Mallory 4309 fpr vac/boost nipple question (boosted Nikki)

#1

Mallory 4309 fpr vac/boost nipple question (boosted Nikki)

For those of you who have installed a Mallory 4309, where did you route the vac/boost nipple? Intake manifold or carb hat?

My specs:

Mallory 4309

MSD 2225 EFI fuel pump

boost prepped 81-85 Nikki

4 port R5 13B

S5 turbo

full 3" exhaust

I was told to hook it up to the carb hat, but that led to a nasty carb flooding problem every time I'd get on it in vacuum. Not even in boost yet! Just accelerating normally with the flow of traffic. It got so bad it'd stall out during a 3rd to 4th shift after getting up to the speed limit of 35 to 40mph and letting off.

A quick glance over at the AEM wideband showed 10.0 (it won't read any richer than that) and the tach was showing the engine had stalled.

The above was my experience with the mallory hooked up to a nipple on the carb hat.

Now I've noticed no one else does it like this. I've searched the forum a bunch today and it appears most blow through carb guys hook up their Mallory to a nipple on the manifold or two (teed together for the DCOE and OER guys). Is this the better choice? Or will the addition of vacuum pulling on the mallory diaphragm introduce a lean condition?

Remember I've always ran my setup hooked to the carb hat so it's always at 2.5psi at idle where it's probably not seeing any vacuum* but I could be wrong. It should only ever see boost here.

Yes I realize the Mallory instructions recommend hooking to the manifold as well so it can see vacuum and boost. I didn't see anything about using the carb hat or charge pipe as the source.

*I don't have a boost gauge hooked directly to the carb hat so I don't know whether it ever experiences vacuum. My boost gauge is hooked to the original so-called altitude compensator port on an old school hitachi manifold (the SA 12A manifolds have the same fitting) which connects both primary runners inside and has a block off bolt with a little 3/16" brass nipple. This brass nipple is Teed to the boost gauge and the BOV. I've since added a second T there which allowed the mallory to see the same boost and vacuum as the rest of the components.

The result? It doesn't flood out anymore! Yay! But then it had a different problem. I think it went lean or rich going up a hill. It sputtered, lost power and the wideband was showing 17.8 which is seriously lean or rich misfiring (could be one or the other, or both?), and I noticed a weird gas smell so I let off and waited a few seconds. The engine was fine after that. It seems the carb was leaking a bunch of gas out of probably the throttle shafts onto the hot intake manifold which caused it to evaporate instantly. It left a yellow stain.

This setup has had minor leaks onto the manifold before, always leaving a small tell-tale stain behind, but this time was a lot more volume than ever before. Did the sputtering have something to do with it? Was it like a super pig-rich condition that led to a rich misfire and sputtering (and leaking!) that led to the wideband showing a false lean condition causing me to originally jump to the wrong conclusion that it was too lean? When in actual reality it was too rich? I was told any time it missfires it will make the wideband read lean. Anyone out there have any thoughts on this?

I've had it sputter like that before from an overly rich condition recently. It was actually 10.0 the other day when I tested the fresh rebuilt racing Nikki with its Grose jets, and it sputtered big time up that very same hill in the same spot (the steep section lol). My conclusion was Grose jets don't like boost and left it at that. The mallory was still connected to the carb hat at that time.

But this other boost prepped 81-85 Nikki never did that before. It's always been the tust mule and it always behaves well in boost. Well, as well as can be expected, that is. Still better than some other Nikkis that get very upset when you force feed them.

One other thing: I've been doing all this testing on the primary circuit only. Trying to get them tuned 100% and because I had several gallons of 87 octane left over from some NA testing I did recently. It only takes a few hours to swap the turbo parts back in so I went for it to test a carb. That led to testing many more carbs while the turbo is in there. This led to the discovery of the anoying flooding problem which I now believe was due to the nipple on the carb hat and never opening the secondaries because of the 87 octane. I don't want to boost it right now for obvious reasons, however I've seen at least 1psi on primaries before I let off, which I think is interesting.

This led to the discovery of the anoying flooding problem which I now believe was due to the nipple on the carb hat and never opening the secondaries because of the 87 octane. I don't want to boost it right now for obvious reasons, however I've seen at least 1psi on primaries before I let off, which I think is interesting.

Anyway I believe part of my carb leakage problem this time around is due to the secondaries never getting opened, so the excess air pressure builds up in the charge pipe and the excess fuel gets forced out through the easiest place, which happens to be the throttle shafts. I'm not worried about that so much because it dries before it can do anything bad, but I still worry about the lean condition I saw. Was it real or false?

Let me say this again. The carb never leaked this much earlier this year back when I'd simply lay the pedal to the floor and break them loose in gear on dry road. I'm sure this was easily allowing all the incoming fuel and air to be consumed by the engine. But then this time around I've maintained strict discipline by never opening the secondaries and instead trying to get to the bottom of why the carb would always go pig rich, even in vacuum, which I seem to have solved by hooking up the mallory to the intake manifold like everybodyh else. But then I experienced a new problem when the wideband said pig-lean even though it flooded out all over the intake manifold. Maybe it was just extremely rich? It sputtered like it was. Heck, maybe simply opening the secondaries would have solved this particular problem or prevented it in the first place.

I'm sure this was easily allowing all the incoming fuel and air to be consumed by the engine. But then this time around I've maintained strict discipline by never opening the secondaries and instead trying to get to the bottom of why the carb would always go pig rich, even in vacuum, which I seem to have solved by hooking up the mallory to the intake manifold like everybodyh else. But then I experienced a new problem when the wideband said pig-lean even though it flooded out all over the intake manifold. Maybe it was just extremely rich? It sputtered like it was. Heck, maybe simply opening the secondaries would have solved this particular problem or prevented it in the first place.

Sorry for the book and any bad grammar. It's just my recent experience with a boosted Nikki. Some of you guys planning a similar setup might find it valuable.

My specs:

Mallory 4309

MSD 2225 EFI fuel pump

boost prepped 81-85 Nikki

4 port R5 13B

S5 turbo

full 3" exhaust

I was told to hook it up to the carb hat, but that led to a nasty carb flooding problem every time I'd get on it in vacuum. Not even in boost yet! Just accelerating normally with the flow of traffic. It got so bad it'd stall out during a 3rd to 4th shift after getting up to the speed limit of 35 to 40mph and letting off.

A quick glance over at the AEM wideband showed 10.0 (it won't read any richer than that) and the tach was showing the engine had stalled.

The above was my experience with the mallory hooked up to a nipple on the carb hat.

Now I've noticed no one else does it like this. I've searched the forum a bunch today and it appears most blow through carb guys hook up their Mallory to a nipple on the manifold or two (teed together for the DCOE and OER guys). Is this the better choice? Or will the addition of vacuum pulling on the mallory diaphragm introduce a lean condition?

Remember I've always ran my setup hooked to the carb hat so it's always at 2.5psi at idle where it's probably not seeing any vacuum* but I could be wrong. It should only ever see boost here.

Yes I realize the Mallory instructions recommend hooking to the manifold as well so it can see vacuum and boost. I didn't see anything about using the carb hat or charge pipe as the source.

*I don't have a boost gauge hooked directly to the carb hat so I don't know whether it ever experiences vacuum. My boost gauge is hooked to the original so-called altitude compensator port on an old school hitachi manifold (the SA 12A manifolds have the same fitting) which connects both primary runners inside and has a block off bolt with a little 3/16" brass nipple. This brass nipple is Teed to the boost gauge and the BOV. I've since added a second T there which allowed the mallory to see the same boost and vacuum as the rest of the components.

The result? It doesn't flood out anymore! Yay! But then it had a different problem. I think it went lean or rich going up a hill. It sputtered, lost power and the wideband was showing 17.8 which is seriously lean or rich misfiring (could be one or the other, or both?), and I noticed a weird gas smell so I let off and waited a few seconds. The engine was fine after that. It seems the carb was leaking a bunch of gas out of probably the throttle shafts onto the hot intake manifold which caused it to evaporate instantly. It left a yellow stain.

