The apex seal is obviously a wear item. Believe it or not the rotor housing is also a wear item. If they had made the housing of a harder material that would not wear so much, the apex seals would have taken more abuse and would have worn prematurely. It works vice versa as well. Mazda has built the rotary with a balance in material hardness between the apex seals and rotor housing surface...if you alter one of those materials' hardness properties significantly you'll change the way that the other wears.

I have seen numerous similar engines with aftermarket apex seals that wear housings in this way. This is why I try to be a little more picky about what I use, either atkins or oem mazda.

Back a few years ago when I was trying out the cermet coated rotor housings I also noticed that they were EATING the steel apex seals because the ceramic surface was harder than the steel apex seal. I tore down one engine that supposedly had about 8-10k miles on it and the apex seals were worn down to 1/3 their original size. The engine had no compression because there was zero spring tension left to keep the seal in contact with the housing...all of the seal had worn away. This was wear that far exceeds what I'd normally see in a stock 200k mile engine.

I also see no bevel on the closing side of that exhaust port...which will eat into the center area of the apex seal over time and cause compression to be lowered as the seal wears in a concave pattern and no longer be flat. The seal flexes into the port hole as it passes over it at high rpm, and you need a 1-2mm bevel to gently bring the seal back out of the port as it passes over the closing edge or you'll get this wear.

I bet if you measure the apex seals they're a bit more worn in the center than on the edges. I'd also like to know what the overall height of the apex seals are (do not measure the end tip where the spring retainers are) as well as the mileage of the engine.

I'm guessing you have some wear/grooving on the iron faces? It's hard to tell in that pic. If you have a channel cut around the outside edge of the iron adjacent to the rotor housing, then that is from the corner seals...odds are you were running aftermarket (hard) corner seals that ate into the softer irons. Another reason why I don't care for aftermarket corner seals unless you just have to run them for some reason.

Last edited by RotaryResurrection; 01-11-13 at 11:57 AM.

Trending Topics

#9

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

yep, its a balance, if you've ever torn apart a carbon seal engine, the rotor housings always look new (but aren't more ways to fail than just the chrome), because the seal is so soft.

i should take a pic between a steel seal 12A rotor housing and carbon, the steel seal engine is just f-ed, and the carbon seal engine looks great.

those look like Ra seals, you're lucky it ran as long as it did

i should take a pic between a steel seal 12A rotor housing and carbon, the steel seal engine is just f-ed, and the carbon seal engine looks great.

those look like Ra seals, you're lucky it ran as long as it did

#10

Everybody loves the aviation seals for some reason, though.

I think it's the price and the "unbreakable seal" claim. They're only about 50 bucks cheaper than atkins (a softer seal which won't eat up the housings) though, and maybe 200 cheaper than mazda OEM (which we know won't eat up the housings) but some people think that's too much expense for THEIR MOTOR WHICH THEY EXPECT TO LAST.

#11

Wanker Club

Thread Starter

iTrader: (3)

Join Date: Sep 2002

Location: Dallas

Posts: 293

Likes: 0

Received 0 Likes

on

0 Posts

Thanks Kevin for the awesome analysis.

This is indeed a BDC motor, “Spec X” half-bridge. Original owner (Tony Farkas) had it built 2002-2003, sold to a gent in Fla for a couple months, sold to me, sold to the current owner Dallas-Florida-Dallas-Dallas!

Engine has not been opened since the build, close to 10yrs now. It is this car:

Tony Farkas

It does look like over-rev but not sure when/how it could have happened, iirc the EMS was set to pull spark at 8500rpm or so.

Current owner is not on this forum so Q&A are being emailed back and forth. I think these are RA seals, I have the specs archived somewhere.

This is indeed a BDC motor, “Spec X” half-bridge. Original owner (Tony Farkas) had it built 2002-2003, sold to a gent in Fla for a couple months, sold to me, sold to the current owner Dallas-Florida-Dallas-Dallas!

Engine has not been opened since the build, close to 10yrs now. It is this car:

Tony Farkas

It does look like over-rev but not sure when/how it could have happened, iirc the EMS was set to pull spark at 8500rpm or so.

Current owner is not on this forum so Q&A are being emailed back and forth. I think these are RA seals, I have the specs archived somewhere.

#14

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,826

Received 2,594 Likes

on

1,842 Posts

Thanks Kevin for the awesome analysis.

This is indeed a BDC motor, “Spec X” half-bridge. Original owner (Tony Farkas) had it built 2002-2003, sold to a gent in Fla for a couple months, sold to me, sold to the current owner Dallas-Florida-Dallas-Dallas!

Engine has not been opened since the build, close to 10yrs now. It is this car:

Tony Farkas

It does look like over-rev but not sure when/how it could have happened, iirc the EMS was set to pull spark at 8500rpm or so.

Current owner is not on this forum so Q&A are being emailed back and forth. I think these are RA seals, I have the specs archived somewhere.

