Suggestions for fixing oil catch can problem

#201

Mad Man

I did not end up T'ing the system yet(concerned about not getting enough oil to the turbo due to pressure on the drain side). I bought a dirt track bag that goes over the breather, and I wrap the breather with three folded sheets of paper towel. I then use the bag to hold the towels in place. Works ok, I will develop a real solution this winter. I push out at least a pint every twenty minutes. That is at ~20 psi on track. I think I cracked my rear iron last race, so I may take this opportunity to customize my rear iron. I'll post any solution come up with. I still need to improve my cooling, so a larger capacity oil system is on my list anyway. My cooling is very inconsistent now, not sure why. I can go out at 20+ psi for 20 minutes no problem, and then overheat in two laps the next time out. Carl

#202

Rotary Enthusiast

Originally Posted by Carl Byck

I can go out at 20+ psi for 20 minutes no problem, and then overheat in two laps the next time out. Carl

#203

Rotary Enthusiast

would be helpful to see if anyone had success with a single, using the 2nd drain port as a vent (prior post).

Another rough thought for stock twins, was to install an internal vent line for hard long rights. It would come across the top of the baffle plate... about 2/3 across to the right side, and bend up the fill tube, about 1' lower than the lateral shift. Idea is to have a vent path for hard rights, Need big 90 elbo in oil cap, and hopefully small catch can. May take more thought to be sure oil doesnt fill the tube before the hard right.

Another rough thought for stock twins, was to install an internal vent line for hard long rights. It would come across the top of the baffle plate... about 2/3 across to the right side, and bend up the fill tube, about 1' lower than the lateral shift. Idea is to have a vent path for hard rights, Need big 90 elbo in oil cap, and hopefully small catch can. May take more thought to be sure oil doesnt fill the tube before the hard right.

#204

FWIW I tried running a 6mm vacuum line from the rear unused turbo oil drain fitting (I run a GT35R single T now) up and over the bell housing to the other port on my catch can. This did NOT help the problem (for me).

A data point for your consideration.

FWIW,

Crispy

A data point for your consideration.

FWIW,

Crispy

#205

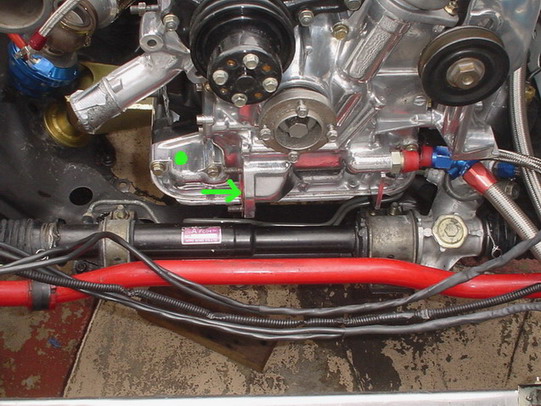

This week I will be drilling and tapping a 1/2 npt hole with -10 line into the front cover to vent the right-front side of the engine. The exact location on the S5 front cover is represented by the green dot in the pic. The green arrow shows the path of our turbo oil return path and location (for TII's). I have the mop removed and run pre-mix but I'm sure this could still be done with the mop crap in place. I am not sure about 3rd gen front covers but something similiar could be figured out for those slowpokes if needed.

For us 2nd gen guys, this means removing the oil pan which in turn means supporting the engine with a hoist since the passenger side engine mount has to come off for this. A little involved but easily accomplished in less than a day while drinking beer.

I am positive this will work. There will be absolutely NO oil in that location to be pushed out. For starters it is located in the front and during acceleration and under boost is when we encounter the problem, particularly during right hand corners. All the oil will want to go towards the back of the engine under acceleration leaving the front cover location unobstructed. Additionally, it is on the right side to alleviate the right hand corner problem with blocking all of the pre-existing vent paths with oil such as the oil filler tube and/or center iron.

I also have a 3/8 npt swivel fitting with a -8an line coming out of the top of my oil filler cap for the left hand turns that has been in place for a couple years. Originally it was -6 line but I would still blow out my dipstick. Switching to -8 line cured that but I still pushed out just under a quart of oil in 20 minutes on tracks such as Infineon and Laguna. There is also a baffle plate between the pan and engine. I have a quick drain fitting attached to the bottom of a 1 quart capacity catch can to make draing a cinch, but I want the oil in the engine where it belongs.

I will do a short write up with pics after completion and will let you know how it works out when put to the test on the track.

For us 2nd gen guys, this means removing the oil pan which in turn means supporting the engine with a hoist since the passenger side engine mount has to come off for this. A little involved but easily accomplished in less than a day while drinking beer.

I am positive this will work. There will be absolutely NO oil in that location to be pushed out. For starters it is located in the front and during acceleration and under boost is when we encounter the problem, particularly during right hand corners. All the oil will want to go towards the back of the engine under acceleration leaving the front cover location unobstructed. Additionally, it is on the right side to alleviate the right hand corner problem with blocking all of the pre-existing vent paths with oil such as the oil filler tube and/or center iron.

I also have a 3/8 npt swivel fitting with a -8an line coming out of the top of my oil filler cap for the left hand turns that has been in place for a couple years. Originally it was -6 line but I would still blow out my dipstick. Switching to -8 line cured that but I still pushed out just under a quart of oil in 20 minutes on tracks such as Infineon and Laguna. There is also a baffle plate between the pan and engine. I have a quick drain fitting attached to the bottom of a 1 quart capacity catch can to make draing a cinch, but I want the oil in the engine where it belongs.

