Latest Experiment…Failure!

#78

"Elusive, not deceptive!”

Thread Starter

The picture shown is an "as run" failed apex seal housing. It shows cracks and polished lips at the spark plug hole. The surfaces on both sides of the plug area have carbon stains indicating that the apex seal is being lifted there.

If we can even out the temps across this area the apex seal will be happier and possibly give us a longer service life.

I look for longevity in my engines and I had trouble finding the "root cause" for this last failure. I don't feel that the apex seal failure was due to detonation so I am looking for another cause, hopefully the "root cause". Is this the smoking gun?

Any other suggestions are appreciated? Thanks for all the discussion so far.

Barry

#79

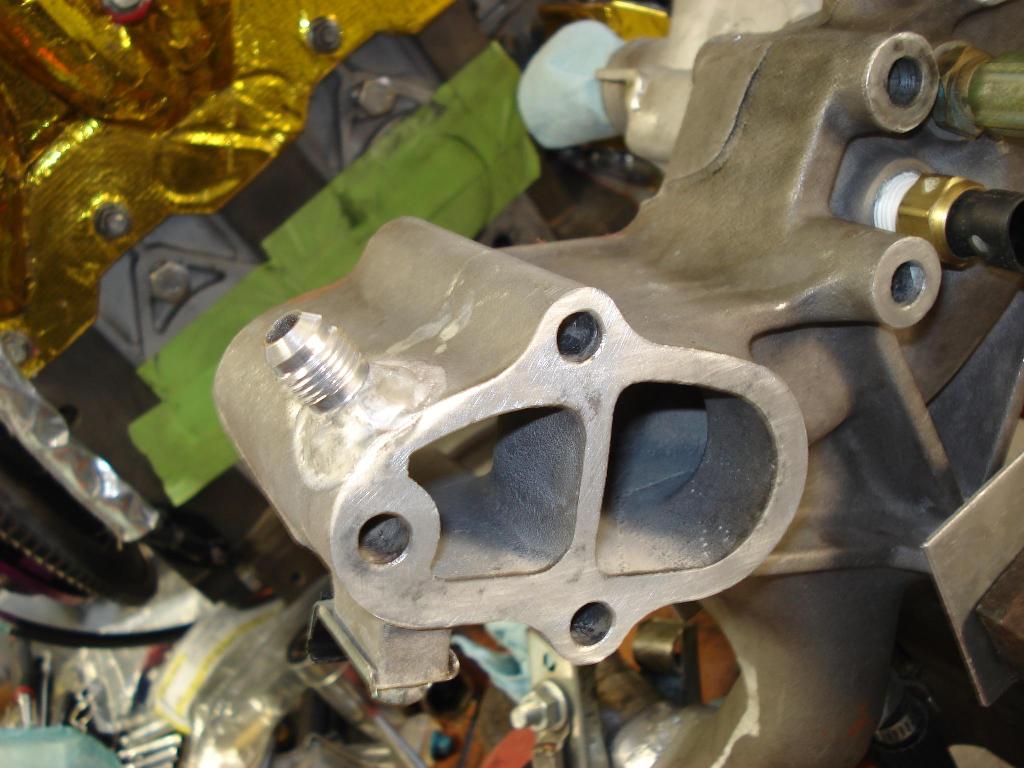

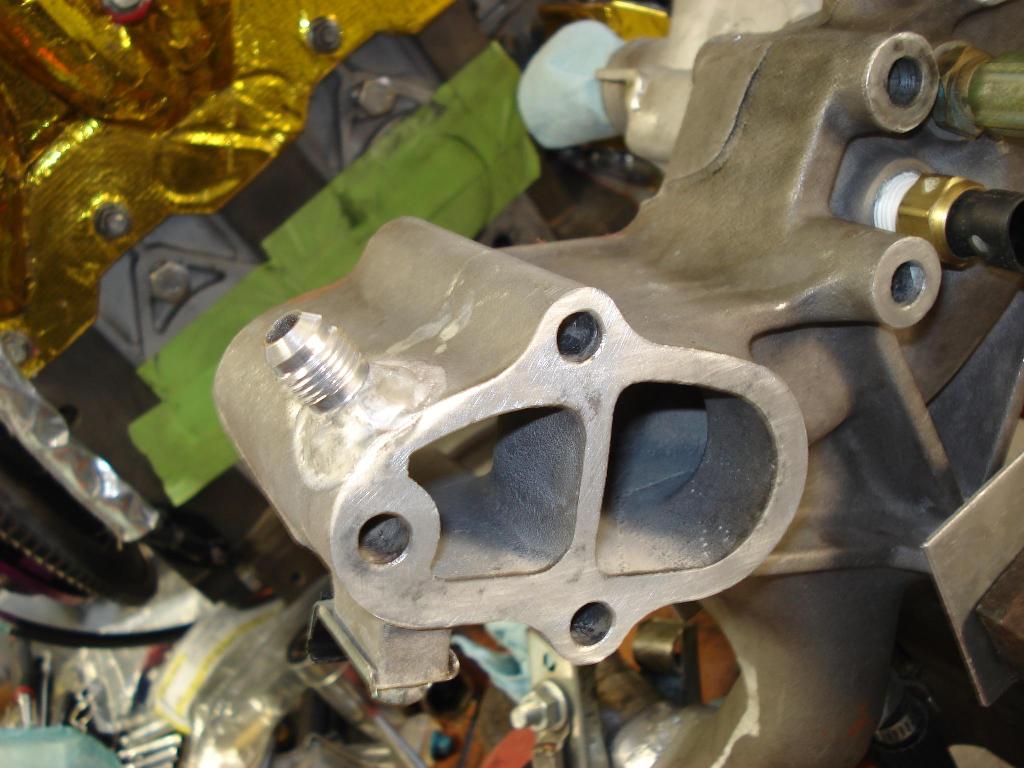

Alright I would like your guys opinion on this before I go forward with doing this on my rotor housings that I will be using.

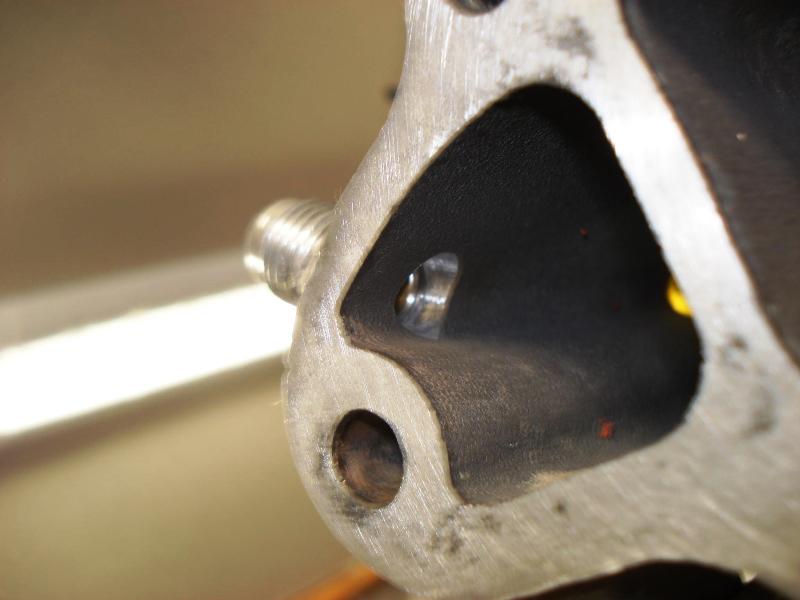

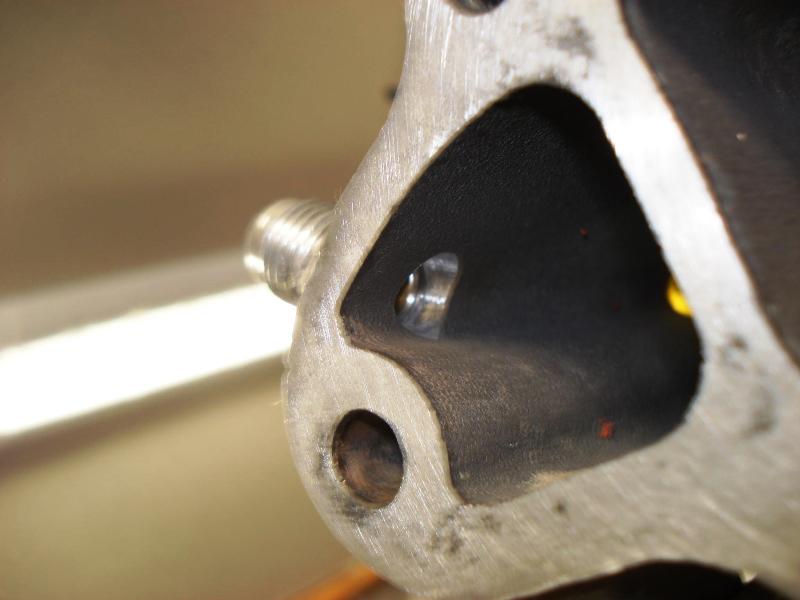

0.125" deep .25" round slot and the bolt holes bored out to 1/2" (originally 0.46" or 11.68 mm)

The slots would be on both sides of each rotor housing and the boring will be done on the three bolt holes near the spark plugs.

FYI, the second bolt picture is of the stock hole size.

0.125" deep .25" round slot and the bolt holes bored out to 1/2" (originally 0.46" or 11.68 mm)

The slots would be on both sides of each rotor housing and the boring will be done on the three bolt holes near the spark plugs.

FYI, the second bolt picture is of the stock hole size.

#80

"Elusive, not deceptive!”

Thread Starter

Adam I used smaller holes. My thinking was that the differential pressure across the restrictive spark plug water passages would force only a small amount of flow to bypass.

Yours are vertical so they bleed air naturally.

I worry about the harmonic vibration of the thru-bolt without a dab of silicon ( which would block our flow passage).

Barry

Yours are vertical so they bleed air naturally.

I worry about the harmonic vibration of the thru-bolt without a dab of silicon ( which would block our flow passage).

