How to size fuel injectors for your app

#1

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

How to size fuel injectors for your app

most of us have been faced w the question as to how much in the way of fuel we need for our particular setup...

there actually is a no nonsense method to properly solve for the answer.

it all starts w a known quantity,

AIR.

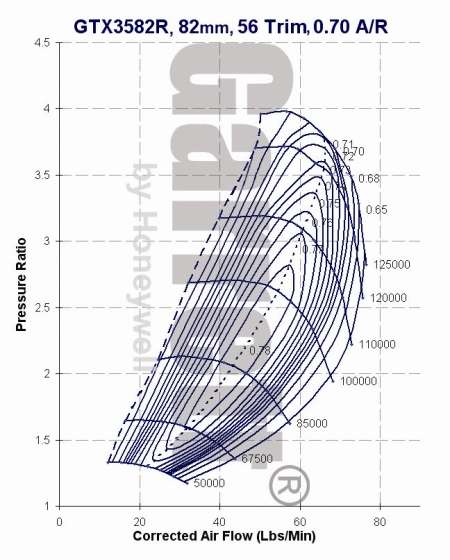

fortunately we have compressor maps to provide air data...

here is the new Garrett GTX3582

as is evident from the map the turbo makes about 75 pounds of air per minute, maximum, at 65% efficiency.

it probably doesn't need to be stated but.... if you are going to run a particular turbo do NOT fixture it for any less than the MAX... a stuck WG or numerous other factors including yur right foot at a moment of indescretion will most assuredly eventually find the turbos max output. so you'd better have the fuel.

so, the known/given is 75 pounds of air.

enter AFR or air fuel ratio. a variable. what do you want to run? probably no leaner than 11.5 to one.

the AFR is WEIGHT. that makes things easy...

75 pounds of air at 11.5 AFR requires

75/11.5 or 6.52 pounds of fuel (let's just talk gasoline as fuel for the moment)

gasoline weighs 6.35 pounds per gallon so let's find gallons

6.52/6.35 = 1.02 gallons (per minute)

now go to one of my favorite convertor websites and solve for CC/Min from GPM

http://online.unitconverterpro.com/u...lpha/flow.html

1.02 GPM = 3861 CC/Min

there are some additional add ons before we settle on Gross Delivery...

while 11.5 to 1 AFR is nice we need additional fuel to run a bit richer if we wish and perhaps make up for any delivery constraints. so let's use 10.5 to one.

11.5/10.5 = 1.095

1.095 X 3861 = 4228

second add on is we want to run the injectors at 85% max not 100% so...

100/85 = 1.176

1.176 X 4228 = 4974

third add on is for lag

lag will vary amongst injectors and for me is empirically derived

looking at a log from a dyno run w 850/1600s where i made 507 at 75% injector duty cycle and also factoring in a certain amount of methanol i see a 23% slippage between hp fuel ratio and fuel used.

based on that, and others are very welcome to chime in on this aspect, i suggest another 20% to account for lag.

4974 X 1.2 = 5968 CC/Min gross delivery

keep in mind this is for 75 pounds per minute

75 X 14.471 = 1085 CFM/ 1.92= 565 SAE RW rotary HP

5968 will allow you to run 10.5 AFR at 85% duty cycle.

you can make 565 w less deliverability but it will not allow you to run 10.5 at 85% max IDC if you wish.

you can effect deliverability w a pressure adjustment but remember that the additional delivery is not linear w the pressure increase as it is the square root of the increase.

BTW, the new Bosch EV 14s can run up to 8 Bar!

finally, if you run a non fuel (water) along w fuel you must deduct the cooling BTUs from your fuel BTUs to solve for net BTUs into the motor for purposes of making HP.

it isn't a big deal... for example

800 CC/Min of water is .21 GPM

.21 X 8087 cooling BTUs/gal = 1698 cooling BTUs

507 rwhp requires 106,716 so the cooling cost is 1.6%

(just shows what a HUGE payback a little water is... saving your motor for 2%...)

while we are talking fuel a slight detour. the FD has tiny primary ports. i spend lots of time making them much much larger. i suppose Mazda wanted them small for around town drive-ability and highway MPG. i don't quite get it because my primaries get 21 mpg highway and are fine from a drive-abilty aspect.

i think it is important to have lots of flow hitting the combustion chamber from both sides of the rotor.

here's my point:

if you are going to have lots of air (w better primary ports) hitting the motor you should ideally have lots of fuel. so i am more than willing to idle a touch rich (w the Power FC) to get a better (more) balance of air-fuel thru my primary ports.

so if you are looking to make lots of HP i suggest you do the motor a favor and don't end up w wimpy fuel delivery thru the primaries.

howard

there actually is a no nonsense method to properly solve for the answer.

it all starts w a known quantity,

AIR.

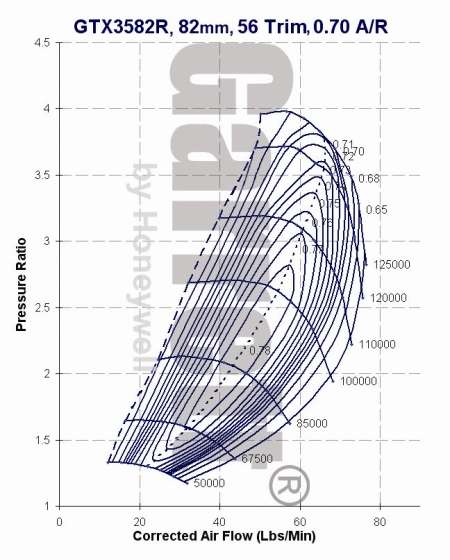

fortunately we have compressor maps to provide air data...

here is the new Garrett GTX3582

as is evident from the map the turbo makes about 75 pounds of air per minute, maximum, at 65% efficiency.

it probably doesn't need to be stated but.... if you are going to run a particular turbo do NOT fixture it for any less than the MAX... a stuck WG or numerous other factors including yur right foot at a moment of indescretion will most assuredly eventually find the turbos max output. so you'd better have the fuel.

so, the known/given is 75 pounds of air.

enter AFR or air fuel ratio. a variable. what do you want to run? probably no leaner than 11.5 to one.

the AFR is WEIGHT. that makes things easy...

