Turbine housing question

#1

Rotary Enthusiast

Thread Starter

Turbine housing question

Okay.. this may be a very silly question but I am struggling to see a negative in my head.

When you opt for the turbo for your engine you choose the compressor from the map that best suits it. Then you size the turbine to allow your exhaust gas to flow and give you optimal spool. Now I can see that if you have an internal wastegate setup and you chose a turbine housing that is too small you will get amazing spool up but then it will choke at high rpm and will not allow enough exhaust to flow. Now on the other hand. If you do the same thing but with a large external wastegate setup.. Would I be correct in thinking you would have great spool and then the excess gases would pass freely through the wastegate or would you just need too big a wastegate for this theory to work? The turbine will still be taking most of the gas to keep it spooling? Maybe I have missed another problem.

Please can someone clear it up for me.

Thank you

Lee

When you opt for the turbo for your engine you choose the compressor from the map that best suits it. Then you size the turbine to allow your exhaust gas to flow and give you optimal spool. Now I can see that if you have an internal wastegate setup and you chose a turbine housing that is too small you will get amazing spool up but then it will choke at high rpm and will not allow enough exhaust to flow. Now on the other hand. If you do the same thing but with a large external wastegate setup.. Would I be correct in thinking you would have great spool and then the excess gases would pass freely through the wastegate or would you just need too big a wastegate for this theory to work? The turbine will still be taking most of the gas to keep it spooling? Maybe I have missed another problem.

Please can someone clear it up for me.

Thank you

Lee

#3

Doesn't work that way, if that was the case we would just run .1x turbine housings with 4 60mm wastegates. There is too much flow coming out of the engine at high rpms and a wastegate's valve barely moves when it opens. Stand behind an rx-7 @ 8k rpms making over 600rwhp and you will see what I'm talking about.

Easy rule of thumb for most compressors between 60-66mm a 1.0 with a P trim wheel will work well to 20psi on stock, and street ports.

Easy rule of thumb for most compressors between 60-66mm a 1.0 with a P trim wheel will work well to 20psi on stock, and street ports.

#4

It depends a lot on how the entry to wastegate runners are.

On my set up I was stuck with a T25ish 1.00 dual scroll housing (stock S5) and using 60-1 compressor.

I had amazing spool but very bad boost creep.

I went up to clipped "P" trim turbine and started going crazy with wastegate porting/external wastegate in stages.

What finally fixed the creep was when I ported the manifold and turbo runners so flow favored the 60mm wastegate (larger runners than turbo entry and directed into wastegate.

But....

This affected turbo spool as there is more turbulence and less velocity going into the turbo scroll, so spool was merely awesome (GT35Rish) and not amazing anymore.

On my set up the wear on the WG shaft definitely shows it opens a significant amount and once it was ported to flow there is definitely more than sound coming out of it.

