Turbo to Manifold Bolts Backing Out?

#1

Turbo to Manifold Bolts Backing Out?

So i've got an issue with the turbo to Manifold bolts keep backing out and getting loose. I've tried high temp loctite, I've used "high temp" lock washers that end up heated up and flattened out. I'm using lock nuts too that are "high temp", but they still keep backing out. Any suggestions?

Trending Topics

#10

Another option!

10mm (1.5 pitch) Stud : atpturbo.com

10mm (1.5 pitch) Nut Locking Head : atpturbo.com

I'm pretty sure the most reliable way of doing it is having the manifold flange holes tapped, and then have studs in those with those copper looking locknuts on it.

I've lost a a bolt or 2 like you are talking about and even had bolts fall out between the CHRA and turbine housing.

Tune it right so the EGT's don't get stupid hot, replace the fastners with new ones and use the correct type where possible.

I also used to have problems with the turbo oil feed flange bolts backing out causing oil leaks and mess.

With problems like this I would be coating the entire thread heavily in permanent strength loktite

10mm (1.5 pitch) Stud : atpturbo.com

10mm (1.5 pitch) Nut Locking Head : atpturbo.com

I'm pretty sure the most reliable way of doing it is having the manifold flange holes tapped, and then have studs in those with those copper looking locknuts on it.

I've lost a a bolt or 2 like you are talking about and even had bolts fall out between the CHRA and turbine housing.

Tune it right so the EGT's don't get stupid hot, replace the fastners with new ones and use the correct type where possible.

I also used to have problems with the turbo oil feed flange bolts backing out causing oil leaks and mess.

With problems like this I would be coating the entire thread heavily in permanent strength loktite

#11

Wastegate John

iTrader: (13)

Join Date: Feb 2008

Location: Long Island NY 11746

Posts: 2,979

Likes: 0

Received 9 Likes

on

9 Posts

I have been using the stage 8 locking nuts along with inconel studs. They are definately not cheap but IMHO are the best you can get. There is no way they can loosen up. After a few thousand miles I had to remove the turbo and once the locks were removed I had to turn the nut one revolution and was able to loosen it the rest of the way by hand. These IMO will last beyond the life of the manifold.

These are the inconel studs from trackspeed engineering. Trackspeed Engineering

These are the inconel studs from trackspeed engineering. Trackspeed Engineering

#13

Matt

#15

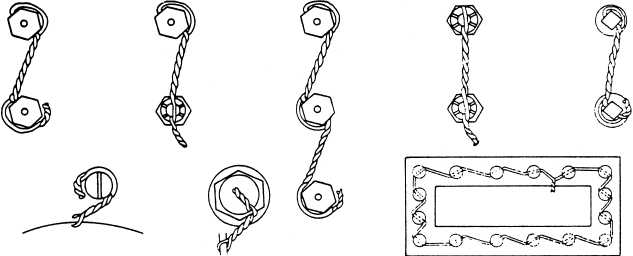

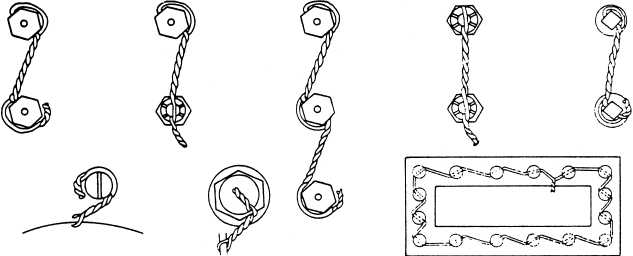

Safety wiring is practically free, we do it a lot on race bikes.

Basically you would take a small drill bit (a drill press is awesome for this) and drill a small hole through the bold head, then feed safety wire through it and connect it to another bolt.

If possible, the angle that you safety wire at should be in the "tightening" direction like so.

Basically you would take a small drill bit (a drill press is awesome for this) and drill a small hole through the bold head, then feed safety wire through it and connect it to another bolt.

If possible, the angle that you safety wire at should be in the "tightening" direction like so.

Thread

Thread Starter

Forum

Replies

Last Post

trickster

2nd Generation Specific (1986-1992)

25

07-01-23 04:40 PM