75 pounds of air at 11.5 AFR requires

75/11.5 or 6.52 pounds of fuel (let's just talk gasoline as fuel for the moment)

gasoline weighs 6.35 pounds per gallon so let's find gallons

6.52/6.35 = 1.02 gallons (per minute)

now go to one of my favorite convertor websites and solve for CC/Min from GPM

http://online.unitconverterpro.com/u...lpha/flow.html

1.02 GPM = 3861 CC/Min

there are some additional add ons before we settle on Gross Delivery...

while 11.5 to 1 AFR is nice we need additional fuel to run a bit richer if we wish and perhaps make up for any delivery constraints. so let's use 10.5 to one.

11.5/10.5 = 1.095

1.095 X 3861 = 4228

second add on is we want to run the injectors at 85% max not 100% so...

100/85 = 1.176

1.176 X 4228 = 4974

third add on is for lag

lag will vary amongst injectors and for me is empirically derived

looking at a log from a dyno run w 850/1600s where i made 507 at 75% injector duty cycle and also factoring in a certain amount of methanol i see a 23% slippage between hp fuel ratio and fuel used.

based on that, and others are very welcome to chime in on this aspect, i suggest another 20% to account for lag.

4974 X 1.2 = 5968 CC/Min gross delivery

keep in mind this is for 75 pounds per minute

75 X 14.471 = 1085 CFM/ 1.92= 565 SAE RW rotary HP

5968 will allow you to run 10.5 AFR at 85% duty cycle.

you can make 565 w less deliverability but it will not allow you to run 10.5 at 85% max IDC if you wish.

you can effect deliverability w a pressure adjustment but remember that the additional delivery is not linear w the pressure increase as it is the square root of the increase.

BTW, the new Bosch EV 14s can run up to 8 Bar!

finally, if you run a non fuel (water) along w fuel you must deduct the cooling BTUs from your fuel BTUs to solve for net BTUs into the motor for purposes of making HP.

it isn't a big deal... for example

800 CC/Min of water is .21 GPM

.21 X 8087 cooling BTUs/gal = 1698 cooling BTUs

507 rwhp requires 106,716 so the cooling cost is 1.6%

(just shows what a HUGE payback a little water is... saving your motor for 2%...)

while we are talking fuel a slight detour. the FD has tiny primary ports. i spend lots of time making them much much larger. i suppose Mazda wanted them small for around town drive-ability and highway MPG. i don't quite get it because my primaries get 21 mpg highway and are fine from a drive-abilty aspect.

i think it is important to have lots of flow hitting the combustion chamber from both sides of the rotor.

here's my point:

if you are going to have lots of air (w better primary ports) hitting the motor you should ideally have lots of fuel. so i am more than willing to idle a touch rich (w the Power FC) to get a better (more) balance of air-fuel thru my primary ports.

so if you are looking to make lots of HP i suggest you do the motor a favor and don't end up w wimpy fuel delivery thru the primaries.

howard

Last edited by Howard Coleman; 12-26-11 at 07:57 AM.

#3

Racing Rotary Since 1983

Thread Starter

iTrader: (6)

"second add on is we want to run the injectors at 85% max not 100% so..."

we figured X amount of gas into the engine given a certain amount of air and AFR.

so we come up w the X number. let's say it is 5000 CC/Min...

if we put 5000 CC/Min of injectors on the motor they will have to be running at 100% duty cycle which is a no no.

85% is a good top number so we need more than X to run the injectors at 85%

that works out to be 1.176 * X in this case

5000 X 1.176 = 5880

hc

we figured X amount of gas into the engine given a certain amount of air and AFR.

so we come up w the X number. let's say it is 5000 CC/Min...

if we put 5000 CC/Min of injectors on the motor they will have to be running at 100% duty cycle which is a no no.

85% is a good top number so we need more than X to run the injectors at 85%

that works out to be 1.176 * X in this case

5000 X 1.176 = 5880

hc

#6

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,815

Received 2,584 Likes

on

1,835 Posts

while we are talking fuel a slight detour. the FD has tiny primary ports. i spend lots of time making them much much larger. i suppose Mazda wanted them small for around town drive-ability and highway MPG. i don't quite get it because my primaries get 21 mpg highway and are fine from a drive-abilty aspect.

howard

howard

in my travels i have run across the port area's for the FD, the 110 cosmo, R100, Rx8, and the MFR engines. comparatively the FD has good sized exhaust ports, but it has the smallest intake area of the bunch. since the FD is the only turbo engine i have info on, i hesitate to make comparisons but the FD is 15cm3 and the Rx8 is 24cm3.

obviously there is a compromise in the FD's port design, the turbos probably let them open the intakes later, which should help emissions (less overlap). the key advantage of the Rx8's side port is that they can close the exhaust earlier, and this frees up the intake port design.

Thread

Thread Starter

Forum

Replies

Last Post

82streetracer

1st Generation Specific (1979-1985)

7

08-23-15 09:28 AM

86rxNa

2nd Generation Specific (1986-1992)

2

08-11-15 11:51 AM