This setup has had minor leaks onto the manifold before, always leaving a small tell-tale stain behind, but this time was a lot more volume than ever before. Did the sputtering have something to do with it? Was it like a super pig-rich condition that led to a rich misfire and sputtering (and leaking!) that led to the wideband showing a false lean condition causing me to originally jump to the wrong conclusion that it was too lean? When in actual reality it was too rich? I was told any time it missfires it will make the wideband read lean. Anyone out there have any thoughts on this?

I've had it sputter like that before from an overly rich condition recently. It was actually 10.0 the other day when I tested the fresh rebuilt racing Nikki with its Grose jets, and it sputtered big time up that very same hill in the same spot (the steep section lol). My conclusion was Grose jets don't like boost and left it at that. The mallory was still connected to the carb hat at that time.

But this other boost prepped 81-85 Nikki never did that before. It's always been the tust mule and it always behaves well in boost. Well, as well as can be expected, that is. Still better than some other Nikkis that get very upset when you force feed them.

One other thing: I've been doing all this testing on the primary circuit only. Trying to get them tuned 100% and because I had several gallons of 87 octane left over from some NA testing I did recently. It only takes a few hours to swap the turbo parts back in so I went for it to test a carb. That led to testing many more carbs while the turbo is in there.

Anyway I believe part of my carb leakage problem this time around is due to the secondaries never getting opened, so the excess air pressure builds up in the charge pipe and the excess fuel gets forced out through the easiest place, which happens to be the throttle shafts. I'm not worried about that so much because it dries before it can do anything bad, but I still worry about the lean condition I saw. Was it real or false?

Let me say this again. The carb never leaked this much earlier this year back when I'd simply lay the pedal to the floor and break them loose in gear on dry road.

I'm sure this was easily allowing all the incoming fuel and air to be consumed by the engine. But then this time around I've maintained strict discipline by never opening the secondaries and instead trying to get to the bottom of why the carb would always go pig rich, even in vacuum, which I seem to have solved by hooking up the mallory to the intake manifold like everybodyh else. But then I experienced a new problem when the wideband said pig-lean even though it flooded out all over the intake manifold. Maybe it was just extremely rich? It sputtered like it was. Heck, maybe simply opening the secondaries would have solved this particular problem or prevented it in the first place.

I'm sure this was easily allowing all the incoming fuel and air to be consumed by the engine. But then this time around I've maintained strict discipline by never opening the secondaries and instead trying to get to the bottom of why the carb would always go pig rich, even in vacuum, which I seem to have solved by hooking up the mallory to the intake manifold like everybodyh else. But then I experienced a new problem when the wideband said pig-lean even though it flooded out all over the intake manifold. Maybe it was just extremely rich? It sputtered like it was. Heck, maybe simply opening the secondaries would have solved this particular problem or prevented it in the first place.

Sorry for the book and any bad grammar. It's just my recent experience with a boosted Nikki. Some of you guys planning a similar setup might find it valuable.

#2

Secondaries and the annoying delay

Speaking of secondaries, I still haven't solved the 1 to 1.5 second delay these carbs seem to have whenever you open the secondaries. It seems everyone who does a boosted Nikki experiences this, ranging from a hiccup, as some have called it, to a bog as others have said.

How to fix it?

I recently had a PM conversation with a guy who knows webers, and he said you need to change the air bleeds to make the secondaries come on sooner. He said since everything in the weber is big, you can block off the air bleeds with a toothpick. Well, I'll see what I can do.

Well, I'll see what I can do.

Actually, the secondary slow air bleeds #1 and #2 might hold the clues. These were sized by Mazda to allow smoother vacuum secondary transition. Well, that's irrelevant with a boosted Nikki with mechanical secondaries. So I assume we can change their sizes and not hurt anything in the driveability department. The only air bleeds we might need to leave alone would be the big main ones. If we make them too small, sure it might make them come online sooner, but it might richen the secondary mixture too much and hurt power. We don't need 10.0, but I think 11.5 or so? Someone correct me here if necessary.

How to fix it?

I recently had a PM conversation with a guy who knows webers, and he said you need to change the air bleeds to make the secondaries come on sooner. He said since everything in the weber is big, you can block off the air bleeds with a toothpick.

Well, I'll see what I can do.

Well, I'll see what I can do.Actually, the secondary slow air bleeds #1 and #2 might hold the clues. These were sized by Mazda to allow smoother vacuum secondary transition. Well, that's irrelevant with a boosted Nikki with mechanical secondaries. So I assume we can change their sizes and not hurt anything in the driveability department. The only air bleeds we might need to leave alone would be the big main ones. If we make them too small, sure it might make them come online sooner, but it might richen the secondary mixture too much and hurt power. We don't need 10.0, but I think 11.5 or so? Someone correct me here if necessary.

#3

Why is there a delay?

I think the delay comes from the incoming boost air forcing all the fuel out of the secondary emulsion circuit and possibly pushing air into the float bowl.

See, carbs work with vacuum. They aren't designed to handle boost, but if you can create conditions where the carb doesn't think it's getting boosted, everything should work as intended.

It's possible the stock Nikki float bowl vent isn't large enough, and the carb might work better if we were to add a brass nipple to the carb top on each side above each float bowl. Connect these nipples to the left over nipple on the carb hat. Ah Ha! I discovered a use for a useless nipple! But will it actually help equalize the pressures above the float bowls and match them to above the venturis better than the float bowl vent alone? It might. Thoughts?

But will it actually help equalize the pressures above the float bowls and match them to above the venturis better than the float bowl vent alone? It might. Thoughts?

The other half of the equation is we have to speed up the secondaries by making the slow air bleeds smaller. Or bigger? Either way, any change in the little nickel plated 60s or the long weird ones is going to affect stuff so you can't really go wrong here. I guess try it one way and then the other.

What do you guys think? Just block off the nickel plated 60s? Make the 140 main secondary air bleeds a little smaller? I know Sterling would mod his air bleeds but left the slow ones alone. I wonder if I should do the same?

You know what sucks is I used to have a set of rare 120 secondary main air bleeds. They went into a carb that is long gone. Oh well. I have a set of stock 120 fuel jets I could use if I machine the air bleed tops to accept them. Thoughts?

See, carbs work with vacuum. They aren't designed to handle boost, but if you can create conditions where the carb doesn't think it's getting boosted, everything should work as intended.

It's possible the stock Nikki float bowl vent isn't large enough, and the carb might work better if we were to add a brass nipple to the carb top on each side above each float bowl. Connect these nipples to the left over nipple on the carb hat. Ah Ha! I discovered a use for a useless nipple!

But will it actually help equalize the pressures above the float bowls and match them to above the venturis better than the float bowl vent alone? It might. Thoughts?

But will it actually help equalize the pressures above the float bowls and match them to above the venturis better than the float bowl vent alone? It might. Thoughts?The other half of the equation is we have to speed up the secondaries by making the slow air bleeds smaller. Or bigger? Either way, any change in the little nickel plated 60s or the long weird ones is going to affect stuff so you can't really go wrong here. I guess try it one way and then the other.

What do you guys think? Just block off the nickel plated 60s? Make the 140 main secondary air bleeds a little smaller? I know Sterling would mod his air bleeds but left the slow ones alone. I wonder if I should do the same?

You know what sucks is I used to have a set of rare 120 secondary main air bleeds. They went into a carb that is long gone. Oh well. I have a set of stock 120 fuel jets I could use if I machine the air bleed tops to accept them. Thoughts?

#4

carb whisperer

My current carb had the same problem with the secondary responsiveness, without a turbo.

I think when they get hogged out, and the linkage is forced open in a mechanical manner, the carbs "transition" into the fuel circuit becomes very difficult. What your friend said is true, and a common cure for the leaning out on high end racing four barrel carbs.

I did the same thing as what I would do on a holley, or demon. I shrank the low and high speed air bleeds (Secondary circuit) making the circuit more responsive with virtually every change I made smaller thereafter. It required I make jet changes, and it slightly altered the fuel curve, but in your case the fuel curve I got was probably better suited for a turbo, anyways.

Mind you, I also very recently did this on a Holley carb, much to the same result. Only there, it didnt affect the fuel curve at all. It just made the circuit come on sooner haha.

I think when they get hogged out, and the linkage is forced open in a mechanical manner, the carbs "transition" into the fuel circuit becomes very difficult. What your friend said is true, and a common cure for the leaning out on high end racing four barrel carbs.

I did the same thing as what I would do on a holley, or demon. I shrank the low and high speed air bleeds (Secondary circuit) making the circuit more responsive with virtually every change I made smaller thereafter. It required I make jet changes, and it slightly altered the fuel curve, but in your case the fuel curve I got was probably better suited for a turbo, anyways.

Mind you, I also very recently did this on a Holley carb, much to the same result. Only there, it didnt affect the fuel curve at all. It just made the circuit come on sooner haha.

#6

'85 12a

iTrader: (10)

I read the above 4 times in the last couple hours in order to learn, which is why I'm here. I can offer only a cooks perspective, which may well be of no value.

A carb does work off of vacuum. But it's the vacuum from the Bernoulli effect, which is a result of velocity thru the venturies. This should be true whether forced from above or pulled from below. There are obviously variables I don't understand, but there's that.

The float bowl vent to the carb hat seems to make sense. Worth a try.

Plug the air bleeds with a toothpick. I would. Cheap and easy. See what happens. Then to open them a tiny bit poke a hole in the toothpick or down its side with a sewing pin or needle, to see what that gets you. It just seems like an easy, or maybe lazy, way to experiment.

That's all I have. I look forward to reading where this goes.

A carb does work off of vacuum. But it's the vacuum from the Bernoulli effect, which is a result of velocity thru the venturies. This should be true whether forced from above or pulled from below. There are obviously variables I don't understand, but there's that.

The float bowl vent to the carb hat seems to make sense. Worth a try.

Plug the air bleeds with a toothpick. I would. Cheap and easy. See what happens. Then to open them a tiny bit poke a hole in the toothpick or down its side with a sewing pin or needle, to see what that gets you. It just seems like an easy, or maybe lazy, way to experiment.

That's all I have. I look forward to reading where this goes.

#7

Some degree of Success!

Thanks. One more way for the carb to receive vacuum would be when the throttle is closed, like at idle, and it's pulling anywhere from 15inHg to like 18inHg. Pretty much related so thought I'd mention it.

Ok so I made some progress on the flooding problem and the too-lean problem.

First of all, I did the same hill test and this time stayed focused on the wideband. Sure enough it does go lean. Yep, lean for real. The carb was literally running out of gas. The wideband read anywhere from 15 to 18.0 and then three dashes which means beyond the gauge's scale. It sputtered and behaved as it should when it's running out of gas. Now I know what bad83 was talking about and why he deleted the stock banjo bolt fuel rail setup in favor of directly feeding each needle and seat with a dedicated line directly from the fpr.

But!!!

It's not necessary to do that. I think I found the solution today.

See, he probably had his fpr, which was likely a mallory 4309, hooked to the manifold as per mallory's instructions. Can't fault him there. I just tried it the same way and ran into serious fuel supply issues. I wonder how many 12A turbo blow through Nikki guys popped an engine due to this.

Good thing I wasn't really boosting my setup as it was still on primaries, but being a 74 ported 13B with a hogged out Nikki, not a stock ported 12A with a stock venturi Nikki, it uses a lot more fuel at any RPM. So the chances of their setups running lean like that at a higher RPM in boost with their secondaries open is far more likely to happen while mine does it at a lower RPM and right around 0inHg or maybe 1psi while still in primaries.

I discussed my findings with a guy who had a boosted DCOE setup and grew to hate it, but before he got rid of his setup, the carb hat had one or more small boost leaks and it never flooded the carb out as far as I know. His mallory was hooked to the carb hat as well so it only saw boost. Never vacuum. Just like my setup, but mine would flood the moment the mallory saw anything above atmospheric. I'm actually using some of his old parts, including the mallory. So we discussed ways to maybe bleed off some of that incoming boost signal, just enough, to prevent the carb from flooding before actually entering boost, but be a small enough leak so it doesn't hurt performance. Something kinda like a leaky carb hat, but controllable and adjustable. A calibrated boost leak!

My solution was to hook a T fitting inline between the carb hat and the mallory. I'm using stock vacuum line at 3/16 which is a common size for T fittings to find at the store. I then grabbed a broken stock primary slow air bleed (the long one) with the 46 stamped on it, ground down the threads a little so it would fit snug in the hose, and test drove it.

Mostly success!

It still kinda wants to flood itself, but it isn't as severe and not as easily or at such a low RPM as it did before. I think I'm going in the right direction! More testing is needed with a slightly larger orifice. So I drilled through the bottom tiny .46mm hole with my trusty 118 drill bit so now the next smallest hole is at the top which looks just a touch larger than a nickel plated 60. I'm visually estimating about 65 or so.

Will this be enough?

So I'm going up from 46 to about 65 or 66. That is a jump of 20. Compare that with the original jump going from nothing to 46 and you can see it is not that drastic of a change. I feel it should improve the flooding problem while not allowing the carb to go dangerously lean like when it was hooked to the manifold, and it won't bleed off any noticeable boost so it won't hurt performance.

I think anyone planning a boosted Nikki should really pay attention to this info. But you know, that's my opinion.

Ok so I made some progress on the flooding problem and the too-lean problem.

First of all, I did the same hill test and this time stayed focused on the wideband. Sure enough it does go lean. Yep, lean for real. The carb was literally running out of gas. The wideband read anywhere from 15 to 18.0 and then three dashes which means beyond the gauge's scale. It sputtered and behaved as it should when it's running out of gas. Now I know what bad83 was talking about and why he deleted the stock banjo bolt fuel rail setup in favor of directly feeding each needle and seat with a dedicated line directly from the fpr.

But!!!

It's not necessary to do that. I think I found the solution today.

See, he probably had his fpr, which was likely a mallory 4309, hooked to the manifold as per mallory's instructions. Can't fault him there. I just tried it the same way and ran into serious fuel supply issues. I wonder how many 12A turbo blow through Nikki guys popped an engine due to this.

Good thing I wasn't really boosting my setup as it was still on primaries, but being a 74 ported 13B with a hogged out Nikki, not a stock ported 12A with a stock venturi Nikki, it uses a lot more fuel at any RPM. So the chances of their setups running lean like that at a higher RPM in boost with their secondaries open is far more likely to happen while mine does it at a lower RPM and right around 0inHg or maybe 1psi while still in primaries.

I discussed my findings with a guy who had a boosted DCOE setup and grew to hate it, but before he got rid of his setup, the carb hat had one or more small boost leaks and it never flooded the carb out as far as I know. His mallory was hooked to the carb hat as well so it only saw boost. Never vacuum. Just like my setup, but mine would flood the moment the mallory saw anything above atmospheric. I'm actually using some of his old parts, including the mallory. So we discussed ways to maybe bleed off some of that incoming boost signal, just enough, to prevent the carb from flooding before actually entering boost, but be a small enough leak so it doesn't hurt performance. Something kinda like a leaky carb hat, but controllable and adjustable. A calibrated boost leak!

My solution was to hook a T fitting inline between the carb hat and the mallory. I'm using stock vacuum line at 3/16 which is a common size for T fittings to find at the store. I then grabbed a broken stock primary slow air bleed (the long one) with the 46 stamped on it, ground down the threads a little so it would fit snug in the hose, and test drove it.

Mostly success!

It still kinda wants to flood itself, but it isn't as severe and not as easily or at such a low RPM as it did before. I think I'm going in the right direction! More testing is needed with a slightly larger orifice. So I drilled through the bottom tiny .46mm hole with my trusty 118 drill bit so now the next smallest hole is at the top which looks just a touch larger than a nickel plated 60. I'm visually estimating about 65 or so.

