My 85 RX7 non-turbo LSD rebuild and question thread!

#1

Junior Member

Thread Starter

My 85 RX7 non-turbo LSD rebuild and question thread!

First I'll mention that I actually own a 1995 Miata which I will be swapping the differential into.

I've been searching around for an LSD for the last three or so months. Originally I was looking for a torsen swap, but after doing some research I decided to see if I can find a clutch type LSD from an RX7. I like that I'll be able to rebuild it if necessary and tune the break away torque if I wish. Plus, if I decide to drift more in the future I can shim that sucker up to full lock if I want.

So I searched and searched and researched and studied everything there is to read about RX7 LSDs, and LSDs in general. I also set up RSS feeds through CraigsHelper to be alerted if anyone across the nation posts up an RX7 LSD. I ended up finding one on eBay and won an auction for $169.99 plus $99 shipping. Not a bad deal I thought. Turns out the seller was a total scammer and fortunately after a few weeks I was able to recover my money though paypal.

Anyways, long story short, a listing popped up for a local guy parting out an 85 non-turbo RX7 WITH an LSD! I called him up and went to check it out. It was still under the car and the guy said he didn't really know the condition so I offered him $50 and off I went with the complete axle assembly. I figured even if it's toast $50 is less than I was planning on paying for shipping.

I got it home the other night and started tearing into it. This is my first time working with a differential so I was just going on what I read on the internets. Here are some pics...

It took me about 45 minutes to get the diff out but here it is!!

How does it look? I don't know much about these things other than what I've read. I am planning on rigging up a way to measure the break away torque first, and then rebuilding it if necessary.

Anyways, I'm totally pumped that I finally found an LSD that appears to be in decent shape. And I can't believe I found it locally for $50. I've got plenty of budget left to rebuild it if need be. I guess good things do come to those who wait!

I've been searching around for an LSD for the last three or so months. Originally I was looking for a torsen swap, but after doing some research I decided to see if I can find a clutch type LSD from an RX7. I like that I'll be able to rebuild it if necessary and tune the break away torque if I wish. Plus, if I decide to drift more in the future I can shim that sucker up to full lock if I want.

So I searched and searched and researched and studied everything there is to read about RX7 LSDs, and LSDs in general. I also set up RSS feeds through CraigsHelper to be alerted if anyone across the nation posts up an RX7 LSD. I ended up finding one on eBay and won an auction for $169.99 plus $99 shipping. Not a bad deal I thought. Turns out the seller was a total scammer and fortunately after a few weeks I was able to recover my money though paypal.

Anyways, long story short, a listing popped up for a local guy parting out an 85 non-turbo RX7 WITH an LSD! I called him up and went to check it out. It was still under the car and the guy said he didn't really know the condition so I offered him $50 and off I went with the complete axle assembly. I figured even if it's toast $50 is less than I was planning on paying for shipping.

I got it home the other night and started tearing into it. This is my first time working with a differential so I was just going on what I read on the internets. Here are some pics...

It took me about 45 minutes to get the diff out but here it is!!

How does it look? I don't know much about these things other than what I've read. I am planning on rigging up a way to measure the break away torque first, and then rebuilding it if necessary.

Anyways, I'm totally pumped that I finally found an LSD that appears to be in decent shape. And I can't believe I found it locally for $50. I've got plenty of budget left to rebuild it if need be. I guess good things do come to those who wait!

#2

Junior Member

Thread Starter

Well, I took the LSD apart today, cleaned it up, and measured everything to see which parts I need to order.

Surprisingly all of the disks are well within spec! The thrust washers need replacing, but everything else is within factory specs.

Here are some pics...

This is what I started with:

It came apart really easily:

Disassembled and spread out on the bench:

Here's one thing that's a bit concerning, look at the edges of these gears, they are the gears that the axles slide into. You can see that the edges have some funky wear on them. Does this look bad enough to worry about? I'm thinking I could easily take a dremel to them and sand them down a bit if need be.

I started to clean the parts up and inspect them for excessive wear or cracks. Looks good so far!

