(IGNITION) How to find TDC?

#1

(IGNITION) How to find TDC?

I read the Haynes manual and did a search. I already have my S5 motor installed. I do not have the timing mark on the pully as i dont have an accessory pully anymore. With the e-shaft bolt on i cant see the e-shaft keyway as advertised in haynes to find TDC. Is there a way to find TDC some other way????

#2

I read the Haynes manual and did a search. I already have my S5 motor installed. I do not have the timing mark on the pully as i dont have an accessory pully anymore. With the e-shaft bolt on i cant see the e-shaft keyway as advertised in haynes to find TDC. Is there a way to find TDC some other way????

#4

https://www.rx7club.com/1st-gen-archive-71/ignition-main-pully-timing-525909/

It's in the Archives.

Brandon,

The notches for the timing marks are not on the accessory pulley but the main one one on the e-shaft. The accessory one is the outside larger one but you still have the inner which has the marks on it.

It's in the Archives.

Brandon,

The notches for the timing marks are not on the accessory pulley but the main one one on the e-shaft. The accessory one is the outside larger one but you still have the inner which has the marks on it.

#6

My way was on an engine with the manifolds and inspection covers in place. Poke a fat wire into the rear leading spark plug hole (L2). Hand crank the engine carefully until an apex seal touches the wire. Back it off a bit and the front rotor should now be at TDC or close enough to get the pulley on right.

Trending Topics

#8

This contradicts wackyracers archived post though as you can see in the post i have 10awg wire in the rear leading spark plug hole on my SE motor (just a spare) and the notch on the flywheel doesnt line up the the inspection plate on the exhaust side. and the e-shaft keyway contradicts haynes orientation for TDC of leading??

#9

Thanks Jeff and Doc, timely post. I took my accessory pulley off the other day and wouldn't you know it, the main pulley, along with the timing marks, fell off too. So I took a guess with a 25% chance of getting it right. I think I lucked out, the car is running OK, but I think I'll use Jeff's wire check method just to be sure.

Ray

Ray

#10

Thanks Jeff and Doc, timely post. I took my accessory pulley off the other day and wouldn't you know it, the main pulley, along with the timing marks, fell off too. So I took a guess with a 25% chance of getting it right. I think I lucked out, the car is running OK, but I think I'll use Jeff's wire check method just to be sure.

Ray

Ray

If you did not remove the dist. The only thing you have to do is remove the cap and hand turn the engine until the rotor is pointed towards L1. If the pulley does not line up with the timing indicator, remove the pulley and reinstall until it does which is usually with one of the bolts facing at the 12:00 position.

#11

This contradicts wackyracers archived post though as you can see in the post i have 10awg wire in the rear leading spark plug hole on my SE motor (just a spare) and the notch on the flywheel doesnt line up the the inspection plate on the exhaust side. and the e-shaft keyway contradicts haynes orientation for TDC of leading??

#13

Doc, this isn't aimed at you. It's just an FYI for everyone.

We are trying to find TDC for L1, and aligning the pulley so when L1 is at TDC, the pulley mark lines up with the little pin in the front cover.

Now ask yourself what position the front rotor must be in in order for it to be at TDC. I'll only give you two choices.

1: With the apex seal sitting between the spark plugs

or

2: with the rotor face sitting next to both spark plugs.

Think a moment.

When do the spark plugs fire? When the apex seal is between them? Or when the rotor face is next to them?

Think a moment.

Ah, there's the answer.

We are trying to find TDC for L1, and aligning the pulley so when L1 is at TDC, the pulley mark lines up with the little pin in the front cover.

Now ask yourself what position the front rotor must be in in order for it to be at TDC. I'll only give you two choices.

1: With the apex seal sitting between the spark plugs

or

2: with the rotor face sitting next to both spark plugs.

Think a moment.

When do the spark plugs fire? When the apex seal is between them? Or when the rotor face is next to them?

Think a moment.

Ah, there's the answer.

#14

This contradicts wackyracers archived post though as you can see in the post i have 10awg wire in the rear leading spark plug hole on my SE motor (just a spare) and the notch on the flywheel doesnt line up the the inspection plate on the exhaust side. and the e-shaft keyway contradicts haynes orientation for TDC of leading??

You are to remove the inspection plate on the exhaust side, not on top of the bellhousing.

#18

Are these methods valid with a TII motor?

I removed the main pully to paint it without thinking about TDC. I have the block in the car but no accessories or manifolds installed yet and I need to put the motor to TDC so I can mount the dizzy and start installing all items to get my project running. Thanks in advance.

Joe

I removed the main pully to paint it without thinking about TDC. I have the block in the car but no accessories or manifolds installed yet and I need to put the motor to TDC so I can mount the dizzy and start installing all items to get my project running. Thanks in advance.