Will this be enough?

So I'm going up from 46 to about 65 or 66. That is a jump of 20. Compare that with the original jump going from nothing to 46 and you can see it is not that drastic of a change. I feel it should improve the flooding problem while not allowing the carb to go dangerously lean like when it was hooked to the manifold, and it won't bleed off any noticeable boost so it won't hurt performance.

I think anyone planning a boosted Nikki should really pay attention to this info. But you know, that's my opinion.

Trending Topics

#9

Just a correction from earlier. It turns out bad83 did plumb his fpr to his carb hat. He also used an aeromotive fpr with an anodized housing. Look. https://www.rx7club.com/build-thread...3/#post7966226

#10

Solder Success!

I got some 92 octane gas, threw on the spare carb with the solder filled secondary slow air bleeds and proceeded to break them loose in gear on dry road without having to wait an eternity for the anoying delay. It's just down to about 1/4 second or a fraction of a second delay now. Orders of magnitude better. It's kinda like my early days of NA mechanical secondary testing  only with a whole new dimension of power

only with a whole new dimension of power

I liked this setup so much I filled enough slow air bleeds to do the other three boost prepped Nikkis. I'm even considering doing two 79 carbs that aren't boost prepped, but still hogged out with mechanical secondaries. So far the secondaries open without a delay, but I wonder.

wankel=awesome, you said your secondaries improved when you made the secondary air bleeds progressively smaller. Could you tell me more about it? I'm anxious for more detail and whether you'd recommend it on my two NA hogged carbs. Thanks.

only with a whole new dimension of power

only with a whole new dimension of powerI liked this setup so much I filled enough slow air bleeds to do the other three boost prepped Nikkis. I'm even considering doing two 79 carbs that aren't boost prepped, but still hogged out with mechanical secondaries. So far the secondaries open without a delay, but I wonder.

wankel=awesome, you said your secondaries improved when you made the secondary air bleeds progressively smaller. Could you tell me more about it? I'm anxious for more detail and whether you'd recommend it on my two NA hogged carbs. Thanks.

#11

I got some 92 octane gas, threw on the spare carb with the solder filled secondary slow air bleeds and proceeded to break them loose in gear on dry road without having to wait an eternity for the anoying delay. It's just down to about 1/4 second or a fraction of a second delay now. Orders of magnitude better. It's kinda like my early days of NA mechanical secondary testing  only with a whole new dimension of power

only with a whole new dimension of power

I liked this setup so much I filled enough slow air bleeds to do the other three boost prepped Nikkis. I'm even considering doing two 79 carbs that aren't boost prepped, but still hogged out with mechanical secondaries. So far the secondaries open without a delay, but I wonder.

wankel=awesome, you said your secondaries improved when you made the secondary air bleeds progressively smaller. Could you tell me more about it? I'm anxious for more detail and whether you'd recommend it on my two NA hogged carbs. Thanks.

only with a whole new dimension of power

only with a whole new dimension of powerI liked this setup so much I filled enough slow air bleeds to do the other three boost prepped Nikkis. I'm even considering doing two 79 carbs that aren't boost prepped, but still hogged out with mechanical secondaries. So far the secondaries open without a delay, but I wonder.

wankel=awesome, you said your secondaries improved when you made the secondary air bleeds progressively smaller. Could you tell me more about it? I'm anxious for more detail and whether you'd recommend it on my two NA hogged carbs. Thanks.

try putting the boost refrence for the fpr in the intake manifold(T the front and rear rotor together for best signal) put a one way valve inline so the regulator only sees boost, no vacuum.. every car is slightly different you have to find what yours likes

its cheese time or me! hope this helps Jeff!

its cheese time or me! hope this helps Jeff!

#12

carb whisperer

By reducing the size of the high speeds, you are effectively strengthening the circuit, and speeding up emulsions. The faster, and more responsive that circuit is, the less time it will take for the jet to catch up with the booster, since with smaller high speeds the jet is literally being sucked on harder for the same amounts of booster speed.

If that makes sense.

If you reduce your secondary air bleed sizes, you will notice the wideband hitting your target AFR for your secondaries sooner, because the massive influx of air can be calibrated to be the right amount of air to be emulsified and shot out of the boosters. My 450 cfm square bore carb takes about .5 second to hit 12.5:1 AFR from the second the secondaries open up. Reducing the size (almost 20 holley bleed sizes) got it there, from something like 3 full seconds of waiting for the air to speed up enough to signal enough fuel and suck the jet hard enough.

Doing this can have a negative effect though, making the same jet size pull more fuel when the airspeed really does speed up, making it overly rich. This can be addressed with tuning aswell, by modifying your emulsions restrictions. Smaller (or even blocked off) low-->mid emulsions restrictions will also strengthen the signal to make your jet pull more at lower air speeds. It is key to compensate for the increased signal, by enlarging your high speed emulsions to slow the jet down when you need it the least, when the carb is flowing large amounts of air (NA). For you, the more fuel up top the better since you have a turbo. But in the event that you achieve the perfect curve and signal strength for when your secondaries first come on, slowing the main jet down via emulsions can perfect your fuel curve much in the same way the OEM's do when building application specific carbs. (crate engine carbs, "tuned carbs", etc.)

TLDR: its complicated, but simple. Just keep in mind carb tuning is 90% making your main jets add fuel when you want it, and not add so much when you dont want it. Sometimes just putting in larger/smaller jets isnt enough, and you have to calibrate your own fuel "curve" by manipulating signal to the jets.

Either way, I have faith youll beat it, or get it as close to perfect as mechanically possible with that platform. Just think outside the box and think back to the days when people somehow did this without widebands, by using flowbenches and doing the physical math based on the carb specs, horsepower demands, and airflow. (And plug reading, lol)

#14

TaK

iTrader: (1)

Haven't boosted a Nikki but have boosted holleys.

The nip on the regulator goes to the boost hat. It goes to the boost hat to reference the bowl vent pressure, for example if you have 6psi fuel and add 6psi boost no fuel would enter the bowl because the air pressure is equal to the fuel pressure. So the reference is 1 to 1 so if you start 6psi fuel and add 6 psi air the regulator will add another 6 psi fuel to the sytem is balanced.

The fuel level rising after boost is common in blowthrough. Best way to fight it a shorten the length of fuel line from the regulator to the carb. Also make sure your return line is large enough to flow the excess fuel back to the tank when the regulator opens after boost. I like to run a larger rerun line than the feed line.

The smaller the fuel line from the regulator to the carb the better if you have a long wide dia line the pressure has no where to go but into the carb after you stop boosting which is why is floods. The needle an seat is the bottle neck in the carb fuel system maybe a 1/8" tops being a large neddle and seat so why run a 1/2" fuel line to that? I use very short runs of 6an line and I believe 4 an is adequate. Yes 4 an is small but if its larger than the total area of you needle and seat it should work and eliminate the flooding issue.

To be safe start with moving the regulator very close to the carb reducing the amount of fuel stored in the fuel line and make sure your return line off the regulator is larger than the feed line. Good luck.

The nip on the regulator goes to the boost hat. It goes to the boost hat to reference the bowl vent pressure, for example if you have 6psi fuel and add 6psi boost no fuel would enter the bowl because the air pressure is equal to the fuel pressure. So the reference is 1 to 1 so if you start 6psi fuel and add 6 psi air the regulator will add another 6 psi fuel to the sytem is balanced.

The fuel level rising after boost is common in blowthrough. Best way to fight it a shorten the length of fuel line from the regulator to the carb. Also make sure your return line is large enough to flow the excess fuel back to the tank when the regulator opens after boost. I like to run a larger rerun line than the feed line.

The smaller the fuel line from the regulator to the carb the better if you have a long wide dia line the pressure has no where to go but into the carb after you stop boosting which is why is floods. The needle an seat is the bottle neck in the carb fuel system maybe a 1/8" tops being a large neddle and seat so why run a 1/2" fuel line to that? I use very short runs of 6an line and I believe 4 an is adequate. Yes 4 an is small but if its larger than the total area of you needle and seat it should work and eliminate the flooding issue.