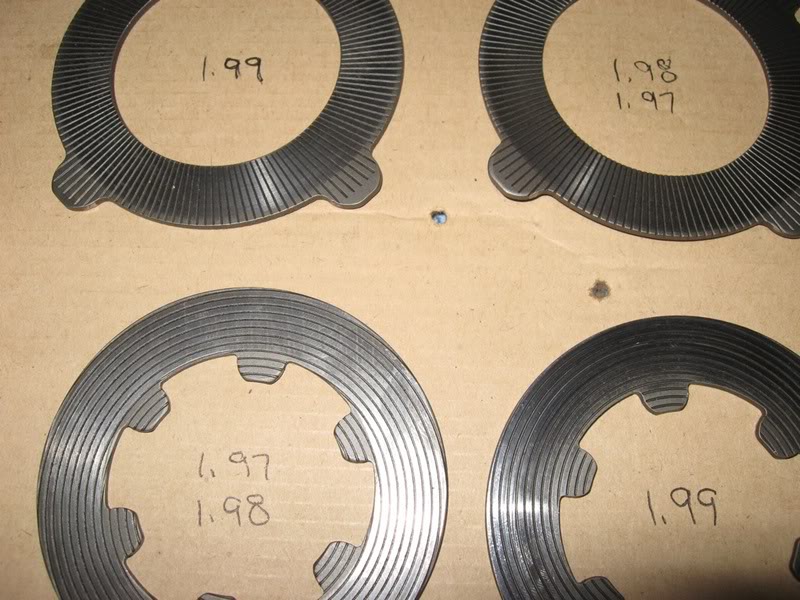

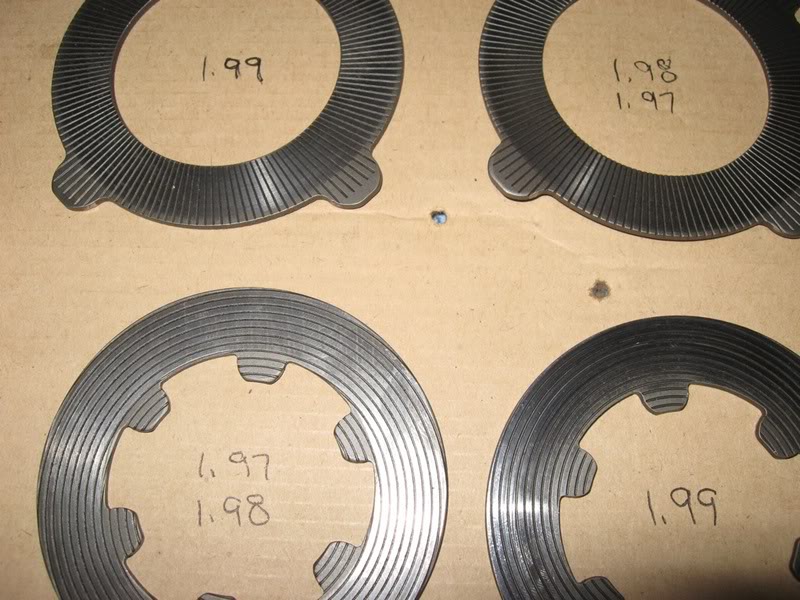

The disks all cleaned up and measured out. The spec is 2.0mm and the lower limit is 1.90mm. All of them are really close to 2.0mm. I'm planning on buying one oversized disk that's 2.1mm, which should help make up for the wear on the other plates, I'll replace the thinnest plate with the new 2.1mm thick one. And as you can see the thrust washers need replacing I'm going to replace them with oversized washers that are 1.8mm thick.

Overall I'm pretty pleased with the condition! I'm going to go ahead and order up some thrust washers and an oversized plate.

Surprisingly all of the disks are well within spec! The thrust washers need replacing, but everything else is within factory specs.

Here are some pics...

This is what I started with:

It came apart really easily:

Disassembled and spread out on the bench:

Here's one thing that's a bit concerning, look at the edges of these gears, they are the gears that the axles slide into. You can see that the edges have some funky wear on them. Does this look bad enough to worry about? I'm thinking I could easily take a dremel to them and sand them down a bit if need be.

I started to clean the parts up and inspect them for excessive wear or cracks. Looks good so far!

The disks all cleaned up and measured out. The spec is 2.0mm and the lower limit is 1.90mm. All of them are really close to 2.0mm. I'm planning on buying one oversized disk that's 2.1mm, which should help make up for the wear on the other plates, I'll replace the thinnest plate with the new 2.1mm thick one. And as you can see the thrust washers need replacing I'm going to replace them with oversized washers that are 1.8mm thick.

Overall I'm pretty pleased with the condition! I'm going to go ahead and order up some thrust washers and an oversized plate.

The following users liked this post:

Relisys190 (12-22-19)

#3

It's about time somone posted a step by step 'How To' on rebuilding diffs. From reading the FSM, the standard break away test is to jack up one wheel and use a torque wrench on a lug bolt to check how many lb/ft it takes to turn, (break away), the wheel. Don't quote me but iirc it's 60-90 lbs. Roadracers/autocrossers tend to set break away around 90-100 lb/ft/

If you can, please go into as much detail, with pics of course, on the rebuild. Regarding the rolled edges on the spider teeth, a metal file will be sufficient for knocking the curl off.

Do a good job on your writeup and you may have the honor of having a 'How To' archived with lowest post count to date. Steve84GS has a writeup in the archives on diff rebuilding, you may wish to take a look at his thread and fill in any blanks needed for us dummys that have never rehabbed an LSD but would like to.

Keep up the good work and welcome to the forum.

For all the members with questions, let Link finish up his rebuild then ask questions at the end please.

If you can, please go into as much detail, with pics of course, on the rebuild. Regarding the rolled edges on the spider teeth, a metal file will be sufficient for knocking the curl off.

Do a good job on your writeup and you may have the honor of having a 'How To' archived with lowest post count to date. Steve84GS has a writeup in the archives on diff rebuilding, you may wish to take a look at his thread and fill in any blanks needed for us dummys that have never rehabbed an LSD but would like to.

Keep up the good work and welcome to the forum.

For all the members with questions, let Link finish up his rebuild then ask questions at the end please.

