V-band flange gasket?

#1

V-band flange gasket?

My V-band clamp from the turbo to DP is leaking. I'm wondering if I can just fab up a gasket for it by cutting an 'O' ring out of some generic sheet gasket material. Has anybody done this? The issues would be if the material will fit in the clamp (thickness my just be enough to keep the 'V' from fitting over everything), and it's ability to hold up to the heat right there. If I do this can anybody recommend good gasket material to buy? Thanks.

Matt

Matt

#2

development

loosen your midpipe...You have to tighten your V-band first, then tighten your midpipe flange down.

I've worked on a couple of friends cars and this was always the problem.

I've worked on a couple of friends cars and this was always the problem.

#5

Front Range Express

Join Date: Jul 2004

Location: Colorado Springs

Posts: 571

Likes: 0

Received 0 Likes

on

0 Posts

http://www.phelpsweb.thomasregister....5/phel3_12.htm

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

#6

Originally Posted by III Gen X

http://www.phelpsweb.thomasregister....5/phel3_12.htm

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

#7

Front Range Express

Join Date: Jul 2004

Location: Colorado Springs

Posts: 571

Likes: 0

Received 0 Likes

on

0 Posts

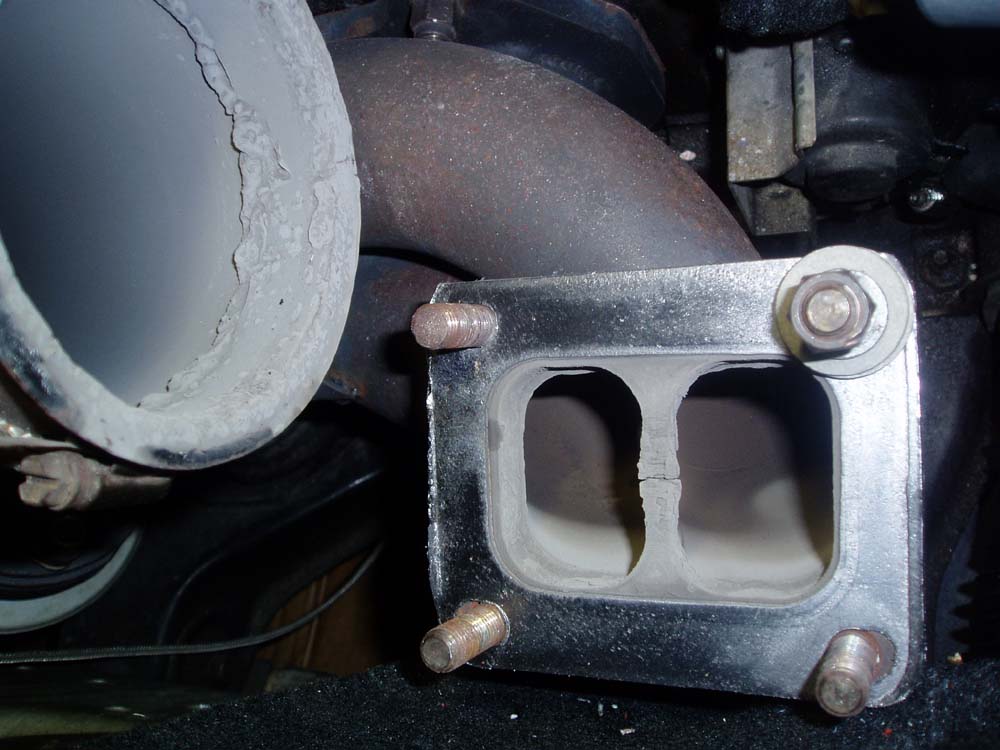

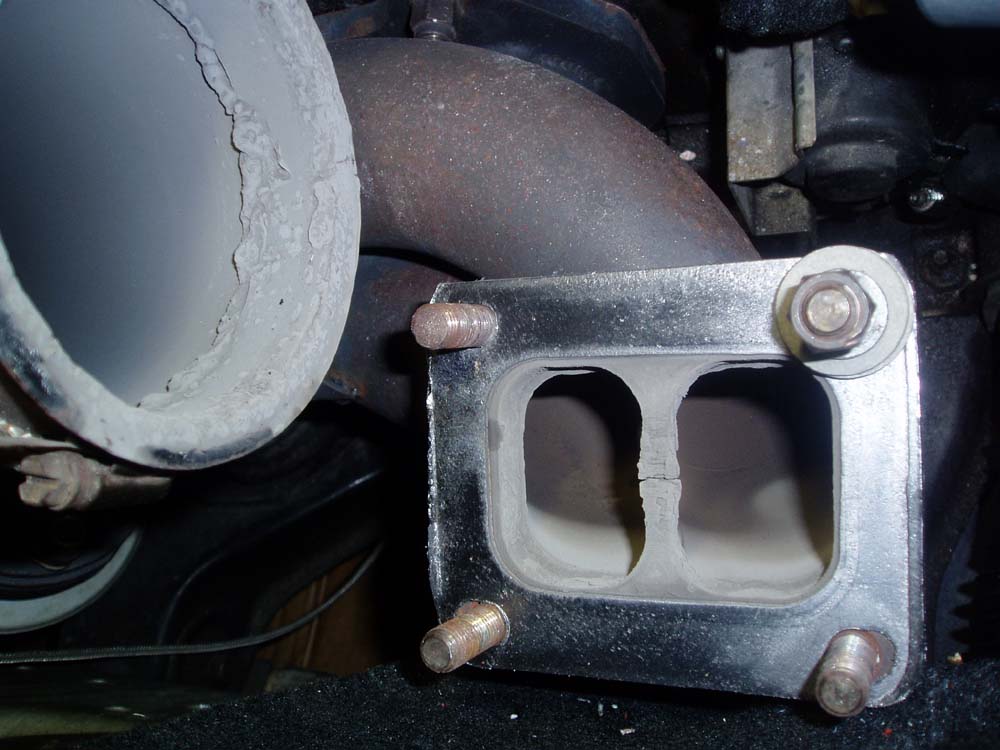

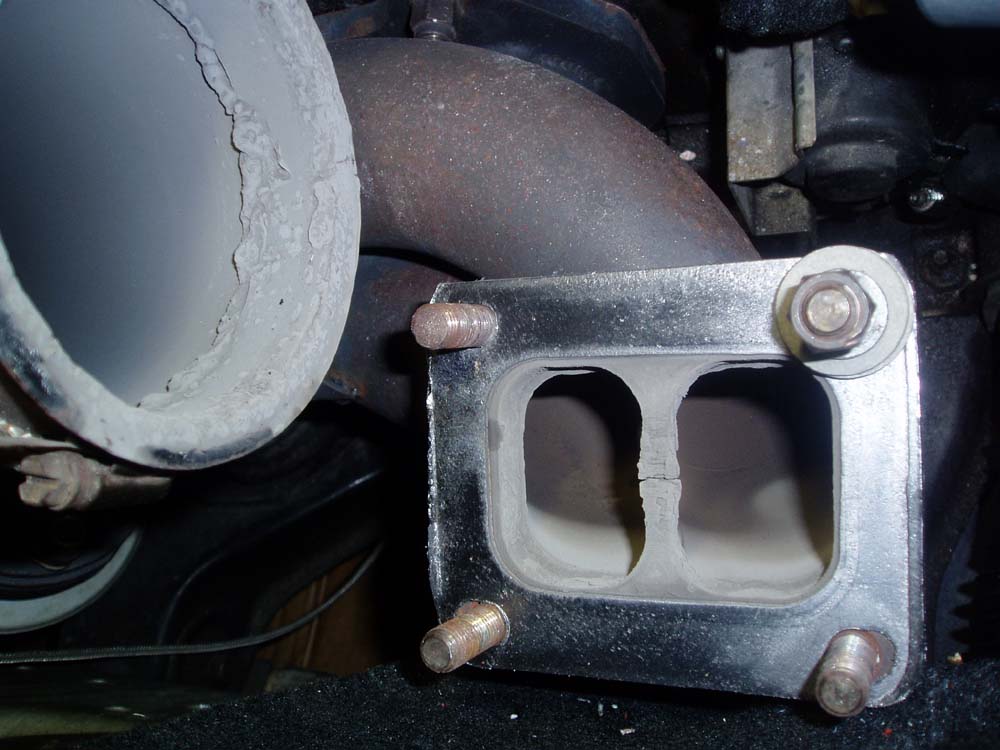

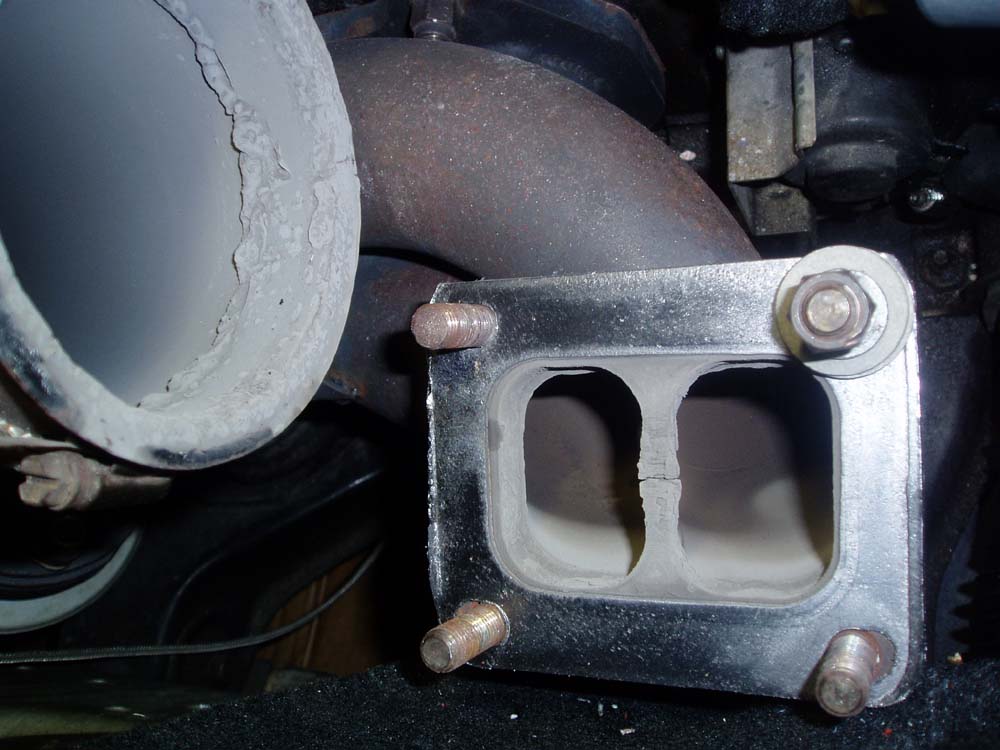

