(DRIVETRAIN) GSL and SE LSD teardown pics,drivetrain tutorials coming soon

#1

FB+FC=F-ME

Thread Starter

(DRIVETRAIN) GSL and SE LSD teardown pics,drivetrain tutorials coming soon

OK,after a couple years of just driving and not working on my car,Ive got the bug again and am tackling some drivetrain issues that have cropped up recently.Namely my noisey TII trans and changing rearend ratios.I scored a very clean TII trans last week with low miles and will be prepping it for install.My old TII will get repaired and will come up for sale,already modded for a 1st gen.I also have a handful of 3rd members that I will be tearing down to spec out the best parts and rebuild with new bearings and a change to 3.96 gears.

Over the next month or so,Ill be performing and documenting(with my new camera) the steps needed to......

Modify a TII trans for a 1st gen install.

Rebuild an LSD and/or change your sidegears for the 84-85 axles.

Rebuild,setup a 1st gen rearend.

These will be more or less step by step.Ill photograph and describe the specific,techincal stuff.I dont have the patience to photo and go into depth on every single step,but if you are attempting some of these jobs on your own,you should already know how to drop a tranny,or remove a rear axle.

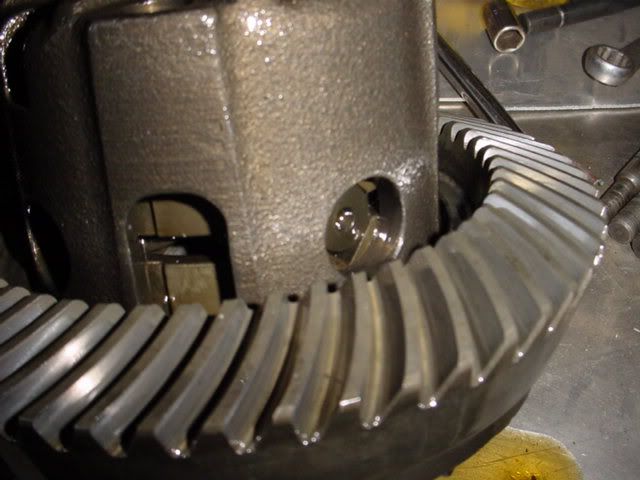

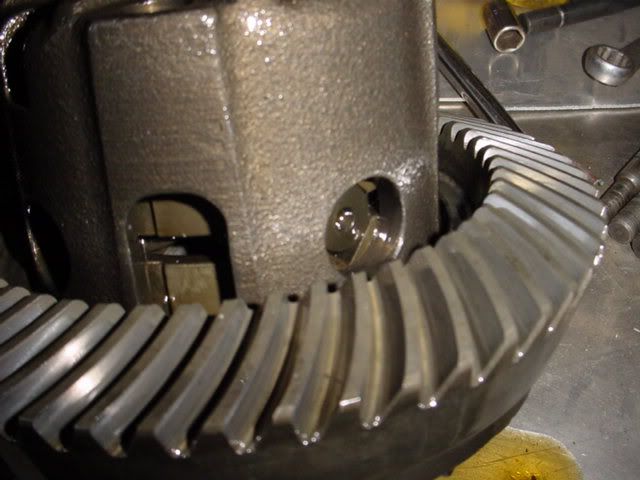

As a preview to these upcoming jobs,heres a few pics of what I found inside two of my diffs.One is the 3rd member from my custom GLC axle I had made long ago using an 81 GSL unit.The other is the original LSD from my GSL-SE axle that I ran for years behind the TII engine.

GSL limited slip parts.

At left are the cone spring and thrust washer,next over are the drive discs and at far right are the driven discs.Note that there are equal numbers of drive and driven discs.Also,I found that when compared to Dana Spicer 44 LSD plates,they are quite large for the size of the carrier that they come from.Its no wonder our LSD's are often well in spec after 20+ years,providing the oil is changed.These came from my V-6 GLC rearend,and are in near perfect condition.They had lots of miles and had to contend with a torquey little V-6,plus the previous miles of the donor vehicle.

GSL-SE limited slip parts.