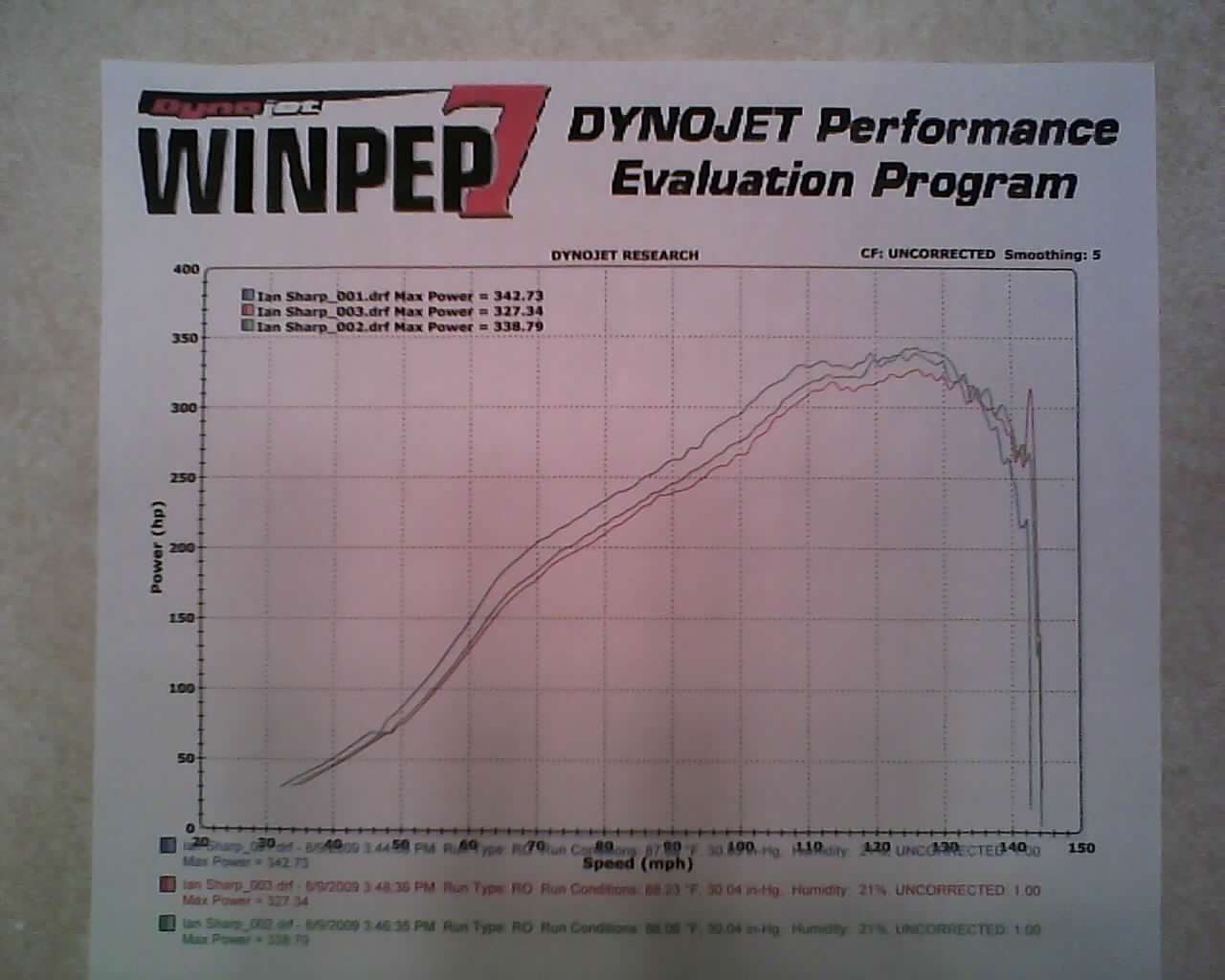

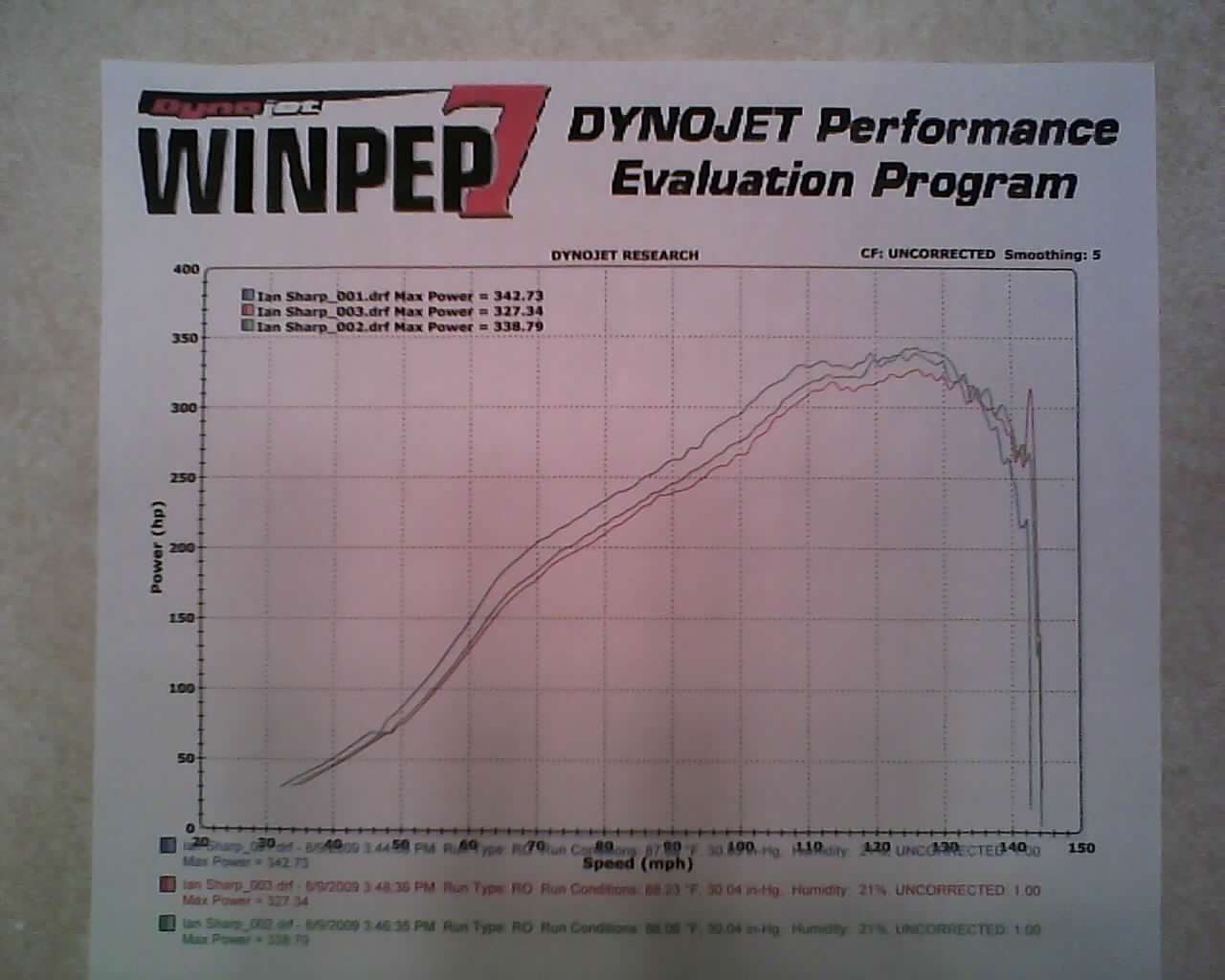

Here it is at 12psi on a dynojet where it spooled a little slower than on the street due to drum inertia and did 12psi instead of the 14psi it did on the street. No fan or anything on the dyno or time to mess with boost controller as it was just a diesel dyno day party I was crashing.

On my set up I was stuck with a T25ish 1.00 dual scroll housing (stock S5) and using 60-1 compressor.

I had amazing spool but very bad boost creep.

I went up to clipped "P" trim turbine and started going crazy with wastegate porting/external wastegate in stages.

What finally fixed the creep was when I ported the manifold and turbo runners so flow favored the 60mm wastegate (larger runners than turbo entry and directed into wastegate.

But....

This affected turbo spool as there is more turbulence and less velocity going into the turbo scroll, so spool was merely awesome (GT35Rish) and not amazing anymore.

On my set up the wear on the WG shaft definitely shows it opens a significant amount and once it was ported to flow there is definitely more than sound coming out of it.

Here it is at 12psi on a dynojet where it spooled a little slower than on the street due to drum inertia and did 12psi instead of the 14psi it did on the street. No fan or anything on the dyno or time to mess with boost controller as it was just a diesel dyno day party I was crashing.

#5

I think a much better way of achieving great spool and top end power out of a single turbo without all the complications of trying to get good wastegate flow without impacting the efficiency of turbine is-

use a Variable Geometry Turbo.