#4

Link,

Here is a thread that is already in the archives and may help you with the rest of your work. :-)

https://www.rx7club.com/1st-gen-archive-71/drivetrain-gsl-se-lsd-teardown-pics-drivetrain-tutorials-coming-soon-717591/

Here is a thread that is already in the archives and may help you with the rest of your work. :-)

https://www.rx7club.com/1st-gen-archive-71/drivetrain-gsl-se-lsd-teardown-pics-drivetrain-tutorials-coming-soon-717591/

#5

Senior Member

iTrader: (2)

Join Date: Dec 2005

Location: Wauwatosa Wisconsin

Posts: 266

Likes: 0

Received 0 Likes

on

0 Posts

Question with converting a Miata open or VLS rearend with a large axle RX7 LS.

I read somewhere that when converting a 1990 Miata to the RX7 LS that there is machine work required to retaing the wire clips on the internal end of the axles & that one sleeve per axle is required.

Can anyone add or subtract from this ^ information.

Is the same required doing a conversion from a 1994 plus to a RX7 LS?

I read somewhere that when converting a 1990 Miata to the RX7 LS that there is machine work required to retaing the wire clips on the internal end of the axles & that one sleeve per axle is required.

Can anyone add or subtract from this ^ information.

Is the same required doing a conversion from a 1994 plus to a RX7 LS?

#6

Junior Member

Thread Starter

Link,

Here is a thread that is already in the archives and may help you with the rest of your work. :-)

https://www.rx7club.com/showthread.php?t=717591

Here is a thread that is already in the archives and may help you with the rest of your work. :-)

https://www.rx7club.com/showthread.php?t=717591

Question with converting a Miata open or VLS rearend with a large axle RX7 LS.

I read somewhere that when converting a 1990 Miata to the RX7 LS that there is machine work required to retaing the wire clips on the internal end of the axles & that one sleeve per axle is required.

Can anyone add or subtract from this ^ information.

Is the same required doing a conversion from a 1994 plus to a RX7 LS?

I read somewhere that when converting a 1990 Miata to the RX7 LS that there is machine work required to retaing the wire clips on the internal end of the axles & that one sleeve per axle is required.

Can anyone add or subtract from this ^ information.

Is the same required doing a conversion from a 1994 plus to a RX7 LS?

I actually tried to check this last night. If you look up at the picture of the side gears that the axle ends slide into, the inner edge is beveled, which in most cases is done so when you pull on the axle the circlip compresses and you can get the axle out. Also, I assembled the center section of the LSD and inserted the 85 axle to see if there is any clearance between the end of the axle and the bevel, to see if the circlips would have a place to seat and there is about 1/8" or more of clearance. So I'm thinking that the stub axles will have a place to seat the circlips and also a bevel to compress them when I want to remove the axles. So from the looks of it I think it will work, but I still want to know for sure.

I am planning on finding some RX7 stub axles and using those along with the RX7 circlips instead of the miata axles and circlips. Once I find some RX7 stub axles I'll test fit them into this LSD and make sure they lock in before I commit to the installation. I don't want to get this thing installed and THEN find out that the axles won't stay in.

I'll definitely document what I find once I get some RX7 axles. I think now I have enough posts to go check out the for sale section on here so I'll go see if I can find some ASAP.

Last edited by Link; 01-27-09 at 11:10 AM.

#7

Senior Member

iTrader: (2)

Join Date: Dec 2005

Location: Wauwatosa Wisconsin

Posts: 266

Likes: 0

Received 0 Likes

on

0 Posts

***They DO recommend that you use 86-91 RX7 non-turbo stub axles,***

This ^ may be key to the whole deal working at the get go. From reading your last response it sounds like you have a very good plan to check out the RX7 LS/axles, before you install the RX7 LS.

Because I may forget to check back will you please e-mail me as you learn & implement this rearend.

ddewhurst1 at wi.rr.com

I had two 85 4:88 large axle LS pumkins. Just received a money order for 1 which I need to ship. I may keep the other & with your success implement it in my 1990 Miata.

Thank you

David

This ^ may be key to the whole deal working at the get go. From reading your last response it sounds like you have a very good plan to check out the RX7 LS/axles, before you install the RX7 LS.

Because I may forget to check back will you please e-mail me as you learn & implement this rearend.

ddewhurst1 at wi.rr.com

I had two 85 4:88 large axle LS pumkins. Just received a money order for 1 which I need to ship. I may keep the other & with your success implement it in my 1990 Miata.

Thank you

David

Trending Topics

#8

Junior Member

Thread Starter

I got my package from MazdaTrix yesterday! That was freakin speedy service. I placed my order on Sunday night from their web site, and the parts were at my doorstep by Thursday afternoon.

Only problem was the order was missing one of the thrust washers I ordered, so I'll have to wait for that, but judging by how fast the last order came it should be here early next week I'd think.

I also picked up a dial indicator with magnetic base, a new beam style torque wrench that goes up to 250lbs, and a few other misc tools that I don't currently have.

I'm down to a short list of stuff left to buy before I'm ready to finish! I think all I have left to buy is,

- axle seals x2

- 86-91 RX7 non-turbo axle stubs (still looking for a decent deal)

- .004" shim stock (I'd rather use real SS shim stock than pop cans)

- 7"-8" micrometer (for measuring bearing preload)

- RX7 axle clips

- gear paint

- transmission fluid

I don't think I'm going to change out the side bearings, they look to be in pretty decent shape.

I'm thinking I should be able to pick up most of this stuff this weekend, and then I'll order the axle stubs and micrometer on line probably, so I should be able to get this rebuilt and installed by next weekend.