Notice first that there are an equal,total number of friction discs,however only ONE of them is a driven disc.The others are drive discs.On the outside of the stack,there are actually two drive discs packed next to each other.....doing NOTHING.The lone driven disc is left to do all the work,and sadly that disc and the adjacent drive discs were well worn and a bit blue.They did after all have to live behind my 13BT for a long time,had to endure my drag strip sessions back then,and they had 100K miles on them before I installed the unit.

Heres what I didnt notice right away........

The lone,driven disc on the right side of the diff actually had its drive tabs sheared off! Having to work by itself was too much and it failed.The other side was OK,since once the right side failed,there was little to no LSD action left.How it ever worked,or when it failed is unknown,but this clearly documents the weaker nature of the GSL-SE LSD unit.

More to come in later threads as I get the time and so long as the weather holds out!

Over the next month or so,Ill be performing and documenting(with my new camera) the steps needed to......

Modify a TII trans for a 1st gen install.

Rebuild an LSD and/or change your sidegears for the 84-85 axles.

Rebuild,setup a 1st gen rearend.

These will be more or less step by step.Ill photograph and describe the specific,techincal stuff.I dont have the patience to photo and go into depth on every single step,but if you are attempting some of these jobs on your own,you should already know how to drop a tranny,or remove a rear axle.

As a preview to these upcoming jobs,heres a few pics of what I found inside two of my diffs.One is the 3rd member from my custom GLC axle I had made long ago using an 81 GSL unit.The other is the original LSD from my GSL-SE axle that I ran for years behind the TII engine.

GSL limited slip parts.

At left are the cone spring and thrust washer,next over are the drive discs and at far right are the driven discs.Note that there are equal numbers of drive and driven discs.Also,I found that when compared to Dana Spicer 44 LSD plates,they are quite large for the size of the carrier that they come from.Its no wonder our LSD's are often well in spec after 20+ years,providing the oil is changed.These came from my V-6 GLC rearend,and are in near perfect condition.They had lots of miles and had to contend with a torquey little V-6,plus the previous miles of the donor vehicle.

GSL-SE limited slip parts.

Notice first that there are an equal,total number of friction discs,however only ONE of them is a driven disc.The others are drive discs.On the outside of the stack,there are actually two drive discs packed next to each other.....doing NOTHING.The lone driven disc is left to do all the work,and sadly that disc and the adjacent drive discs were well worn and a bit blue.They did after all have to live behind my 13BT for a long time,had to endure my drag strip sessions back then,and they had 100K miles on them before I installed the unit.

Heres what I didnt notice right away........

The lone,driven disc on the right side of the diff actually had its drive tabs sheared off! Having to work by itself was too much and it failed.The other side was OK,since once the right side failed,there was little to no LSD action left.How it ever worked,or when it failed is unknown,but this clearly documents the weaker nature of the GSL-SE LSD unit.

More to come in later threads as I get the time and so long as the weather holds out!

#3

FB+FC=F-ME

Thread Starter

I wont be pulling the tailshaft,no need for it when doing the 1st gen mods to the TII trans.The writeup will cover the mods to the shifter housing and my approach to making a simple crossmember.

Im 99.9% sure my old TII trans just needs an input shaft pocket bearing,so I wont be doing a full teardown of that unit either.Every other aspect of that tranny still works fine,which is why Im gonna sell her off.

Doing tranny work really requires that you either document well, or re-assemble soon after so that you dont forget stuff.Ive yet to tear all the way into a rotary trans,but units that I have done typically dont call for removing the tailshaft from the mainshaft assembely unless you are doing a full rebuild(syncros,pocket bearings,ect)

Im 99.9% sure my old TII trans just needs an input shaft pocket bearing,so I wont be doing a full teardown of that unit either.Every other aspect of that tranny still works fine,which is why Im gonna sell her off.

Doing tranny work really requires that you either document well, or re-assemble soon after so that you dont forget stuff.Ive yet to tear all the way into a rotary trans,but units that I have done typically dont call for removing the tailshaft from the mainshaft assembely unless you are doing a full rebuild(syncros,pocket bearings,ect)

#5

FB+FC=F-ME

Thread Starter

On the GSL yes,as the first pics shows.

On the SE,there are 3 drive and only one driven.This fact has been covered in the past,Im just providing pics and experience.