I would like my next turbo to be a sliding nozzle Holset HE351VE variable geometry turbo. I would still try to get a good merge to the 60mm wastegate with this set up but not to the point it impacts turbine flow/velocity significantly.

use a Variable Geometry Turbo.

I would like my next turbo to be a sliding nozzle Holset HE351VE variable geometry turbo. I would still try to get a good merge to the 60mm wastegate with this set up but not to the point it impacts turbine flow/velocity significantly.

#7

Rotary Enthusiast

Thread Starter

Funny you mention Holset! Cat out the bag!! I have an HX52 sat in the garage right now with a 16cm housing. But I want to run it on a 20B! I was intending to change the turbine housing for a larger one but I am having difficulty getting any info out of Holset. So far they have confirmed there is no straight swap turbine housing for my unit.. They are now looking into a blade/ turbine combo for me that I can bolt to my core. But amidst this the chap said have you thought of running an external wastegate. After initially thinking what is he on. Of course I will be using an external gate as my turbine housing doesn't have one! I then started to see where he was getting at and thought it might just work? I cannot read a compressor map but from my HX40 success on the 13B I am pretty confident the HX52 is a good size for the 20B? The 19cm turbine on the HX40 was a little slow to spool for street use for my liking so I would have guessed to get an equivalent on the 20B I would be looking at maybe a 22cm or possibly 24cm housing.. Then just possibly the 16cm could cut it if I can get a wastegate or two to flow enough?

