Air to water intercooler

#1

Air to water intercooler

So with my custom v-mount that I've made, I'm running into 120°F intake temperatures. That's a LOT of heat soak, which tells me my hood is not properly drawing air through the intercooler, but instead causing a high pressure area on top of it. Here's the hood. It's a steel hood from a coupe that has a hole cut in it, with a vent from an Evo 8. Stupid, I know. It doesn't really look bad, but function is everything for me. This is obviously not functioning.

So, take 2. I just got another aluminum hood for my car, and thank GOD I'm so happy now. I absolutely HATE the steel hood on my turbo vert. So, now I'm going to have a completely stock-looking car from the outside, and I'm really excited about this. Now, on to what's really cool!

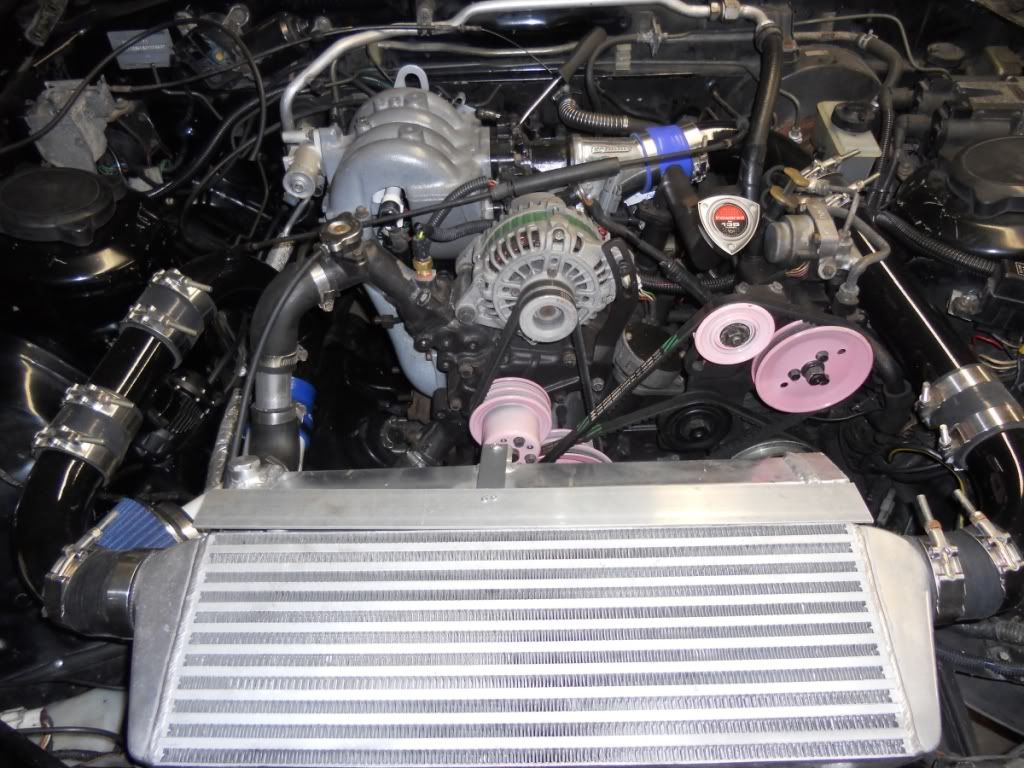

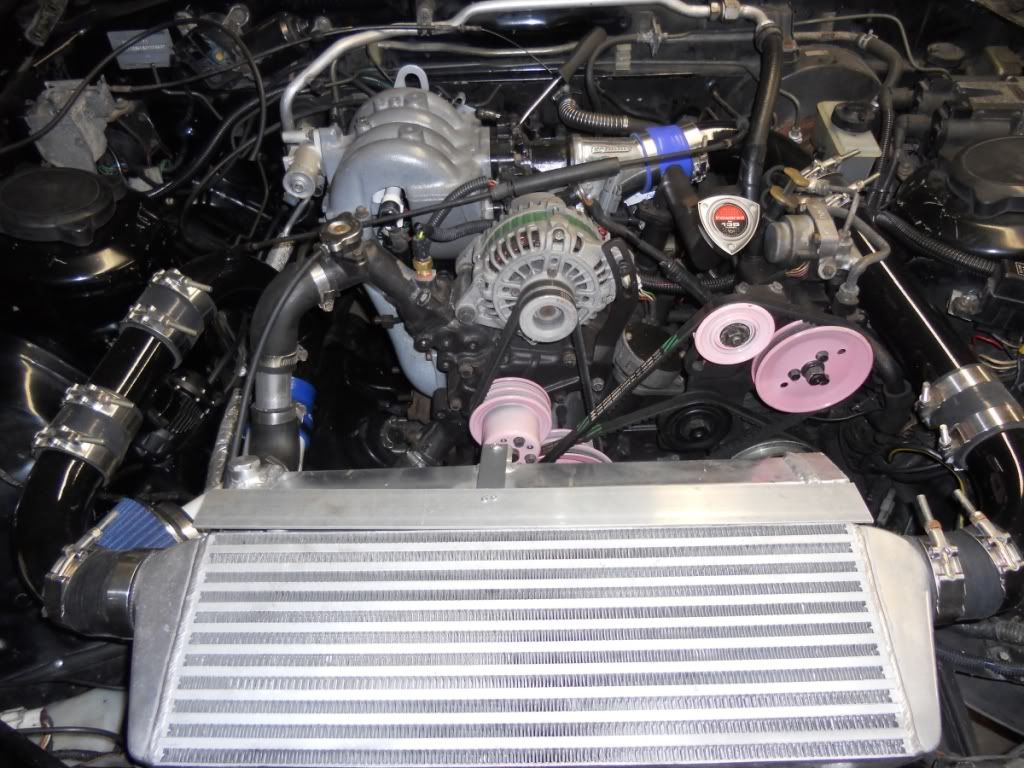

I'm going to be taking this exact same setup:

And I'm going to turn the regular air-to-air intercooler into an air to water intercooler! I figure that if I build an aluminum box around it with some 1/2" pipe nipples, plumb some hoses, get a little 12v water pump (not one of those high-volume water pumps, just something to circulate enough water) and a small radiator to fit up front and I'll be set!

Here's the catch. I can't weld aluminum. Yet. I saw Jackhild59 posted about this stuff a little while ago, and I got interested.

http://www.alumiweld.com/