The only reason I can see for making the SE's LSD more tame would be to reduce the chance of the rearend side-stepping under the increased power and lower rearend ratio, that the SE posses.Its not a wildly powerful car,so LSD longevity is not an issue,but the 1st gens tailhappy nature was well known,and the torquey SE 13B would have made it worse if the LSD were very grabby.

On the SE,there are 3 drive and only one driven.This fact has been covered in the past,Im just providing pics and experience.

The only reason I can see for making the SE's LSD more tame would be to reduce the chance of the rearend side-stepping under the increased power and lower rearend ratio, that the SE posses.Its not a wildly powerful car,so LSD longevity is not an issue,but the 1st gens tailhappy nature was well known,and the torquey SE 13B would have made it worse if the LSD were very grabby.

#7

wheres the water goin?

iTrader: (9)

Join Date: May 2005

Location: Nor Cal

Posts: 1,586

Likes: 0

Received 0 Likes

on

0 Posts

sorry to hear that your car is going to be down for alil while, but its for the best.

just wondering if your going to show us how to set the back lash and how to set everything up when putting the diff back together?

just wondering if your going to show us how to set the back lash and how to set everything up when putting the diff back together?

Trending Topics

#8

FB+FC=F-ME

Thread Starter

It wont be down long actually, since I have enough spares to do it all at my leisure.

The tranny mods and swap will only take a day or two,without rushing.

The rearend I can build entirely with my spare units.I have bearings on order and enough gearsets and LSD parts to pick and choose the best pieces.Then its just remove and replace......a few hours tops for the rearend swap.

Ill be ordering new cone springs from Mazdatrix just to be sure,but I have lots of good LSD plates to use.Bearings will be Timkin units from Napa....far cheaper than Mazdatrixs' price,and I trust Timkin since thats all I use in my rockcrawler.

I will be documenting the rearend setup in regards to the lash,pattern and pinion preload settings.

In the meantime,here is a link that is very relevent and can be used as a handy guide for setting up all types of diffs,including Japanese 3rd members,like ours......

http://www.pirate4x4.com/tech/billav...structions.pdf

The tranny mods and swap will only take a day or two,without rushing.

The rearend I can build entirely with my spare units.I have bearings on order and enough gearsets and LSD parts to pick and choose the best pieces.Then its just remove and replace......a few hours tops for the rearend swap.

Ill be ordering new cone springs from Mazdatrix just to be sure,but I have lots of good LSD plates to use.Bearings will be Timkin units from Napa....far cheaper than Mazdatrixs' price,and I trust Timkin since thats all I use in my rockcrawler.

I will be documenting the rearend setup in regards to the lash,pattern and pinion preload settings.

In the meantime,here is a link that is very relevent and can be used as a handy guide for setting up all types of diffs,including Japanese 3rd members,like ours......

http://www.pirate4x4.com/tech/billav...structions.pdf

#9

Hunting Skylines

Join Date: Apr 2001

Location: Brisbane, Queensland, Australia.

Posts: 3,431

Likes: 0

Received 2 Likes

on

2 Posts

I highly recommend machining the left LSD case if you want to tighten things up a bit. Mine was on the weak side with very low break away torque but on disassembly everything was still well within spec. I took .5mm off the case and it tightened things up nicely. Breakaway torque is now up around the 100ft/lb mark which is a bit more than what it was new from the factory.

#10

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,805

Received 2,578 Likes

on

1,831 Posts

I highly recommend machining the left LSD case if you want to tighten things up a bit. Mine was on the weak side with very low break away torque but on disassembly everything was still well within spec. I took .5mm off the case and it tightened things up nicely. Breakaway torque is now up around the 100ft/lb mark which is a bit more than what it was new from the factory.

#11

FB+FC=F-ME

Thread Starter

Ill be taking all measurements as the build progresses.There are 4 measurements taken that will give you wear specs on the inner core and outer carrier where the end discs and thrust washers rub.The factory cure is to install thicker thrust washers which will push the LSD core into heavier contact with the clutchpacks and springs,taking up the slack and achieving the same results as machining the case.

As of now,Im in VERY good shape in regards to disc specs.

