20B FD transplant

#1

Rotary Enthusiast

Thread Starter

20B FD transplant

Hi Guy's I will be starting an FD3 20B conversion in the new year and wanted to check a couple of things I am unclear on.

What clutch and gearbox option is best to use with the FD3? I gather the FD box will fit but am I correct in thinking the FD flywheel/clutch assy will not work as you need to use the 20B counterweight to bolt it too? Please let me know my options here.

can someone also explain why the counterwight is needed and why you cannot use an FD flywheel straight on the E-shaft? is it simply a harmonic blancing issue?

Curently it is setup in an 1988 FC with a turbo II box.

Cheers

Lee

What clutch and gearbox option is best to use with the FD3? I gather the FD box will fit but am I correct in thinking the FD flywheel/clutch assy will not work as you need to use the 20B counterweight to bolt it too? Please let me know my options here.

can someone also explain why the counterwight is needed and why you cannot use an FD flywheel straight on the E-shaft? is it simply a harmonic blancing issue?

Curently it is setup in an 1988 FC with a turbo II box.

Cheers

Lee

#2

The heavy Fd flywheel is balanced to that particular rotating assembly. Do not use that on a 20b. Clutch is dependant on power goals. 20b already has a rear counter weight. Just remove the auto trany flex plate off the counter weight and install a light weight aftermarket 13b turbo flywheel in it's place. That way you can used the fd style upgraded pull type clutches. Fd tranny is bolt on but is power limited with hi torque! Overall there's nothing grossly different between a 20b and 13b other than the extra rotor.

#3

Rotary Enthusiast

Thread Starter

Okay. Thank you for that. I was thrown by the counterweight that's all! So an aftermarket FD flywheel would use this option too then? Learn something every day. The OEM 13B flywheel is certainly a beast!

Being that all the boxes can be swapped around, is say an FC flywheel and clutch usable in an FD box or maybe if not mthe clutch is the FC and FD aftermarket flywheels the same and will accept each others clutch assemblies?

Thank you

Lee

Being that all the boxes can be swapped around, is say an FC flywheel and clutch usable in an FD box or maybe if not mthe clutch is the FC and FD aftermarket flywheels the same and will accept each others clutch assemblies?

Thank you

Lee

#4

Okay. Thank you for that. I was thrown by the counterweight that's all! So an aftermarket FD flywheel would use this option too then? Learn something every day. The OEM 13B flywheel is certainly a beast!

Being that all the boxes can be swapped around, is say an FC flywheel and clutch usable in an FD box or maybe if not mthe clutch is the FC and FD aftermarket flywheels the same and will accept each others clutch assemblies?

Thank you

Lee

Being that all the boxes can be swapped around, is say an FC flywheel and clutch usable in an FD box or maybe if not mthe clutch is the FC and FD aftermarket flywheels the same and will accept each others clutch assemblies?

Thank you

Lee

Any aftermarket 13b turbo flywheel would work Fd or Fc it doesn't matter because they are the same however, NEVER use those FACTORY flywheels on a 20b as the counter weights are built into those heavy flywheels. You also have to match the clutch with the transmission. Fd has a pull type clutch and will only work with the fd tranny. You can't cross those. What your trying to do would be nothing more than an auto to manual swap on the fd. Those guys have to do exactly what your trying to do.

#5

Rotary Enthusiast

Thread Starter

Hi again!

Thanks for the info. I gather it is a must to run the 20B counterweight from the posts I have read on the conversion. I have the option of a turbo II box or an FD box? I gather the TurboII is shorter so will sit the engine further back and hence maybe mean less mods to suspension geometry, better balance etc. But then is it heavy duty enough do you know? I am not going silly power. Maybe nice to touch on 600bhp at the flywheel.. The torque will be the killer though!

There seem to be very few threads on 20B conversion in general and hardly any for FD's so it would be good to swap advice and ideas with someone else familar with it if you don't mind. I got other considerations like to try and avoid moving the steering rack but not cutting the bulkhead.. potentially an external oil pump susposidly solves this with I guess a modified billet front housing?

Are you just a hobbyist/enthusiast like myself or run a workshop or something?