Joe

#20

Retired Moderator, RIP

iTrader: (142)

Join Date: Sep 2005

Location: Smiths Falls.(near Ottawa!.Mapquest IT!)

Posts: 25,581

Likes: 0

Received 131 Likes

on

114 Posts

I was told that the Pulley Bolts can only Go on One Way.The holes for the Bolts will only Line up,if the Pulley is installed correctly.According to My "friend",he says that the Threaded holes are just a little bit off so that the Pulley will only go one One way,and that prevents the pulley from being put on Incorrectly,and Thus putting the Timing Marks Out of whack in Proportion to the position of the rotors(internally).I'm going to Watch this thread!( for more more Info..this is getting Good!)..I had One HELL of a time when I got my "new" engine.It seems "someone" had decided to take the CAS out and just Put it back in.I was Lucky and Found some little Dents on the Pulley.But I had to Really Look.Miraculously I Found it.(and Witghout Using My Glasses!..haha!).the good thing is I found that there are marks on the Little gear on the bottom shaft of the CAS to Realign the CAS,and on the Shaft housing surrounding that gear..So,Now IF I need to find TDC,and Can do so Without the Pulley marks,that would,Again, Make me One Happy Camper!

#21

On an 81+ motors, the pulley consists of 2 parts: the dual sleeve and the hub itself (cant remember the real name for it). If you remove all 4 10mm bolts, these items come apart but can can be reinstalled in 4 positions. but therre is only 1 right way where your engine will start.

Some of you may say its bullshit, I will just take the e-shaft bolt and make sure that the e-shaft key is @ 9:00. However, that takes too much work. Some bolts are hard to remove. Wacky's TDC finder will save you time and headache and bruised knuckles.

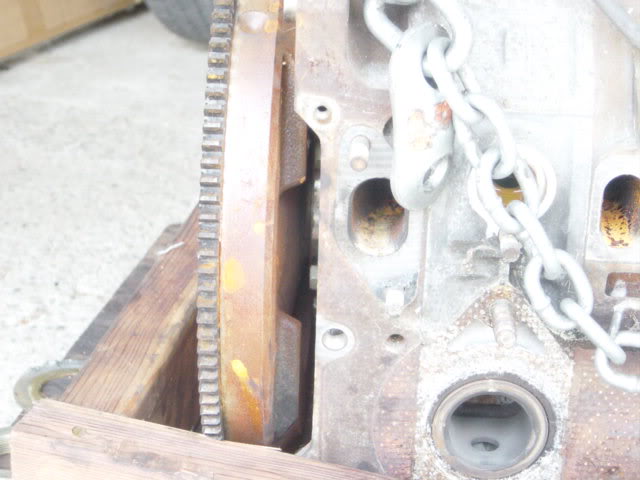

pix of what I'm referring to:

Once the bolts are out, this is what you will find

And this is the old school ones. It has a rivet so you cant take them apart.

Some of you may say its bullshit, I will just take the e-shaft bolt and make sure that the e-shaft key is @ 9:00. However, that takes too much work. Some bolts are hard to remove. Wacky's TDC finder will save you time and headache and bruised knuckles.

pix of what I'm referring to:

Once the bolts are out, this is what you will find

And this is the old school ones. It has a rivet so you cant take them apart.

#23

Copied from the other thread to keep everything centralized

Sorry to be so dense, the more I looked at Brandon's thread and tried to figure out what Wacky and Jeff were doing, the more confusing it got, so I was just hoping for some clarification specific for finding TDC on my installed 12A motor.

First question - Jeff says to put the wire in the rear plug whole L2, then when you feel the rotor (apex seal) the front rotor is TDC. But Wacky seems to be saying the opposite:

"You can do it too like what Jeff said except, I use both leading spark plug holes. To be at TDC, with the wire, you should be able to feel the rotor in front housing while none in the rear."

Am I missing something? Jeff and Wacky seem to agree on the wire method, but Jeff is saying use the rear rotor while Wacky is saying use the front rotor to "find" the wire and establish TDC.

Related to this, I am also confused about why any one of the three apex seals on a rotor could line up with the leading spark plug whole (front or rear) to give you TDC. Shouldn't there be only one position of the rotor (and therefore only one of the rotor's three apex seals) that, when detected with the wire in the leading plug hole, determines TDC?

So I've all but given up on the wire approach.

Question 2: Is there any way that the inspection plate on top of the bell housing can be used to line up the fly wheel properly? Wacky says to use the one on the exhaust side, not the top one, but even if I can get a wrench in there to take the plate off, I'm not sure I could see past the intake manifold to get a good look at the flywheel. And, after looking at the pictures in Wacky's pictures in this thread:

https://www.rx7club.com/showthread.php?t=525909

it is not clear to me what I should be looking for anyway. Should that dimple, which I have been able to locate with the top inspection plate removed, be pointing straight up at TDC? If so, it seems like the top inspection plate would work fine for this. Or is it rotated counterclockwise a bit, as it looks to be in the picture? Maybe this is why Wacky is saying to use the lower inspection plate by the manifolds?