All the discs from my GSL unit measured between 1.96mm and 1.98mm thick.Brand new they are 2.00mm and the limit is 1.90mm,so thats VERY little wear at all.The thrust washers measured 1.55mm with a new thickness of 1.60 and a minimum of 1.40mm,so thats also promisingly little wear.Neither side of the carrier had any substantial wear or steps in the thrust surface,nor did the spider core case.

Even just one 1.80mm, oversize thrust washer would put me over the new specs,so Ill be leaving that alone barring any out of spec numbers once I measure the stack installed in the carrier.A a set of new cone springs and I should be all set.

Im actually going to replace the two thinnest drive discs (1.96 and 1.97) with a pair from my worn SE unit......why?......because the very outer left and right drive disc in the SE unit, are flanked by the case, and another drive disc.This means they NEVER spin against anything for their entire life!

Indeed,both extreme outer drive discs measured 2.00mm and had nary a scratch after I cleaned and inspected them.If I use them to replace my two most worn discs in the the GSL unit,Ill pick up another .07mm of thickness and be only .04mm below spec, for a brandnew unit.

As of now,Im in VERY good shape in regards to disc specs.

All the discs from my GSL unit measured between 1.96mm and 1.98mm thick.Brand new they are 2.00mm and the limit is 1.90mm,so thats VERY little wear at all.The thrust washers measured 1.55mm with a new thickness of 1.60 and a minimum of 1.40mm,so thats also promisingly little wear.Neither side of the carrier had any substantial wear or steps in the thrust surface,nor did the spider core case.

Even just one 1.80mm, oversize thrust washer would put me over the new specs,so Ill be leaving that alone barring any out of spec numbers once I measure the stack installed in the carrier.A a set of new cone springs and I should be all set.

Im actually going to replace the two thinnest drive discs (1.96 and 1.97) with a pair from my worn SE unit......why?......because the very outer left and right drive disc in the SE unit, are flanked by the case, and another drive disc.This means they NEVER spin against anything for their entire life!

Indeed,both extreme outer drive discs measured 2.00mm and had nary a scratch after I cleaned and inspected them.If I use them to replace my two most worn discs in the the GSL unit,Ill pick up another .07mm of thickness and be only .04mm below spec, for a brandnew unit.

#13

sounds like you really know what you're doing and are very happy to post information for all of us. I'm glad you're posting about the lsd since I've been experiencing the major torque in my street ported SE. I was wondering if the LSD would have to be replaced for aggressive drifting. I'm currently looking into getting the t2 trans and installing it with a t4 but I'm not sure where to get the special fit drive shaft cheap. Unless an fc's will fit. So there are three parts to the lsd and only one is used? is it because of it's not a turbo? or is it simply because it's an se?

Every day I research my car more and more I keep learning that the engine in the SE is very aggressive due to its 6 port design. I hope pineapple racing will be up when I get the turbo stuff for my car so I can really rip up the track. Of course the t2 engine will be cheaper since it's already turbo and I can get one from ebay with ecu but what's the fun in that? I would like some comments towards my goals of a turbo SE since I'm still new to the rex I still may not know the pros and cons of the stock vehicle.

Every day I research my car more and more I keep learning that the engine in the SE is very aggressive due to its 6 port design. I hope pineapple racing will be up when I get the turbo stuff for my car so I can really rip up the track. Of course the t2 engine will be cheaper since it's already turbo and I can get one from ebay with ecu but what's the fun in that? I would like some comments towards my goals of a turbo SE since I'm still new to the rex I still may not know the pros and cons of the stock vehicle.

#16

Hunting Skylines

Join Date: Apr 2001

Location: Brisbane, Queensland, Australia.

Posts: 3,431

Likes: 0

Received 2 Likes

on

2 Posts

I was talking about machining the left case flange to obtain more crush on the clutch pack. But now that you mention it I've got a bit of a clunk that I've been trying to diagnose. What causes the wear on the shaft surface? Obviously there's no way to fix it.

#17

FB+FC=F-ME

Thread Starter

Rearend lash that is not attributable to the ring and pinion can only be from two other places......

1st......The axle shaft/sidegear splines.

This is obvious since the splines are easily inspected.

2nd.....The spider "core" of the LSD.

