"Best" Exhaust Manifold for FD Single Turbo?

#26

I thought Arctek was essentially the HKS manifold, but with a fully divided wastegate runner right up to the valve face. All their literature and pics show it as fully divided, I'm surprised to hear otherwise.

Even the long runner Turblown manifold is un-equal length. And if you want an e-gate, it's twice the cost.

The FD has packaging issues with the frame rail. If you want equal length, you will have more bends. If you want a short manifold, you will have tighter bends. It's just a reality of the chassis unless you get creative with a sawzall and a welder..

Even the long runner Turblown manifold is un-equal length. And if you want an e-gate, it's twice the cost.

The FD has packaging issues with the frame rail. If you want equal length, you will have more bends. If you want a short manifold, you will have tighter bends. It's just a reality of the chassis unless you get creative with a sawzall and a welder..

The following users liked this post:

mr2peak (02-23-24)

#28

I haven't found any dynos with it. If anyone finds anything, please post it up. If the Full Race IWG e-gate doesn't work properly, it might be a good shorty EWG option. I've emailed Arctek in the past asking about EFR fitment and Turbosmart e-gate fitment, never got an answer.

#31

Rx72c said he dynoed with the Artec a little while ago in here somewhere, but he said it was inferior to the turblown.

I wouldn't take an exterior kink on a casting to be too indicative of the interior either. There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

I wouldn't take an exterior kink on a casting to be too indicative of the interior either.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

#32

Anyone who thinks the Artec provides the same spool advantages as the Turblown EWG isn't going to get them. Yes we did a back to back and the Artec manifold behaved like a NON fully divided manifold, no boost till there was boost and around 4-500rpm later in boost compared to Turblown EWG. Test was done on a g40-900

#33

G40 on Artec manofold is a mismatch in my mind.

One manifold design does not fit all turbo sizes.

A high flowing exhaust side turbo like G40-900 is going to benefit from the longer straighter runners of turblown EWG manifold. More time/volume for the exhaust to expand before it hits the turbine and less testriction.

Conversely, on a smaller lower flowing exhaust side turbo the short convoluted Artec manifold may provide better response between throttle input and turbo shaft RPM since the turbo is physically closer coupled (less delay).

At a given RPM if the smaller turbos turbine is more of a restriction than the bends of the short manifold the short manifold wont be hampering overall flow (which affects spool).

Exhaust energy difference between full boost at 3,000rpm and full boost at 4,000rpm is big difference on rotary. 150hp of exhaust flow at 3,000rpm VS 250hp worth of exhaust flow at 4,000rpm.

So, my rule of thumb would be if you choose a small turbo with peak boost around 3,000rpm short runners will serve you well with throttle response and bends might not wreck your spool.

If you choose a larger turbo with peak boost at 4,000rpm or later you have commited to turbo turbo tip in throttle response lag and might as well get the high flowing turbo manifold that will provide highest flow to bring peak boost RPM down (completely different than transient throttle lag) by delivering the most exhaust energy to the turbine (less restriction, more expansion).

A lot of people cant separate turbo transient response from boost onset threshold RPM from peak boost threshold RPM in their minds.

They are all critical factors in designing a turbo system.

One manifold design does not fit all turbo sizes.

A high flowing exhaust side turbo like G40-900 is going to benefit from the longer straighter runners of turblown EWG manifold. More time/volume for the exhaust to expand before it hits the turbine and less testriction.

Conversely, on a smaller lower flowing exhaust side turbo the short convoluted Artec manifold may provide better response between throttle input and turbo shaft RPM since the turbo is physically closer coupled (less delay).

At a given RPM if the smaller turbos turbine is more of a restriction than the bends of the short manifold the short manifold wont be hampering overall flow (which affects spool).

Exhaust energy difference between full boost at 3,000rpm and full boost at 4,000rpm is big difference on rotary. 150hp of exhaust flow at 3,000rpm VS 250hp worth of exhaust flow at 4,000rpm.

So, my rule of thumb would be if you choose a small turbo with peak boost around 3,000rpm short runners will serve you well with throttle response and bends might not wreck your spool.