It can be bought at Harbor Freight for around $15. It seemed pretty cool, so I bought a tube of it. I tried welding with it already, but haven't had any luck with my little plumber's propane torch. I'm going to try and get a mapp torch for it to see how things work out.

If anyone's got any pointers, let me know. Otherwise, follow along, and I'll keep posting results.

So, take 2. I just got another aluminum hood for my car, and thank GOD I'm so happy now. I absolutely HATE the steel hood on my turbo vert. So, now I'm going to have a completely stock-looking car from the outside, and I'm really excited about this. Now, on to what's really cool!

I'm going to be taking this exact same setup:

And I'm going to turn the regular air-to-air intercooler into an air to water intercooler! I figure that if I build an aluminum box around it with some 1/2" pipe nipples, plumb some hoses, get a little 12v water pump (not one of those high-volume water pumps, just something to circulate enough water) and a small radiator to fit up front and I'll be set!

Here's the catch. I can't weld aluminum. Yet. I saw Jackhild59 posted about this stuff a little while ago, and I got interested.

http://www.alumiweld.com/

It can be bought at Harbor Freight for around $15. It seemed pretty cool, so I bought a tube of it. I tried welding with it already, but haven't had any luck with my little plumber's propane torch. I'm going to try and get a mapp torch for it to see how things work out.

If anyone's got any pointers, let me know. Otherwise, follow along, and I'll keep posting results.