Only problem was the order was missing one of the thrust washers I ordered, so I'll have to wait for that, but judging by how fast the last order came it should be here early next week I'd think.

I also picked up a dial indicator with magnetic base, a new beam style torque wrench that goes up to 250lbs, and a few other misc tools that I don't currently have.

I'm down to a short list of stuff left to buy before I'm ready to finish! I think all I have left to buy is,

- axle seals x2

- 86-91 RX7 non-turbo axle stubs (still looking for a decent deal)

- .004" shim stock (I'd rather use real SS shim stock than pop cans)

- 7"-8" micrometer (for measuring bearing preload)

- RX7 axle clips

- gear paint

- transmission fluid

I don't think I'm going to change out the side bearings, they look to be in pretty decent shape.

I'm thinking I should be able to pick up most of this stuff this weekend, and then I'll order the axle stubs and micrometer on line probably, so I should be able to get this rebuilt and installed by next weekend.

#9

Junior Member

Thread Starter

Okay I've made some progress and I'm almost there!

I bought some shim stock from a local Ace hardware store and cut two .008" shims. I'm going to put one on each side and see where that puts me for breakaway torque.

The shims were harder to make than I had anticipated. It's hard working with thin metal and trying to cut it into the shape of a large washer. Maybe I was doing it wrong but it took me a few hours to get it right.

I have everything else I need pretty much, the 86-91 NA axle stubs will be here this afternoon.

By the way, the first thing I'm going to do when the axles get here is to test fit them to see if they will lock into the 85 diff. I've been reading and some say they fit, some say they don't. I will be sure to post up what I find for future reference.

I'll make another post tonight with my findings. If the axles don't clip into the 85 diff I'm going to have to either see if I can get the 85 diff machined to work, or sell it and pick up an 86-88 diff. I'm really crossing my fingers and hoping that the axles will clip in, I don't want to have to start the search all over for another diff!

I bought some shim stock from a local Ace hardware store and cut two .008" shims. I'm going to put one on each side and see where that puts me for breakaway torque.

The shims were harder to make than I had anticipated. It's hard working with thin metal and trying to cut it into the shape of a large washer. Maybe I was doing it wrong but it took me a few hours to get it right.

I have everything else I need pretty much, the 86-91 NA axle stubs will be here this afternoon.

By the way, the first thing I'm going to do when the axles get here is to test fit them to see if they will lock into the 85 diff. I've been reading and some say they fit, some say they don't. I will be sure to post up what I find for future reference.

I'll make another post tonight with my findings. If the axles don't clip into the 85 diff I'm going to have to either see if I can get the 85 diff machined to work, or sell it and pick up an 86-88 diff. I'm really crossing my fingers and hoping that the axles will clip in, I don't want to have to start the search all over for another diff!

#10

Senior Member

iTrader: (2)

Join Date: Dec 2005

Location: Wauwatosa Wisconsin

Posts: 266

Likes: 0

Received 0 Likes

on

0 Posts

****I'll make another post tonight with my findings. If the axles don't clip into the 85 diff I'm going to have to either see if I can get the 85 diff machined to work, or sell it and pick up an 86-88 diff. ****

link, if I remember correctly the 2nd gen 86-88 diff has a long in length pinion & will not fit the Miata diff housing. Per say the 1st gen diff has a short in length pinion. Also when I look at the Mazda Motor Sports mechanical LS they give different part numbers for the 1st gen LS unit & the 2nd gen LS unit.

All that to suggest that you do some research before you attempt to mix & match a mechanical from a 2nd gen LS unit or buy a 2nd gen diff if the 1st gen diff parts don't work.

Someone may jump in with more info or they may correct my info if I am wrong.

Fast forward with your project

David

link, if I remember correctly the 2nd gen 86-88 diff has a long in length pinion & will not fit the Miata diff housing. Per say the 1st gen diff has a short in length pinion. Also when I look at the Mazda Motor Sports mechanical LS they give different part numbers for the 1st gen LS unit & the 2nd gen LS unit.

All that to suggest that you do some research before you attempt to mix & match a mechanical from a 2nd gen LS unit or buy a 2nd gen diff if the 1st gen diff parts don't work.

Someone may jump in with more info or they may correct my info if I am wrong.

Fast forward with your project

David

#11

Junior Member

Thread Starter

Well... it appears this project is going to take longer than anticipated. The axles don't fit!

The axles are too big!

Everything I read says that 86-91 non-turbo axles will fit in the 85 diff. This apparently is not true.

So, I need to figure out if I need to change the diff or the axles. I measured the axles and they are approximately 28mm. I need to find out if that is the correct size for 86-91 non-turbo axles.

Does anyone know if 28mm is the correct diameter for 86-91 non-turbo axle stubs?

I am going to have to do some more research, but damn, I was really hoping to get this thing installed soon. I suppose I will have to wait and keep searching for parts!

I also cleaned up the gears quite a bit and they look much better:

The axles are too big!

Everything I read says that 86-91 non-turbo axles will fit in the 85 diff. This apparently is not true.

So, I need to figure out if I need to change the diff or the axles. I measured the axles and they are approximately 28mm. I need to find out if that is the correct size for 86-91 non-turbo axles.