If you choose a larger turbo with peak boost at 4,000rpm or later you have commited to turbo turbo tip in throttle response lag and might as well get the high flowing turbo manifold that will provide highest flow to bring peak boost RPM down (completely different than transient throttle lag) by delivering the most exhaust energy to the turbine (less restriction, more expansion).

A lot of people cant separate turbo transient response from boost onset threshold RPM from peak boost threshold RPM in their minds.

They are all critical factors in designing a turbo system.

The following 2 users liked this post by BLUE TII:

diabolical1 (02-24-24),

mr2peak (02-25-24)

#34

Anyone who thinks the Artec provides the same spool advantages as the Turblown EWG isn't going to get them. Yes we did a back to back and the Artec manifold behaved like a NON fully divided manifold, no boost till there was boost and around 4-500rpm later in boost compared to Turblown EWG. Test was done on a g40-900

but that’s the least of your concerns, I recently heard that “you’re in trouble”, the real kind, she said so … 🤣🤣🤣

.

#35

Sorry to hear it's not working well, I thought we might have had another decent option. The manifold gate mount can be shaved down to fit a larger gate, and the divider could then be ported to match the valve face. I wonder if that would make a large difference?

No matter what you still have the extra volume of the wastegate runner to soak up pulse energy, so, can't win them all.

Sounds like the shorty IWG actually is a pretty good option vs what is available

No matter what you still have the extra volume of the wastegate runner to soak up pulse energy, so, can't win them all.

Sounds like the shorty IWG actually is a pretty good option vs what is available

#36

#37

G40 on Artec manofold is a mismatch in my mind.

One manifold design does not fit all turbo sizes.

A high flowing exhaust side turbo like G40-900 is going to benefit from the longer straighter runners of turblown EWG manifold. More time/volume for the exhaust to expand before it hits the turbine and less testriction.

Conversely, on a smaller lower flowing exhaust side turbo the short convoluted Artec manifold may provide better response between throttle input and turbo shaft RPM since the turbo is physically closer coupled (less delay).

At a given RPM if the smaller turbos turbine is more of a restriction than the bends of the short manifold the short manifold wont be hampering overall flow (which affects spool).

Exhaust energy difference between full boost at 3,000rpm and full boost at 4,000rpm is big difference on rotary. 150hp of exhaust flow at 3,000rpm VS 250hp worth of exhaust flow at 4,000rpm.

So, my rule of thumb would be if you choose a small turbo with peak boost around 3,000rpm short runners will serve you well with throttle response and bends might not wreck your spool.

If you choose a larger turbo with peak boost at 4,000rpm or later you have commited to turbo turbo tip in throttle response lag and might as well get the high flowing turbo manifold that will provide highest flow to bring peak boost RPM down (completely different than transient throttle lag) by delivering the most exhaust energy to the turbine (less restriction, more expansion).

A lot of people cant separate turbo transient response from boost onset threshold RPM from peak boost threshold RPM in their minds.

They are all critical factors in designing a turbo system.

One manifold design does not fit all turbo sizes.

A high flowing exhaust side turbo like G40-900 is going to benefit from the longer straighter runners of turblown EWG manifold. More time/volume for the exhaust to expand before it hits the turbine and less testriction.

Conversely, on a smaller lower flowing exhaust side turbo the short convoluted Artec manifold may provide better response between throttle input and turbo shaft RPM since the turbo is physically closer coupled (less delay).

At a given RPM if the smaller turbos turbine is more of a restriction than the bends of the short manifold the short manifold wont be hampering overall flow (which affects spool).

Exhaust energy difference between full boost at 3,000rpm and full boost at 4,000rpm is big difference on rotary. 150hp of exhaust flow at 3,000rpm VS 250hp worth of exhaust flow at 4,000rpm.

So, my rule of thumb would be if you choose a small turbo with peak boost around 3,000rpm short runners will serve you well with throttle response and bends might not wreck your spool.

