VW's impressive OEM air-to-water intercooling system

#1

VW's impressive OEM air-to-water intercooling system

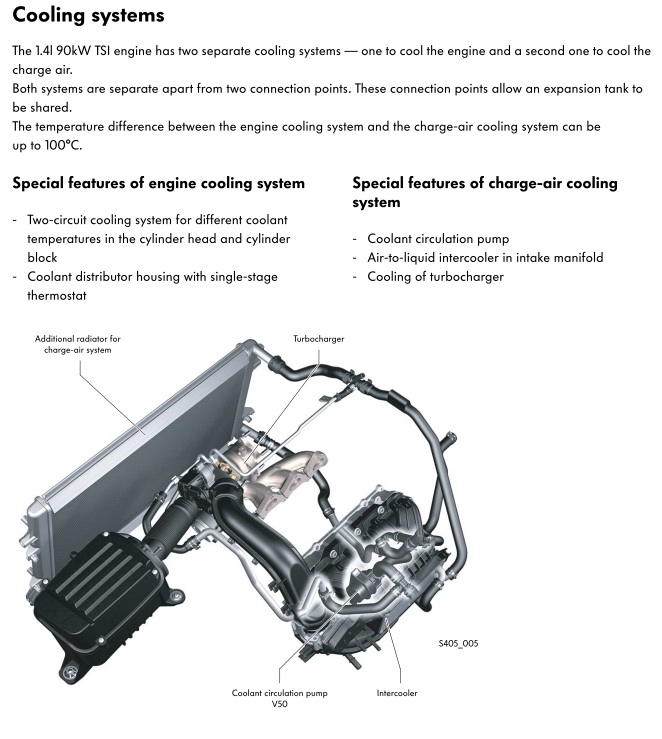

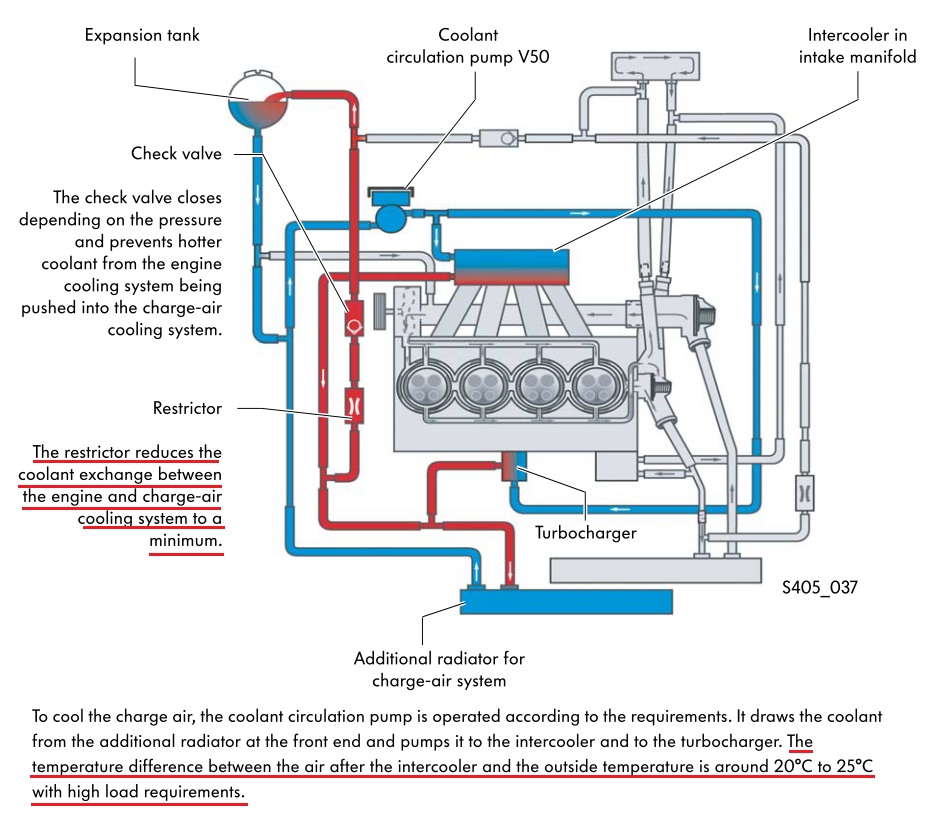

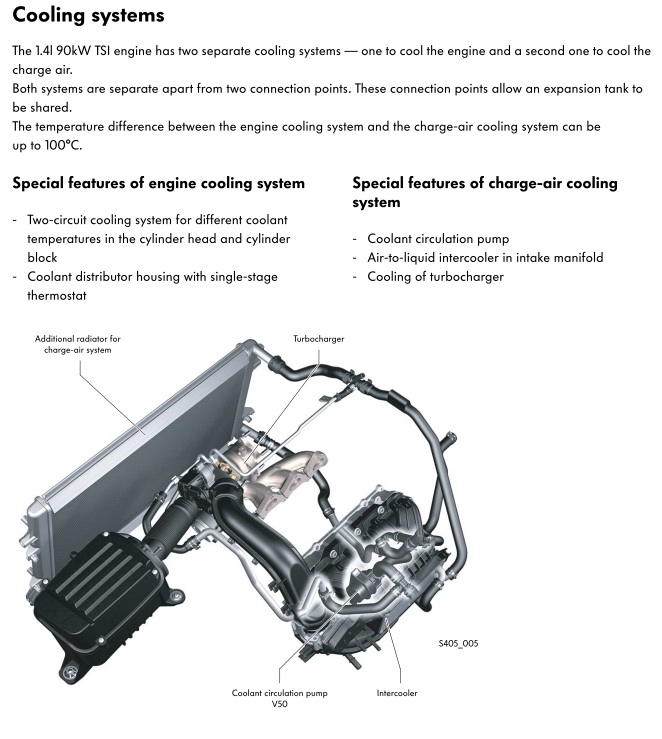

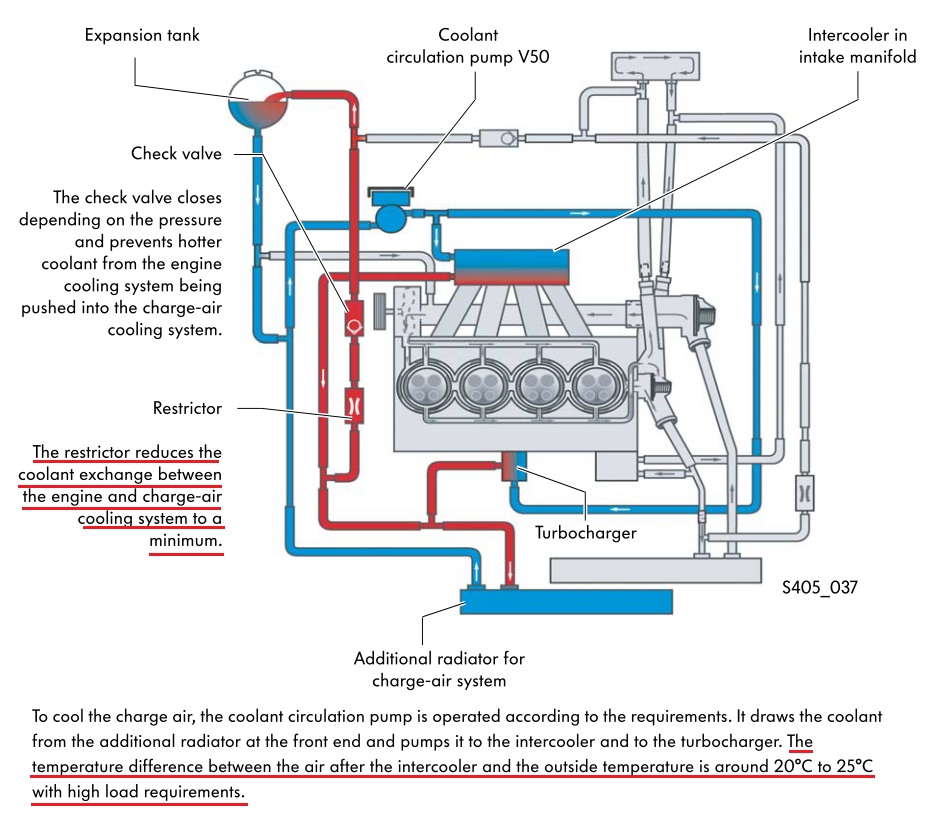

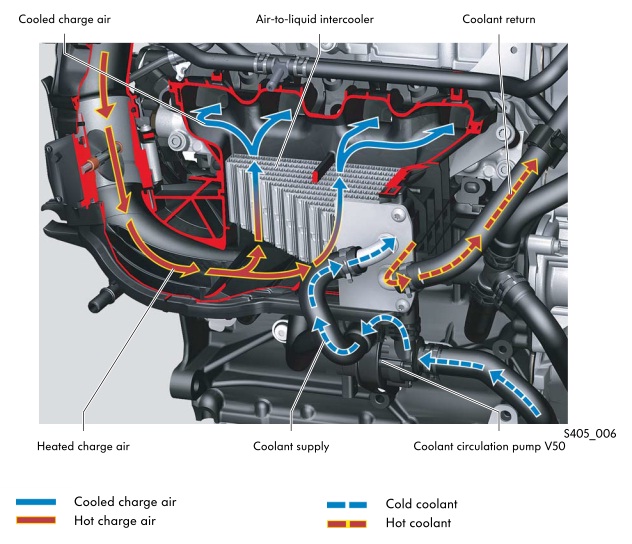

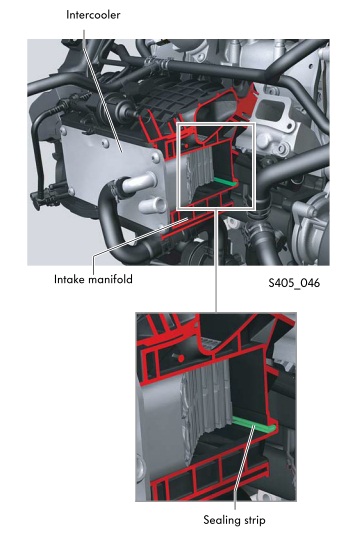

This just shows what the OEM's can do with the resources they have available. The VW 1.4L direct injected turbo 4 uses an air-to-water intercooler built into the intake manifold. The intercooler has an almost completely separated cooling circuit from the engine, which addresses the main flaw in air-to-water intercoolers. I don't want to pic bomb this thread so I'll post the main system schematics:

#3

"The temperature difference between the air after the intercooler and the outside temperature is around 20C to 25C with high load requirements."

That sounds like after full boost to me. Now, the 1.4 TSI is basically a 122hp economy car engine (optional Golf powerplant?). It's not like this particular iteration of the intercooling system is meant for something akin to sustained track use. The overall system demonstrates interesting engineering solutions though.

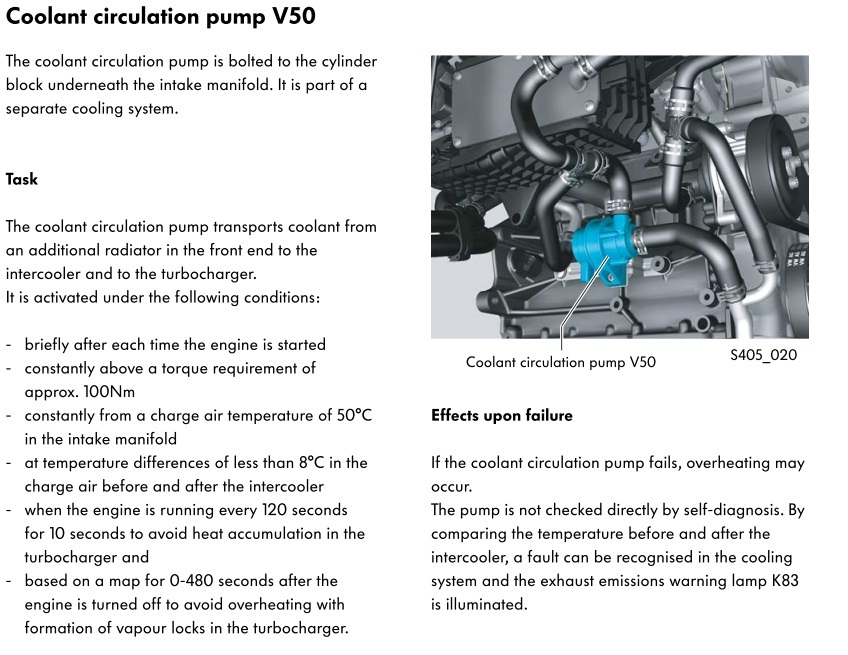

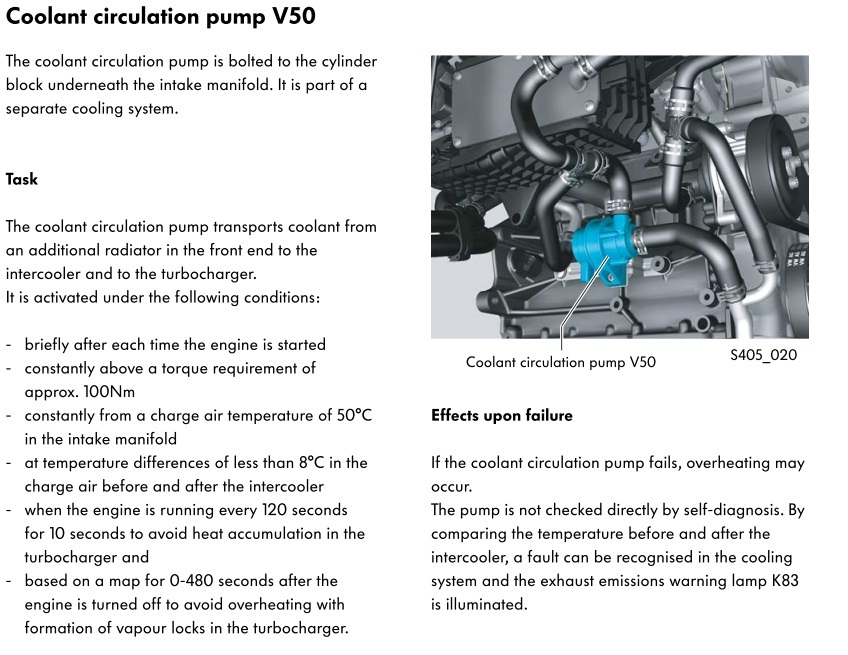

For example, the intercooler's cooling system uses its own electric water pump which cycles on and off based on demand. Having an electric pump and IAT feedback system allows it to keep the intercooler running efficiently and to improve cooling of the turbo when the engine is off. The cycling conserves power and extends the life of the pump. This engine is speed density like an FD, but like most modern speed density engines (Ford Ecoboost) it uses 2 or more combined MAP/IAT sensors. So the ECU compares the IAT before and after the intercooler to determine whether this electric coolant pump should be activated.

That sounds like after full boost to me. Now, the 1.4 TSI is basically a 122hp economy car engine (optional Golf powerplant?). It's not like this particular iteration of the intercooling system is meant for something akin to sustained track use. The overall system demonstrates interesting engineering solutions though.

For example, the intercooler's cooling system uses its own electric water pump which cycles on and off based on demand. Having an electric pump and IAT feedback system allows it to keep the intercooler running efficiently and to improve cooling of the turbo when the engine is off. The cycling conserves power and extends the life of the pump. This engine is speed density like an FD, but like most modern speed density engines (Ford Ecoboost) it uses 2 or more combined MAP/IAT sensors. So the ECU compares the IAT before and after the intercooler to determine whether this electric coolant pump should be activated.

#4

Racing Rotary Since 1983

iTrader: (6)

i assume high load is high boost.

so IAT after the intercooler is 72.5 F more than ambient. (using 22.5 C ).

maybe 250 out of the turbo. 75 ambient + 72.5 for 147.5. 250 minus 147.5 or about 100 F.

considering you need a coolant pump, coolant/charge air intercooler and a heat exchanger for the coolant for the intercooler... that's not an insubstantial amount of stuff.

certainly not a bad setup but i will just settle for my simple air/air system.

it is always great to see turbo'd OE vehicles.

WTG VW.

howard

so IAT after the intercooler is 72.5 F more than ambient. (using 22.5 C ).

maybe 250 out of the turbo. 75 ambient + 72.5 for 147.5. 250 minus 147.5 or about 100 F.

considering you need a coolant pump, coolant/charge air intercooler and a heat exchanger for the coolant for the intercooler... that's not an insubstantial amount of stuff.

certainly not a bad setup but i will just settle for my simple air/air system.

it is always great to see turbo'd OE vehicles.

WTG VW.

howard

Last edited by Howard Coleman; 11-28-10 at 03:51 PM.

#5

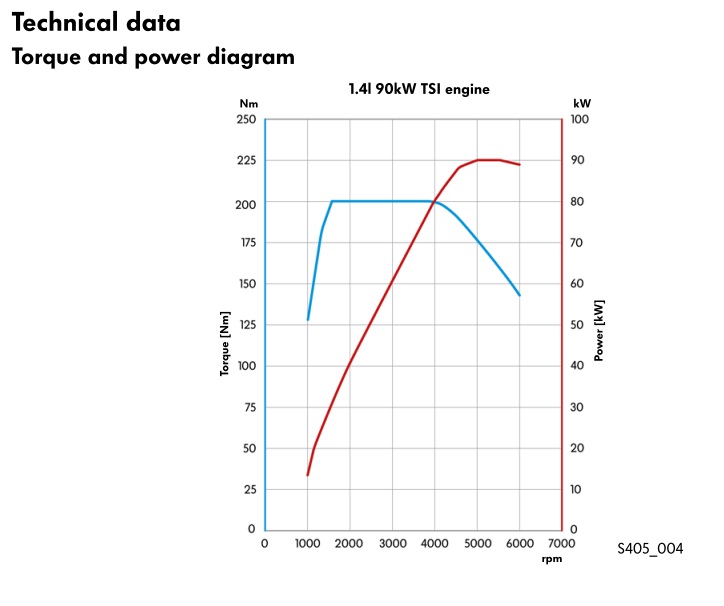

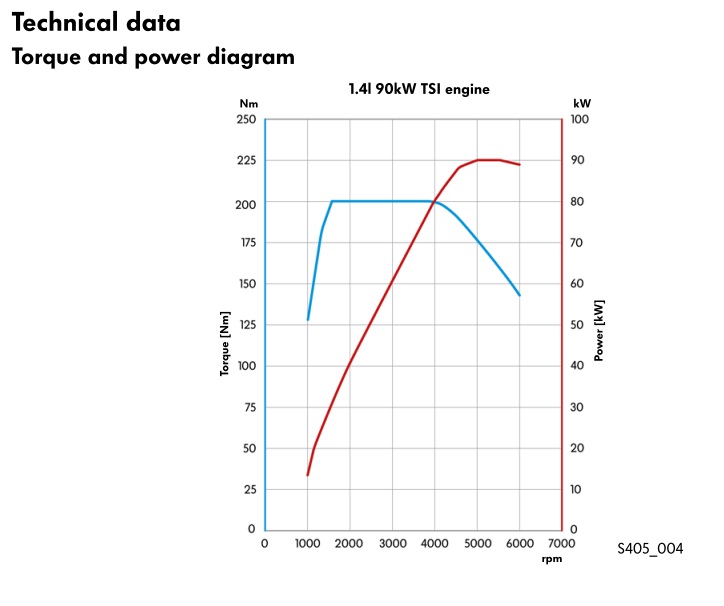

This system (or an approximation of it) isn't feasible on a DIY aftermarket application for sure, and this isn't a high output engine on a fast car. The engineering is still well done for a responsive daily driver with good fuel economy. I'm sure the intercooler plumbing helps this engine achieve peak torque at 1500rpm and hold that torque through most of the useable [daily driver] powerband.

That is actually slightly better than the average 1750-2000rpm peak that most turbo engines are hitting now, with the exception of the real high strung ones (Evo 4B11T engine for example).

That is actually slightly better than the average 1750-2000rpm peak that most turbo engines are hitting now, with the exception of the real high strung ones (Evo 4B11T engine for example).

Trending Topics

#8

Banned. I got OWNED!!!

iTrader: (1)

Join Date: Jun 2006

Location: Denver

Posts: 697

Likes: 0

Received 0 Likes

on

0 Posts

Well, if Howards math based on thier statements is right they are really doing the WAIC thing wrong. Your average A/A intercooler here at altitude (assuming the following- efficiently sized turbocharger, boost level in efficiency range, and airflow through the core) we will see a firaly stable 95-110 IAT on the dyno given an ambient temp of say 85-90deg (summer). With a WAIC we will often see IAT's under boost of 10-15deg below ambient. Obviously, this did depend on the water capacity and cooling system used. On track, we found that over a 25-min session at Laguna IATs would start at about 10-15deg below ambient and rise to ambient or slightly higher. Slowing the water pump down and increasing heat exchanger size improved duration.

#11

#15

An aftermarket WAIC system is feasable for a DIY: https://www.rx7club.com/20b-forum-95/rebuild-update-982419/

Should bring temps dowm more than the above oem system due to:

1) Circ pump is located in direct air flow, not under the intake manifold connected to the block

2) IC is in a better location other than inside the intake manifold

3) Vented hood probably helps, but not really related to WAIC vs AAIC

4) Fan is constantly pulling air through the front heat exchanger and circ pump is always on

Should bring temps dowm more than the above oem system due to:

1) Circ pump is located in direct air flow, not under the intake manifold connected to the block

2) IC is in a better location other than inside the intake manifold

3) Vented hood probably helps, but not really related to WAIC vs AAIC

4) Fan is constantly pulling air through the front heat exchanger and circ pump is always on

#16

Senior Member

iTrader: (3)

Nice system for an OEM diesel application, but it would be less than desirable for aftermarket performance. The reason is that the cooling system used for the air charge is also used to cool the turbo bearings. For safety and performance sake, I would rather have lower intake manifold temps than lower bearing temps.

#17

~!@#$%^&*()_+

Join Date: Oct 2001

Location: Mpls, MN

Posts: 461

Likes: 0

Received 0 Likes

on

0 Posts

Im not to impressed with it. If I was to mod a car with this setup, Id start by dumping all that crap and running a fmic, to get even better maybe add some alky or water injection.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

#18

Im not to impressed with it. If I was to mod a car with this setup, Id start by dumping all that crap and running a fmic, to get even better maybe add some alky or water injection.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

#19

Several OEM vehicles have WAIC systems, Im not impressed with VW's particular system either but that doesn't mean the system it not suitable for race/street cars depending on the setup.

Their are draw backs to both FMIC and WAIC systems and I'll be the first to admit WAIC is a more complicated system but certainly has its advantages.

Their are draw backs to both FMIC and WAIC systems and I'll be the first to admit WAIC is a more complicated system but certainly has its advantages.

#20

~!@#$%^&*()_+

Join Date: Oct 2001

Location: Mpls, MN

Posts: 461

Likes: 0

Received 0 Likes

on

0 Posts

Odd, Ive daily driven them for 24 years, my last one had over 500k on it and was still going when I switched to a new shell (original head gasket). Im pretty sure every one Ive had went well over 200k before I sold them.

Now my TII had 3 engines between 1987 and 1999 (before I got it) and it has 79k on it. talk about going to ****....

Now my TII had 3 engines between 1987 and 1999 (before I got it) and it has 79k on it. talk about going to ****....

#21

Odd, Ive daily driven them for 24 years, my last one had over 500k on it and was still going when I switched to a new shell (original head gasket). Im pretty sure every one Ive had went well over 200k before I sold them.

Now my TII had 3 engines between 1987 and 1999 (before I got it) and it has 79k on it. talk about going to ****....

Now my TII had 3 engines between 1987 and 1999 (before I got it) and it has 79k on it. talk about going to ****....

#22

Doing the Ricky Bobby

iTrader: (1)

Join Date: Jan 2008

Location: Dallas, Texas

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

Im not to impressed with it. If I was to mod a car with this setup, Id start by dumping all that crap and running a fmic, to get even better maybe add some alky or water injection.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

Water to air belongs on boats or one pass race cars. When that over engineered mess ends up on the lift in front of a tech with 200k miles and a leak, nobody involved is going to like it much.

Problem with engineers is most of what they learned was out of a book. Thats how you end up with stuff like this.

This reminds me of the dumbass engineers who created the sequential system for the FD. In theory its a pretty cool idea, and I'm sure the engineering department thought it looked great, but with rats nest of rubber lines is a reliability nightmare. I'll bet when they designed it most of the lines ere made out of hard metal lines, but as GregW said, the engineers of the company are stuck in academic knowledge world instead of the real world.

#23

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,812

Received 2,582 Likes

on

1,834 Posts

This reminds me of the dumbass engineers who created the sequential system for the FD. In theory its a pretty cool idea, and I'm sure the engineering department thought it looked great, but with rats nest of rubber lines is a reliability nightmare. I'll bet when they designed it most of the lines ere made out of hard metal lines, but as GregW said, the engineers of the company are stuck in academic knowledge world instead of the real world.

one of the reasons the FD was such a nightmare is that the first thing any mechanic had to do was pull the vacuum rail off for the fuel recall!

it turns out that the FD is much more reliable if you don't work on it.

#24

Doing the Ricky Bobby

iTrader: (1)

Join Date: Jan 2008

Location: Dallas, Texas

Posts: 137

Likes: 0

Received 0 Likes

on

0 Posts

no there are pics in the FD book of the prototype mules blowing the hoses off... I actually got to talk to Koby about that, and when the FD came out in 1992 NOBODY knew how to work on it, not even the factory!

one of the reasons the FD was such a nightmare is that the first thing any mechanic had to do was pull the vacuum rail off for the fuel recall!

it turns out that the FD is much more reliable if you don't work on it.

one of the reasons the FD was such a nightmare is that the first thing any mechanic had to do was pull the vacuum rail off for the fuel recall!

it turns out that the FD is much more reliable if you don't work on it.

Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.

Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.The FD might have been more reliable if it wasn't worked on and it was kept almost stock, but if your going all out you can take care of a lot of issues by going single turbo and ripping out unnecessary junk. a gt30r would have as good as spool and make as much power as the stock twins do without the reliability nightmares if not interested in making a significant amount of power. Once single turbo you have no more overly complicated vacuum system and no cast manifold and turbo setup that hugs and cooks one side of the engine.

#25

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,812

Received 2,582 Likes

on

1,834 Posts

Interesting, so they pretty much knew it was going to be a problem in testing and decided to do nothing about it anyways?  Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.

Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.

The FD might have been more reliable if it wasn't worked on and it was kept almost stock, but if your going all out you can take care of a lot of issues by going single turbo and ripping out unnecessary junk. a gt30r would have as good as spool and make as much power as the stock twins do without the reliability nightmares if not interested in making a significant amount of power. Once single turbo you have no more overly complicated vacuum system and no cast manifold and turbo setup that hugs and cooks one side of the engine.

Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.

Way to go Mazda, that's a great way to promote customer loyalty. I think many people have learned the hard way that Mazda dealerships have no clue what they are doing when it comes to repairing rotary engines, so why they made an incredibly complex vacuum system that didn't really perform much better than non sequential twins in the first place should have ended with the termination of the person who approved the system to be put into production.The FD might have been more reliable if it wasn't worked on and it was kept almost stock, but if your going all out you can take care of a lot of issues by going single turbo and ripping out unnecessary junk. a gt30r would have as good as spool and make as much power as the stock twins do without the reliability nightmares if not interested in making a significant amount of power. Once single turbo you have no more overly complicated vacuum system and no cast manifold and turbo setup that hugs and cooks one side of the engine.

secondly, when the FD arrived in the US, nobody in the world knew how to fix it. not the US, the world, i've heard some interesting stories, but the Japanese had to figure out the thing too. and B do you really expect a $15/hour oil change guy to figure out the turbo system?

i'm not sure about the customer loyalty thing either, when something bad happens on a BMW, like when the rear suspension pulled out of the 90's M3's, BMW blames the owners, yet BMW sells a lot of cars....

for the second part, Mazda had to deliver a 50% increase in power, WHILE improving fuel economy, and emissions while having a 50,000mile warranty. they knew how to make power, its the other three that are tricky.

plus the twins are cool! and they make the car seem like its a rocket ship.