This can induce a lot of lash because there are multiple wear points including the bevel gears themselves,the 4 spider pins,and the ramps on the pins and thrust blocks.Ramp wear will usually occur on the "drive" side of the ramps since there is usually more torque coming from the engine than back up the drivetrain from the wheel,like when letting off the throttle abruptly.Since its unlikely youll ever find a brandnew set of gears,spider and/or thrust blocks,its best to probably fish around for a lower milage LSD to replace the one you have.Worn discs will not induce lash since they dont actually transmit any torque,they just help to keep both wheels spinning at the same speed when torque is applied.

Heres a shot of the spider pin ramps.Ramps on both sides means the LSD will lock on accel and decel.The angle of the ramps when the unit is designed will determine the abruptness of lockup.The ring gear turns the carrier,the carrier is locked to the thrust blocks you see poking through the left side hole.The thrust blocks bear against the 4 round spider pins via the ramps,and the spider turns the 2 spider gears,which turn the side gears that are splined to the axles.Any wear,anywhere inside the core of the diff will cause lash between the axle shafts and the ring/pinion.

Ive seen Jeep diffs so worn out internally that you could turn the driveshaft over 1/4 turn and the wheels would not move.....and the ring/pinion backlash was fine!

The ideal,aggresive LSD will be from an 81-85 12A car,regardless of what it goes into.Just be aware that the side gear splines changed in 84,so you would have to mix and match parts if your car is older.Im using my GSL-SE spider core with its bigger axle splines,then my 81 LSD plates and carrier for their greater locking ability.

The GSL-SE LSD is identical in all respects except that the disc stack is laid out so that the LSD is less grabby.Even increasing clamp load will not change the fact that there are only 2 friction surfaces on each axle(2 per driven disc),rather than 4 on each axle in the GSL.

Drifting is hard on ALL drivetrain components,in fact its hard on EVERY part of the car.Extreme lateral stress on everything,extended high HP application,relatively low vehicle speeds,lots of clutch popping,ect.Anytime your turning and spinning both tires,any LSD will have to slip at some point,which is when the discs will wear.If there is a lot of torque going into the LSD at the time,then clamping loads will be at their highest,which means friction will be at its highest,and that makes HEAT!

A locker,spool or welded diff is the only way to not generate excess heat in a diff when drifting.But a locked rearend would probably be dangerously hard to control and predict since there is NO give at all.....snap oversteer anyone?!

1st......The axle shaft/sidegear splines.

This is obvious since the splines are easily inspected.

2nd.....The spider "core" of the LSD.

This can induce a lot of lash because there are multiple wear points including the bevel gears themselves,the 4 spider pins,and the ramps on the pins and thrust blocks.Ramp wear will usually occur on the "drive" side of the ramps since there is usually more torque coming from the engine than back up the drivetrain from the wheel,like when letting off the throttle abruptly.Since its unlikely youll ever find a brandnew set of gears,spider and/or thrust blocks,its best to probably fish around for a lower milage LSD to replace the one you have.Worn discs will not induce lash since they dont actually transmit any torque,they just help to keep both wheels spinning at the same speed when torque is applied.

Heres a shot of the spider pin ramps.Ramps on both sides means the LSD will lock on accel and decel.The angle of the ramps when the unit is designed will determine the abruptness of lockup.The ring gear turns the carrier,the carrier is locked to the thrust blocks you see poking through the left side hole.The thrust blocks bear against the 4 round spider pins via the ramps,and the spider turns the 2 spider gears,which turn the side gears that are splined to the axles.Any wear,anywhere inside the core of the diff will cause lash between the axle shafts and the ring/pinion.

Ive seen Jeep diffs so worn out internally that you could turn the driveshaft over 1/4 turn and the wheels would not move.....and the ring/pinion backlash was fine!

The ideal,aggresive LSD will be from an 81-85 12A car,regardless of what it goes into.Just be aware that the side gear splines changed in 84,so you would have to mix and match parts if your car is older.Im using my GSL-SE spider core with its bigger axle splines,then my 81 LSD plates and carrier for their greater locking ability.