To be safe start with moving the regulator very close to the carb reducing the amount of fuel stored in the fuel line and make sure your return line off the regulator is larger than the feed line. Good luck.

#15

Shredduuhh

Thanks for that but I already tried hooking the fpr to the manifold. It leaned out horribly under load (near or at 0 vacuum) instead of flooding out. I'd rather flood a bit for safety than lean out so I moved it back to the carb hat and just added about a 1mm calibrated boost leak to the fpr's boost sensing line right in the middle of the hose run. This small leak fixed about 80 to 90 percent of the flooding issues and still allows the fpr to push fuel into the carb under boost. It still wants to flood after boost though... Of course more testing is needed to make sure the calibrated boost leak is the right size. I can easily go bigger or smaller by swapping out the modded slow air bleeds I'm using.  So far I've tested 46, 66 and now 100 (1mm) and I might need to go a little bigger to fine tune when the mallory reacts, but I'm close.

So far I've tested 46, 66 and now 100 (1mm) and I might need to go a little bigger to fine tune when the mallory reacts, but I'm close.

I just looked online and a diagram recommended .042" hole. My 118 drill bit is around .045" or .046" so I could try this size next.

So far I've tested 46, 66 and now 100 (1mm) and I might need to go a little bigger to fine tune when the mallory reacts, but I'm close.

So far I've tested 46, 66 and now 100 (1mm) and I might need to go a little bigger to fine tune when the mallory reacts, but I'm close.I just looked online and a diagram recommended .042" hole. My 118 drill bit is around .045" or .046" so I could try this size next.

#16

wankel=awesome

It kinda makes sense. Smaller secondary bleeds made the fuel come online sooner, but can also make it richer so maybe some smaller fuel jets are in order. Stock fuel jets are 160, and I have 155, 150, 145 and 140 available. But then bad83 and others who boosted their Nikkis a few years ago were saying you have to make the secondary fuel jets bigger. When I tried some 200 (it was closer to 208), it bogged so long I had to let up and not bother trying them again. Like 3 seconds I guess? Then I tried 150 and it wasn't much different than 160 for the 1.5 second delay, only a little leaner but within the safety margin for the stock S5 boost level I was running (at 7psi or so). This was in the early days before I settled on stock 160 jets and living with the 1.5 to 2 second delay.

I had only some secondary testing time yesterday, but what I gathered is when the secondaries open, you have to pay more attention to where the car's front end is pointing and can't look at the wideband lol. Even in 2nd gear . But yes I'm thinking the secondaries have gotten slightly richer now that the slow bleeds have been blocked. Not a bad thing on a turbo, like you said. Gotta get to a point of being able to look at the wideband under boost, though, to know for sure.

. But yes I'm thinking the secondaries have gotten slightly richer now that the slow bleeds have been blocked. Not a bad thing on a turbo, like you said. Gotta get to a point of being able to look at the wideband under boost, though, to know for sure.

What I'd like to try next is reduce the size of the fast bleeds? It that the main 140 air bleeds you're talking about? Anyway I used to have some stock 120 air bleeds so I'm thinking about modding a set of stock 160 bleeds, which I will never use, to try some 120 fuel jets. Or get some Holley air bleeds which are very similar in size and thread pitch. I'll just try the 120s first and see how it goes before buying anything. I also have some 100s and 130s for fine tuning.

I'm not going to try filling the tops with solder to drill because it can trickle down into the emulsion tube ruining it.

Ok, I just re-read the part where you might be implying going to maybe a slightly larger main air bleed. I take it to mean maybe try the 160 air bleeds again? They increased the delay from 1.5 to 2 seconds or more. I guess I'm confused.

Thanks. Yeah, I used to do NA tuning without a wideband. Just plug and tail pipe reading, and seat of the pants. What a dark age. Since I added a bung to my RB long primary, it's made a world of difference for NA tuning. And I can't even imagine a boosted setup without a wideband.

I had only some secondary testing time yesterday, but what I gathered is when the secondaries open, you have to pay more attention to where the car's front end is pointing and can't look at the wideband lol. Even in 2nd gear

. But yes I'm thinking the secondaries have gotten slightly richer now that the slow bleeds have been blocked. Not a bad thing on a turbo, like you said. Gotta get to a point of being able to look at the wideband under boost, though, to know for sure.

. But yes I'm thinking the secondaries have gotten slightly richer now that the slow bleeds have been blocked. Not a bad thing on a turbo, like you said. Gotta get to a point of being able to look at the wideband under boost, though, to know for sure.What I'd like to try next is reduce the size of the fast bleeds? It that the main 140 air bleeds you're talking about? Anyway I used to have some stock 120 air bleeds so I'm thinking about modding a set of stock 160 bleeds, which I will never use, to try some 120 fuel jets. Or get some Holley air bleeds which are very similar in size and thread pitch. I'll just try the 120s first and see how it goes before buying anything. I also have some 100s and 130s for fine tuning.

I'm not going to try filling the tops with solder to drill because it can trickle down into the emulsion tube ruining it.

Ok, I just re-read the part where you might be implying going to maybe a slightly larger main air bleed. I take it to mean maybe try the 160 air bleeds again? They increased the delay from 1.5 to 2 seconds or more. I guess I'm confused.

Thanks. Yeah, I used to do NA tuning without a wideband. Just plug and tail pipe reading, and seat of the pants. What a dark age. Since I added a bung to my RB long primary, it's made a world of difference for NA tuning. And I can't even imagine a boosted setup without a wideband.

#17

Cookboy

You may yet get a hogged Nikki in your car. Maybe do the work yourself like glazedham42 and t_g_farrel. I'm sure all the ins and outs we've figured out and shared on the forum could be used by anyone successfully, but there is still a leap of faith involved. You have to be willing to ruin your carb.  Also a few basic tools are needed to make the venturis bigger in a controllable way. Don't just "hog them out" like we say.

Also a few basic tools are needed to make the venturis bigger in a controllable way. Don't just "hog them out" like we say.

Also a few basic tools are needed to make the venturis bigger in a controllable way. Don't just "hog them out" like we say.

Also a few basic tools are needed to make the venturis bigger in a controllable way. Don't just "hog them out" like we say.

#18

ghost1000

Yes, it's a "boost referenced" fpr at 1:1, not a "rising rate" as some folks mistakenly said a few years ago. I didn't know the difference or that there was a difference until only very recently when I got a mallory and had to correct my terminology. But you already know about this stuff. It's more for the noobs when they read this thread.

So if the mallory's lowest pressure is rated at 3psi, and the Nikki typically wants 2.5psi, what am I to do? It turns out my mallory is capable of 2 to 2.5 psi based on its mood, the ambient temp and how much fuel is in the tank. Oh also the condition of the filter in front of the fuel pump. My tank was kinda gross inside but a few filter swaps is getting rid of the majority of the "stuff" and then a couple gas treatments later, it should be pretty good. It has a nice metal EFI rated filter after the pump and it does a good job. The carb only ends up with a few microscopic bits of sediment these days. They're the same size as pollen grains which are way smaller than the smallest orifice in the carb, which happens to be the primary fuel jets at 118. Not even the accel pump is blocked as it too has been drilled to the same size (118 or about .45" or .46", while Sterling recommends drilling the squirter nozzles to .050" but I just didn't have that size lying around lol).

Getting back to the mallory, unfortunately my send line is bigger than my return. The send was upgraded to 3/8" and the return is the stock GSL-SE 5/16" (8mm). I think this could be contributing to some of my issues. I might swap in a 5/16" send line at some point but I like what you're saying about making the return bigger than the send. It's also what mallory recommends. If I could just swap mine around, it might make life easier. But something insteresting I can mention is on PercentSevenC's car, it got my stock GSL-SE 5/16" send line and he said the mallory could go all the way down to 1psi when he used his stock 5/16 send as a return (or vice versa - they were both 5/16"). We were both using MSD fuel pumps and I now have his mallory so the only significant change is my new 3/8" send. I'm sure this is at least partially responsible for the minor flooding I'm experiencing.