Does anyone know if 28mm is the correct diameter for 86-91 non-turbo axle stubs?

I am going to have to do some more research, but damn, I was really hoping to get this thing installed soon. I suppose I will have to wait and keep searching for parts!

I also cleaned up the gears quite a bit and they look much better:

#13

Senior Member

iTrader: (2)

Join Date: Dec 2005

Location: Wauwatosa Wisconsin

Posts: 266

Likes: 0

Received 0 Likes

on

0 Posts

Did you try the Miata stub axles in the 85 LS? I have a 85 LS & a early Miata Comp LS but no 85 axles.

Link, e-mail me at ddewhurst1 at wi.rr.com & I will provide you a name that will know the answer to your diff questions.

Link, e-mail me at ddewhurst1 at wi.rr.com & I will provide you a name that will know the answer to your diff questions.

#14

Junior Member

Thread Starter

Last night I measured the axles that came with the 85 diff and they were 25mm, which I've discovered is the "small axle".

Everything I've read said that the small axle didn't come in the 85, only the older RX7s. But I know for sure this diff came from an 85, I pulled it myself. I suppose it's possible that the rear end had been changed out at one point or another to the smaller axle rear end.

Anyways, what it comes down to is that this diff isn't usable to me. I will have to find a large axle diff instead. Hopefully I'll be able to sell this one for something.

Everything I've read said that the small axle didn't come in the 85, only the older RX7s. But I know for sure this diff came from an 85, I pulled it myself. I suppose it's possible that the rear end had been changed out at one point or another to the smaller axle rear end.

Anyways, what it comes down to is that this diff isn't usable to me. I will have to find a large axle diff instead. Hopefully I'll be able to sell this one for something.

#15

Senior Member

iTrader: (2)

Join Date: Dec 2005

Location: Wauwatosa Wisconsin

Posts: 266

Likes: 0

Received 0 Likes

on

0 Posts

I measured a 90/93 Miata stub axle diameter & it is 25 mm same as the RX7 small axle. The Miata 94 plus axle is larger. The large axle spline diameter is 27 mm.

Below is some info that should help.

Miata Drivetrain Interchange Guide

REAR:

The 1990-93 1.6 liter Miata used a rear that was derived from the rear of the 88 323GTX AWD and dates back to the 1978 RWD GLC. It had a 6" ring gear and is not very strong.

In 1994 Mazda used a larger and beefier rear unit for the 1.8 Miata that has a 7" ring gear and is derived from the 1986-1991 NA RX-7 rear with the exception of the shorter pinion and front pinion housing.

The 94+ Miata uses the same length pinion as the 1st gen RX-7 (and B2000/2000 trucks/RWD626) and the front housing is unique to the Miata to allow a mount for the PPF. Swapping the later 94+ rear into a 1990-93 Miata is a bolt-in but requires replacing the entire diff housings assembly, driveshaft and half-shafts from the later 1994+ cars. If you can't find a 1994+ Miata rear in a salvage yard then try the rear aluminum housing from a '86-91 NA RX7, they are nearly the same. You'll still need the short pinion cast iron front housing from the 94+ Miata (for the PPF mounting) and Miata specific rubber mounting bushings.

differential shaft diameters and splines:

7" small axle = 25mm x 24 spline [/COLOR](808, RX-3, 79-83 RX-7)

7" large axle = 27mm x 26 spline

7" S2000 = 29mm x 28 spline

7.5" small axle = 27mm x 26 spline '84-03 B2000/B2200 & early 95-97 Sportage

7.5" large axle = 29mm x 28 spline ('98-05 Sportage)

8" = 31mm x 30 spline. TT/TII/929

Below is some info that should help.

Miata Drivetrain Interchange Guide

REAR:

The 1990-93 1.6 liter Miata used a rear that was derived from the rear of the 88 323GTX AWD and dates back to the 1978 RWD GLC. It had a 6" ring gear and is not very strong.

In 1994 Mazda used a larger and beefier rear unit for the 1.8 Miata that has a 7" ring gear and is derived from the 1986-1991 NA RX-7 rear with the exception of the shorter pinion and front pinion housing.

The 94+ Miata uses the same length pinion as the 1st gen RX-7 (and B2000/2000 trucks/RWD626) and the front housing is unique to the Miata to allow a mount for the PPF. Swapping the later 94+ rear into a 1990-93 Miata is a bolt-in but requires replacing the entire diff housings assembly, driveshaft and half-shafts from the later 1994+ cars. If you can't find a 1994+ Miata rear in a salvage yard then try the rear aluminum housing from a '86-91 NA RX7, they are nearly the same. You'll still need the short pinion cast iron front housing from the 94+ Miata (for the PPF mounting) and Miata specific rubber mounting bushings.

differential shaft diameters and splines:

7" small axle = 25mm x 24 spline [/COLOR](808, RX-3, 79-83 RX-7)

7" large axle = 27mm x 26 spline

7" S2000 = 29mm x 28 spline

7.5" small axle = 27mm x 26 spline '84-03 B2000/B2200 & early 95-97 Sportage

7.5" large axle = 29mm x 28 spline ('98-05 Sportage)

8" = 31mm x 30 spline. TT/TII/929

#16

Junior Member

Thread Starter

Okay, the game is back on!

