Help with lining everything up for first time crank

#1

Wankeled 86

Thread Starter

iTrader: (3)

Join Date: May 2010

Location: Houston, TX

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

I've got a 12A and the water pump/fan, alt and crank pulleys were off. Now I'm in the process of turning the motor over for the first time.

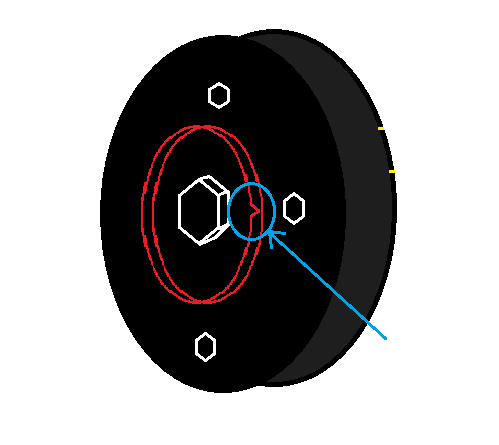

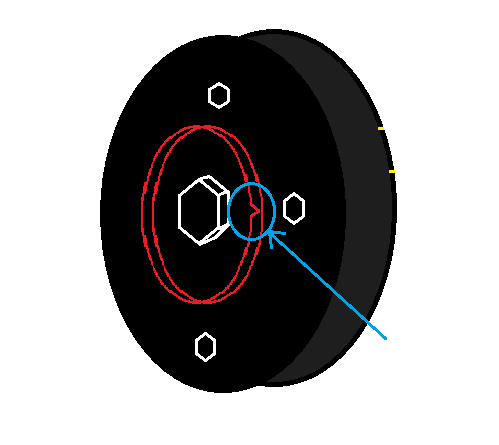

How should the crank pulley be installed on so I know the correct point at which the motor is at TDC? There's a little notch on the inner ring of the x-centric shift "inner pulley(?)"; what does that indicate? Here's a picture of what I'm talking about:

Does that "notch out" determine how the pulley should be bolted up to the shaft?

This is my first rotary motor experience. I've been referring to the FSM but none of the instructions or pictures are helping. The motor is already in the furnace and the radiator is installed and full of coolant so it'll be very difficult for me to get to the shaft bolt to remove it. The motor is in a corolla by-the-way and there's not much space between the rad and the crank pulley.

I'd appreciate any useful advice/guidance. Thanks in advance.

doc

How should the crank pulley be installed on so I know the correct point at which the motor is at TDC? There's a little notch on the inner ring of the x-centric shift "inner pulley(?)"; what does that indicate? Here's a picture of what I'm talking about:

Does that "notch out" determine how the pulley should be bolted up to the shaft?

This is my first rotary motor experience. I've been referring to the FSM but none of the instructions or pictures are helping. The motor is already in the furnace and the radiator is installed and full of coolant so it'll be very difficult for me to get to the shaft bolt to remove it. The motor is in a corolla by-the-way and there's not much space between the rad and the crank pulley.

I'd appreciate any useful advice/guidance. Thanks in advance.

doc

#2

The notch on the inside of the e shaft pulley is the key way for a woodruff key that is on the eccentric shaft itself, so the pulley only goes on one way. I can't tell from your post if the e shaft pulley is off the engine or if you are planning on replacing the e shaft pulley, either way you need to be aware of the bearings that are behind the front cover, the link below will explain what Im talking about.

http://www.mazdatrix.com/faq/pulley.htm

http://www.mazdatrix.com/faq/pulley.htm

#3

Wankeled 86

Thread Starter

iTrader: (3)

Join Date: May 2010

Location: Houston, TX

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

Sorry for the confusion.

It's the belt pulley that I just want to mount back on properly so I can properly line up the lead and trail timing marks. I'm just wanting to stab the distributor in properly.

It's the belt pulley that I just want to mount back on properly so I can properly line up the lead and trail timing marks. I'm just wanting to stab the distributor in properly.

#4

Wankeled 86

Thread Starter

iTrader: (3)

Join Date: May 2010

Location: Houston, TX

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

Quick update:

I had checked everything out a couple of days ago and it all did line up: with the flat portion of the flywheel parallel to the exhaust flange, the distributor rotor did line up with L1. I did some more discovery and found that both the accel coils that came with the engine were either bad or possibly the incorrect type (maybe the internal resistor type for points?). When I tested the trailing coil (MSD Blaster Coil 2), that checked out to be in working order.

I'm going to double-check my DLIDFIS wiring for the leads just to be sure.

I had checked everything out a couple of days ago and it all did line up: with the flat portion of the flywheel parallel to the exhaust flange, the distributor rotor did line up with L1. I did some more discovery and found that both the accel coils that came with the engine were either bad or possibly the incorrect type (maybe the internal resistor type for points?). When I tested the trailing coil (MSD Blaster Coil 2), that checked out to be in working order.

I'm going to double-check my DLIDFIS wiring for the leads just to be sure.

#5

Wankeled 86

Thread Starter

iTrader: (3)

Join Date: May 2010

Location: Houston, TX

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

Quick update: Found the problem with the DLIDFIS setup - the "vertical" male/spade connector of the lead pickup connection on the dizzy was bent slightly enough that when I connected the 2 wire connector it would just miss to the side of the connector housing. I couldn't see this becase the rubber boot over the connector was hiding this fact. Lead and trailing coils are all firing properly now after straightening out that spade connector. I also noticed that this time there was a bit more noticeable resistance when slipping the connector on. I confirmed spark.

Thought I'd share for those interested.

Thought I'd share for those interested.

#6

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,841

Received 2,605 Likes

on

1,848 Posts

ive done that too! on the timing front, worst case there are 4 ways the pulley goes on, so worst case you try it 4 times....

#7

Wankeled 86

Thread Starter

iTrader: (3)

Join Date: May 2010

Location: Houston, TX

Posts: 161

Likes: 0

Received 0 Likes

on

0 Posts

I'm anxious to get home and fire her up. If I can just make certain the motor will run steadily and "dependably" with how I've got everything wired in and take care of any leaks, the rest will be a walk in the park.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM