4-Rotor FC Build

#1876

Exhaust Manifold Leak

pumps dont really mind it as long as they get some oil now and then. what is bad is if for example when the engine is tilted backwards and you have one pickup at the front of the pan and one at the rear. if you are unlucky then when non of the oil from the front bearing makes it too the front pickup. one section will run dry during idle phases and that could be bad.

#1878

Exhaust Manifold Leak

#1881

Exhaust Manifold Leak

#1882

Wasted spark plug

Are you thinking about a reservoir with level sensor in the dry sump set up?

I mean, just in case the pick-up stalls and you run out of oil on your devilish machine...

Grtz Dennis

I mean, just in case the pick-up stalls and you run out of oil on your devilish machine...

Grtz Dennis

#1883

"Elusive, not deceptive!”

The nature of dry sump systems is that they pump 2 to 3 times as much air as oil through the scavenger side (the ratio of pressure segment to scavenger segments).

The load on these segments is very low because of the added air so there should be no fear of damage to them.

Screens on the inlets and maybe a couple of magnetic drain plugs on sump plate would help.

On turbine engines the tank is vented back to the engine case and one high speed gear acts as centrifugal oil separator to vent excess air overboard.

Admire your great work as usual...

Barry

The load on these segments is very low because of the added air so there should be no fear of damage to them.

Screens on the inlets and maybe a couple of magnetic drain plugs on sump plate would help.

On turbine engines the tank is vented back to the engine case and one high speed gear acts as centrifugal oil separator to vent excess air overboard.

Admire your great work as usual...

Barry

#1884

Full Member

Join Date: Nov 2011

Location: orange, ca

Posts: 105

Likes: 0

Received 0 Likes

on

0 Posts

I don't know what John is planning, but usually a dry-sump setup will have a VERY large, 1-2 gallon, main reservoir so that oil starvation will not be a problem.

#1885

Exhaust Manifold Leak

if pick up in sump stalls it will only be matter of 3-5 seconds before oil is flying everywhere.. our 13B PP has smallest nascar dry sump tank I could find and in total there is a about 12-13l oil inside. in the engine itself can maybe fit 2 liters?

#1886

First of all, wow over one million views! Thanks everyone :-)

Second of all, sorry for the lack of updates again, been doing a lot of stuff besides the 4-rotor , Mostly work on other cars, ported a few heads, worked on a few intakes, and fabricated a lot of suspension components. Also sold my RX-8 and got another car. The 8 was really nice, and it drove really well! But I kindoff like having a crappy old car for a daily driver because now I don't have to be carefull about warming it up or keeping it nice or anything. I can just hop in with my oily working clothes, fill up the front seat, back seat and trunk with oily engine bits (or whole engines) and go

, Mostly work on other cars, ported a few heads, worked on a few intakes, and fabricated a lot of suspension components. Also sold my RX-8 and got another car. The 8 was really nice, and it drove really well! But I kindoff like having a crappy old car for a daily driver because now I don't have to be carefull about warming it up or keeping it nice or anything. I can just hop in with my oily working clothes, fill up the front seat, back seat and trunk with oily engine bits (or whole engines) and go  . The car I've got now is an audi 80 1.8 8v somebody gave me for free. Actually pretty comfortable!, But sadly it gets about the same MPG as the RX-8 got, while having 1/3rd of the power

. The car I've got now is an audi 80 1.8 8v somebody gave me for free. Actually pretty comfortable!, But sadly it gets about the same MPG as the RX-8 got, while having 1/3rd of the power  . It's got one of those mechanical K-Jetronic injection systems from the 80s, and the air/fuel is waaayyyy off. Not sure if I want to mess with it, I think I have an old megasquirt, some injectors, and some sensors lying around. Might try to megasquirt it on the cheap, will make for a nice weekend project.

. It's got one of those mechanical K-Jetronic injection systems from the 80s, and the air/fuel is waaayyyy off. Not sure if I want to mess with it, I think I have an old megasquirt, some injectors, and some sensors lying around. Might try to megasquirt it on the cheap, will make for a nice weekend project.

Also disassembled a few spare engines I had lying around here, because I was scared of them rusting away if left alone. One of the engines was a S4 n/a I bought locally for cheap. These engines don't come for sale too often here in the netherlands, so when one comes up cheap locally I usually get them. This one broke an apex seal which trashed one of the rotors and rotor housings, so no good. The other one was an S4 TII, which looked better. It's been standing for a while, so the seals were a bit stuck. I managed to get them out, but broke a few of the side seals in the progress. Rotor housings looked excellent, which is rare. I usually find bad chrome near the edges on the older S4 housings.

