Rearend setup experts - Please school me!

#1

Rearend setup experts - Please school me!

OK guys, So I have used the search function and have been reading a lot as I know this had been covered but please help me out here.

I have an 84 gsl-se. It's a racecar so not worried but about petty practicalities like noise and comfort

I need to fix the back end though. It comes around way too easy and way to fast! But I need to do it on a budget and while I have a buddy who can weld I don't want to ask too much of him, lest he not get involved in any of my projects ever again.

I understand the main issue is binding caused by both the watts linkage and the end links.

So in order to mitigate these problems without running out of "friend-welder capital" I have come up with the following: please tell me why they shouldn't work.

1. Ditching the watts for a panhard but BUT keeping the stock 4-link setup. It seems like everyone does panhard and tri-link or nothing. Why can't I just do panhard and stock 4 link?

2. Heim joints on all 4 links. It seems like people only do the bottom. Aren't the upper zig-zaged ones the main problem?

Thanks!

I have an 84 gsl-se. It's a racecar so not worried but about petty practicalities like noise and comfort

I need to fix the back end though. It comes around way too easy and way to fast! But I need to do it on a budget and while I have a buddy who can weld I don't want to ask too much of him, lest he not get involved in any of my projects ever again.

I understand the main issue is binding caused by both the watts linkage and the end links.

So in order to mitigate these problems without running out of "friend-welder capital" I have come up with the following: please tell me why they shouldn't work.

1. Ditching the watts for a panhard but BUT keeping the stock 4-link setup. It seems like everyone does panhard and tri-link or nothing. Why can't I just do panhard and stock 4 link?

2. Heim joints on all 4 links. It seems like people only do the bottom. Aren't the upper zig-zaged ones the main problem?

Thanks!

#2

its supposed to do that

The unequal 4-link is a bigger problem than the watts in my opinion(and many others). If you heim the upper stock links, then all of the negative aspects of the stock setup will be incredibly magnified. The binding of those upper links is what causes most of the unpleasantries.

A panhard (or decent watts) and a tri-link make an amazing improvement.

Isaac

A panhard (or decent watts) and a tri-link make an amazing improvement.

Isaac

#3

Heim joints on all four will make the problem worse. The uppers cause most of the problem. The stock watts link actually works quite well keeping the rear moving straight up and down until its extreme limits. The problem is the roll center is too high. The panhard bar lowers the rear roll center and levels out the roll axis.

#4

thanks for the replies guys. I suppose I should suck it up and do a tri-link then. Just not sure I have time before next race in May.

I was talking to someone who purchased an old IT-7 and he said it uses a panhard and stock 4 link so I was thinking that must be a decent improvement if it was an scca standard set-up.

I was talking to someone who purchased an old IT-7 and he said it uses a panhard and stock 4 link so I was thinking that must be a decent improvement if it was an scca standard set-up.

#5

Anyone else running an FB as a track car only and uses stock suspension geometry with good results?

Currently I have stock rear springs cut 1" w/ no rear bar. and 125lb coilovers up front with stock bar.

I am going to do the PB&J mod PBandJ Racing-Rear Susension to try and mitigate the binding...

maybe I will run 350/150 like the respeed kit.

oh yeah and tokico blues

Currently I have stock rear springs cut 1" w/ no rear bar. and 125lb coilovers up front with stock bar.

I am going to do the PB&J mod PBandJ Racing-Rear Susension to try and mitigate the binding...

maybe I will run 350/150 like the respeed kit.

oh yeah and tokico blues

#7

I am coming to realize some overall stiffer springs would be a good way to go here.

Does anyone know where you can get specific weight springs in specific sizes? I went on mazdatrix and they have the different kits available but those only went up to 174/110... nothing like 350/175 which I think is what I'm looking for.

Trending Topics

#8

The old Pro 7 and Spec 7 rules required the use of the stock suspension. According to Mazdatrix, what worked were upper and lower control arms with new rubber bushings. The issue with the stock four link is that the upper and lower arms move in different arcs. This leads to the binding that everyone reports. The fresh stock rubber bushings allow the rear end to articulate without bind. After all, that is what Mazda engineered in the first place.