The fuel line from the mallory to the carb is as short as possible. It is only 5/16 hose. However the line from the pump freely flows into the carb using the mallory housing like a pass through. This is again according to mallory's instructions. Hmm, now I can see where some of the flooding may be comming from. Yeah if nothing else, if I were to simply downsize the 3/8 send from the pump to the mallory to a 5/16", that might just fix it. Cool! Now I have a fair weather project.

I have a couple of other mallory installs for future turbo setups, and because they work great for NA too compared with most other FPRs; one has the correct Mallory recommended 5/16" send and 3/8" return on a rotary baja project. I built this system from the ground up according to the instructions because the last thing I want to have happen is for it to flood out while gunning it up a hill trying to keep the tires from filling with mud or snow, only to have it stall partway up the hill. Still debating whether to even go turbo on this setup because of that possiblity, oh and the drivetrain parts are stock VW so adding an extra 100HP doesn't sound like a such a good idea. But even if it's kept NA, the larger return should allow the mallory to function properly. The other project is a rotary truck with the stock 5/16" send and 1/4" return. So far the mallory, NA, doesn't seem to flood the carb but it's a very young setup. Truth be told the baja hasn't even been tested yet. Still got lots of wiring to do. At least the truck should handle the extra power fine.

So if the mallory's lowest pressure is rated at 3psi, and the Nikki typically wants 2.5psi, what am I to do? It turns out my mallory is capable of 2 to 2.5 psi based on its mood, the ambient temp and how much fuel is in the tank. Oh also the condition of the filter in front of the fuel pump. My tank was kinda gross inside but a few filter swaps is getting rid of the majority of the "stuff" and then a couple gas treatments later, it should be pretty good. It has a nice metal EFI rated filter after the pump and it does a good job. The carb only ends up with a few microscopic bits of sediment these days. They're the same size as pollen grains which are way smaller than the smallest orifice in the carb, which happens to be the primary fuel jets at 118. Not even the accel pump is blocked as it too has been drilled to the same size (118 or about .45" or .46", while Sterling recommends drilling the squirter nozzles to .050" but I just didn't have that size lying around lol).

Getting back to the mallory, unfortunately my send line is bigger than my return. The send was upgraded to 3/8" and the return is the stock GSL-SE 5/16" (8mm). I think this could be contributing to some of my issues. I might swap in a 5/16" send line at some point but I like what you're saying about making the return bigger than the send. It's also what mallory recommends. If I could just swap mine around, it might make life easier. But something insteresting I can mention is on PercentSevenC's car, it got my stock GSL-SE 5/16" send line and he said the mallory could go all the way down to 1psi when he used his stock 5/16 send as a return (or vice versa - they were both 5/16"). We were both using MSD fuel pumps and I now have his mallory so the only significant change is my new 3/8" send. I'm sure this is at least partially responsible for the minor flooding I'm experiencing.

The fuel line from the mallory to the carb is as short as possible. It is only 5/16 hose. However the line from the pump freely flows into the carb using the mallory housing like a pass through. This is again according to mallory's instructions. Hmm, now I can see where some of the flooding may be comming from. Yeah if nothing else, if I were to simply downsize the 3/8 send from the pump to the mallory to a 5/16", that might just fix it. Cool! Now I have a fair weather project.

I have a couple of other mallory installs for future turbo setups, and because they work great for NA too compared with most other FPRs; one has the correct Mallory recommended 5/16" send and 3/8" return on a rotary baja project. I built this system from the ground up according to the instructions because the last thing I want to have happen is for it to flood out while gunning it up a hill trying to keep the tires from filling with mud or snow, only to have it stall partway up the hill. Still debating whether to even go turbo on this setup because of that possiblity, oh and the drivetrain parts are stock VW so adding an extra 100HP doesn't sound like a such a good idea. But even if it's kept NA, the larger return should allow the mallory to function properly. The other project is a rotary truck with the stock 5/16" send and 1/4" return. So far the mallory, NA, doesn't seem to flood the carb but it's a very young setup. Truth be told the baja hasn't even been tested yet. Still got lots of wiring to do. At least the truck should handle the extra power fine.

#19

carb whisperer

The emulsions curve for NA cant even be close to what a turbo car would need.

Anyone have any pictures of the nikkis etube? iirc the etube is made into the high speed bleed?

But yes, smaller air bleeds to speed up emulsions, but further mods to the actual etube "holes in the straw" to perfect the curve.

Further, what is your AFR # just after the bog starts on the wideband?

And, this may sound obvious but have you tried lowering the floats at the 3 psi that the mallory is happy with?

#20

I would like to keep the stock 160 fuel jets and 140 air bleeds.

You're right that the curve had to be adjusted from NA to boost. NA mode likes primary air bleeds of around 70 but boost likes 90 just as one example. Boost also seems to like smaller primary fuel jets. NA likes around 130 while boost likes around my custom drilled 118 which is actually closer to about a stock 122 or 123? It seems bigger than a stock 120 as the drill bit will not fit but passes easily through a 130.

It just happens that some primary air bleeds have 6 sets of progression holes, some have 7 and I think some have 8. The secondaries have fewer holes and they're further down.

I guess I could get a couple pics of Nikki etubes. Yes, the high speed air bleed and etube are a unit.

I see what you're talking about the holes in the straw. The secondaries have less holes allowing the fuel level to drop quite a bit in the bowls before they're uncovered. I actually did a bit of primary etube tuning with my 90s as some have 6 and others have 7 sets of prog holes. I found the carbs with 7 holes tend to feel a bit flat. I'll test this theory when the weather clears up. I can't do these tests on wet road. lol

As for the wideband reading just after the bog starts, it's kind of colored by the accel pump. Remember I had to do the Sterling accel pump mod to compensate for the lack of a secondary accel pump, so it squirts well enough to not allow a bog in NA mode. This was even before I filled the secondary slow bleeds with solder.

Speaking of which, I just swapped in some solder filled sec slow bleeds into both NA 79 carbs. I figured why not? They're both set up for high performance, one being a racing carb with 26mm primary venturis and 31mm secondaries and the other having 24.7mm primaries and stock or maybe hogged out secondaries (still debating what to do). Neither of these carbs bogged which received the same accel pump treatment as the turbo carbs.

I can typically see a jump of a few numbers when I tap the pedal It can go from 12 or 13 down to 11 or 10 when I give a quick stab of the pedal. But I'll see what I can do about paying attention to the wideband just after the bog starts.

As for the last question you asked, the Nikkis tend to have the float level (fuel level in the windows) right in the middle at idle. I understand this is ideal to take advantage of the stock holes in the straw, but I know there is some tuning to be done here. Unfortunately I'm still kinda new at it so I've made sure all the carbs tend to be right in the middle. Some can be above or below by a mm or two and not hurt anything. Of course I know that the level can change a lot while driving from slosh to the mallory doing its job letting in more than 2.5 psi whenever called to do so.

You're right that the curve had to be adjusted from NA to boost. NA mode likes primary air bleeds of around 70 but boost likes 90 just as one example. Boost also seems to like smaller primary fuel jets. NA likes around 130 while boost likes around my custom drilled 118 which is actually closer to about a stock 122 or 123? It seems bigger than a stock 120 as the drill bit will not fit but passes easily through a 130.

It just happens that some primary air bleeds have 6 sets of progression holes, some have 7 and I think some have 8. The secondaries have fewer holes and they're further down.

I guess I could get a couple pics of Nikki etubes. Yes, the high speed air bleed and etube are a unit.

I see what you're talking about the holes in the straw. The secondaries have less holes allowing the fuel level to drop quite a bit in the bowls before they're uncovered. I actually did a bit of primary etube tuning with my 90s as some have 6 and others have 7 sets of prog holes. I found the carbs with 7 holes tend to feel a bit flat. I'll test this theory when the weather clears up. I can't do these tests on wet road. lol

As for the wideband reading just after the bog starts, it's kind of colored by the accel pump. Remember I had to do the Sterling accel pump mod to compensate for the lack of a secondary accel pump, so it squirts well enough to not allow a bog in NA mode. This was even before I filled the secondary slow bleeds with solder.