Anyway, about the 4-rotor FC. I did some more work on the front cover, welded in a plate, machined the mating surfaces flat and added some mounting threads, and a pocket for the front seal:

Now the plan is to just cut out an aluminium plate which mounts to the front cover. That plate will have mounting points for both the dry sump pump and alternator, and I will have to add some tentioners. Only issue is that my alternator has a swivel mount, so I ordered another one which mounts differently. It's a 90A bosch unit from some mercedes, should be here tomorrow

Second of all, sorry for the lack of updates again, been doing a lot of stuff besides the 4-rotor

, Mostly work on other cars, ported a few heads, worked on a few intakes, and fabricated a lot of suspension components. Also sold my RX-8 and got another car. The 8 was really nice, and it drove really well! But I kindoff like having a crappy old car for a daily driver because now I don't have to be carefull about warming it up or keeping it nice or anything. I can just hop in with my oily working clothes, fill up the front seat, back seat and trunk with oily engine bits (or whole engines) and go

, Mostly work on other cars, ported a few heads, worked on a few intakes, and fabricated a lot of suspension components. Also sold my RX-8 and got another car. The 8 was really nice, and it drove really well! But I kindoff like having a crappy old car for a daily driver because now I don't have to be carefull about warming it up or keeping it nice or anything. I can just hop in with my oily working clothes, fill up the front seat, back seat and trunk with oily engine bits (or whole engines) and go  . The car I've got now is an audi 80 1.8 8v somebody gave me for free. Actually pretty comfortable!, But sadly it gets about the same MPG as the RX-8 got, while having 1/3rd of the power

. The car I've got now is an audi 80 1.8 8v somebody gave me for free. Actually pretty comfortable!, But sadly it gets about the same MPG as the RX-8 got, while having 1/3rd of the power  . It's got one of those mechanical K-Jetronic injection systems from the 80s, and the air/fuel is waaayyyy off. Not sure if I want to mess with it, I think I have an old megasquirt, some injectors, and some sensors lying around. Might try to megasquirt it on the cheap, will make for a nice weekend project.

. It's got one of those mechanical K-Jetronic injection systems from the 80s, and the air/fuel is waaayyyy off. Not sure if I want to mess with it, I think I have an old megasquirt, some injectors, and some sensors lying around. Might try to megasquirt it on the cheap, will make for a nice weekend project. Also disassembled a few spare engines I had lying around here, because I was scared of them rusting away if left alone. One of the engines was a S4 n/a I bought locally for cheap. These engines don't come for sale too often here in the netherlands, so when one comes up cheap locally I usually get them. This one broke an apex seal which trashed one of the rotors and rotor housings, so no good. The other one was an S4 TII, which looked better. It's been standing for a while, so the seals were a bit stuck. I managed to get them out, but broke a few of the side seals in the progress. Rotor housings looked excellent, which is rare. I usually find bad chrome near the edges on the older S4 housings.

Anyway, about the 4-rotor FC. I did some more work on the front cover, welded in a plate, machined the mating surfaces flat and added some mounting threads, and a pocket for the front seal:

Now the plan is to just cut out an aluminium plate which mounts to the front cover. That plate will have mounting points for both the dry sump pump and alternator, and I will have to add some tentioners. Only issue is that my alternator has a swivel mount, so I ordered another one which mounts differently. It's a 90A bosch unit from some mercedes, should be here tomorrow

#1887

Exhaust Manifold Leak

That audi just needs a TDI in there, 150 hp for 0 euros invested and uses barely any fuel. (some time to make wiring). let me know if U need one. I'll bring u one for free =)

#1888

A TDI would be nice, but it's more taxes (€530 / year difference), and with the low amount of km's I make it doesn't make sense. Thanks for the offer though!