Putting spherical bearings in all of the stock arms has been tried - it is an SCCA legal mod. The results were upper arm failures. The stock watts link stud will also break off at the axle. I saw both of these issues occur first hand.

Using Urethane bushings seems to work in Solo but people that have tried this on the track reported that the car wasn't very drivable. Lots of over steer.

When I raced in ITA/IT7 my car had a G-Force panhard bar and a tri link. The stock lower control arms had spherical bearings in them. For spring rates I ran 400-450 on front and 200-300 on the rear. I had a Racing Beat front sway bar and no rear bar. Wheels were 13x7 with DOT racing tires.

The rear suspension needs to articulate without bind. Bind breaks things and or causes the rear tires to unload when you need traction.

Putting spherical bearings in all of the stock arms has been tried - it is an SCCA legal mod. The results were upper arm failures. The stock watts link stud will also break off at the axle. I saw both of these issues occur first hand.

Using Urethane bushings seems to work in Solo but people that have tried this on the track reported that the car wasn't very drivable. Lots of over steer.

When I raced in ITA/IT7 my car had a G-Force panhard bar and a tri link. The stock lower control arms had spherical bearings in them. For spring rates I ran 400-450 on front and 200-300 on the rear. I had a Racing Beat front sway bar and no rear bar. Wheels were 13x7 with DOT racing tires.

The rear suspension needs to articulate without bind. Bind breaks things and or causes the rear tires to unload when you need traction.

#9

Absolute Power is Awesome

Jim Susko told me that only replacing the watts with a panhard makes the majority of improvements in his suspension set up. It significantly alters the roll center of the rear axle.

#11

The old Pro 7 and Spec 7 rules required the use of the stock suspension. According to Mazdatrix, what worked were upper and lower control arms with new rubber bushings. The issue with the stock four link is that the upper and lower arms move in different arcs. This leads to the binding that everyone reports. The fresh stock rubber bushings allow the rear end to articulate without bind. After all, that is what Mazda engineered in the first place.

Putting spherical bearings in all of the stock arms has been tried - it is an SCCA legal mod. The results were upper arm failures. The stock watts link stud will also break off at the axle. I saw both of these issues occur first hand.

Using Urethane bushings seems to work in Solo but people that have tried this on the track reported that the car wasn't very drivable. Lots of over steer.

When I raced in ITA/IT7 my car had a G-Force panhard bar and a tri link. The stock lower control arms had spherical bearings in them. For spring rates I ran 400-450 on front and 200-300 on the rear. I had a Racing Beat front sway bar and no rear bar. Wheels were 13x7 with DOT racing tires.

The rear suspension needs to articulate without bind. Bind breaks things and or causes the rear tires to unload when you need traction.

Putting spherical bearings in all of the stock arms has been tried - it is an SCCA legal mod. The results were upper arm failures. The stock watts link stud will also break off at the axle. I saw both of these issues occur first hand.

Using Urethane bushings seems to work in Solo but people that have tried this on the track reported that the car wasn't very drivable. Lots of over steer.

When I raced in ITA/IT7 my car had a G-Force panhard bar and a tri link. The stock lower control arms had spherical bearings in them. For spring rates I ran 400-450 on front and 200-300 on the rear. I had a Racing Beat front sway bar and no rear bar. Wheels were 13x7 with DOT racing tires.

The rear suspension needs to articulate without bind. Bind breaks things and or causes the rear tires to unload when you need traction.

I in fact have the ST poly bushings in the rear. I think I may replace them with stock rubber and then also drill out the uppers per the PB&J racing write up.

I may also try and get the panhard bar done.

Does anyone have an opinion of the ones you can buy on ebay that are just generic? Since you can't get the gforce one everyone uses.

I wonder if you went to a local speed shop if they could fab you one? Since this seems like a standard american muscle type mod

#12

Thanks mustanghammer, this is exactly the anecdotal information I was looking for!

