Methodology for adding timing

#1

Context: FD, BNRs, PowerFC, 91 pump gas, then 50/50 water/meth after tuning for safety.

Last year I blew my motor. It appears to have possibly been due to bad gas but that is not for certain.

When I installed the new motor, the first thing I did was to pull about two degrees of timing out of the map everywhere it was in boost.

Next week I have some dyno time, and besides some general experimentation, my main goal is to add timing back in. I'd like some tips about how to go about doing this is.

Here is what I am thinking:

- Starting with one row at a time, add a degree of timing in. Do a few runs touching every/most cells in that row. If there is a spike in knock at a given cell, remove a degree of timing and mark down which cell it was so you know not to add more timing there again.

- Repeat on that row until you have either maxed out the timing on each cell or you can see a pattern/make an inference about adjacent cells and feel confident you've added about as much timing as you can.

- Move to the next row and repeat.

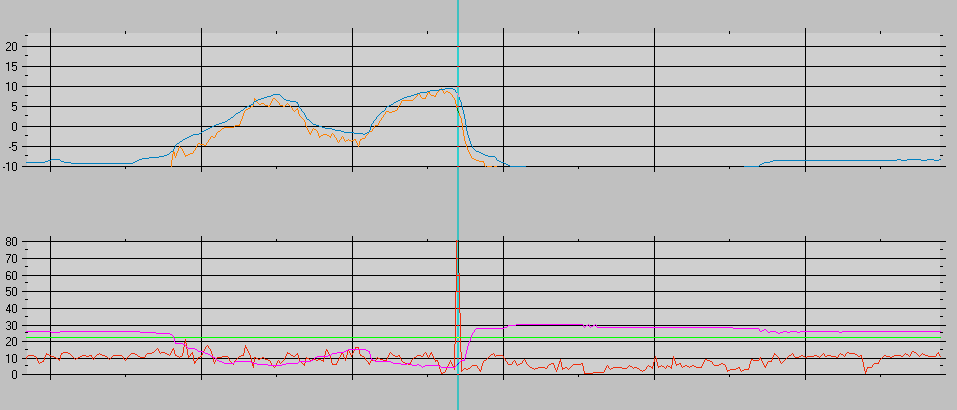

One thing I have been told (by Ari none the less) is that the knock noise floor will increase with RPM. It's not so much important what the actual knock value is, you really just want to avoid any sudden spikes.

Does that all sound about right? What words of advice might you give? And exactly how scared of knock spikes should I be during the tuning process? For example, if I am regularly seeing spikes from say ~20 to 80 or 100 during the tuning process before tuning them out, am I doing it wrong?

Much thanks, very interested to hear what people have to say.

Last year I blew my motor. It appears to have possibly been due to bad gas but that is not for certain.

When I installed the new motor, the first thing I did was to pull about two degrees of timing out of the map everywhere it was in boost.

Next week I have some dyno time, and besides some general experimentation, my main goal is to add timing back in. I'd like some tips about how to go about doing this is.

Here is what I am thinking:

- Starting with one row at a time, add a degree of timing in. Do a few runs touching every/most cells in that row. If there is a spike in knock at a given cell, remove a degree of timing and mark down which cell it was so you know not to add more timing there again.

- Repeat on that row until you have either maxed out the timing on each cell or you can see a pattern/make an inference about adjacent cells and feel confident you've added about as much timing as you can.

- Move to the next row and repeat.

One thing I have been told (by Ari none the less) is that the knock noise floor will increase with RPM. It's not so much important what the actual knock value is, you really just want to avoid any sudden spikes.

Does that all sound about right? What words of advice might you give? And exactly how scared of knock spikes should I be during the tuning process? For example, if I am regularly seeing spikes from say ~20 to 80 or 100 during the tuning process before tuning them out, am I doing it wrong?

Much thanks, very interested to hear what people have to say.

Last edited by mkd; 12-20-22 at 12:02 AM.

#3

Moderator

iTrader: (3)

Join Date: Mar 2001

Location: https://www2.mazda.com/en/100th/

Posts: 30,818

Received 2,589 Likes

on

1,839 Posts

do you have EGT? or a way to measure power? you don't need either, but its helpful. the FC Tweak software goes the other way, if it sees knock, it'll pull a degree from that spot

The following users liked this post:

j9fd3s (12-20-22)

#7

Racing Rotary Since 1983

iTrader: (6)

i ran a PFC w a Datalogit from 03 til 2013. it is still a good system but somewhat limited. FWIW, i found driving around knock was around 50 or a bit higher. when i did a pull knock dropped to around 10. if i didn't see the drop i knew something required attention. the varying quality of gasoline is a key factor w re to knock. you can have everything perfect but if you have a low quality tank of gas you will get knock. a reduction of timing will be the fix. modern ECUs can zero out timing when encountering knock. PFC users simply have to log their pulls and check knock.

i encountered a tank of bad gas. fortunately, i looked at the log after the first pull and noticed it. i did not notice from the driver's seat. i removed 6 degrees timing, made another run and made 17 more hp than the prior run w 5 or 6 degrees lead.

unfortunately, fuel is a constant variable and a reactive knock system is the primary solution.

i encountered a tank of bad gas. fortunately, i looked at the log after the first pull and noticed it. i did not notice from the driver's seat. i removed 6 degrees timing, made another run and made 17 more hp than the prior run w 5 or 6 degrees lead.

unfortunately, fuel is a constant variable and a reactive knock system is the primary solution.

Last edited by Howard Coleman; 12-20-22 at 06:11 PM.

The following users liked this post:

NathanBoutin (02-21-24)

Thread

Thread Starter

Forum

Replies

Last Post

NAN777

3rd Generation Specific (1993-2002)

7

03-06-07 12:32 PM