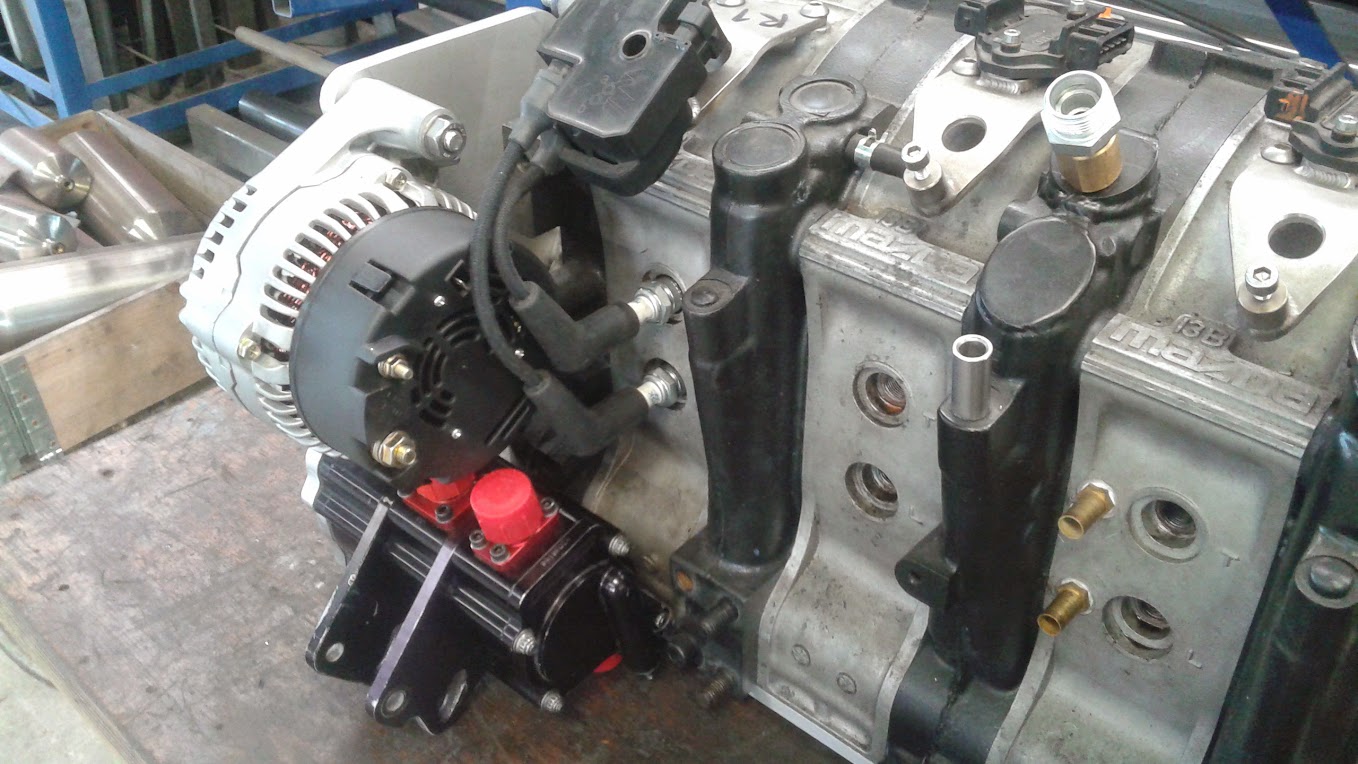

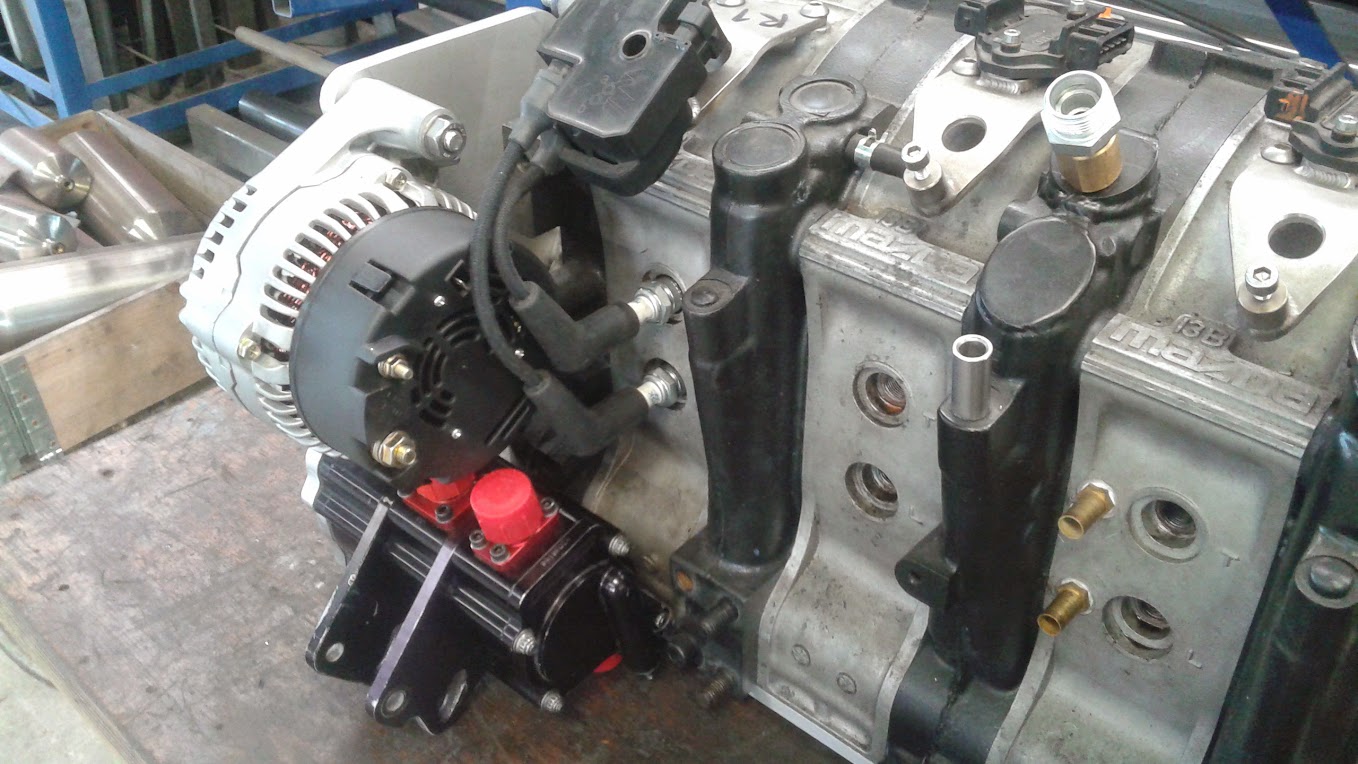

Had a few hours leftover last weekend, so I did this:

So at least the pump and alternator fit , now I need some pullys and belts, and figure out where to fit a pair of tensioners. Also need to figure out the pickup lines, still not sure if Ill go with AN fittings and hose, or hardlines.

, now I need some pullys and belts, and figure out where to fit a pair of tensioners. Also need to figure out the pickup lines, still not sure if Ill go with AN fittings and hose, or hardlines.

Had a few hours leftover last weekend, so I did this:

So at least the pump and alternator fit

, now I need some pullys and belts, and figure out where to fit a pair of tensioners. Also need to figure out the pickup lines, still not sure if Ill go with AN fittings and hose, or hardlines.

, now I need some pullys and belts, and figure out where to fit a pair of tensioners. Also need to figure out the pickup lines, still not sure if Ill go with AN fittings and hose, or hardlines.

#1889

Tiny bit of progress, I modified the dry sump pump a little bit, shaven the normal mounting points off and moved the scavange oil outlet since the normal one fouled with the alternator. The 2 scavange sections are different, so I couldn't just swap them, I had to blank the normal outlet off, and then add an outlet to the other section. It was too tight for a 90 degree AN-12 elbow in there, so I made a stainless steel fitting, will weld an AN-12 fitting to this.

So now I'm thinking about how to do the rest of the oil system. I previously had an external oil filter manifold with 2 large filters, but I dunno, might just remove all that and just run a line from the pump to an oem oil filter pedestal and filter, and then fit a sandwich plate with 2 looplines The PPRE 6-rotor also just uses the normal pedestal and filter, so if it's good enough for them...

The PPRE 6-rotor also just uses the normal pedestal and filter, so if it's good enough for them...

Oh, and I ordered an MS3!, The microsquirt I had worked, but I really want to be able to log everything, and have more IO. Will try to get the leading-trailing split working, to see if it makes a difference. Also got another wideband because my old one broke.

