technical minded flow map question

#1

Auto-Ex Noob

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: new hampshire

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

technical minded flow map question

im taking a s4 n/a motor with a full bridge port and putting twin turbos on it the turbos are garrett T3 50 trims i plan on trying to push them to 15 lbs( i know they are kinda small) im having trouble with the flow map i was wondering if anyone could help. im useing the following formulas. im not a math major or anything like that so plz feel free to correct me if i am wrong

Engine Air Flow Requirements

(CID × RPM x VE%) ÷3456 = CFM

(80 × 7500 x 0.85) ÷ 3456 = 147.56 CFM (assuming 85 % VE)

Pressure Ratio

(15 + 14.7) ÷ 14.7 = 2.020 pressure ratio

Temperature Rise

T2 = T1 (P2 ÷ P1)to the .283 power

Where:

T2 = Outlet Temperature °R

T1 = Inlet Temperature °R

°R = °F + 460

P1 = Inlet Pressure Absolute

P2 = Outlet Pressure Absolute

assuming 75 degree inlet temp T1 = 75 + 460 = 535°R

P2 = 14.7 + 15 = 29.7 psi

pressure will be the outlet pressure of the turbo

T2 = 535 (29.7 ÷ 14.7)0.283 = 652.81°R

convert from degree R to degree F

652.81-460=192.81

which would give me a ideal temp rise of 117.81 degrees F

Adiabatic Efficiency

IOTR ÷ AE = AOTR

Where:

IOTR = Ideal Outlet Temperature Rise

AE = Adiabatic Efficiency

AOTR = Actual Outlet Temperature Rise

assumeing 70% adiabatic efficiency

117.81 ÷ 0.7 = 168.3 °F Actual Outlet Temperature Rise

now i add the temp rise to the inlet temp

75 + 168.3 = 243.3 °F Actual Outlet Temperature

Density Ratio

(Inlet °R ÷ Outlet °R) × (Outlet Pressure ÷ Inlet

Pressure) = Density Ratio

(535 ÷ 652.81) × (29.7 ÷ 14.7) = 1.655 Density Ratio

Compressor Inlet Airflow

Outlet CFM × Density Ratio = Actual Inlet CFM

147.56 CFM × 1.655= 244.211 CFM Inlet Air Flow

convert to lbs/min by

244.211 CFM × 0.069 = 16.85 lbs/min

no using all the information above considering that im useing 2 turbos i cut the flow in half to 8.425lbs/min

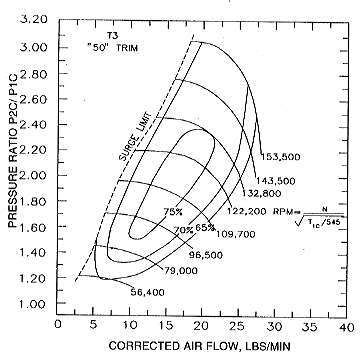

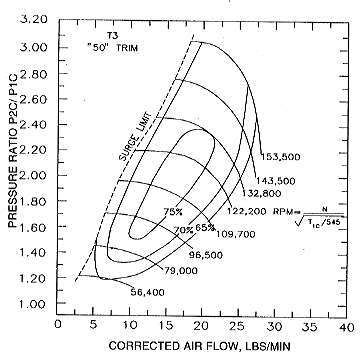

when i map it on the map below it seems like one turbo this size would be more efficent then two, or that two turbos will put me in the surge limit

any help with this would be great

thanks

-joe

Engine Air Flow Requirements

(CID × RPM x VE%) ÷3456 = CFM

(80 × 7500 x 0.85) ÷ 3456 = 147.56 CFM (assuming 85 % VE)

Pressure Ratio

(15 + 14.7) ÷ 14.7 = 2.020 pressure ratio

Temperature Rise

T2 = T1 (P2 ÷ P1)to the .283 power

Where:

T2 = Outlet Temperature °R

T1 = Inlet Temperature °R

°R = °F + 460

P1 = Inlet Pressure Absolute

P2 = Outlet Pressure Absolute

assuming 75 degree inlet temp T1 = 75 + 460 = 535°R

P2 = 14.7 + 15 = 29.7 psi

pressure will be the outlet pressure of the turbo

T2 = 535 (29.7 ÷ 14.7)0.283 = 652.81°R

convert from degree R to degree F

652.81-460=192.81

which would give me a ideal temp rise of 117.81 degrees F

Adiabatic Efficiency

IOTR ÷ AE = AOTR

Where:

IOTR = Ideal Outlet Temperature Rise

AE = Adiabatic Efficiency

AOTR = Actual Outlet Temperature Rise

assumeing 70% adiabatic efficiency

117.81 ÷ 0.7 = 168.3 °F Actual Outlet Temperature Rise

now i add the temp rise to the inlet temp

75 + 168.3 = 243.3 °F Actual Outlet Temperature

Density Ratio

(Inlet °R ÷ Outlet °R) × (Outlet Pressure ÷ Inlet

Pressure) = Density Ratio

(535 ÷ 652.81) × (29.7 ÷ 14.7) = 1.655 Density Ratio

Compressor Inlet Airflow

Outlet CFM × Density Ratio = Actual Inlet CFM

147.56 CFM × 1.655= 244.211 CFM Inlet Air Flow

convert to lbs/min by

244.211 CFM × 0.069 = 16.85 lbs/min

no using all the information above considering that im useing 2 turbos i cut the flow in half to 8.425lbs/min

when i map it on the map below it seems like one turbo this size would be more efficent then two, or that two turbos will put me in the surge limit

any help with this would be great

thanks

-joe

#2

Rotary Enthusiast

Join Date: Jan 2002

Location: 15143

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

Sorry, but I stopped reading at this point...

#3

Auto-Ex Noob

Thread Starter

iTrader: (1)

Join Date: Nov 2003

Location: new hampshire

Posts: 209

Likes: 0

Received 0 Likes

on

0 Posts

so considering that i am useing two turbos i would have to cut the 160cid in half which is 80cid what the above calc are set up for, correct? which would set me almost dead nuts in the 75% island.

#4

Rotary Enthusiast

wouldn't you use 160cid and then half your final lbs/min, like you already have ?

(you halved your cid at the start and again at the end, so ending up with a lesser figure.)

I dont know, just the way I read it

Also you are bridge ported so you will flow more then calced anyway.

Why not do a search and see what other people have done quite a few twin setup about.

quite a few twin setup about.

(you halved your cid at the start and again at the end, so ending up with a lesser figure.)

I dont know, just the way I read it

Also you are bridge ported so you will flow more then calced anyway.

Why not do a search and see what other people have done

quite a few twin setup about.

quite a few twin setup about.

#5

Rotary Enthusiast

Join Date: Jan 2002

Location: 15143

Posts: 859

Likes: 0

Received 0 Likes

on

0 Posts

Feel free to get detailed in your calcs, but there's an easy way to check that you're in the ballpark: expected RWHP divided by 7.5 = lbs/min of air. So your 17 lbs/min turbos will give about 250rwhp on a 13b, which sounds like a bad idea for your bridgeport IMO.

#6

Racing Rotary Since 1983

iTrader: (6)

according to the map each turbo will make 27 lbs/min max.

27*2=54/1.3=41.5*10= 415 max rear wheel rotary hp.

or 54*14.471= 781 cfm/1.92= 406 max rear wheel rotary hp.

take your pick.

as to the turbos, being T3s... you will need either the .63 or .82 hotside housings w a stage 3 turbine wheel or you will split the housings due to backpressure and heat. do not run the .48 housings.

i currently have over 10,000 miles on my twin setup.

27*2=54/1.3=41.5*10= 415 max rear wheel rotary hp.

or 54*14.471= 781 cfm/1.92= 406 max rear wheel rotary hp.

take your pick.

as to the turbos, being T3s... you will need either the .63 or .82 hotside housings w a stage 3 turbine wheel or you will split the housings due to backpressure and heat. do not run the .48 housings.

i currently have over 10,000 miles on my twin setup.

Thread

Thread Starter

Forum

Replies

Last Post

Skeese

Adaptronic Engine Mgmt - AUS

65

03-28-17 03:30 PM

msilvia

3rd Generation Specific (1993-2002)

28

04-14-16 12:58 PM

rx8volks

Canadian Forum

0

08-13-15 04:55 AM