The GSL-SE LSD is identical in all respects except that the disc stack is laid out so that the LSD is less grabby.Even increasing clamp load will not change the fact that there are only 2 friction surfaces on each axle(2 per driven disc),rather than 4 on each axle in the GSL.

Drifting is hard on ALL drivetrain components,in fact its hard on EVERY part of the car.Extreme lateral stress on everything,extended high HP application,relatively low vehicle speeds,lots of clutch popping,ect.Anytime your turning and spinning both tires,any LSD will have to slip at some point,which is when the discs will wear.If there is a lot of torque going into the LSD at the time,then clamping loads will be at their highest,which means friction will be at its highest,and that makes HEAT!

A locker,spool or welded diff is the only way to not generate excess heat in a diff when drifting.But a locked rearend would probably be dangerously hard to control and predict since there is NO give at all.....snap oversteer anyone?!

#18

This is working up to be a thread full of win and awesome.

What I'd *really* like to know (but may not be within the scope of your transmission repairs) is how to change the speedo gear, if that's possible.

The reason being that if you start playing with gear ratios like putting in a TII trans or changing the rear gear ratio, your speedometre reads incorrectly. If there's a way to make the speedometre read stock after installing a TII tranny and upgrading the rear gear then I'd be a helluva lot more likely to do it.

And heck... I might even be tempted to buy your old TII trans and one of your LSD rears and ship the damn things up to Canada

Jon

What I'd *really* like to know (but may not be within the scope of your transmission repairs) is how to change the speedo gear, if that's possible.

The reason being that if you start playing with gear ratios like putting in a TII trans or changing the rear gear ratio, your speedometre reads incorrectly. If there's a way to make the speedometre read stock after installing a TII tranny and upgrading the rear gear then I'd be a helluva lot more likely to do it.

And heck... I might even be tempted to buy your old TII trans and one of your LSD rears and ship the damn things up to Canada

Jon

#19

FB+FC=F-ME

Thread Starter

Changing the speedo gear isnt hard,its the application that is hard.Its an obscure vehicle,and no one ever really NEEDS to change the speedo drive ratio.Finding a bigger or smaller gear to fit our trannies would be a trial and error process.It has to fit the output shaft OD,mesh with the driven gear's pitch and of course be a different size than the stock gear!

Jeeps and such need that all the time because lift kits,tires and gear changes are the norm for them.There are lots of speedo gears availible for 4x4's,they are color coded by ratio.We probably will have to hit the yards and start filling our pockets with little plastic gears, to try out!

That said,my speedo is dead-nuts-accurate with a TII tranny,4.07 gears and my 17" tires.The taller 5th gear is cancelled out by my slightly shorter rearend ratio and my tires while 17",are only 35 series,so the circumference is close to stock.The TII trans 5th gear ratio is almost the same as an SE trans 5th gear,so if you run an SE rearend ratio,the only thing that will alter speedo accuracy is the tire size.

Jeeps and such need that all the time because lift kits,tires and gear changes are the norm for them.There are lots of speedo gears availible for 4x4's,they are color coded by ratio.We probably will have to hit the yards and start filling our pockets with little plastic gears, to try out!

That said,my speedo is dead-nuts-accurate with a TII tranny,4.07 gears and my 17" tires.The taller 5th gear is cancelled out by my slightly shorter rearend ratio and my tires while 17",are only 35 series,so the circumference is close to stock.The TII trans 5th gear ratio is almost the same as an SE trans 5th gear,so if you run an SE rearend ratio,the only thing that will alter speedo accuracy is the tire size.

#21

Hunting Skylines

Join Date: Apr 2001

Location: Brisbane, Queensland, Australia.

Posts: 3,431

Likes: 0

Received 2 Likes

on

2 Posts

Rearend lash that is not attributable to the ring and pinion can only be from two other places......

1st......The axle shaft/sidegear splines.

This is obvious since the splines are easily inspected.

2nd.....The spider "core" of the LSD.

This can induce a lot of lash because there are multiple wear points including the bevel gears themselves,the 4 spider pins,and the ramps on the pins and thrust blocks.Ramp wear will usually occur on the "drive" side of the ramps since there is usually more torque coming from the engine than back up the drivetrain from the wheel,like when letting off the throttle abruptly.Since its unlikely youll ever find a brandnew set of gears,spider and/or thrust blocks,its best to probably fish around for a lower milage LSD to replace the one you have.Worn discs will not induce lash since they dont actually transmit any torque,they just help to keep both wheels spinning at the same speed when torque is applied.