Another thing I'm thinking about doing is fabbing up another intake. The sliding throttle intake I currently have does work, but I don't like the rattling, and that I'm not able to sync up the rotors at idle and lower loads. I also would like to try larger runners and throttles after looking at other setups. Seems like it's not too uncommon to have a 55mm or so throttlebody on a 50mm or so PP. So I figured it would be nice to have a normal butterfly valve intake which is a bit larger in size. Now I could fabricate everything myself, but I don't really want to spend the time on that. I could also buy a trick setup, but don't really want to spend the money on that. So I went to look for existing throttlebodies that I could use, one that doesn't have too much cluttery stuff around it, and found this:

It's a throttlebody from a 90s BMW, which just happens to tick all the boxes. It's 56mm in diameter, has a nice mounting flange with an o-ring on the front and an air filter fitting on the back. No clutter, just a TPS sensor which uses a easy to get bosch connector, and one vaccuum nipple. And it has a mechanism that opens the throttle progressively which is nice. These things are easy to find and cheap. Might just get 4 of these, and weld an aluminium intake together using a pair of flanges, and aluminium bends. It's not a really trick baller setup, but I bet it will work just fine

So now I'm thinking about how to do the rest of the oil system. I previously had an external oil filter manifold with 2 large filters, but I dunno, might just remove all that and just run a line from the pump to an oem oil filter pedestal and filter, and then fit a sandwich plate with 2 looplines

The PPRE 6-rotor also just uses the normal pedestal and filter, so if it's good enough for them...

The PPRE 6-rotor also just uses the normal pedestal and filter, so if it's good enough for them...

Oh, and I ordered an MS3!, The microsquirt I had worked, but I really want to be able to log everything, and have more IO. Will try to get the leading-trailing split working, to see if it makes a difference. Also got another wideband because my old one broke.

Another thing I'm thinking about doing is fabbing up another intake. The sliding throttle intake I currently have does work, but I don't like the rattling, and that I'm not able to sync up the rotors at idle and lower loads. I also would like to try larger runners and throttles after looking at other setups. Seems like it's not too uncommon to have a 55mm or so throttlebody on a 50mm or so PP. So I figured it would be nice to have a normal butterfly valve intake which is a bit larger in size. Now I could fabricate everything myself, but I don't really want to spend the time on that. I could also buy a trick setup, but don't really want to spend the money on that. So I went to look for existing throttlebodies that I could use, one that doesn't have too much cluttery stuff around it, and found this:

It's a throttlebody from a 90s BMW, which just happens to tick all the boxes. It's 56mm in diameter, has a nice mounting flange with an o-ring on the front and an air filter fitting on the back. No clutter, just a TPS sensor which uses a easy to get bosch connector, and one vaccuum nipple. And it has a mechanism that opens the throttle progressively which is nice. These things are easy to find and cheap. Might just get 4 of these, and weld an aluminium intake together using a pair of flanges, and aluminium bends. It's not a really trick baller setup, but I bet it will work just fine

#1890

Exhaust Manifold Leak

stock oilfilter seems a bad idea to me. you need about double the flow of a 13B, if not more. what u could do is give it a try and block the bypass valve in the oem filter and measrure the pressure drop over it at high rpm.

#1891

Madman

Join Date: Oct 2013

Location: Lake of the Ozarks, Missouri

Posts: 25

Likes: 0

Received 0 Likes

on

0 Posts

I can't get enough of this build! Just the pictures are pure eye candy. Hey John, is there a part number or something on that throttle body? I could use one like that if I can find one around here.

#1892

Messed some more with it today, I assembled a mockup motor with an e-shaft so I can work on the front pullys. Already machined the main V-belt pully, and ordered some parts so I could do the rest next week or so.

#1894

Exhaust Manifold Leak

What are you running on the 13B PP? I saw an adapter with an AN fitting on the rear iron, but couldn't see the remote filter. After searching around it seems that the wix spin-on racing filters are popular with dry sump systems, often mounted remotely. I looked them up, and they are rated for about 28-30gpm, and about twice the size of the oem rx7 filter. Seems like the better option then!

According to realoem the bmw partnr. is: 13541734719, it's a throttlebody from a BMW M43 engine. The early ones don't have a idle valve, but the later ones do.

Messed some more with it today, I assembled a mockup motor with an e-shaft so I can work on the front pullys. Already machined the main V-belt pully, and ordered some parts so I could do the rest next week or so.

According to realoem the bmw partnr. is: 13541734719, it's a throttlebody from a BMW M43 engine. The early ones don't have a idle valve, but the later ones do.

Messed some more with it today, I assembled a mockup motor with an e-shaft so I can work on the front pullys. Already machined the main V-belt pully, and ordered some parts so I could do the rest next week or so.