#2

Since you already have the backup hood- hence, nothing to lose- I propose an experiment.

I'm thinking that if you built a lip in front of the Evo vent, it'd create a low pressure area behind it

and increase extraction through the vent.

Getting the hood vent to work properly, which I think is the optimal solution, would be a shitton easier than what you're thinking of.

I'm thinking that if you built a lip in front of the Evo vent, it'd create a low pressure area behind it

and increase extraction through the vent.

Getting the hood vent to work properly, which I think is the optimal solution, would be a shitton easier than what you're thinking of.

#3

Replacing a busted wiper switch with a stock one would be a shitton easier than cobbling one together from a late-model car  That's why I do this sort of stuff. Not because it's easier, because it's different, and I also REALLY want my car to look as stock as possible on the outside.

That's why I do this sort of stuff. Not because it's easier, because it's different, and I also REALLY want my car to look as stock as possible on the outside.

But I'll give it a try. I've tried building a lip like you're talking about with my other, very badly busted aluminum hood. I'm not good with body work.

Looking at some of these kits online, it seems like they go way too far with what's necessary. I really can't see it needing a large heat exchanger (radiator) to get rid of the heat in the system. I'm thinking a small radiator from a motorcycle would suffice. And I see NO reason for a fan on this system. Really, how much heat is being generated in the intake charge when sitting still? I understand there's heat soak, but if there's a radiator keeping the intake charge cool, it'd be a stretch to use a fan. Although it probably couldn't hurt, I don't see it as necessary. And how about the water pump? It looks like people are using the kinds you use on a high performance engine. How much flow is really needed?

That's why I do this sort of stuff. Not because it's easier, because it's different, and I also REALLY want my car to look as stock as possible on the outside.

That's why I do this sort of stuff. Not because it's easier, because it's different, and I also REALLY want my car to look as stock as possible on the outside.But I'll give it a try. I've tried building a lip like you're talking about with my other, very badly busted aluminum hood. I'm not good with body work.

Looking at some of these kits online, it seems like they go way too far with what's necessary. I really can't see it needing a large heat exchanger (radiator) to get rid of the heat in the system. I'm thinking a small radiator from a motorcycle would suffice. And I see NO reason for a fan on this system. Really, how much heat is being generated in the intake charge when sitting still? I understand there's heat soak, but if there's a radiator keeping the intake charge cool, it'd be a stretch to use a fan. Although it probably couldn't hurt, I don't see it as necessary. And how about the water pump? It looks like people are using the kinds you use on a high performance engine. How much flow is really needed?

#7

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

http://www.turboneticsinc.com/node/83

So you realize that your proposed air/liquid intercooler will most likely cause higher inlet air temps than the 120°F that you are currently complaining about?

About 5-10 gpm.

http://www.depcopump.com/datasheets/...18510-000X.pdf

Trending Topics

#8

Rotary Enthusiast

iTrader: (2)

Join Date: May 2005

Location: E-L Netherlands

Posts: 1,165

Likes: 0

Received 0 Likes

on

0 Posts

Add proper ducting...

My v-mount produces intake temps of only max 10 degrees celcius higher then ambient temp.

My intercooler sits flush against the hood, without any real gaps.

On the bottom i made a kind of undertray, which keeps the hot air from the raidator going up before the end of the engine bay.

Hot air goes out below or out of the hood, without getting any chance to build up in the engine bay which would be the reason of heat soak.

Get the engine bay temps down, and your intake temps will follow

My v-mount produces intake temps of only max 10 degrees celcius higher then ambient temp.

My intercooler sits flush against the hood, without any real gaps.

On the bottom i made a kind of undertray, which keeps the hot air from the raidator going up before the end of the engine bay.

Hot air goes out below or out of the hood, without getting any chance to build up in the engine bay which would be the reason of heat soak.