Let me know your thoughts

Cheers

Lee

P.S. I posted here rather than the 20B form as there is a lot more knowledge on holsets and general single turbo conversions I would say. 20B section is still relatively small.

Let me know your thoughts

Cheers

Lee

P.S. I posted here rather than the 20B form as there is a lot more knowledge on holsets and general single turbo conversions I would say. 20B section is still relatively small.

Trending Topics

#9

If flow past the turbine wheel didnt matter everyone would run tiny turbine wheels and housings, giant compressor sides, and 2 giant wastegates.

But it doesnt work like that, not in the slightest. TBH do you not think it would be done all the time if it was? The reality is you simply got to balance your turbine side size between the response you want and the backpressure/heat/restricton/det threshold your engine spec can take.

The less the turbine flow the higher the backpressure. The more the wastegate vents to keep the boost at a certain level the higher the backpressure.

Turbos are span by 3 things, heat, flow, pressure. Lessen one and the others have to rise to keep the boost stable.

Tiny turbine side= Welcome to megabackpressureheatanddetville, population, you.

But it doesnt work like that, not in the slightest. TBH do you not think it would be done all the time if it was? The reality is you simply got to balance your turbine side size between the response you want and the backpressure/heat/restricton/det threshold your engine spec can take.

The less the turbine flow the higher the backpressure. The more the wastegate vents to keep the boost at a certain level the higher the backpressure.

Turbos are span by 3 things, heat, flow, pressure. Lessen one and the others have to rise to keep the boost stable.

Tiny turbine side= Welcome to megabackpressureheatanddetville, population, you.

#11

If flow past the turbine wheel didnt matter everyone would run tiny turbine wheels and housings, giant compressor sides, and 2 giant wastegates.

There is a balance in the system that must be met. In your example the wastegates would likely open initially and then close to keep the boost up because of the poor power available to drive the large compressor through the tiny exhaust wheel and housing.

But isn't the original poster is talking about a moderately sized turbo/exhaust housing with balanced compressor and exhaust wheels?

Increased wastegate flow does increase power in this situation. Look at the power gains from people running their WG open air vented as opposed to plumbed back in.

People see those large EMP increases you mention when the wastegate opens partly from horrible wastegate runner design. The motor has to push the exhaust out an increasingly restrictive turbine housing or through horribly restrictive wastegate runners, so the EMP skyrockets.

Turbos are span by 3 things, heat, flow, pressure. Lessen one and the others have to rise to keep the boost stable.

With a moderately sized turbo the flow increases greatly after the wastegate opens to keep the boost stable. In my dyno graph above the wastegate opens at 3,400rpm @115rwhp and obviously exhaust flow has greatly increased at say 6,000rpm and 340rwhp.

It is a complicated dynamic situation- to just say that EMP has had to increase to drive the compressor is missing some variables.

I do not dispute the EMP rise you mention as I have also seen those resuts, but I believe it is based on large turbos at high boost that make peak boost near peak engine power and have horrible wastegate design impeding flow.

I have also seen results of engines where the EMP decreases after the wastegate opens and 1:1 boost/EMP is maintained through careful turbo selection and wastegate size and routing and running at a lower boost pressure.

There is a balance in the system that must be met. In your example the wastegates would likely open initially and then close to keep the boost up because of the poor power available to drive the large compressor through the tiny exhaust wheel and housing.

But isn't the original poster is talking about a moderately sized turbo/exhaust housing with balanced compressor and exhaust wheels?

Increased wastegate flow does increase power in this situation. Look at the power gains from people running their WG open air vented as opposed to plumbed back in.

People see those large EMP increases you mention when the wastegate opens partly from horrible wastegate runner design. The motor has to push the exhaust out an increasingly restrictive turbine housing or through horribly restrictive wastegate runners, so the EMP skyrockets.

Turbos are span by 3 things, heat, flow, pressure. Lessen one and the others have to rise to keep the boost stable.

With a moderately sized turbo the flow increases greatly after the wastegate opens to keep the boost stable. In my dyno graph above the wastegate opens at 3,400rpm @115rwhp and obviously exhaust flow has greatly increased at say 6,000rpm and 340rwhp.