Cheers

Lee

Thanks for the info. I gather it is a must to run the 20B counterweight from the posts I have read on the conversion. I have the option of a turbo II box or an FD box? I gather the TurboII is shorter so will sit the engine further back and hence maybe mean less mods to suspension geometry, better balance etc. But then is it heavy duty enough do you know? I am not going silly power. Maybe nice to touch on 600bhp at the flywheel.. The torque will be the killer though!

There seem to be very few threads on 20B conversion in general and hardly any for FD's so it would be good to swap advice and ideas with someone else familar with it if you don't mind. I got other considerations like to try and avoid moving the steering rack but not cutting the bulkhead.. potentially an external oil pump susposidly solves this with I guess a modified billet front housing?

Are you just a hobbyist/enthusiast like myself or run a workshop or something?

Cheers

Lee

#6

20b counter weight stays with 20b engine. There's plenty of 20b fd swap info already on this forum. You just got to search for it. Running the turbo II tranny in the Fd chassis is way too much trouble. PPF mounting vs tranny mounts. Curious do you not know anything about the vehicle your getting ready to do a swap on? If you don't have enough general knowledge about the Fd, you need to search more.

Trending Topics

#8

This should help http://www.banzai-racing.com/20B_eng...transition.htm

Again, keep up the great work!

#9

Stock rebuilt FD trans in the stock location, with the PPF intact. Moving the engine back would require a lot of additional work to gain 4" of real estate in the engine bay. This still would not be enough for a functional v-mount. You would need to massage the firewall and move everything back to the point af having the shifter in a not-so-friendly locatation.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

#10

Stock rebuilt FD trans in the stock location, with the PPF intact. Moving the engine back would require a lot of additional work to gain 4" of real estate in the engine bay. This still would not be enough for a functional v-mount. You would need to massage the firewall and move everything back to the point af having the shifter in a not-so-friendly locatation.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

#11

Rotary Enthusiast

Thread Starter

Thanks for that Banzai, Great link.. Will have a good look at that!

I am more than familiar with my FD but not so familiar with other models of RX7 as I jumped right in with the FD originally. Just so happens I have picked up a 20B from an FC with box and bits to do te swap. So trying to determine the best way to go with the options of bits I have!

Personally I thought putting some mounts in the floor to mount the T2 box would not be that much work compared to cutting the bulkhead about at least?! Also I think the PPF is nasty! Maybe it is a better idea that a seperately chassis mounted box and diff? Mazda obvously thoguht so! I can see there is a plus of linking the two together but still.. I am not sure about it!

Cheers

Lee

I am more than familiar with my FD but not so familiar with other models of RX7 as I jumped right in with the FD originally. Just so happens I have picked up a 20B from an FC with box and bits to do te swap. So trying to determine the best way to go with the options of bits I have!

Personally I thought putting some mounts in the floor to mount the T2 box would not be that much work compared to cutting the bulkhead about at least?! Also I think the PPF is nasty! Maybe it is a better idea that a seperately chassis mounted box and diff? Mazda obvously thoguht so! I can see there is a plus of linking the two together but still.. I am not sure about it!

Cheers

Lee

#12

Stock rebuilt FD trans in the stock location, with the PPF intact. Moving the engine back would require a lot of additional work to gain 4" of real estate in the engine bay. This still would not be enough for a functional v-mount. You would need to massage the firewall and move everything back to the point af having the shifter in a not-so-friendly locatation.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

That being said and knowing this forum I am sure someone will come on and try to prove me wrong.

No offense but you act like all your knowledge is golden. Have you not been here that long? Autotech Motorsports was doing this 7 years ago. You can get 5 1/2" messaging the firewall, making a custom LIM, moving the shifter to that front access cover on top of the tranny. This will sit the engine just behind the rack and puts the engine 2" lower than the Fd's engine and the front in the exact same place as the Fd giving you plenty of room to do a V-mount.

It is a ton of work but it can be done. Back in 2004 there was a Fd done exactly this way (no V-mount) that showed up at sevenstock 7 by the above company. That car an their process gave me my inspiration in how to get my engine where it is.

It is a ton of work but it can be done. Back in 2004 there was a Fd done exactly this way (no V-mount) that showed up at sevenstock 7 by the above company. That car an their process gave me my inspiration in how to get my engine where it is.