Speaking of which, I just swapped in some solder filled sec slow bleeds into both NA 79 carbs. I figured why not? They're both set up for high performance, one being a racing carb with 26mm primary venturis and 31mm secondaries and the other having 24.7mm primaries and stock or maybe hogged out secondaries (still debating what to do). Neither of these carbs bogged which received the same accel pump treatment as the turbo carbs.

I can typically see a jump of a few numbers when I tap the pedal It can go from 12 or 13 down to 11 or 10 when I give a quick stab of the pedal. But I'll see what I can do about paying attention to the wideband just after the bog starts.

As for the last question you asked, the Nikkis tend to have the float level (fuel level in the windows) right in the middle at idle. I understand this is ideal to take advantage of the stock holes in the straw, but I know there is some tuning to be done here. Unfortunately I'm still kinda new at it so I've made sure all the carbs tend to be right in the middle. Some can be above or below by a mm or two and not hurt anything. Of course I know that the level can change a lot while driving from slosh to the mallory doing its job letting in more than 2.5 psi whenever called to do so.

#21

carb whisperer

I would like to keep the stock 160 fuel jets and 140 air bleeds.

You're right that the curve had to be adjusted from NA to boost. NA mode likes primary air bleeds of around 70 but boost likes 90 just as one example. Boost also seems to like smaller primary fuel jets. NA likes around 130 while boost likes around my custom drilled 118 which is actually closer to about a stock 122 or 123? It seems bigger than a stock 120 as the drill bit will not fit but passes easily through a 130.

You're right that the curve had to be adjusted from NA to boost. NA mode likes primary air bleeds of around 70 but boost likes 90 just as one example. Boost also seems to like smaller primary fuel jets. NA likes around 130 while boost likes around my custom drilled 118 which is actually closer to about a stock 122 or 123? It seems bigger than a stock 120 as the drill bit will not fit but passes easily through a 130.

Then youll notice it leaner than you like up top, so then enlarging your jet will make it fatter where your bog is, but just right where bog isnt after the etube is modded... if that makes sense?

Unless, the goal is to lean your bog out more. I still dont know what direction your bog is in, rich or lean?

#22

Ok, that sounds like a cool idea to try. I have a good candidate set of 140 air bleeds that had a little corrosion inside. I could see about drilling the progression holes out to 118 which should only be a slight bump in size from their stock size of around 1mm or so. I'll take a look at them and get back to you.

I also have a .065" drill bit which is just a tad larger than a stock 160 fuel jet. I see about 161 on my digital caliper. It will not fit a stock 160 - again probably due to the stamped sizes not being actually the actual sizes like j9fd3s mentioned. So it should be a very small increase in size and may or may not be noticeable, but I think I follow what you're saying, so I am willing to try it.

As for whether the bog is lean or rich, I think it could be a lean bog. My reasoning is based on what happens in a single accel pump carb when mechanical secondaries are opened. As you reach the top of the primary circuit and all that air is flowing through, then you suddenly open the secondaries, it used to bog for a long time. This was obviously due to the slow bleeds letting too much air into the circuit (if my reasoning is correct). So by blocking them off with solder, that incoming air is eliminated and the result cuts the bog time down from 1.5 to 2 seconds to a quarter second up to a max of about a half second. So more fuel, sooner. Thus by richening up the secondaries in that way, it shortened the bog time considerably. Therefore I believe the bog was due to a lean condition. Oh, also because the single accel pump can only deliver so much fuel - it's like back in the day when I was first doing mechanical sec mods and got a very similar bog until I did the Sterling accel pump mod. Seems as if the extra air from the turbo requires... yep, extra fuel.

To put it in other words, while on primaries only, fuel was flowing fine. But as soon as you open the secondaries, there is not enough additional fuel flowing yet, hence a lean condition.

So if we work from the conclusion that it is a lean bog, I will do the mods listed above and let you know. I'll only do this on the secondary etubes because the primary circuits seem pretty good.

Ok, I'm going to ****** the carb off the engine in between rain storms today and let you know my progress. Maybe take a couple pics too.

I also have a .065" drill bit which is just a tad larger than a stock 160 fuel jet. I see about 161 on my digital caliper. It will not fit a stock 160 - again probably due to the stamped sizes not being actually the actual sizes like j9fd3s mentioned. So it should be a very small increase in size and may or may not be noticeable, but I think I follow what you're saying, so I am willing to try it.

As for whether the bog is lean or rich, I think it could be a lean bog. My reasoning is based on what happens in a single accel pump carb when mechanical secondaries are opened. As you reach the top of the primary circuit and all that air is flowing through, then you suddenly open the secondaries, it used to bog for a long time. This was obviously due to the slow bleeds letting too much air into the circuit (if my reasoning is correct). So by blocking them off with solder, that incoming air is eliminated and the result cuts the bog time down from 1.5 to 2 seconds to a quarter second up to a max of about a half second. So more fuel, sooner. Thus by richening up the secondaries in that way, it shortened the bog time considerably. Therefore I believe the bog was due to a lean condition. Oh, also because the single accel pump can only deliver so much fuel - it's like back in the day when I was first doing mechanical sec mods and got a very similar bog until I did the Sterling accel pump mod. Seems as if the extra air from the turbo requires... yep, extra fuel.

To put it in other words, while on primaries only, fuel was flowing fine. But as soon as you open the secondaries, there is not enough additional fuel flowing yet, hence a lean condition.

So if we work from the conclusion that it is a lean bog, I will do the mods listed above and let you know. I'll only do this on the secondary etubes because the primary circuits seem pretty good.

Ok, I'm going to ****** the carb off the engine in between rain storms today and let you know my progress. Maybe take a couple pics too.

#23

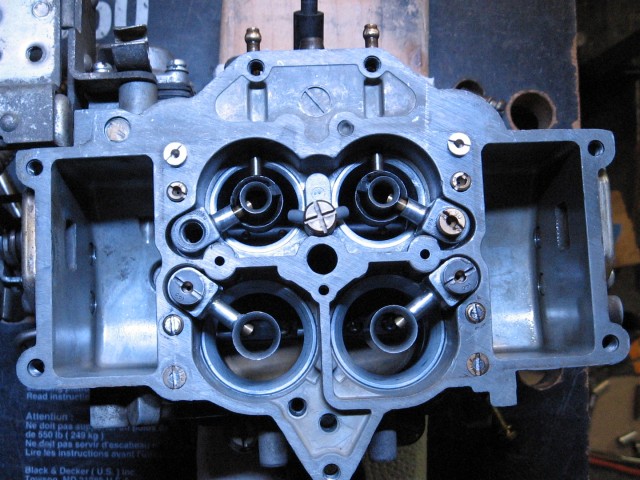

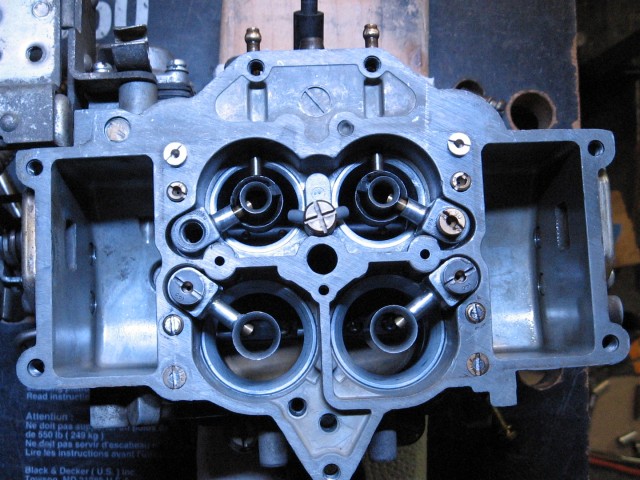

Ok here are some pics.