I in fact have the ST poly bushings in the rear. I think I may replace them with stock rubber and then also drill out the uppers per the PB&J racing write up.

I may also try and get the panhard bar done.

Does anyone have an opinion of the ones you can buy on ebay that are just generic? Since you can't get the gforce one everyone uses.

I wonder if you went to a local speed shop if they could fab you one? Since this seems like a standard american muscle type mod

I in fact have the ST poly bushings in the rear. I think I may replace them with stock rubber and then also drill out the uppers per the PB&J racing write up.

I may also try and get the panhard bar done.

Does anyone have an opinion of the ones you can buy on ebay that are just generic? Since you can't get the gforce one everyone uses.

I wonder if you went to a local speed shop if they could fab you one? Since this seems like a standard american muscle type mod

I think it would be unlikely that you would find a collection of parts on eBay that would work on your car.

#14

Rotary Freak

#15

OK final question. Is there a definitive thread about fabbing up a custom panhard bar? I have searched and can find bits of information but thats all.

basic things like:

What thickness steel bar to use. (or chrome molly?)

What sort of rod ends do people use.

etc

Thanks

basic things like:

What thickness steel bar to use. (or chrome molly?)

What sort of rod ends do people use.

etc

Thanks

#16

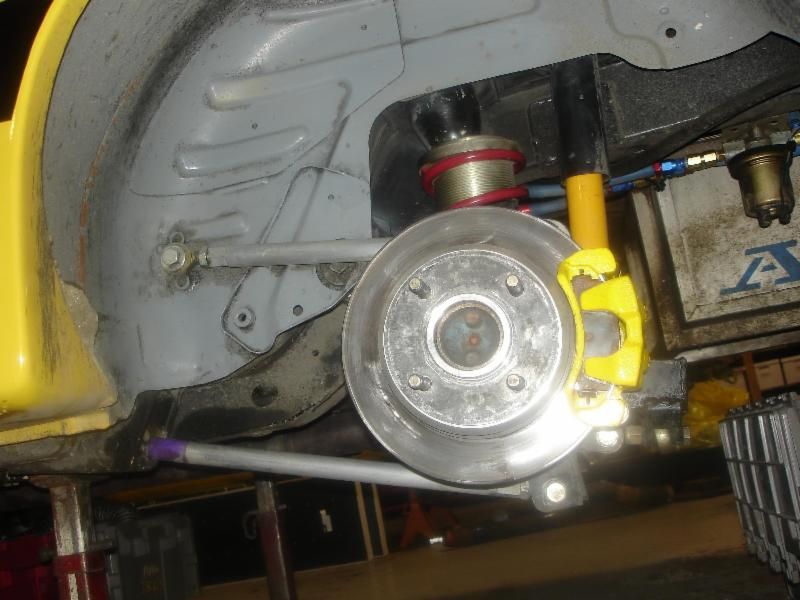

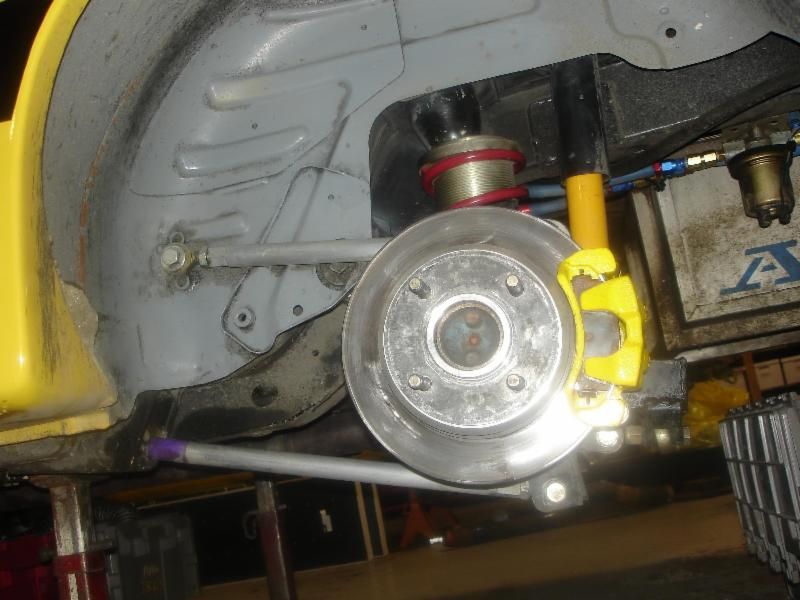

I have had two panhard rod setups on my race car. The first used a G Force mount on the chassis and a mount I added to the axle. It had 1/2" rod ends with a 1"x .090 DOM tube with threaded bungs welded in the ends. It worked fine but was a little short. Here are a couple of shots. This car had a tri-link too.

My current setup:

5/8" Aurora Rod ends - on the axle I am using a rod end that has a 5/8 shank with a 1/2" through bolt. On the chassis it is a 5/8 shank/through bolt rod end.

The tube I have decided to use is 7/8" diameter x .120 tube x 35" DOM steel tube that I got from Coleman Racing. It frankly looks too small but there is a method to the madness. The tube is stiff enough for the loads it will carry but if I take a hit it will bend before other parts of the car do. In the photos I have a 1.25" x .090 DOM tube with 5/8 bungs welded on the ends. Either should be fine - I would never use an aluminum tube.

This is an early photo. I later added a square tube cross member from frame rail to frame rail that connect the chassis mount to the diagonal brace.

My current setup:

5/8" Aurora Rod ends - on the axle I am using a rod end that has a 5/8 shank with a 1/2" through bolt. On the chassis it is a 5/8 shank/through bolt rod end.