One trick I use to set the gasket in place is a piece of scotch tape. This gasket material is delicate, and it will take some caution handling it. Clean the bottom outside edge of the turbine flange and stick a two inch piece of tape along it, with just enough edge of the tape sticking out to cradle the bottom of the gasket and hold it up in place. Have your helper keep pressure on the down pipe after you guide it gently there (this **** is delicate and you don't want to nick or scratch it) and don't let your helper release pressure until that v-band it set. Just as an aside.... when I went recently to a larger turbo, my down pipe had to get reworked, and the fabricator got close enough by getting the right center height of the DP, but his angle was off. I was tired of screwing around, needed to get the car back before my wife suspected more than what was really happening, so I doubled up the gaskets and got a complete seal. In this case, the v-band wasn't set perfectly all around, but I had enough in the V to pull it together and keep it there for a long time. I recently had the DP off while changing to a water cool turbo set-up, and took the opportunity to correct the angle of it. I corrected it by just cutting it most of the way and then bending it towards the turbine flange and taking it down to muffler man for a quick weld to close it up. The gap you see here is equivalent to the gap I had previously filled by doubling up on the gaskets.

Last edited by Old Slow Coach; 10-10-05 at 11:09 PM.

Trending Topics

#9

Mad Man

I'm trying to remember where I've seen that before, I want to say that some OEMs use it. It seems to be like compressed graphite, or some such thing(does that sound right?). It is either Toyota, or Mazda. I also have seen it on some wastegates. I only mention this wondering if someone offers it pre-cut. Anyway, let us know how it works, Carl

#10

development

why do you have a divided flange? if you are going to gasket it like this?

Moehler - v-bands do not need gaskets, that's one reason they are great...we use them on aircraft, they work when installed properly.

Moehler - v-bands do not need gaskets, that's one reason they are great...we use them on aircraft, they work when installed properly.

#11

Originally Posted by dubulup

Moehler - v-bands do not need gaskets, that's one reason they are great...we use them on aircraft, they work when installed properly.

).

).I got a small piece of the gasket for $25 so it's no real loss.

#12

Front Range Express

Join Date: Jul 2004

Location: Colorado Springs

Posts: 571

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by dubulup

why do you have a divided flange? if you are going to gasket it like this?

Moehler - v-bands do not need gaskets, that's one reason they are great...we use them on aircraft, they work when installed properly.

Moehler - v-bands do not need gaskets, that's one reason they are great...we use them on aircraft, they work when installed properly.

Also, v-band's only seal two flanges when 100 percent of the opposing flanges are in contact. Imperfections in the DP flange face may not be rectified by torquing down the v-band. In that case, a compressible gasket will seal the deal.