I found a GSL-SE limited slip differential and pumpkin, which I purchased and should be here within the next few weeks.

It was a total pain to find another differential. It seems like I can never find that one specialized part that I'm looking for when I'm looking for it. I guess that's the way these things go.

Anyways, so it's coming! As soon as the GSL-SE LSD gets here I'll take some pics of the tear down and rebuild. I'm just happy that this project will continue, the LSD has been sitting in parts on my work bench for weeks now.

I found a GSL-SE limited slip differential and pumpkin, which I purchased and should be here within the next few weeks.

It was a total pain to find another differential. It seems like I can never find that one specialized part that I'm looking for when I'm looking for it. I guess that's the way these things go.

Anyways, so it's coming! As soon as the GSL-SE LSD gets here I'll take some pics of the tear down and rebuild. I'm just happy that this project will continue, the LSD has been sitting in parts on my work bench for weeks now.

#17

Junior Member

Thread Starter

I received the second diff today! And the axles fit! I did notice that there's no groove for the circlip but I don't think that will be a problem since they fit so tight.

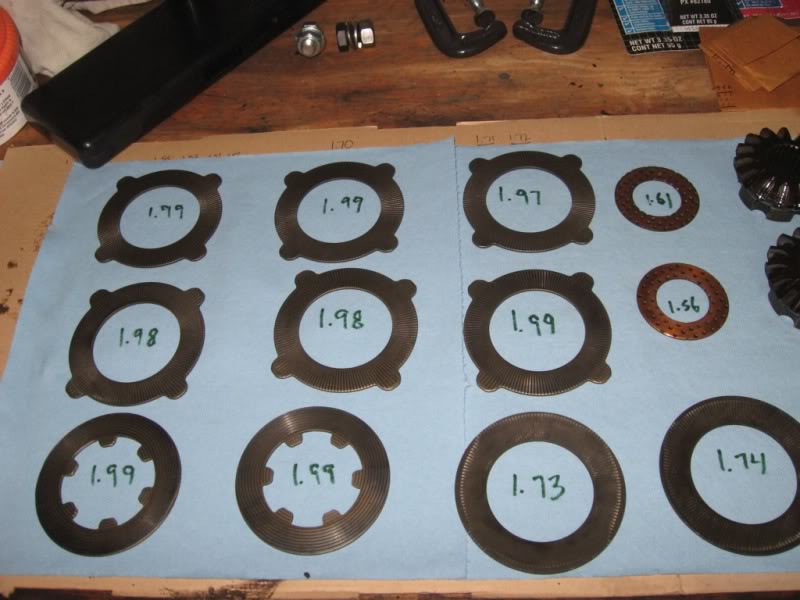

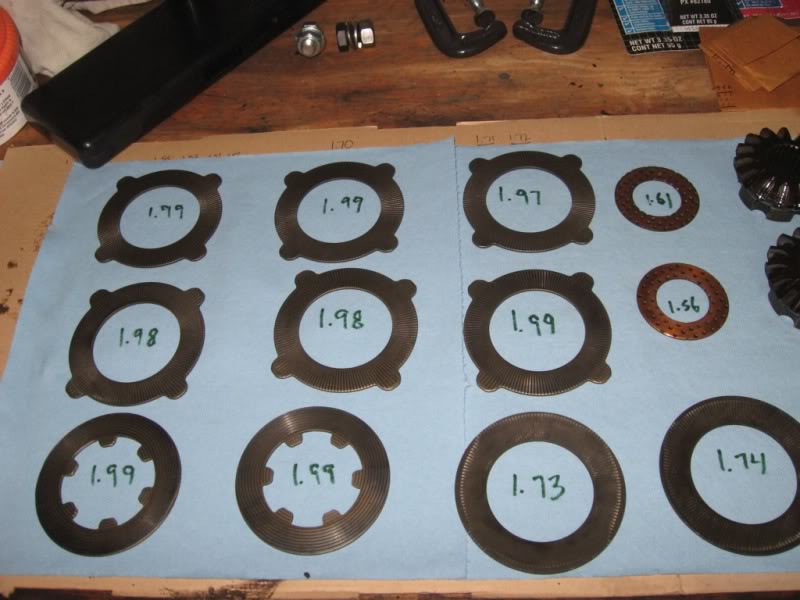

I got the pumpkin in the mail and had it stripped down in less than 10 minutes. Then I cleaned up the disks a bit and measured them out. This diff had a different build than the other one, for some reason this one only has one disk with the internal tabs, where the other one had two.

I have no idea why they did it this way but I'm going to rebuild it with alternating disks. This diff I got today was from an 85 GSL-SE.

Here are some pics...

The two housings with pinions, I don't need these anymore and I have no idea how I'm going to get rid of them. Anyways,,,

Here's the housing, this diff was way darker than the first it looks like it didn't get the regular oil changes that the other one got.

This is the order the disks were in, doesn't make much sense to do it this way so I'm going to rebuild it differently.

All these disks measure out really well, I won't have a problem building a super tight and fresh LSD by choosing the best disks from each diff.

This Sunday I am going to rebuild the diff and start testing the break away torque so I can dial it in. I'm glad that I finally found a diff that's going to work for me! Unfortunately it won't be done in time for the first autocross of the season this Saturday, but that just means I'll be in STS2 for one more event!