The tube I have decided to use is 7/8" diameter x .120 tube x 35" DOM steel tube that I got from Coleman Racing. It frankly looks too small but there is a method to the madness. The tube is stiff enough for the loads it will carry but if I take a hit it will bend before other parts of the car do. In the photos I have a 1.25" x .090 DOM tube with 5/8 bungs welded on the ends. Either should be fine - I would never use an aluminum tube.

This is an early photo. I later added a square tube cross member from frame rail to frame rail that connect the chassis mount to the diagonal brace.

#17

Earlier, you were asking about running a 4 link rear suspension. Here is one that works. This is on an E-Production first gen. The upper arms are relocated at the chassis and are much longer. The upper arms are also adjustable for squat/anti-squat. The second picture shows the mount that is on the inside of the car. Note that the location of the lower arm is different than stock - 2.5" lower. The arms are aluminum and have 5/8" rod ends This particular car won the Runoffs several years after this photo was taken.

Here are some shots of the panhard rod on this car. It was REALLY LONG but not adjustable.

Here is the car

Here are some shots of the panhard rod on this car. It was REALLY LONG but not adjustable.

Here is the car

Last edited by mustanghammer; 04-07-14 at 11:49 PM. Reason: more photos

#18

I can't thank you enough on this mustanghammer. Seriously seriously helpful.

I talked to my "lead mechanic" and we are going to start our panhard setup fab next weekend.

We will probably do something similar to your first setup above. I realize the longer the bar the better but this design just seems simpler for first timers.

Your 4-link setup seems very managable too I must say, although we just don't have time before our next race. We are just going to put new factory rubber bushings all around and drill holes in the uppers to soften them further.

I talked to my "lead mechanic" and we are going to start our panhard setup fab next weekend.

We will probably do something similar to your first setup above. I realize the longer the bar the better but this design just seems simpler for first timers.

Your 4-link setup seems very managable too I must say, although we just don't have time before our next race. We are just going to put new factory rubber bushings all around and drill holes in the uppers to soften them further.

#20

Happy to help Wally!

Kaaarl12a,

I believe the upper arms are shorter than the lowers. The factory watts link places the roll center too high and is prone to failure in high load applications like road racing. A pan hard rod is a better/cheaper choice. Or a well engineered watts that has a lower pivot.