This is indeed a BDC motor, “Spec X” half-bridge. Original owner (Tony Farkas) had it built 2002-2003, sold to a gent in Fla for a couple months, sold to me, sold to the current owner Dallas-Florida-Dallas-Dallas!

Engine has not been opened since the build, close to 10yrs now. It is this car:

Tony Farkas

It does look like over-rev but not sure when/how it could have happened, iirc the EMS was set to pull spark at 8500rpm or so.

Current owner is not on this forum so Q&A are being emailed back and forth. I think these are RA seals, I have the specs archived somewhere.

#15

THIS.

Everybody loves the aviation seals for some reason, though.

I think it's the price and the "unbreakable seal" claim. They're only about 50 bucks cheaper than atkins (a softer seal which won't eat up the housings) though, and maybe 200 cheaper than mazda OEM (which we know won't eat up the housings) but some people think that's too much expense for THEIR MOTOR WHICH THEY EXPECT TO LAST.

Everybody loves the aviation seals for some reason, though.

I think it's the price and the "unbreakable seal" claim. They're only about 50 bucks cheaper than atkins (a softer seal which won't eat up the housings) though, and maybe 200 cheaper than mazda OEM (which we know won't eat up the housings) but some people think that's too much expense for THEIR MOTOR WHICH THEY EXPECT TO LAST.

Agree with the RA seals, however to be fair, its not really about the price difference, but more so of a just in case. I guess its better to have to rebuild an engine because the apex seals ate the rotor housings, than having to replace a rotor, housing and maybe an iron due to OEM seals causing havoc.

#17

Wanker Club

Thread Starter

iTrader: (3)

Join Date: Sep 2002

Location: Dallas

Posts: 293

Likes: 0

Received 0 Likes

on

0 Posts

9yrs is pretty good for a build, yes?  This motor/car has been through a lot: test mule for BDC, auto-x and drag toy, dd duty, most recently Tx Mile and HPDE whip. It survived the 110F track day which cooked my GTUs and caused a few drivers to suffer heat exhaustion. Most recently it was annoying the Vette owners group at a local track. Always a good time.

This motor/car has been through a lot: test mule for BDC, auto-x and drag toy, dd duty, most recently Tx Mile and HPDE whip. It survived the 110F track day which cooked my GTUs and caused a few drivers to suffer heat exhaustion. Most recently it was annoying the Vette owners group at a local track. Always a good time.

This motor/car has been through a lot: test mule for BDC, auto-x and drag toy, dd duty, most recently Tx Mile and HPDE whip. It survived the 110F track day which cooked my GTUs and caused a few drivers to suffer heat exhaustion. Most recently it was annoying the Vette owners group at a local track. Always a good time.

This motor/car has been through a lot: test mule for BDC, auto-x and drag toy, dd duty, most recently Tx Mile and HPDE whip. It survived the 110F track day which cooked my GTUs and caused a few drivers to suffer heat exhaustion. Most recently it was annoying the Vette owners group at a local track. Always a good time.

#18

Wanker Club

Thread Starter

iTrader: (3)

Join Date: Sep 2002

Location: Dallas

Posts: 293

Likes: 0

Received 0 Likes

on

0 Posts

Some more info:

The engine is an updated Series 5, with a series 4 lower compression rotor with following modify.

Atkins solid corner seals, worn down to 0.258 - 0.265 (spec. 0.268 - 0.276)

Rotary aviation 2pc 2 mm apex seals, (ding ding ding!) worn down to 0.290 along the length. (spec. 0.315 limit 0.256)

FD3 S corner seals and springs.

Racing beat 80-85 oil pressure regulator

Crankshaft oil jets changed to Weber-style 2.2mm air jets

OMP blocked off and running premix. Using Idemitsu syn. blend premix 1.5 oz/gal.

Rotary Aviation o-ring kit.

The Engine were supposed to have less than 2K miles in 2005 ( Chassis 200K )

We have used the car twice a year for the last 4 years at Texas Mile and produced 170+ mph. ( about 10 - 15 passes per race)

Rev limiter warning set at 7500 RPM

We have about 0.002 deep scars on the iron faces, to much for lapping !!??

The engine is an updated Series 5, with a series 4 lower compression rotor with following modify.

Atkins solid corner seals, worn down to 0.258 - 0.265 (spec. 0.268 - 0.276)

Rotary aviation 2pc 2 mm apex seals, (ding ding ding!) worn down to 0.290 along the length. (spec. 0.315 limit 0.256)

FD3 S corner seals and springs.

Racing beat 80-85 oil pressure regulator

Crankshaft oil jets changed to Weber-style 2.2mm air jets

OMP blocked off and running premix. Using Idemitsu syn. blend premix 1.5 oz/gal.

Rotary Aviation o-ring kit.