If you choose a larger turbo with peak boost at 4,000rpm or later you have commited to turbo turbo tip in throttle response lag and might as well get the high flowing turbo manifold that will provide highest flow to bring peak boost RPM down (completely different than transient throttle lag) by delivering the most exhaust energy to the turbine (less restriction, more expansion).

A lot of people cant separate turbo transient response from boost onset threshold RPM from peak boost threshold RPM in their minds.

They are all critical factors in designing a turbo system.

When I get a chance to back to back on a smaller turbo then I'll cross that road when the time comes, for now, Turblown manifold it is.

#38

Im always thankful to read your experiences and dont doubt the validity of your results.

I just used too many words to postulate there may be an application where Artec is preferred and why I think so.

Throttle/turbo response will really only show up on high sample rate data logs and driver impressions.

Even then, lots of drivers love the "turbo feel" of delayed transient response.

I just used too many words to postulate there may be an application where Artec is preferred and why I think so.

Throttle/turbo response will really only show up on high sample rate data logs and driver impressions.

Even then, lots of drivers love the "turbo feel" of delayed transient response.

#39

Im always thankful to read your experiences and dont doubt the validity of your results.

I just used too many words to postulate there may be an application where Artec is preferred and why I think so.

Throttle/turbo response will really only show up on high sample rate data logs and driver impressions.

Even then, lots of drivers love the "turbo feel" of delayed transient response.

I just used too many words to postulate there may be an application where Artec is preferred and why I think so.

Throttle/turbo response will really only show up on high sample rate data logs and driver impressions.

Even then, lots of drivers love the "turbo feel" of delayed transient response.

In regards to your post, Just so I am not coming off the wrong way, I don't know enough to really to agree or disagree with you, I enjoy doing the testing and sometimes it lets you connect dots together and sometimes it adds more dots

The following 4 users liked this post by rx72c:

#40

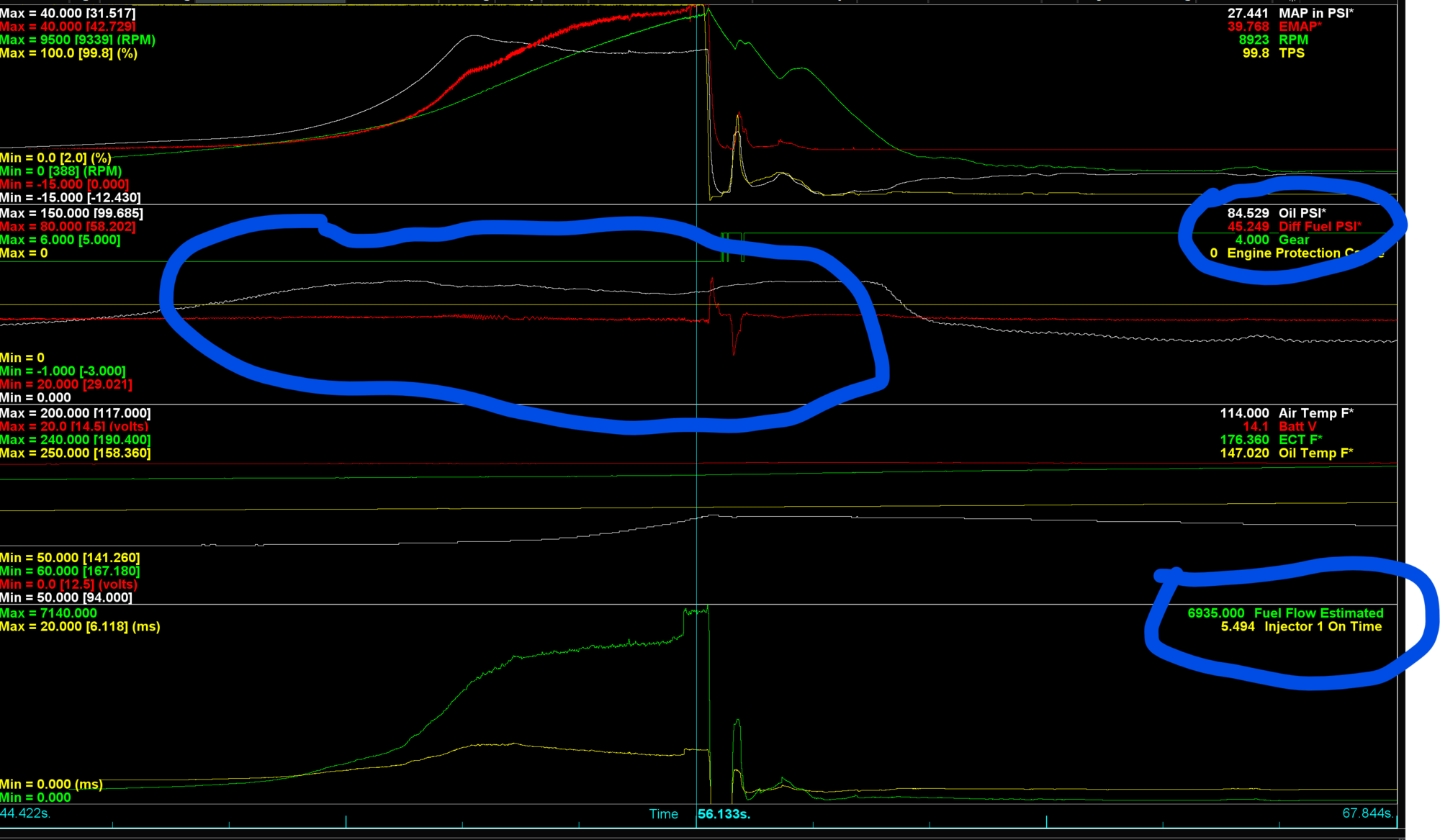

Ignore the circled parts, i was just showing fuelab that their single brushless pump kicks *** at this level. The top red line is EMAP. you can see the pulses and the harmonics at about 6000 rpm. Seeing the pulses strong enough to be measured by a mediocre pressure sensor certainly reinforces the turblown cast manifold benefits.

What was the of emap of the G35 1050 and G40 900 at the similar boost levels please? I appreciate the setups of the vette and the fc are different. Just wondering if you are able to share any emap data at 14-15psi, 20psi, 25 psi and 30psi for both turbos if possible.

Cheers,

Pat

#41

I’d offer up that for someone with a lower HP goal; Pulsar paired their G-series version of the -770 compressor from the G30 line to the G35 turbine (PTG-5862). Which Garrett has yet to offer.

What this does is create a similar comp-turb sizing ratio as the G40-900. In theory it should be good for around 550 whp max on a proper 13B. However, the only divided T4 housing that Pulsar offers for it is a 0.85 A/R. Which should be fine for someone looking for better response and willing to sacrifice some max top end potential (autocross etc.).

The Pulsar turbine housing is also cast iron, but at least is the more ductile HiSiMo material. So you’d really need to pair the Pulsar supercore with the Garrett G35 1.06 A/R div T4 SS turbine housing for that peak power limit/lowest emap. The Garrett housing is a bit pricey, but the quality is outstanding. It will still be quite a bit less total $$$ than a full Garrett G turbo (under $1800 USD with the flanges etc.).

https://www.pulsarturbo.com/product/...hp-rating-770/

.

What this does is create a similar comp-turb sizing ratio as the G40-900. In theory it should be good for around 550 whp max on a proper 13B. However, the only divided T4 housing that Pulsar offers for it is a 0.85 A/R. Which should be fine for someone looking for better response and willing to sacrifice some max top end potential (autocross etc.).

The Pulsar turbine housing is also cast iron, but at least is the more ductile HiSiMo material. So you’d really need to pair the Pulsar supercore with the Garrett G35 1.06 A/R div T4 SS turbine housing for that peak power limit/lowest emap. The Garrett housing is a bit pricey, but the quality is outstanding. It will still be quite a bit less total $$$ than a full Garrett G turbo (under $1800 USD with the flanges etc.).

https://www.pulsarturbo.com/product/...hp-rating-770/

.

Last edited by TeamRX8; 02-26-24 at 08:33 PM.