Thanks for your patience, any help would be much appreciated.

Ray

First question - Jeff says to put the wire in the rear plug whole L2, then when you feel the rotor (apex seal) the front rotor is TDC. But Wacky seems to be saying the opposite:

"You can do it too like what Jeff said except, I use both leading spark plug holes. To be at TDC, with the wire, you should be able to feel the rotor in front housing while none in the rear."

Am I missing something? Jeff and Wacky seem to agree on the wire method, but Jeff is saying use the rear rotor while Wacky is saying use the front rotor to "find" the wire and establish TDC.

Related to this, I am also confused about why any one of the three apex seals on a rotor could line up with the leading spark plug whole (front or rear) to give you TDC. Shouldn't there be only one position of the rotor (and therefore only one of the rotor's three apex seals) that, when detected with the wire in the leading plug hole, determines TDC?

So I've all but given up on the wire approach.

Question 2: Is there any way that the inspection plate on top of the bell housing can be used to line up the fly wheel properly? Wacky says to use the one on the exhaust side, not the top one, but even if I can get a wrench in there to take the plate off, I'm not sure I could see past the intake manifold to get a good look at the flywheel. And, after looking at the pictures in Wacky's pictures in this thread:

https://www.rx7club.com/showthread.php?t=525909

it is not clear to me what I should be looking for anyway. Should that dimple, which I have been able to locate with the top inspection plate removed, be pointing straight up at TDC? If so, it seems like the top inspection plate would work fine for this. Or is it rotated counterclockwise a bit, as it looks to be in the picture? Maybe this is why Wacky is saying to use the lower inspection plate by the manifolds?

Thanks for your patience, any help would be much appreciated.

Ray

Ray,

Sorry about the confusion but people have different methods in finding TDC. To elimnate the confusion, I will refer you to the "flywheel" method.

1. Remove the inspeciton plate located on the passenger side engine where the engine and tranny meets.

2. Rotate the e-shaft using a 19mm socket in the front pulley.

3. Using the flywheel, line up the flat side of the flywheel (back) with the engine block.

Pix A: S5 flywheel but all stock flywheels has a flat side.

Pix B: This is a stock pre-RX-712-A engine and flywheel but it has same result.

4. Once step #3 is done, look at your front pulley. The notch should be at the pointer.

****If its not the same as the above pix, that pulley has been molested. So, remove the 4 10mm bolts, and re-install the pulley with the notches @ 12:00 position.

SUB-TOPIC for aluminum or lightened steel flywheels including automatic trannies:

Remove inspection plate on top of bellhousing/engine. Rotate the engine until the tip of the rear counterweight is visible That should get you to TDC.

#24

This is also a carry-over from Ray's thread for those with an installed engine with all manifolds and inspection covers in place, but no means to remove the 19mm front bolt. I wouldn't recommend it anyway because of all the potential problems like a damaged copper washer, damage to the trust bearings, leaks etc.

-------------------------------------------

Remove all spark plugs. Poke wire in L2 hole first. Rotate engine until apex touches wire. Back off a little. Poke wire in L1 hole and it should hit the rotor face.

If your wire happens to be small enough to fit through the smallish trailing hole, poke it through T2 and it should reach in really deeply. Then try T1 and it should hit the rotor face.

---------------------------------------

I think anyone with enough tools and smarts to succesfully remove and reinstall a set of spark plugs could find TDC this way. Just keep sliding the wire in and out of T2 while slowly hand turning the engine until the wire gets snug from the apex seal pressing against it. Don't poke the wire in too deeply, obviously. An inch or so is fine.

-------------------------------------------

Remove all spark plugs. Poke wire in L2 hole first. Rotate engine until apex touches wire. Back off a little. Poke wire in L1 hole and it should hit the rotor face.

If your wire happens to be small enough to fit through the smallish trailing hole, poke it through T2 and it should reach in really deeply. Then try T1 and it should hit the rotor face.

---------------------------------------

I think anyone with enough tools and smarts to succesfully remove and reinstall a set of spark plugs could find TDC this way. Just keep sliding the wire in and out of T2 while slowly hand turning the engine until the wire gets snug from the apex seal pressing against it. Don't poke the wire in too deeply, obviously. An inch or so is fine.

#25

Thanks Wacky, it is all becoming crystal clear! Now I see why you are using the passenger side inspection plate and why you are showing that flat side of the flywheel! And as already noted in the other thread (which I promise not to post on again) Jeff's wire method is making sense too. I will try both tonight, sure had hope they agree with each other!