1st......The axle shaft/sidegear splines.

This is obvious since the splines are easily inspected.

2nd.....The spider "core" of the LSD.

This can induce a lot of lash because there are multiple wear points including the bevel gears themselves,the 4 spider pins,and the ramps on the pins and thrust blocks.Ramp wear will usually occur on the "drive" side of the ramps since there is usually more torque coming from the engine than back up the drivetrain from the wheel,like when letting off the throttle abruptly.Since its unlikely youll ever find a brandnew set of gears,spider and/or thrust blocks,its best to probably fish around for a lower milage LSD to replace the one you have.Worn discs will not induce lash since they dont actually transmit any torque,they just help to keep both wheels spinning at the same speed when torque is applied.

#22

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,805

Received 2,578 Likes

on

1,831 Posts

Changing the speedo gear isnt hard,its the application that is hard.Its an obscure vehicle,and no one ever really NEEDS to change the speedo drive ratio.Finding a bigger or smaller gear to fit our trannies would be a trial and error process.It has to fit the output shaft OD,mesh with the driven gear's pitch and of course be a different size than the stock gear!

Jeeps and such need that all the time because lift kits,tires and gear changes are the norm for them.There are lots of speedo gears availible for 4x4's,they are color coded by ratio.We probably will have to hit the yards and start filling our pockets with little plastic gears, to try out!

That said,my speedo is dead-nuts-accurate with a TII tranny,4.07 gears and my 17" tires.The taller 5th gear is cancelled out by my slightly shorter rearend ratio and my tires while 17",are only 35 series,so the circumference is close to stock.The TII trans 5th gear ratio is almost the same as an SE trans 5th gear,so if you run an SE rearend ratio,the only thing that will alter speedo accuracy is the tire size.

Jeeps and such need that all the time because lift kits,tires and gear changes are the norm for them.There are lots of speedo gears availible for 4x4's,they are color coded by ratio.We probably will have to hit the yards and start filling our pockets with little plastic gears, to try out!

That said,my speedo is dead-nuts-accurate with a TII tranny,4.07 gears and my 17" tires.The taller 5th gear is cancelled out by my slightly shorter rearend ratio and my tires while 17",are only 35 series,so the circumference is close to stock.The TII trans 5th gear ratio is almost the same as an SE trans 5th gear,so if you run an SE rearend ratio,the only thing that will alter speedo accuracy is the tire size.

http://members.aol.com/solomiata/Drivetrain.html near the bottom he lists the stock speedo gears, seems like theres enough selection to acommidate the sane people...

#23

So if I understand it right, the only things that affect the speedo gear are the rear gear and the tire circumference. The gear is driven at the same speed as the driveshaft, so the gears inside the tranny don't affect it. They only affect the difference in speed between the flywheel and the driveshaft.

So does that mean that with a TII tranny and a stock rear end I could just swap the speedo gear from my stock tranny and be done with it?

Of course I'd probably figure out the math and get a speedo gear to match a higher rear end gear ratio, but I just want to know if I'm on the right track.

Jon

So does that mean that with a TII tranny and a stock rear end I could just swap the speedo gear from my stock tranny and be done with it?

Of course I'd probably figure out the math and get a speedo gear to match a higher rear end gear ratio, but I just want to know if I'm on the right track.

Jon

#24

FB+FC=F-ME

Thread Starter

Your right,momenetary lapse of brain power there.

The gear ratios in the trans only determine engine RPM relative to vehicle speed for a given gear.Since the speedo gear is on the output shaft,only rearend gear ratio and tire size will affect speedo accuracy.And of course,the ratio of the speedo gears themselves will affect it.

Got all my parts clean and ready tonite.

Im starting the assembely and measurment of the stack right now to determine if there is any case wear.Pics to follow.......

The gear ratios in the trans only determine engine RPM relative to vehicle speed for a given gear.Since the speedo gear is on the output shaft,only rearend gear ratio and tire size will affect speedo accuracy.And of course,the ratio of the speedo gears themselves will affect it.