#13

Front Range Express

Join Date: Jul 2004

Location: Colorado Springs

Posts: 571

Likes: 0

Received 0 Likes

on

0 Posts

Originally Posted by moehler

I tried everything... it just doesn't want to seal 100%. I stink like exhaust when I get out of the car (I have a metallic cat to stop me from stinking  ).

).

I got a small piece of the gasket for $25 so it's no real loss.

).

).I got a small piece of the gasket for $25 so it's no real loss.

Hey, hope you have a friend to help you put the DP on, cause it's pretty hard (not impossible though) to do this single handed because the gasket is so easy to damage. You hold the gasket in place while friend holds DP against it and does not let off pressure until v-band is gripping!

#14

Originally Posted by III Gen X

Hey, hope you have a friend to help you put the DP on, cause it's pretty hard (not impossible though) to do this single handed because the gasket is so easy to damage. You hold the gasket in place while friend holds DP against it and does not let off pressure until v-band is gripping!

It was sort of a pain in the *** to install myself (I needed an extra arm

), but I managed with the help of some masking tape.

), but I managed with the help of some masking tape. In the end it worked perfectly - no more leak!! We'll see how it holds up, but with a temperature rating of 5000 deg F, I think it will work just fine.

I should also mention that these guys shipped it out to me the next day (for $5) and were really easy to deal with. They also have smaller sections than advertised. I got a "center section" for $20 that was an oval shaped piece 11"x15".

#15

Front Range Express

Join Date: Jul 2004

Location: Colorado Springs

Posts: 571

Likes: 0

Received 0 Likes

on

0 Posts

It's probably the same stuff... Flexible Graphite Style 7500? Does it leave a graphite coating on your fingers when you handle it? Maybe photos above pick up the real appeance of it all that well. What thickness did you order?

Here's one last tip for you... Loosen up the v-band just enough to where you could rotate it by using a hammer and a punch to tap the bolt. Torque down a little more then tap anywhere you can around the side and top of the v-band to get it to seat better. Torque down a little more and repeat. This will help get the deepest seat of the v-band possible and assure maximum compression of the gasket and long life from it.

Here's one last tip for you... Loosen up the v-band just enough to where you could rotate it by using a hammer and a punch to tap the bolt. Torque down a little more then tap anywhere you can around the side and top of the v-band to get it to seat better. Torque down a little more and repeat. This will help get the deepest seat of the v-band possible and assure maximum compression of the gasket and long life from it.

#16

Originally Posted by III Gen X

It's probably the same stuff... Flexible Graphite Style 7500? Does it leave a graphite coating on your fingers when you handle it? Maybe photos above pick up the real appeance of it all that well. What thickness did you order?

#17

Originally Posted by III Gen X

http://www.phelpsweb.thomasregister....5/phel3_12.htm

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

My flange got all jacked up once so I went looking and found this stuff. Now that my flange is fixed, I still use this between DP and Turbine housing. You can buy a 40"x40" sheet for $70. Pretty amazing price considering this is the **** they use to seal flanges in nuclear power plants! You can get it in 1/64, 1/32, 1/16, and 1/8 thickness. I use the 1/16th. It is compressible! It has sealed better than anything else I've everused. I reused the one I made for the turbine/manifold application because it showed no signs of degredation after extended abuse. I put a cutting torch to it to see how it would take the heat, and the edges just glowed a little red. I've toasted other supposed high temp gasket material before with a Bic lighter!

#18

Round&Round not Up&Down

Join Date: Aug 2001

Location: West Bloomfield, MI

Posts: 2,805

Likes: 0

Received 0 Likes

on

0 Posts

Sounds like this stuff would be beter than ordering the turbo to manifold gaskets from Mazda for ~$40. Has anyone tried them in that location?

#22

Junior Member

Join Date: Nov 2006

Location: morrisville pa

Posts: 40

Likes: 0

Received 0 Likes

on

0 Posts

what great for me was using copper sheet and gutting rings. Cutting was almost identical to the compass used above. relatively cheap for a roll from a craft store. I used three layers of 36 gauge copper roll. Have tons of the roll left over.

scotch tape works great for holding them together the first time. after that they are nicely baked together I haven't had them split apart yet.

scotch tape works great for holding them together the first time. after that they are nicely baked together I haven't had them split apart yet.

Thread

Thread Starter

Forum

Replies

Last Post

Turblown

Vendor Classifieds

12

10-17-20 03:25 PM