The following users liked this post:

diabolical1 (03-01-24)

#42

Rx72c said he dynoed with the Artec a little while ago in here somewhere, but he said it was inferior to the turblown.

I wouldn't take an exterior kink on a casting to be too indicative of the interior either. There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

I wouldn't take an exterior kink on a casting to be too indicative of the interior either.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.

There's probably a 99% chance that 321 fabricated manifold mentioned was welded using 347 wire too.it’s easy to overlook the details, more or less makes the divider a moot point. The manifold also has an excessive amount of volume compared to the runner length.

too much gap

true that ER347 is the common filler wire choice for 321 and there are a bunch of blah-blah-blah technical reasons for it, but the two intermix in the weld pool and isn’t the same thing as 347 material. Which has a lower strength to high temp rating than 321.

I have a Renesis turbo manifold design that can be laser cut and welded from flat sheet/plate rather than round tube/pipe for a tighter space fitment. I can buy the material in both 347 and 321, but 321 is the better choice.

It’s really a moot argument, other than to point out that the people who throw the 347 material argument out are generally just parroting some marketing schlock they read and not as fully informed as they like to project. Which is why I countered the comment.

.

Last edited by TeamRX8; 02-26-24 at 09:13 PM.

#43

I had also meant to address the not seeing the interior comment; I’ve not only seen it, I’ve seen the results that define it better than the visual perspective. In addition to also seeing how it can be improved, and also having stated more about it than just that.

The history of the rear rotor always running substantially hotter with that particular design when all else is equal is well established, recognized, and has been commented on before by others. The EGT between R1 and R2 can be brought closer with various corrections. Which only emphasizes the imbalance that exists when one runner is so short and directly open while the other is substantially longer and convoluted.

Life is always full of compromises, but sometimes we err and compromise too much or overlook recognizing an alternative with less compromise. Trying to pretend otherwise is what leads to the n-th time of making a “best that ever was” claim and then pretending that never happened at the next n+1 rinse and repeat time.

I suppose I’ll get all up and salty by stating there hasn’t ever been any shortage of those birds of a feather flocking together; merchandisers of men are always going to do just that.

.

The history of the rear rotor always running substantially hotter with that particular design when all else is equal is well established, recognized, and has been commented on before by others. The EGT between R1 and R2 can be brought closer with various corrections. Which only emphasizes the imbalance that exists when one runner is so short and directly open while the other is substantially longer and convoluted.

Life is always full of compromises, but sometimes we err and compromise too much or overlook recognizing an alternative with less compromise. Trying to pretend otherwise is what leads to the n-th time of making a “best that ever was” claim and then pretending that never happened at the next n+1 rinse and repeat time.

I suppose I’ll get all up and salty by stating there hasn’t ever been any shortage of those birds of a feather flocking together; merchandisers of men are always going to do just that.

.

Last edited by TeamRX8; 02-29-24 at 06:16 AM.

The following users liked this post:

iceman4357 (03-02-24)

The following users liked this post:

estevan62274 (03-02-24)

#48

The following users liked this post:

estevan62274 (03-02-24)

#50

Originally Posted by TeamRX8

true that ER347 is the common filler wire choice for 321 and there are a bunch of blah-blah-blah technical reasons for it, but the two intermix in the weld pool and isn’t the same thing as 347 material. Which has a lower strength to high temp rating than 321.

I have a Renesis turbo manifold design that can be laser cut and welded from flat sheet/plate rather than round tube/pipe for a tighter space fitment. I can buy the material in both 347 and 321, but 321 is the better choice.

It’s really a moot argument, other than to point out that the people who throw the 347 material argument out are generally just parroting some marketing schlock they read and not as fully informed as they like to project. Which is why I countered the comment.

I have a Renesis turbo manifold design that can be laser cut and welded from flat sheet/plate rather than round tube/pipe for a tighter space fitment. I can buy the material in both 347 and 321, but 321 is the better choice.

It’s really a moot argument, other than to point out that the people who throw the 347 material argument out are generally just parroting some marketing schlock they read and not as fully informed as they like to project. Which is why I countered the comment.