I got the pumpkin in the mail and had it stripped down in less than 10 minutes. Then I cleaned up the disks a bit and measured them out. This diff had a different build than the other one, for some reason this one only has one disk with the internal tabs, where the other one had two.

I have no idea why they did it this way but I'm going to rebuild it with alternating disks. This diff I got today was from an 85 GSL-SE.

Here are some pics...

The two housings with pinions, I don't need these anymore and I have no idea how I'm going to get rid of them. Anyways,,,

Here's the housing, this diff was way darker than the first it looks like it didn't get the regular oil changes that the other one got.

This is the order the disks were in, doesn't make much sense to do it this way so I'm going to rebuild it differently.

All these disks measure out really well, I won't have a problem building a super tight and fresh LSD by choosing the best disks from each diff.

This Sunday I am going to rebuild the diff and start testing the break away torque so I can dial it in. I'm glad that I finally found a diff that's going to work for me! Unfortunately it won't be done in time for the first autocross of the season this Saturday, but that just means I'll be in STS2 for one more event!

#18

Junior Member

Thread Starter

*UPDATE*

I rebuilt and shimmed the diff to exactly 100lbs ft of breakaway torque. The difference between 50lbs ft and 100lbs ft was one MtDew-can shim. A very small difference in the shims can make a HUGE difference in the breakaway torque. So I'm lucky that I hit the 100lbs ft that I was shooting for.

Last Saturday I pulled the rear end out of the Miata and swapped the RX7 differential in. Everything went pretty much as planned except I spent a few hours fighting with stubborn bolts, which is to be expected. I always tell my wife that it "shouldn't" take more than a few hours, unless I break a bolt, or run into some other issue. Which is always the case!

So I installed the diff with the RX7 stub axles and clips and everything went together as expected. I filled it up with gear oil and went out for a test drive.

My first impression was that thing thing is TIGHT! Wow, pretty much locked. Every turn would result in skidding and hopping. I drove it around a bit and down to a local parking lot where I could do some low speed turning, I could feel the diff slipping some of the time and it would make kind of a grinding noise which I figured was probably the disks slipping.

Anyways, so I drove back home and noticed that it's leaking gear oil out from around the axle seals.

It's not leaking a ton, but it's definitely leaking. This weekend I am going to pull the axle seals out and replace them with new seals, I've heard that they are really delicate so I'm hoping that replacing them will solve the leaking issue.

I will keep this thing updated, so hopefully someone in the future can find this info useful.

I rebuilt and shimmed the diff to exactly 100lbs ft of breakaway torque. The difference between 50lbs ft and 100lbs ft was one MtDew-can shim. A very small difference in the shims can make a HUGE difference in the breakaway torque. So I'm lucky that I hit the 100lbs ft that I was shooting for.

Last Saturday I pulled the rear end out of the Miata and swapped the RX7 differential in. Everything went pretty much as planned except I spent a few hours fighting with stubborn bolts, which is to be expected. I always tell my wife that it "shouldn't" take more than a few hours, unless I break a bolt, or run into some other issue. Which is always the case!

So I installed the diff with the RX7 stub axles and clips and everything went together as expected. I filled it up with gear oil and went out for a test drive.

My first impression was that thing thing is TIGHT! Wow, pretty much locked. Every turn would result in skidding and hopping. I drove it around a bit and down to a local parking lot where I could do some low speed turning, I could feel the diff slipping some of the time and it would make kind of a grinding noise which I figured was probably the disks slipping.

Anyways, so I drove back home and noticed that it's leaking gear oil out from around the axle seals.

It's not leaking a ton, but it's definitely leaking. This weekend I am going to pull the axle seals out and replace them with new seals, I've heard that they are really delicate so I'm hoping that replacing them will solve the leaking issue.

I will keep this thing updated, so hopefully someone in the future can find this info useful.

#19

great thread i rebilt mine today and check the parts, they were all withi spec so put it back together, it didn't fit up snug so i pulled it apart and checked it twice, everyting went in the way it came out i ended up putting it in the vice to close it the last bit (1 - 1.5 mm) is that normal?

#21

Junior Member

Thread Starter

great thread i rebilt mine today and check the parts, they were all withi spec so put it back together, it didn't fit up snug so i pulled it apart and checked it twice, everyting went in the way it came out i ended up putting it in the vice to close it the last bit (1 - 1.5 mm) is that normal?

Here are the specs:

Ring gear backlash (0.0036-0.0043)

Bearing preload (7.3004-7.3031)

Bearing cap bolt torque (27-38 ft-lb)

Lock plates on bearing caps (13-19 ft-lb)

ring gear to the differential (51-61 ft-lb)

* Sometimes it's hard to get the backlash perfectly in spec all the way around the ring gear. Just get it as close as possible then use gear marking compound to ensure the gears are meshing correctly.

#22

Junior Member

Thread Starter

** UPDATE **

I took Friday off work so I could knock this out and had success!

This time I started at 8:00 am and used my air tools. I timed myself and had the rear end out of the car in 40 minutes. Hours faster than the first time!

Before I pulled the rear end I tested the break away torque at the axle nut. No wonder it felt tight, I couldn't get it to slip, not even at past 250lbs ft! No wonder it felt locked. It was!