The Engine were supposed to have less than 2K miles in 2005 ( Chassis 200K )

We have used the car twice a year for the last 4 years at Texas Mile and produced 170+ mph. ( about 10 - 15 passes per race)

Rev limiter warning set at 7500 RPM

We have about 0.002 deep scars on the iron faces, to much for lapping !!??

#19

Send the irons to chips motorsports for lapping *and renitriding*.

Replace the rotor housings or maybe check with goopy to see if they can be resurfaced (I would say not, and I'd just trash them and get another set rather than put more money into them and winding up with a still imperfect surface). Put a bevel on the exhaust port closing side.

Install different apex seals and mazda corner seals. I don't do a lot of high power racing oriented stuff, but in my experience it takes a LOT to break a corner seal, even a stock one.

Use OEM coolant seals.

Either lighten the s4 rotors or run s5+ rotors. Although if it has not been revving past 7500rpm I do not understand why it's had so much shaft flex.

Replace the rotor housings or maybe check with goopy to see if they can be resurfaced (I would say not, and I'd just trash them and get another set rather than put more money into them and winding up with a still imperfect surface). Put a bevel on the exhaust port closing side.

Install different apex seals and mazda corner seals. I don't do a lot of high power racing oriented stuff, but in my experience it takes a LOT to break a corner seal, even a stock one.

Use OEM coolant seals.

Either lighten the s4 rotors or run s5+ rotors. Although if it has not been revving past 7500rpm I do not understand why it's had so much shaft flex.

#21

BDC Motorsports

It is. I'd have to dig up the pictures but it was built I think in either late 2003 or early 2004. That engine went through a few builds and normally had a rotor housing or set of seals replacement. I didn't change the bearings, gears or shaft out. It had good S5 irons in it. During the last build if I remember right (I need to dig up old pictures) we changed it to the S4 rotor/counterweight assembly. I think. It's been a real long time.

#22

BDC Motorsports

March 8 2004 Build Pictures

Just dug the pictures up. It was built March 8 2004. I replaced bearings in it. I also used the Rotary Aviation o-ring kit in it. I don't use those anymore (stopped in Sept 2006). I had several engines fail with across-the-board, "blown head gasket" type symptoms with consumption of water.

Exhaust port bevel, I didn't do it back then. Started somewhere in 2005 I think. Got the idea from looking at one of Judge Ito's ports and an explanation on it. I never saw evidence prior to it that any of the engines I'd done with the sharp closing edge caused an issue, but I figured since it was a few extra minutes on each port, it'd be worth doing by way of being cautious. Have done them ever since.

The port job I did on it was what I called a "spec-X". I had goofy names back then for things for personal use. I'll attach a couple of pictures of the port. The fact that this kind of secondary bridgeport lasted this long pretty much, for me, crushes the notion that they're unreliable. The iron bridge leftover was close to paper thing; far more aggressive that what I've normally done for customers in the past and for my own car.

I'm with Kevin on the explanation. Possibly too high RPM usage, bending crank. The rotating assembly was NOT balanced then as it wasn't something I started doing for another 2 1/2 yrs or so afterwards. The combination of the two may explain it.

Adding more photos shortly.

B

Exhaust port bevel, I didn't do it back then. Started somewhere in 2005 I think. Got the idea from looking at one of Judge Ito's ports and an explanation on it. I never saw evidence prior to it that any of the engines I'd done with the sharp closing edge caused an issue, but I figured since it was a few extra minutes on each port, it'd be worth doing by way of being cautious. Have done them ever since.

The port job I did on it was what I called a "spec-X". I had goofy names back then for things for personal use. I'll attach a couple of pictures of the port. The fact that this kind of secondary bridgeport lasted this long pretty much, for me, crushes the notion that they're unreliable. The iron bridge leftover was close to paper thing; far more aggressive that what I've normally done for customers in the past and for my own car.

I'm with Kevin on the explanation. Possibly too high RPM usage, bending crank. The rotating assembly was NOT balanced then as it wasn't something I started doing for another 2 1/2 yrs or so afterwards. The combination of the two may explain it.

Adding more photos shortly.

B

#24

BDC Motorsports

Send the irons to chips motorsports for lapping *and renitriding*.

Replace the rotor housings or maybe check with goopy to see if they can be resurfaced (I would say not, and I'd just trash them and get another set rather than put more money into them and winding up with a still imperfect surface). Put a bevel on the exhaust port closing side.

Replace the rotor housings or maybe check with goopy to see if they can be resurfaced (I would say not, and I'd just trash them and get another set rather than put more money into them and winding up with a still imperfect surface). Put a bevel on the exhaust port closing side.

Install different apex seals and mazda corner seals. I don't do a lot of high power racing oriented stuff, but in my experience it takes a LOT to break a corner seal, even a stock one.

Use OEM coolant seals.

Either lighten the s4 rotors or run s5+ rotors. Although if it has not been revving past 7500rpm I do not understand why it's had so much shaft flex.

B