#14

Hopefully! That too is one of my goals. That tranny is slightly bulkier and the shifter would be really hard for me modify. I know I could figure something out if I just had junk tranny here to test fit. I'm waiting on Rzmotorsports's report on his rotary t56 conversion kit.

#16

WOW your arrogant! The real joke is your lack of respect of other peoples experience and knowledge. I have the above vehicle recorded on vhs when I was at Sevenstock 7. You want a copy? This company I think is out of business. The Autotech vehicle had a Gt-40 turbo and plenty of room to do any V-mount because the engine sits lower and in the same place as the stock rew. I virtually duplicated what they did with their engine positioning for my own swap. My engine sits in the same place. FIY my stock 20b UIM will fit if I decide I want to use it however, I wont need it as I engineered my intake to also be turbo charged later.

#17

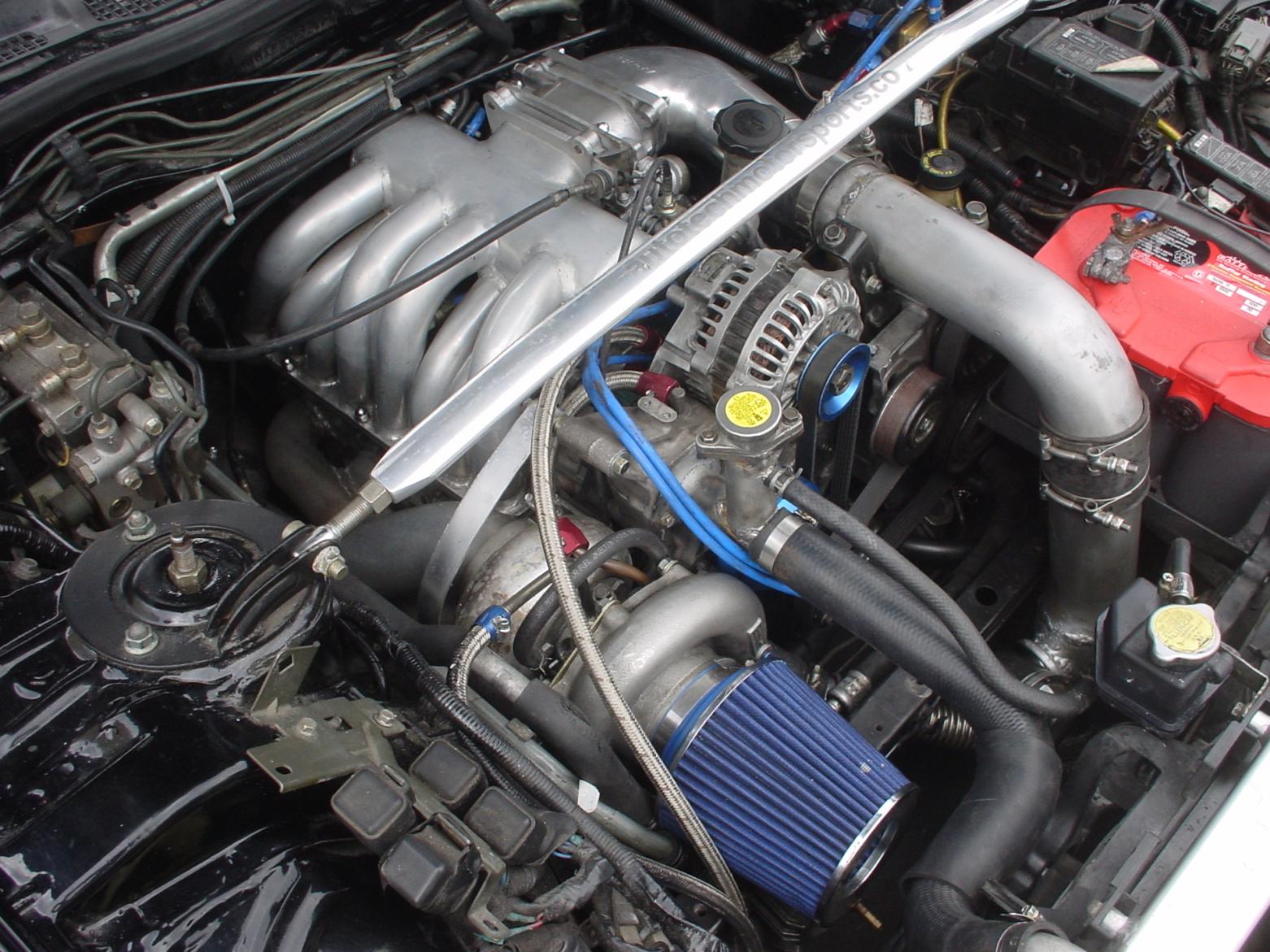

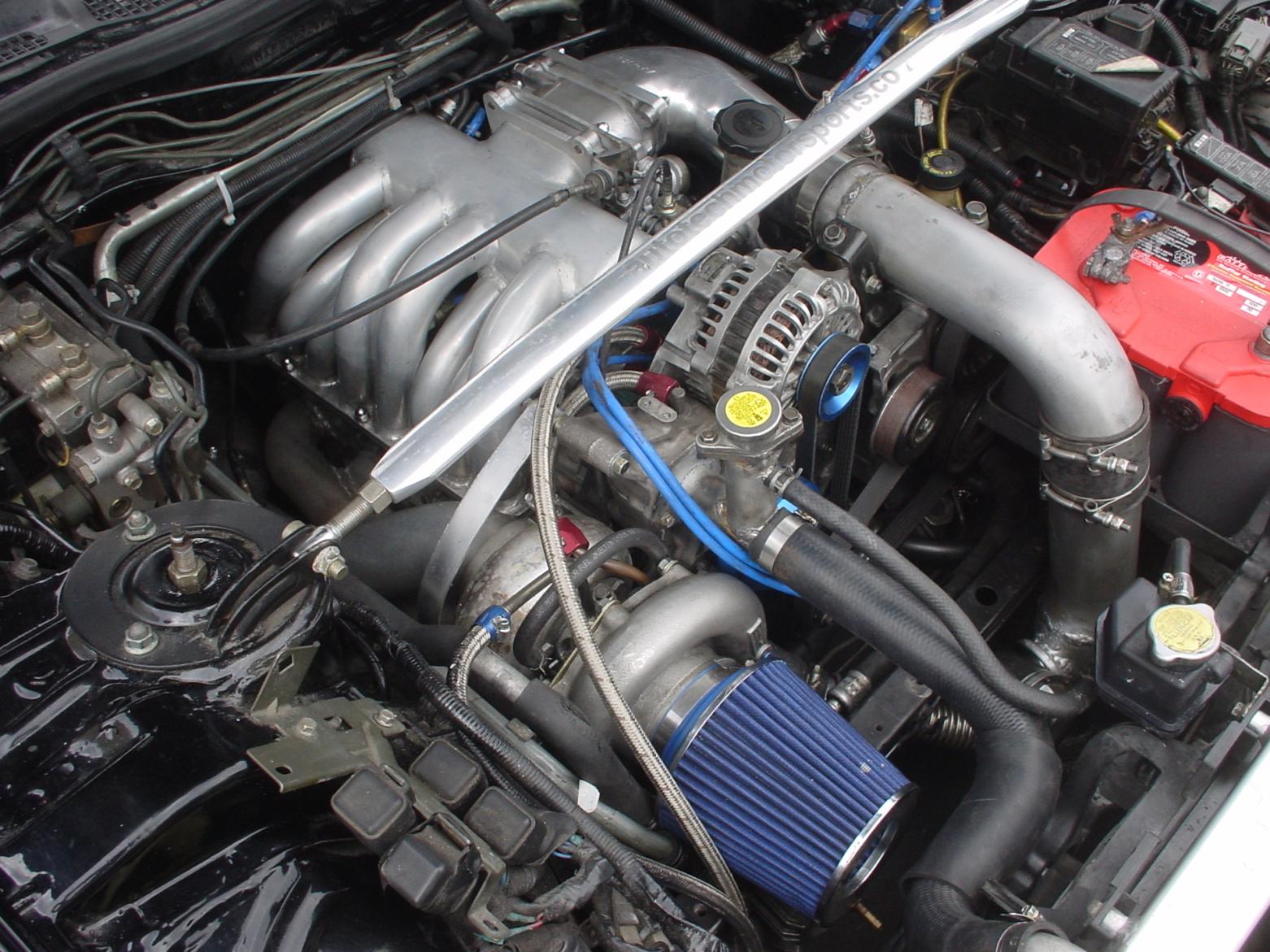

Still the best version of a 20b swap I've seen.