Keep in mind that this 4 link is installed in a car with a wide body kit so inner wheel well room isn't an issue. But on a car with stock fenders this setup would make things crowded inside the wheel well

This car was built by KC Raceware

Kaaarl12a,

I believe the upper arms are shorter than the lowers. The factory watts link places the roll center too high and is prone to failure in high load applications like road racing. A pan hard rod is a better/cheaper choice. Or a well engineered watts that has a lower pivot.

Keep in mind that this 4 link is installed in a car with a wide body kit so inner wheel well room isn't an issue. But on a car with stock fenders this setup would make things crowded inside the wheel well

This car was built by KC Raceware

#22

#23

I have had two panhard rod setups on my race car. The first used a G Force mount on the chassis and a mount I added to the axle. It had 1/2" rod ends with a 1"x .090 DOM tube with threaded bungs welded in the ends. It worked fine but was a little short. Here are a couple of shots. This car had a tri-link too.

My current setup:

5/8" Aurora Rod ends - on the axle I am using a rod end that has a 5/8 shank with a 1/2" through bolt. On the chassis it is a 5/8 shank/through bolt rod end.

The tube I have decided to use is 7/8" diameter x .120 tube x 35" DOM steel tube that I got from Coleman Racing. It frankly looks too small but there is a method to the madness. The tube is stiff enough for the loads it will carry but if I take a hit it will bend before other parts of the car do. In the photos I have a 1.25" x .090 DOM tube with 5/8 bungs welded on the ends. Either should be fine - I would never use an aluminum tube.

This is an early photo. I later added a square tube cross member from frame rail to frame rail that connect the chassis mount to the diagonal brace.

My current setup:

5/8" Aurora Rod ends - on the axle I am using a rod end that has a 5/8 shank with a 1/2" through bolt. On the chassis it is a 5/8 shank/through bolt rod end.

The tube I have decided to use is 7/8" diameter x .120 tube x 35" DOM steel tube that I got from Coleman Racing. It frankly looks too small but there is a method to the madness. The tube is stiff enough for the loads it will carry but if I take a hit it will bend before other parts of the car do. In the photos I have a 1.25" x .090 DOM tube with 5/8 bungs welded on the ends. Either should be fine - I would never use an aluminum tube.

This is an early photo. I later added a square tube cross member from frame rail to frame rail that connect the chassis mount to the diagonal brace.

Quick question. I am basically going to base mine off your fist example. I notice however that the center of your bar is not centered to the axle. That is: Your frame connecting bracket is right under the passenger side frame rail but your connection to the axle is past the driver side frame rail.

Am I incorrect in thinking the theoretical pivot point of the panhard bar is the center of the bar, and so it should be centered with respect to the axle?

Or is it more important to make it longer?

Thanks again.

#24

Doesn't matter where the pivots are. A longer rod doesn't move the axle laterally as much as a shorter one does when the car goes through roll. So, my latest design puts the axle mount out side of the left side shock. Later on I had to move the axle mount to the right about an inch for tire clearance.

Also, this design allows me to use the OE rear sway bar and the earlier design didn't. Keep that in mind when you are fabricating your axle mount.

Note that with the exception of the lateral brace that connects to the back of the banjo, nothing is welded to an axle tube or the housing itself. If you weld to an axle housing it is highly likely that you will warp it. Warping the axle housing will introduce tow or camber to the rear wheels that you don't want. This will kill axle bearings.

We have always located the pan hard bar so that it level with the OE shock mount in the axle housing. It is in the same place on my new rear axle, however it looks different because I lowered the shock mounts on the axle housing.

Also, this design allows me to use the OE rear sway bar and the earlier design didn't. Keep that in mind when you are fabricating your axle mount.

Note that with the exception of the lateral brace that connects to the back of the banjo, nothing is welded to an axle tube or the housing itself. If you weld to an axle housing it is highly likely that you will warp it. Warping the axle housing will introduce tow or camber to the rear wheels that you don't want. This will kill axle bearings.

We have always located the pan hard bar so that it level with the OE shock mount in the axle housing. It is in the same place on my new rear axle, however it looks different because I lowered the shock mounts on the axle housing.