It is a complicated dynamic situation- to just say that EMP has had to increase to drive the compressor is missing some variables.

I do not dispute the EMP rise you mention as I have also seen those resuts, but I believe it is based on large turbos at high boost that make peak boost near peak engine power and have horrible wastegate design impeding flow.

I have also seen results of engines where the EMP decreases after the wastegate opens and 1:1 boost/EMP is maintained through careful turbo selection and wastegate size and routing and running at a lower boost pressure.

#12

Rotary Enthusiast

Thread Starter

Liking the replies guys. Thank you. I would say as above. I am enquiring about a matched compressor and turbine wheel with an exhaust housing that is probably marginally too small?

Have people run HX40's with 16cm housings on a 13B successfully anyone know?

Have people run HX40's with 16cm housings on a 13B successfully anyone know?

#13

Yes, people have used the HX40 16cm2 on 13b.

But, the HX40 16cm2 is about equal to a T3 .80 AR with a 60mm compressor and a 65mm exhaust wheel.

Your HX52 16cm2 is about equal to a T4 .80 AR with a 67mm compressor and a big 71mm exhaust wheel.

The Holset's smaller/lower A/R exhaust housing (compared to what most people recommend on Garrett turbo rotaries) with large exhaust wheel works out great on rotaries as you get high velocity exhaust for quick spool and a large turbine area for good flow and a great balance of exhaust wheel size to compressor wheel size compared to Garrett stuff.

HX52 compared to HX40 exhaust housings

But, the HX40 16cm2 is about equal to a T3 .80 AR with a 60mm compressor and a 65mm exhaust wheel.

Your HX52 16cm2 is about equal to a T4 .80 AR with a 67mm compressor and a big 71mm exhaust wheel.

The Holset's smaller/lower A/R exhaust housing (compared to what most people recommend on Garrett turbo rotaries) with large exhaust wheel works out great on rotaries as you get high velocity exhaust for quick spool and a large turbine area for good flow and a great balance of exhaust wheel size to compressor wheel size compared to Garrett stuff.

HX52 compared to HX40 exhaust housings

#14

Rotary Enthusiast

Thread Starter

You got an HX52 as well! I thought the HX52 16cm housing looks more like the size of an HX40 19cm one? Most people say the HX40 1cm is too small for a Rotary but I never tried it and having run a 19cm one I would think it would work pretty well ? Maybe not for a big ported screamer.. but for a mild street car? Would be interested to see some power/boost plots for an HX40/16cm on a 13B

Anyway. It's just a case now of if the HX52 16cm will work or not for the 20B with a 60mm External gate vented to atmosphere? If it's a possibility I might just give it a shot! What's the worst that can happen? It doesn't work so I buy another turbo. I have to say I would be far happier if it was a 19cm housing.

If I do give it a shot is there anything I should plan to monitor carefully on the dyno engine wise? Like EGT for example?

Cheers

Lee

Anyway. It's just a case now of if the HX52 16cm will work or not for the 20B with a 60mm External gate vented to atmosphere? If it's a possibility I might just give it a shot! What's the worst that can happen? It doesn't work so I buy another turbo. I have to say I would be far happier if it was a 19cm housing.

If I do give it a shot is there anything I should plan to monitor carefully on the dyno engine wise? Like EGT for example?

Cheers

Lee

#16

I have a he351ve on my car now and it seems to be holding up so far. I am waiting for the snow to melt and roads to clear up to really test it out. http://www.youtube.com/watch?v=PeP_--vf63Q

http://www.youtube.com/watch?v=eE5siUs3quQ

The only thing I am worried about is back pressure on the turbine. with the vane always trying to close. Might need to come up with a better solution to control the vgt. I also think even vane all the way open might be to small. I have a 60 mm wastesgate. Boost stays very steady at 7psi right now.

http://www.youtube.com/watch?v=eE5siUs3quQ

The only thing I am worried about is back pressure on the turbine. with the vane always trying to close. Might need to come up with a better solution to control the vgt. I also think even vane all the way open might be to small. I have a 60 mm wastesgate. Boost stays very steady at 7psi right now.

Thread

Thread Starter

Forum

Replies

Last Post

jetlude

Single Turbo RX-7's

4

08-18-15 04:53 PM