Got all my parts clean and ready tonite.

Im starting the assembely and measurment of the stack right now to determine if there is any case wear.Pics to follow.......

#25

FB+FC=F-ME

Thread Starter

Alright,here we go with the assembely and measurements for the LSD rebuild.......

As expected,Im well in spec.Things were looking quite good outright and nearly all my discs were in like new condition.This setup ought to be quiet,smooth and plenty grippy.

First step is to lay everything out in order.Here is the entire differential assembely in the order its assembled.You can see the spider at the center,spider gears,the side gears,thrust blocks and case halves.The LSD discs go between the thrust blocks and case halves.

Here are the drive portions of the diff within the carrier unit.The outer case,thrust blocks and drive discs all have corresponding tabs that lock together and rotate them as a unit.

Here are the driven portions that are part of each axle shaft.The side gear is splined to the axle and the driven LSD discs have tabs that engage the side gear which makes them all spin as a unit.

Here you can see the ramps on the thrust blocks and the spider.If you look close,youll see that one side of the spider has heavier wear and the other has lighter wear.This is also visible on the bottom ramp of the thrust block.The heavy side wear is input torque from the engine and the light wear side is caused by coasting torque from the wheels.The wear marks can help you to determine which side is which should you misplace the thrust blocks or get the spider flipped over backwards.

Step 1 is to determine the clearance you have inside the case for the LSD core.It can be anywhere from 0 to .20MM standard clearance with a maximum gap of 1.0MM.

First measure the thickness(not the height) of each cone spring and record it.Then measure the width of the LSD unit with all the discs installed...measure to the outer side of each end disc and be sure to hold everything tightly together.I took 4 measurements from all around the discs and averaged them.Heres what I got.....

The carrier case inside width will not change or wear because the point where the factory measures it is behind the cone springs,and they do not move relative to the carrier,so no wear is possible.The carrier width is 84.0MM, so you take your LSD core width,add the width of the cone springs and them subtract that number from 84.0MM.......I got .11MM total clearance,which means that each cone spring is within .055MM of being totally crushed flat when the LSD is assembled.....that about as much preload as can be obtained provided that the cone springs are in new condition.

Step 2 coming up.........

As expected,Im well in spec.Things were looking quite good outright and nearly all my discs were in like new condition.This setup ought to be quiet,smooth and plenty grippy.

First step is to lay everything out in order.Here is the entire differential assembely in the order its assembled.You can see the spider at the center,spider gears,the side gears,thrust blocks and case halves.The LSD discs go between the thrust blocks and case halves.

Here are the drive portions of the diff within the carrier unit.The outer case,thrust blocks and drive discs all have corresponding tabs that lock together and rotate them as a unit.

Here are the driven portions that are part of each axle shaft.The side gear is splined to the axle and the driven LSD discs have tabs that engage the side gear which makes them all spin as a unit.

Here you can see the ramps on the thrust blocks and the spider.If you look close,youll see that one side of the spider has heavier wear and the other has lighter wear.This is also visible on the bottom ramp of the thrust block.The heavy side wear is input torque from the engine and the light wear side is caused by coasting torque from the wheels.The wear marks can help you to determine which side is which should you misplace the thrust blocks or get the spider flipped over backwards.

Step 1 is to determine the clearance you have inside the case for the LSD core.It can be anywhere from 0 to .20MM standard clearance with a maximum gap of 1.0MM.

First measure the thickness(not the height) of each cone spring and record it.Then measure the width of the LSD unit with all the discs installed...measure to the outer side of each end disc and be sure to hold everything tightly together.I took 4 measurements from all around the discs and averaged them.Heres what I got.....

The carrier case inside width will not change or wear because the point where the factory measures it is behind the cone springs,and they do not move relative to the carrier,so no wear is possible.The carrier width is 84.0MM, so you take your LSD core width,add the width of the cone springs and them subtract that number from 84.0MM.......I got .11MM total clearance,which means that each cone spring is within .055MM of being totally crushed flat when the LSD is assembled.....that about as much preload as can be obtained provided that the cone springs are in new condition.

Step 2 coming up.........