Barry

#81

Red Pill Dealer

iTrader: (10)

You don't think silicone in the center plate alone would be enough? Maybe I don't understand. Does the coolant passage around the tension bolt have to go through the center plate also?

#83

Adam I used smaller holes. My thinking was that the differential pressure across the restrictive spark plug water passages would force only a small amount of flow to bypass.

Yours are vertical so they bleed air naturally.

I worry about the harmonic vibration of the thru-bolt without a dab of silicon ( which would block our flow passage).

Barry

Yours are vertical so they bleed air naturally.

I worry about the harmonic vibration of the thru-bolt without a dab of silicon ( which would block our flow passage).

Barry

The center housing and rear housing will remain the stock hole diameter. So I don't think harmonics of the bolts will really be that bad. However, as a preventive measure I can put silicone at the center housing, enough to fill up the gap and allow it to solidify. Harmonics should be addressed then.

I disagree, the simple fact that even some coolant getting into that region will help in normalizing the temperature of that region. Yes the flow won't be great, but something is better than nothing.

Last edited by afgmoto1978; 06-20-08 at 01:25 AM.

#84

"Elusive, not deceptive!”

Thread Starter

I think I will reduce the size of the drain openings, but retain the specified size on the top holes. My reasoning is you want the holes big enough to fill that volume and have flow decent enough to be actually useful.

The more surface area the more cooling ability.

The center housing and rear housing will remain the stock hole diameter. So I don't think harmonics of the bolts will really be that bad. However, as a preventive measure I can put silicone at the center housing, enough to fill up the gap and allow it to solidify. Harmonics should be addressed then.

Good idea, can I steal that one?

I disagree, the simple fact that even some coolant getting into that region will help in normalizing the temperature of that region. Yes the flow won't be great, but something is better than nothing.

The more surface area the more cooling ability.

The center housing and rear housing will remain the stock hole diameter. So I don't think harmonics of the bolts will really be that bad. However, as a preventive measure I can put silicone at the center housing, enough to fill up the gap and allow it to solidify. Harmonics should be addressed then.

Good idea, can I steal that one?

I disagree, the simple fact that even some coolant getting into that region will help in normalizing the temperature of that region. Yes the flow won't be great, but something is better than nothing.

I agree with you Adam, air is an insulator, when water is introduced into the bores cooling area is added.

Good Plan,

Barry

#87

Infrared and a tear down next year. I was thinking temp sensors, but that doesn't really give a really good idea other than what the general temp is of coolant at that point.

Though, I should be able to tell a difference in the tune and when I tear it down. Beyond that I would be guessing.

Though, I should be able to tell a difference in the tune and when I tear it down. Beyond that I would be guessing.

#88

"Elusive, not deceptive!”

Thread Starter

Infrared and a tear down next year. I was thinking temp sensors, but that doesn't really give a really good idea other than what the general temp is of coolant at that point.

Though, I should be able to tell a difference in the tune and when I tear it down. Beyond that I would be guessing.

Though, I should be able to tell a difference in the tune and when I tear it down. Beyond that I would be guessing.

The good/bad news is that we won't get to analyze the success of the experiment till the next tear-down and if it is successful that could be a hopefully very long time.

Let me reconsider this last point. I will have to remove mine soon to fix the spark plug water leak. And with Adam constantly testing the envelope, we will probably see the inside of his engine in a reasonable amount of time too!

Barry

#89

Red Pill Dealer

iTrader: (10)

I really got to hand it to you guys! This is a great thread.

You guys are also sharing your information. Congrats.

afgmoto1978, nice trick with the ball end mill.

You guys are also sharing your information. Congrats.

afgmoto1978, nice trick with the ball end mill.

#90

#91

"Elusive, not deceptive!”

Thread Starter

I do run the Mazmart pump and re-contour the leading edges.

I now worry that the belt is slipping from the higher pumping efficiencies. The earlier and later RX8 pumps, turning the opposite direction, would allow more pulley contact.

Below is a Boyesen design water pump, from the motorcycle industry, with claims of lower HP drain and higher efficiency.

I now worry that the belt is slipping from the higher pumping efficiencies. The earlier and later RX8 pumps, turning the opposite direction, would allow more pulley contact.

Below is a Boyesen design water pump, from the motorcycle industry, with claims of lower HP drain and higher efficiency.

#93

"Elusive, not deceptive!”

Thread Starter

#94

No that one goes to the turbo. You will see where it will be located later this week. I need to have everything mounted to see what room I have available. I will have to make another custom oil catch tank to accomodate to give you an idea of where it will be located.

#97

"Elusive, not deceptive!”

Thread Starter

#99

"Elusive, not deceptive!”

Thread Starter

#100

Here are photos of the external cooling line. No issues with all the external engine accessories as well. Interesting to see how well it works, after thinking about it Imay have to go back and weld in a fitting that will aid in water going into that line from the water pump housing....

The wire coils are called Unicoil's, they aid in putting tight bend's on cooling lines without collapsing the coolant line at the bend.

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE]

The wire coils are called Unicoil's, they aid in putting tight bend's on cooling lines without collapsing the coolant line at the bend.

[/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE]

[/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE] [/QUOTE]

[/QUOTE]