Get the engine bay temps down, and your intake temps will follow

#9

Ok, ok. I know the hood's design is inferior, that's what I said in the original post. This whole air to water intercooler thing is an experiment anyways. I read up all about them, and from what it seems, there are Chinese knock-off companies that take regular bar and plate intercoolers and box them in like I'm doing. The efficiency is not as good as it could be, but it's still apparently better than air to air.

So I'm doing this anyways. It seems, though, that I'm having an issue trying to get this alumiweld stuff to work. I started with a regular plumber's propane torch, but it didn't get the intercooler hot enough. Then I got a Mapp/Oxy torch from Lowe's, but I STILL can't get the intercooler hot enough for the alumiweld to melt. There has to be something I'm doing wrong, but I'll keep trying.

So I'm doing this anyways. It seems, though, that I'm having an issue trying to get this alumiweld stuff to work. I started with a regular plumber's propane torch, but it didn't get the intercooler hot enough. Then I got a Mapp/Oxy torch from Lowe's, but I STILL can't get the intercooler hot enough for the alumiweld to melt. There has to be something I'm doing wrong, but I'll keep trying.

#10

The key with AlumniWeld is to get the metal (not the stick) to the right temperature. IIRC you want to heat the item you're welding and keep touching the rod to the piece (with the torch away) until the rod melts on its own. There are several videos on YouTube you might want to watch.

I suspect you're gonna have a tough time getting a water tight seal. You might be able to get a local radiator shop to do it for you. Although as cheap as FrozenBoost and CXRacing's A2W intercoolers are (this one is $108 shipped) I'm not sure it's worth the time trying to kludge yours up. Plus if your experiment fails you can go back to your current system.

A couple of thoughts on comments you've made.

My understanding is that high water flow is key. Convection is a primary way to exchange heat and that requires flow and turbulence. In a front engine car you won't have a lot of pressure loss from long hose runs so the bait well pump should be adequate although the Bosch pump that was designed for OEM A2W systems is a $100 delivered so I'm not sure I'd bother half-assing there. You will want to run at least 3/4" water hoses to reduce pressure loss though.

I don't know for sure but it seems to me that the motorcycle radiator was designed to keep an engine at 180 degrees where your goal with the A2W heat exchanger is to get it as close to ambient as possible. From my reading the two most important parts of an A2W intercooler systems are the pump (to maintain high flow @ 3-5 psi) and a large efficient heat exchanger. If you have those two pieces you don't need large volumes of water or storage tanks.

I would love to figure out how to put an A2W intercooler in place of the stock TMIC and make it looks like it belongs. Like this Celica GT4 that came with A2W from the factory.

Looking forward to see how your and Clokker's windmill tilting projects proceed!

I suspect you're gonna have a tough time getting a water tight seal. You might be able to get a local radiator shop to do it for you. Although as cheap as FrozenBoost and CXRacing's A2W intercoolers are (this one is $108 shipped) I'm not sure it's worth the time trying to kludge yours up. Plus if your experiment fails you can go back to your current system.

A couple of thoughts on comments you've made.

My understanding is that high water flow is key. Convection is a primary way to exchange heat and that requires flow and turbulence. In a front engine car you won't have a lot of pressure loss from long hose runs so the bait well pump should be adequate although the Bosch pump that was designed for OEM A2W systems is a $100 delivered so I'm not sure I'd bother half-assing there. You will want to run at least 3/4" water hoses to reduce pressure loss though.

I don't know for sure but it seems to me that the motorcycle radiator was designed to keep an engine at 180 degrees where your goal with the A2W heat exchanger is to get it as close to ambient as possible. From my reading the two most important parts of an A2W intercooler systems are the pump (to maintain high flow @ 3-5 psi) and a large efficient heat exchanger. If you have those two pieces you don't need large volumes of water or storage tanks.

I would love to figure out how to put an A2W intercooler in place of the stock TMIC and make it looks like it belongs. Like this Celica GT4 that came with A2W from the factory.

Looking forward to see how your and Clokker's windmill tilting projects proceed!