Stock shifter location, no relocation/manipulation of the steering rack, no cutting of the firewall, and the entire engine sits behind the front wheels just like the stock 13b.

This was the car.

Here is their custom 12a based 4-rotor. Too bad these guys didn't make it.

Stock shifter location, no relocation/manipulation of the steering rack, no cutting of the firewall, and the entire engine sits behind the front wheels just like the stock 13b.

This was the car.

Here is their custom 12a based 4-rotor. Too bad these guys didn't make it.

#18

^ Exactly! Best 20b conversion bar non. Thank you for posting that. As you can see there is plenty of room for a V-mount. After seeing how they did that car, there was no way I was going to install the Rx7 Specialties subframe that I already had bought since it drops the rack and sits the engine higher in the engine bay. I later sold that subframe and made my own. IMO this is how Mazda would have positioned a 20b in the Fd.

Edit: I forgot about the 12a based 4 rotor they did. It also sits in the stock location and still retained the PS and A/C. After all these years, I have yet to see another vendor step up their game and offer this kind of swap. Everything is too cookie cutter now and days. When it came to properly positioning the engines, Autotech knew what the hell they were doing.

Edit: I forgot about the 12a based 4 rotor they did. It also sits in the stock location and still retained the PS and A/C. After all these years, I have yet to see another vendor step up their game and offer this kind of swap. Everything is too cookie cutter now and days. When it came to properly positioning the engines, Autotech knew what the hell they were doing.

#19

Rotary Enthusiast

Thread Starter

Nice shout indeed! So you are saying they have got the engine back far enough in the bay without cutting the firewall and retained the stock shifter location and also cleared the steering rack so that retains the stock position?

T-von I thought you said you were re-fabbing your firewall to achieve this?

Re the steering rack location.. I haven't had time to actually look at the suspension in great detail yet but would it not be possible to move the rack forward.. not up or down. an inch or so and modify the hubs to lengthen the steering arms so the trackrods were still all lined up as per stock setup? I cannot thin of a hadnling issue this would cause? You would get lighter steering!? T-Von are you retaining power steering or is there a decent unpowered rack that can be swapped in to help save some space?

With the geometry issues I guess the aim is to try and retain the same effective geometry as stock. With spacers etc. I am not kean on droping the subframe too far as obviously that eventually will give ground clearance issues. but how about if you are dropping the subframe. Drop the the upper wishbone mounting points down as well by the same amount? Obviously not a 5min job but would help retain the geometry better. You would need adjustable length shocks to accomodate but hey?

Like T-Von I aim to do this all myself. Fabbing and the works. So hopefully I can come

With a good solution.. When I get stuck into it I will no doubt be posting regularly for thoughts on ideas I have etc!!

Cheers

Lee

T-von I thought you said you were re-fabbing your firewall to achieve this?

Re the steering rack location.. I haven't had time to actually look at the suspension in great detail yet but would it not be possible to move the rack forward.. not up or down. an inch or so and modify the hubs to lengthen the steering arms so the trackrods were still all lined up as per stock setup? I cannot thin of a hadnling issue this would cause? You would get lighter steering!? T-Von are you retaining power steering or is there a decent unpowered rack that can be swapped in to help save some space?

With the geometry issues I guess the aim is to try and retain the same effective geometry as stock. With spacers etc. I am not kean on droping the subframe too far as obviously that eventually will give ground clearance issues. but how about if you are dropping the subframe. Drop the the upper wishbone mounting points down as well by the same amount? Obviously not a 5min job but would help retain the geometry better. You would need adjustable length shocks to accomodate but hey?

Like T-Von I aim to do this all myself. Fabbing and the works. So hopefully I can come

With a good solution.. When I get stuck into it I will no doubt be posting regularly for thoughts on ideas I have etc!!