Hogged boost prepped nikki.

Notice the primary air bleed is missing on the left side. I pulled it for a comparison picture below.

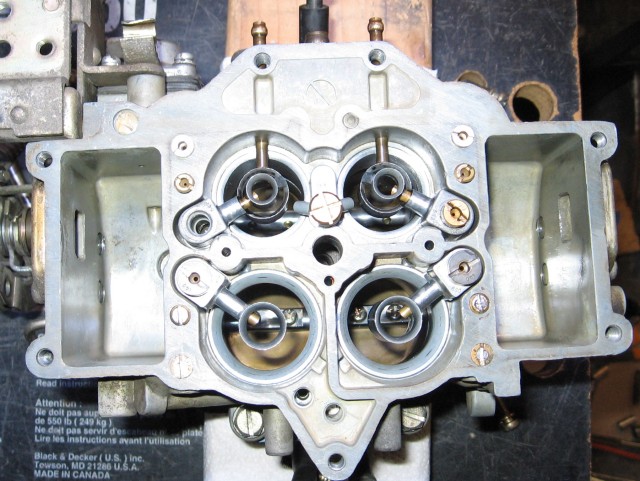

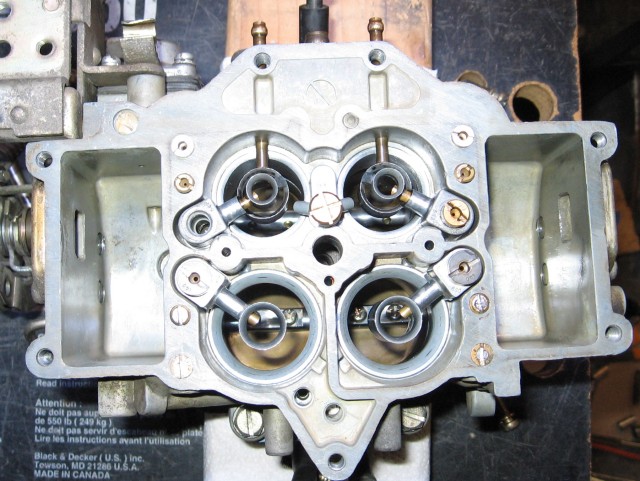

With flash. Notice the solder in the secondary slow bleeds.

Air bleed comparison. Count the progression holes.

Here is a broken primary slow air bleed I ground the threads down enough to fit inside a vacuum hose Teed from the line between the carb hat and the mallory. It eliminated most of my annoying flooding problem. The calibrated boost leak is right around .66mm visually speaking. I have no way to accruately measure it but it looks like a nickel plated 60, only a tad larger. I drilled the bottom 46 hole out to 118 so the next smallest restriction is the 66 looking hole at the top. Notice you can see the broken off piece in the picture. And another ready to break bleed will get the same treatment for my next turbo setup.

Hogged boost prepped nikki.

Notice the primary air bleed is missing on the left side. I pulled it for a comparison picture below.

With flash. Notice the solder in the secondary slow bleeds.

Air bleed comparison. Count the progression holes.

Here is a broken primary slow air bleed I ground the threads down enough to fit inside a vacuum hose Teed from the line between the carb hat and the mallory. It eliminated most of my annoying flooding problem. The calibrated boost leak is right around .66mm visually speaking. I have no way to accruately measure it but it looks like a nickel plated 60, only a tad larger. I drilled the bottom 46 hole out to 118 so the next smallest restriction is the 66 looking hole at the top. Notice you can see the broken off piece in the picture. And another ready to break bleed will get the same treatment for my next turbo setup.

#24

carb whisperer

those look like a reasonable place to start.

if your bog is going lean, less holes are better.

if rich, more holes.

then the size of those holes are possible to modify to further manipulate signal

if your bog is going lean, less holes are better.

if rich, more holes.

then the size of those holes are possible to modify to further manipulate signal

#25

Thank you!

I tested two carbs today. The first one flooded itself out badly. I think the floats got stuck. I drove it home sputtering and shut it off. The windows were full and upon removing the carb hat, it looked like gas was pooling on the secondary butterflies. Sounds like a failed float bowl vent solenoid, but it didn't happen while driving in vacuum. It only happened when the carb saw boost. It was easy to start back up, even flooded, because I turned off the fuel pump and let it run until it was out of gas. It's strange because this carb never did this before. I'll pull the top later and see if there's anything out of place. It could have happened during the soldered sec slo bleed install. I'm thinking this carb will need to be driven NA for a while to "burnish" the needles. Then we'll test it with boost again later.

The other carb was flawless in vacuum and marginally flooded in boost. The bog was tiny and barely noticeable in 1st and 2nd, and was absent in 3rd. The small flooding will probably be solved by changing the fuel lines to mallory's recommended 5/16" send and 3/8" return. Now I'm letting this carb sit overnight with gas in it to observe how much it leaks down into the engine tomorrow. Divindriver had this same problem for a while.

The small flooding will probably be solved by changing the fuel lines to mallory's recommended 5/16" send and 3/8" return. Now I'm letting this carb sit overnight with gas in it to observe how much it leaks down into the engine tomorrow. Divindriver had this same problem for a while.

Just one more carb to test with soldered bleeds and then my boosted nikki testing will be complete.

As for whether it's a lean bog or rich, the roads were wet or damp today, so I couldn't look at the wideband very often.

Oh one thing I did notice is one of the carbs went lean before the boost kicked in. So, maybe a lean bog? Kinda what I suspected all along. So the fix is less holes in the primary or secondary etubes?

I saw 15, 16 then 17 before it started going richer. Remember I have a calibrated boost leak I sized for the bigger Nikki the other day, so this medium sized Nikki will need slightly less of a leak. Makes sense. My Nikki sizes range from 24.5, 24.7 and 24.9mm venturis. The 24.9 carb comes into boost the soonest while the 24.5 seems to take longer. The middle carb is just right for a rotary truck or a baja because the driveability (low end torque) is the best.

I tested two carbs today. The first one flooded itself out badly. I think the floats got stuck. I drove it home sputtering and shut it off. The windows were full and upon removing the carb hat, it looked like gas was pooling on the secondary butterflies. Sounds like a failed float bowl vent solenoid, but it didn't happen while driving in vacuum. It only happened when the carb saw boost. It was easy to start back up, even flooded, because I turned off the fuel pump and let it run until it was out of gas. It's strange because this carb never did this before. I'll pull the top later and see if there's anything out of place. It could have happened during the soldered sec slo bleed install. I'm thinking this carb will need to be driven NA for a while to "burnish" the needles. Then we'll test it with boost again later.

The other carb was flawless in vacuum and marginally flooded in boost. The bog was tiny and barely noticeable in 1st and 2nd, and was absent in 3rd.

The small flooding will probably be solved by changing the fuel lines to mallory's recommended 5/16" send and 3/8" return. Now I'm letting this carb sit overnight with gas in it to observe how much it leaks down into the engine tomorrow. Divindriver had this same problem for a while.

The small flooding will probably be solved by changing the fuel lines to mallory's recommended 5/16" send and 3/8" return. Now I'm letting this carb sit overnight with gas in it to observe how much it leaks down into the engine tomorrow. Divindriver had this same problem for a while.Just one more carb to test with soldered bleeds and then my boosted nikki testing will be complete.

As for whether it's a lean bog or rich, the roads were wet or damp today, so I couldn't look at the wideband very often.

Oh one thing I did notice is one of the carbs went lean before the boost kicked in. So, maybe a lean bog? Kinda what I suspected all along. So the fix is less holes in the primary or secondary etubes?

I saw 15, 16 then 17 before it started going richer. Remember I have a calibrated boost leak I sized for the bigger Nikki the other day, so this medium sized Nikki will need slightly less of a leak. Makes sense. My Nikki sizes range from 24.5, 24.7 and 24.9mm venturis. The 24.9 carb comes into boost the soonest while the 24.5 seems to take longer. The middle carb is just right for a rotary truck or a baja because the driveability (low end torque) is the best.