My guess is that this is because I initially bench tested the break away torque before the ring gear was installed. I'm thinking that when I torqued the ring gear down it tightened up the diff housing enough to pretty much lock it.

So I took the LSD apart AGAIN, checked the disks, and removed one of the shims. I then retested it and on the bench without the ring gear it was at 58lbs ft. Then I installed and torqued the ring gear down and tested it again, this time it was at 100lbs ft.

I dropped it back in, set the backlash and preload, and put it all back together. By the way I LOVE the GM gear marking compound. I've used a few other compounds and none show the contrast like the GM stuff. It cost me $12 for the small tube I bought, but it was worth it.

When I put it back together I swapped out the axle seals for new units and used two new axle clips when I put the axles back in. Everything went back into the car smoothly and it was back off jack stands in another hour or so.

I'm happy to announce that it's working great! No more leaks around the seals, and the LSD action is MUCH improved. It is smooth going around corners and doesn't hop, pop, or crunch anymore. It's nice and smooth when I ease onto the throttle mid turn and the LSD action engages.

I'm very pleased with this setup now and I'm glad I was able to get it to work. It's amazing how much of a difference it makes!

After driving around a bit I went back to check for leakage and I rechecked the break away torque at the axle nut, this time it slips smoothly at 100 - 102 lbs ft. Which is tight but it feels smooth when I'm driving so I'm happy with it. I'm sure that will come down a bit once I drive on it some more though.

I can't wait for the next autocross so I can really get a feel for the new capabilities. By the way, what class does the LSD bump me into? I was in STS before... CSP?

I took Friday off work so I could knock this out and had success!

This time I started at 8:00 am and used my air tools. I timed myself and had the rear end out of the car in 40 minutes. Hours faster than the first time!

Before I pulled the rear end I tested the break away torque at the axle nut. No wonder it felt tight, I couldn't get it to slip, not even at past 250lbs ft! No wonder it felt locked. It was!

My guess is that this is because I initially bench tested the break away torque before the ring gear was installed. I'm thinking that when I torqued the ring gear down it tightened up the diff housing enough to pretty much lock it.

So I took the LSD apart AGAIN, checked the disks, and removed one of the shims. I then retested it and on the bench without the ring gear it was at 58lbs ft. Then I installed and torqued the ring gear down and tested it again, this time it was at 100lbs ft.

I dropped it back in, set the backlash and preload, and put it all back together. By the way I LOVE the GM gear marking compound. I've used a few other compounds and none show the contrast like the GM stuff. It cost me $12 for the small tube I bought, but it was worth it.

When I put it back together I swapped out the axle seals for new units and used two new axle clips when I put the axles back in. Everything went back into the car smoothly and it was back off jack stands in another hour or so.

I'm happy to announce that it's working great! No more leaks around the seals, and the LSD action is MUCH improved. It is smooth going around corners and doesn't hop, pop, or crunch anymore. It's nice and smooth when I ease onto the throttle mid turn and the LSD action engages.

I'm very pleased with this setup now and I'm glad I was able to get it to work. It's amazing how much of a difference it makes!

After driving around a bit I went back to check for leakage and I rechecked the break away torque at the axle nut, this time it slips smoothly at 100 - 102 lbs ft. Which is tight but it feels smooth when I'm driving so I'm happy with it. I'm sure that will come down a bit once I drive on it some more though.

I can't wait for the next autocross so I can really get a feel for the new capabilities. By the way, what class does the LSD bump me into? I was in STS before... CSP?

#24

Junior Member

Join Date: Jan 2009

Location: Richmond, BC

Posts: 11

Likes: 0

Received 0 Likes

on

0 Posts

Wow, this is an awesome writeup!! Very good pictures too! I am going to be rebuilding my dif right away and this has helped a lot. I have a couple questions.

First, when putting the discs back in does the order really matter? I've been told to make sure i put them back in exactly as they came out because of how the discs have worn against each other over time. I really don't think it's a big deal and would rather put them back in an order that makes sense. What do you guys think about this?

Second, when you guys refer to setting the backlash, what exactly do you mean and what unit of measurement are you using? As far as i know, backlash is the distance of "back and forth" travel between gear teeth contact and would be set by the distance between the gear centers, how do you set this in the dif?

First, when putting the discs back in does the order really matter? I've been told to make sure i put them back in exactly as they came out because of how the discs have worn against each other over time. I really don't think it's a big deal and would rather put them back in an order that makes sense. What do you guys think about this?

Second, when you guys refer to setting the backlash, what exactly do you mean and what unit of measurement are you using? As far as i know, backlash is the distance of "back and forth" travel between gear teeth contact and would be set by the distance between the gear centers, how do you set this in the dif?

#25

Download the 85 FSM from either of the following links.

In regards to the difference in the discs between the GSL and GSL-SE, that's how they came from the factory. I suspect it's to provide a softer breakaway in the SE diffs.

http://foxed.ca/foxed/index.php?page=rx7manual

http://www.wankel.net/~krwright/cars/rx7/manuals.html

In regards to the difference in the discs between the GSL and GSL-SE, that's how they came from the factory. I suspect it's to provide a softer breakaway in the SE diffs.

http://foxed.ca/foxed/index.php?page=rx7manual

http://www.wankel.net/~krwright/cars/rx7/manuals.html