#11

Rotorhead

Join Date: Feb 2001

Location: Charlottesville, Virginia, USA

Posts: 9,136

Likes: 0

Received 39 Likes

on

33 Posts

After your experiment, I recommend that you replace your ruined air-air intercooler with a new air-air intercooler that has end tanks with inlets/outlets that point toward the firewall. This will reduce the bends, which in turn will reduce the pressure loss, resulting in slightly better temperatures and slightly better boost rise. Your current intercooler has end tanks with inlets/outlets that point 90 degrees to the firewall, requiring an additional 180 degrees (or in your case it looks like more than 180 degrees) of otherwise unnecessary bends that cause a reduction in performance. This is what you want:

#12

im doing the same thing, however im using a 2nd 2nd gen oil cooler for a water cooler and a resovour in the storage bin.

keep in mind, to heat up the water you will need a ton of thermal energy so the more water in the system, the longer it takes to heat up.

also, you need a radiator cap and coolant for the system so it can bleed out.

keep in mind, to heat up the water you will need a ton of thermal energy so the more water in the system, the longer it takes to heat up.

also, you need a radiator cap and coolant for the system so it can bleed out.

#13

With the Rx7 being the experiment car, I hardly find anything a waste of time on it. And it's not ignorance, I understand I can just go straight out and purchase an A2W kit for around $300. I also understand that I could spend a lot of time and money upgrading and improving the v-mount, but then it'd be like everyone else, and I don't want that (under the hood, at least). In order for the v-mount to work, I would need to either 1) buy a hood that already has a vent cut in it, or 2) take my aluminum hood to a body shop to have them make me a vent. In the end, I still have a hole in my hood, and I don't want that any more. I'm just playing around with some new toys, so just chill out everyone.

I think I'm going to find a welder or local radiator shop to help me out with this project. The Alumiweld is good, but I just can't seem to get the intercooler hot enough. I've expended an entire cylinder of O2 heating the end tank of my IC and it still never got to the proper temp to melt the alumiweld. The propane torch is not hot enough, nor is a Mapp torch. So this puts a hampering on my low-buck build, but at least I learned how to braze (sort of) and I now have a nice torch.

If the pump ends up not working, I'll get a bigger one. 800 gph equals 13.3 gpm, and it comes with 3/4" inlet and outlet. If it doesn't work, I'll have a new live well pump to go fishing with.

I just wish the alumiweld would have worked out for me.

I think I'm going to find a welder or local radiator shop to help me out with this project. The Alumiweld is good, but I just can't seem to get the intercooler hot enough. I've expended an entire cylinder of O2 heating the end tank of my IC and it still never got to the proper temp to melt the alumiweld. The propane torch is not hot enough, nor is a Mapp torch. So this puts a hampering on my low-buck build, but at least I learned how to braze (sort of) and I now have a nice torch.

If the pump ends up not working, I'll get a bigger one. 800 gph equals 13.3 gpm, and it comes with 3/4" inlet and outlet. If it doesn't work, I'll have a new live well pump to go fishing with.

I just wish the alumiweld would have worked out for me.

#15

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,864

Received 2,621 Likes

on

1,858 Posts

#16

With the Rx7 being the experiment car, I hardly find anything a waste of time on it. And it's not ignorance, I understand I can just go straight out and purchase an A2W kit for around $300. I also understand that I could spend a lot of time and money upgrading and improving the v-mount, but then it'd be like everyone else, and I don't want that (under the hood, at least). In order for the v-mount to work, I would need to either 1) buy a hood that already has a vent cut in it, or 2) take my aluminum hood to a body shop to have them make me a vent. In the end, I still have a hole in my hood, and I don't want that any more. I'm just playing around with some new toys, so just chill out everyone.