Pressure drop on cooler is about 2 bar at high rpm. it a big bar and plate core around 30cm high. pressure drop suprised me a bit

#1896

Yeah, we're using a big wix remote filter on a raceline filter pedestral with integrated oil pressure regulator. The regulator in the pump is set a bit higher and is only there to protect the oil cooler on a cold start. all lines are -12 and just before the engine we split in 2 -10, one to rear bearing and one to front bearing. suction line from tank to engine is -16. from pump scavenge section 2 -12 lines go back to tank, one for air and one for oil.

Pressure drop on cooler is about 2 bar at high rpm. it a big bar and plate core around 30cm high. pressure drop suprised me a bit

Pressure drop on cooler is about 2 bar at high rpm. it a big bar and plate core around 30cm high. pressure drop suprised me a bit

That's right, I'll be using distribution belt idlers, and make up some sort of tensioner.

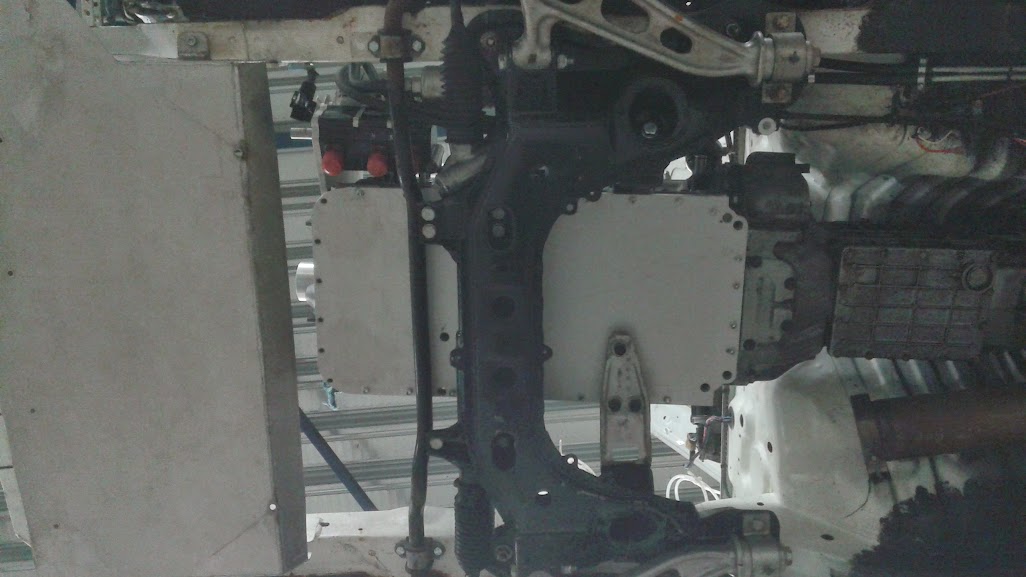

Anyway, today I got the car in the workshop again, removed some stuff from the engine bay, and installed the engine with the dry sump pump for mockup.

Because the flat oil pan is much thicker than the stock pan the engine sits at a slight angle. I need to machine the right side engine mount a bit flatter to solve this.

Here is the rear side of the engine looking from underneath the car:

And this is the front side of the engine. Previously with the oil pan in front of the steering rack there was no chance of ever having a sway bar, but now with the dry sump I think I can make one fit.

Ok so this shows how the engine sits in regards to the subframe, I'm trying to determine where to put the scavange pickups. The engine is tilted a bit to the rear, so maybe it's best to put both pickups behind the subframe, kindoff like the way that time attack dry sump setup has it.

#1898

Need updates!

Also saw this recently, and thought of your quad throttle body setup,

Apparently its for a Honda s2000, I also thought it was super interesting it was using fd fuel rails with side feed injectors and injectors very similar to stock fd flow rates.

550rwhp @ 7800rpm and 490nm

Also saw this recently, and thought of your quad throttle body setup,

Apparently its for a Honda s2000, I also thought it was super interesting it was using fd fuel rails with side feed injectors and injectors very similar to stock fd flow rates.

550rwhp @ 7800rpm and 490nm

#1900

Exhaust Manifold Leak

Need updates!

Also saw this recently, and thought of your quad throttle body setup,

Apparently its for a Honda s2000, I also thought it was super interesting it was using fd fuel rails with side feed injectors and injectors very similar to stock fd flow rates.

550rwhp @ 7800rpm and 490nm

Also saw this recently, and thought of your quad throttle body setup,

Apparently its for a Honda s2000, I also thought it was super interesting it was using fd fuel rails with side feed injectors and injectors very similar to stock fd flow rates.

550rwhp @ 7800rpm and 490nm