Cheers

Lee

#20

All Autotech did with their firewall has use a rubber mallet to beat the upper portion of the firewall to round it out so the tranny will clear. That's what I did! I have a lot of people PM'ing me for pics. I'll be pulling my engine out this weekend so I don't mind taking pics and showing my subrame, firewall, and shifter relocate. It's funny because the shifter relocate was the easiest mod. Keep in mind when you move the engine back you will also have to modify the oil filter pedestal. I relocated mine! Seriously this is a lot of work if you go this route. You still have to either make tranny mounts, diff mount, or shorten the PPF (which was another easy mod). New shorter drive shaft, custom LIM. I didn't have any prior fabrication experience or specialized training other than aviation maintenance training back in college. Even in that class we never fabed anything. I simply just started fitting things as I went. Oh yea, never move the rack forward. That will change the tie rob end angles in a negative way!

#21

Rotary Enthusiast

Thread Starter

Arrhh. I see.. They have moved the engine back then. I read it as they had not because of the stock shifter location mention and no cutting of firewall!

Pics of yours would be nice out of interest. I understand you cannot just move the rack forward without messing up geometry badly which is why I suggested the possibility of extending the arms on the hubs the track rods bolt to so that the effect geometry has not changed.

Is a standard oil relocation kit not sufficient and simple enough to relocate the filter with? I can see access would be tight or impossible without doing this.

Any thoughts on dropping the entire subframe and suspension to sit lower? I say this although I am not sure how far you need to drop it to gain clearance on the rack just yet? Much more than and inch or so and it's probably too much ground clearance to sacrifice?

I guess if it's just an inch though you can drop the rack only and fit 1" spacers on the track rod ends to level the arms out?

Cheers

Lee

Pics of yours would be nice out of interest. I understand you cannot just move the rack forward without messing up geometry badly which is why I suggested the possibility of extending the arms on the hubs the track rods bolt to so that the effect geometry has not changed.

Is a standard oil relocation kit not sufficient and simple enough to relocate the filter with? I can see access would be tight or impossible without doing this.

Any thoughts on dropping the entire subframe and suspension to sit lower? I say this although I am not sure how far you need to drop it to gain clearance on the rack just yet? Much more than and inch or so and it's probably too much ground clearance to sacrifice?

I guess if it's just an inch though you can drop the rack only and fit 1" spacers on the track rod ends to level the arms out?

Cheers

Lee

#22

There is a simple way to modify the trans and move the engine back, you'll gain a few inches there. Also we ran a v-mount on a 20B for a customer with the engine mounted in the standard location as shown above, not requiring the engine be moved back. A lot will depend on wiring for the car as well as IC rad configuration, but it can be done no need for you guys to be all hostile.

~S~

~S~

#23

There is a simple way to modify the trans and move the engine back, you'll gain a few inches there. Also we ran a v-mount on a 20B for a customer with the engine mounted in the standard location as shown above, not requiring the engine be moved back. A lot will depend on wiring for the car as well as IC rad configuration, but it can be done no need for you guys to be all hostile.

~S~

~S~

Your good Zero!

I just can't stand when certain vendors come in soliciting business on DIY threads and telling people what can't be done. Just because THEY don't have the capability, doesn't mean is can't be done.

I just can't stand when certain vendors come in soliciting business on DIY threads and telling people what can't be done. Just because THEY don't have the capability, doesn't mean is can't be done.

#24

Rotary Enthusiast

Thread Starter

Thanks for all the info so far guy's I have a fair bit to ponder on now. and when I get the engine somewhere near the engine bay I can come back with some more questions or ideas and see what you all reckon before I get the welder out! and go hacking and slashing left right and centre!

First job is remove the blown 13B from the FD and then strip the 20B engine from it's host and sort out what I am going to do on ancillaries!

Cheers

Lee

First job is remove the blown 13B from the FD and then strip the 20B engine from it's host and sort out what I am going to do on ancillaries!

Cheers

Lee

#25

FWIW, both cars used stock trannies but did the shifter mod as you mentioned above. I think you gain a hair over four inches iirc.

Kudos on the v-mount with a standard install.