I think I'm going to find a welder or local radiator shop to help me out with this project. The Alumiweld is good, but I just can't seem to get the intercooler hot enough. I've expended an entire cylinder of O2 heating the end tank of my IC and it still never got to the proper temp to melt the alumiweld. The propane torch is not hot enough, nor is a Mapp torch. So this puts a hampering on my low-buck build, but at least I learned how to braze (sort of) and I now have a nice torch.

If the pump ends up not working, I'll get a bigger one. 800 gph equals 13.3 gpm, and it comes with 3/4" inlet and outlet. If it doesn't work, I'll have a new live well pump to go fishing with.

I just wish the alumiweld would have worked out for me.

I think I'm going to find a welder or local radiator shop to help me out with this project. The Alumiweld is good, but I just can't seem to get the intercooler hot enough. I've expended an entire cylinder of O2 heating the end tank of my IC and it still never got to the proper temp to melt the alumiweld. The propane torch is not hot enough, nor is a Mapp torch. So this puts a hampering on my low-buck build, but at least I learned how to braze (sort of) and I now have a nice torch.

If the pump ends up not working, I'll get a bigger one. 800 gph equals 13.3 gpm, and it comes with 3/4" inlet and outlet. If it doesn't work, I'll have a new live well pump to go fishing with.

I just wish the alumiweld would have worked out for me.

Seriously, why don't you sell your existing inter-cooler and use the proceeds to buy one of those A2W ebay specials? Then experiment on the rest of the system.

#18

I wasn't trying to add enough heat to braze a large aluminum panel to an aluminum intercooler that was *designed* to dissipate heat...

BTW, you did remove the surface oxidation with a stainless steel brush, right?

#19

Yes, I read the instructions. I also watched some of the youtube videos.

#21

It will be interesting to see if the chosen pump works. From the extensive A2W thread on MR2OC by Gandalf...

I did a HPDE in a Lotus Evora with an A2W intercooler and my friend had the return line visible in the back window so he see it when running.

When a pump is advertised as a 1500 GPH pump, it is usually an "open-flow" rating, which means @zero pressure. As pressure increases a few psi, the flow-rate can decrease dramatically. Rule pumps are a good example. Look at what the pump puts out at above 5 psi. If you cannot find any stats on what a pump puts out above zero psi, avoid it. Rule pumps are generally bilge-pumps, not intended for pressure. Our A2W systems are circulation, often with 3/4" lines, likely having pressure somewhere in the 5 - 8 psi range, depending on your pump output and overall pressure-drop. I am not coming down on Rule specifically, but they have misleading stats and I see them often used in pressure situations that they are not intended for.

You may find that with all the pressure from the I/C, H/E and plumbing it won't move much if any water at all. Keeping in the spirit of cheap experimentation you might want to use at least one section of clear tubing with the hope you'll be able to see if anything is flowing. I did a HPDE in a Lotus Evora with an A2W intercooler and my friend had the return line visible in the back window so he see it when running.

#22

Like a G6

iTrader: (1)

Join Date: Dec 2007

Location: In the Dutch Mountains

Posts: 713

Likes: 0

Received 0 Likes

on

0 Posts

I love these "Problems", since it's so easy to experiment, and find a solution. You already have the hardware in place, and obviously can monitor intake temps. First of all: You're current vant is in the correct location. It's a low pressure zone on the hood. Like Clokker I propose a flap at the fron of the vent to further reduce pressure over the vent. Also you want to make sure the ducting to the IC is in order. This might require a (adjustable) slitter panel, to split the air going through the IC and radiator. Also I would advise to make some ducting between the top of the IC and the hood is (close to) air tight. These expiremental mods can be done for the fraction of the costst of a working W2A IC system, and might be just as gratifing for you as you solved a problem yourself by engineering a better system. The concept VMIC is a working one. If you still have problems, replacing parts for better parts might be the solution, or in case heatsoak is the actual problem, maybe some fans will help for standing traffc etc.

Good luck.

Riz.

Good luck.

Riz.

#23

Rotary Enthusiast

iTrader: (2)

Join Date: May 2005

Location: E-L Netherlands

Posts: 1,165

Likes: 0

Received 0 Likes

on

0 Posts

Being different is one thing, but why be different if all the odds and experience point against what you are doing..

Why do you think people have setups like that? Because they work..!

You dont need to re-invent the wheel, but you can still be different.

I bought a shine-hood, like many others.

I made a v-mount, like many others

But by making the right choices, chosing the right parts and being creative, it turns out one-of-a-kind.

I don't have the welding skills for aluminium either, so i let someone else do it for me. I just mocked it all up using sheet of aluminium and tape.

Do what you got in mind, and i hope it turns out the way you intended without costing you an arm and a leg.

just be carefull for all those guys saying "i told you so" in the end

Why do you think people have setups like that? Because they work..!

You dont need to re-invent the wheel, but you can still be different.

I bought a shine-hood, like many others.

I made a v-mount, like many others

But by making the right choices, chosing the right parts and being creative, it turns out one-of-a-kind.

I don't have the welding skills for aluminium either, so i let someone else do it for me. I just mocked it all up using sheet of aluminium and tape.

Do what you got in mind, and i hope it turns out the way you intended without costing you an arm and a leg.

just be carefull for all those guys saying "i told you so" in the end

#24

Well, I guess the aluminum welding thing is not for me. I'm not buying a TIG welder, nobody I know has one, and welding shops will charge me close to the same price to do the job as buying a quality core.

So, I'm off to figure out a plan B. I'm going to make one that works, one way or another. I'm also going to get a couple of intake temperature sensors and feed the inputs into my Megasquirt to see what the temperature drop is once it's all said and done with.

I may have to do it in a different material though. Steel is cheap, so I may make a prototype out of it first then move on to something else that's less corrosion prone. Right now, I'm thinking of using a basic shell-and-tube design. The air will flow through the tubes, water circulates around them. What's going on in my mind is a melding of different designs, so I think I'd like to incorporate the v-mount design like Evil Aviator showed with the end tanks pointing towards the firewall. So the intercooler would look something similar (but not as... industrial) to this:

Thoughts?

So, I'm off to figure out a plan B. I'm going to make one that works, one way or another. I'm also going to get a couple of intake temperature sensors and feed the inputs into my Megasquirt to see what the temperature drop is once it's all said and done with.

I may have to do it in a different material though. Steel is cheap, so I may make a prototype out of it first then move on to something else that's less corrosion prone. Right now, I'm thinking of using a basic shell-and-tube design. The air will flow through the tubes, water circulates around them. What's going on in my mind is a melding of different designs, so I think I'd like to incorporate the v-mount design like Evil Aviator showed with the end tanks pointing towards the firewall. So the intercooler would look something similar (but not as... industrial) to this:

Thoughts?

#25

Rotary Enthusiast

iTrader: (2)

Join Date: May 2005

Location: E-L Netherlands

Posts: 1,165

Likes: 0

Received 0 Likes

on

0 Posts

You will need something else then steel tubing, because it doesnt transfer the heat like you want it to do.

So you'll be needing copper, like in the picture. which brings the problem of getting a perfect seal in the plates on the side. Soldering would be the best option i guess

Thats about as far i can go with helping you

But remember..

Copper tubing isnt cheap, and take all of the small things into account like couplers, hoses, bungs, wiring. Small things add up quickly!

i think all in all that before you have a proper working prototype, you'll have spent more money then the cost of a complete kit of which you know it works

I think you are making life much more complicated this way

So you'll be needing copper, like in the picture. which brings the problem of getting a perfect seal in the plates on the side. Soldering would be the best option i guess

Thats about as far i can go with helping you

But remember..

Copper tubing isnt cheap, and take all of the small things into account like couplers, hoses, bungs, wiring. Small things add up quickly!

i think all in all that before you have a proper working prototype, you'll have spent more money then the cost of a complete kit of which you know it works

I think you are making life much more complicated this way