I will do a short write up with pics after completion and will let you know how it works out when put to the test on the track.

#206

Originally Posted by CrispyRX7

FWIW I tried running a 6mm vacuum line from the rear unused turbo oil drain fitting (I run a GT35R single T now) up and over the bell housing to the other port on my catch can. This did NOT help the problem (for me).

A data point for your consideration.

FWIW,

Crispy

A data point for your consideration.

FWIW,

Crispy

#207

Mad Man

What about T'ing into the turbo drain line, essentially the same place as yours. i have a -10 fitting there now. I assumed it was a stock location, is it? It is a tight fit, my -10 line is only ~2-3" out of the turbo drain. Thoughts? Has anyone measured pressure or lack of it there? Carl

#208

Rotary Enthusiast

Chris, 6mm may be too small. Here is the pm I gave Gus. He went from filling a 1Q can, to less than 1". He already had your oil cap vent. Don't know what size line he used, or if he added the expansion thing.

"Make sure line is initially vertical as practical from old turbo drain ... if going quickly from a long hard left to a similar right, want any oil backed up in vent to drain quickly. if an issue, added expansion in the line (ex: 3/4" or 1" copper pipe with reducers) would trap residual oil in line at that point, and drain back after corner"

"Make sure line is initially vertical as practical from old turbo drain ... if going quickly from a long hard left to a similar right, want any oil backed up in vent to drain quickly. if an issue, added expansion in the line (ex: 3/4" or 1" copper pipe with reducers) would trap residual oil in line at that point, and drain back after corner"

#210

Well I got around to installing the breather line in the front cover today. It came out pretty good...hopefully it works.

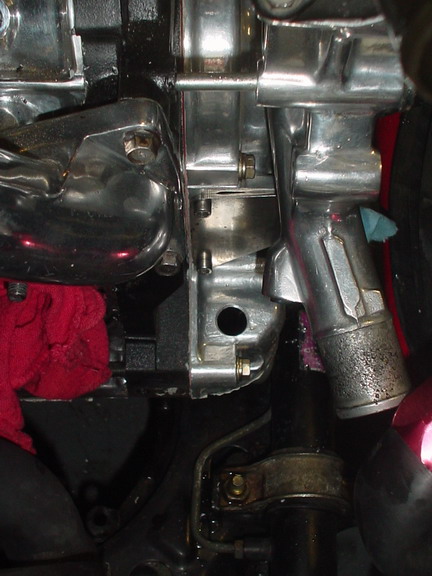

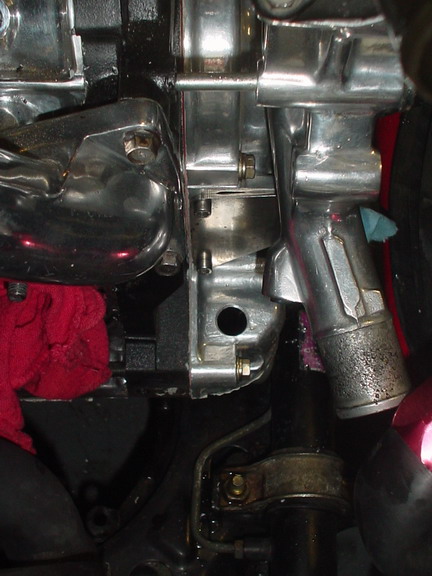

Here is where I drilled the hole for the 1/2" npt to -10 an fitting. This is obviously a 2nd gen front cover and I have the mop blocked off since I use pre-mix. I'm pretty sure it would work with the mop installe too. This location does not interfere with the turbo drain line or anything else for that matter.

The casting of the front cover is just thick enough to get some threads into it from a tap for the npt/an adapter.

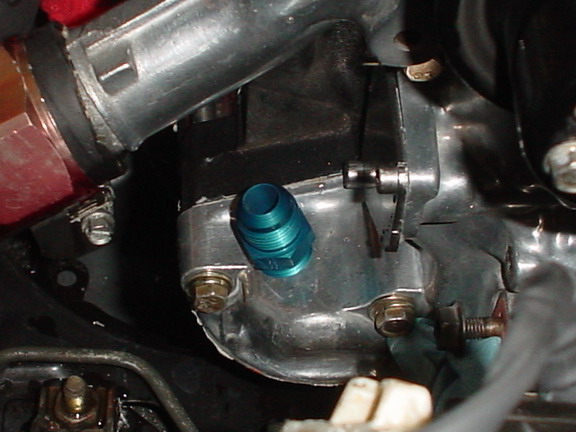

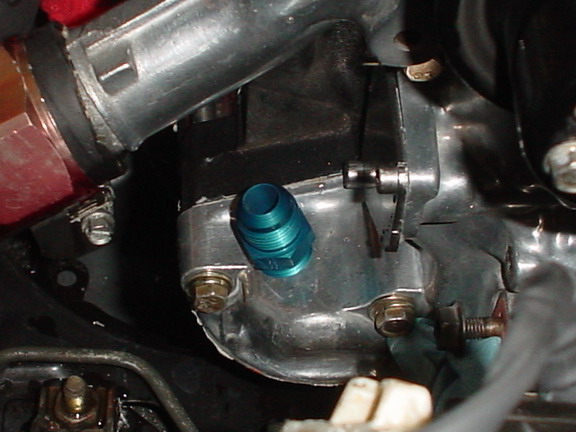

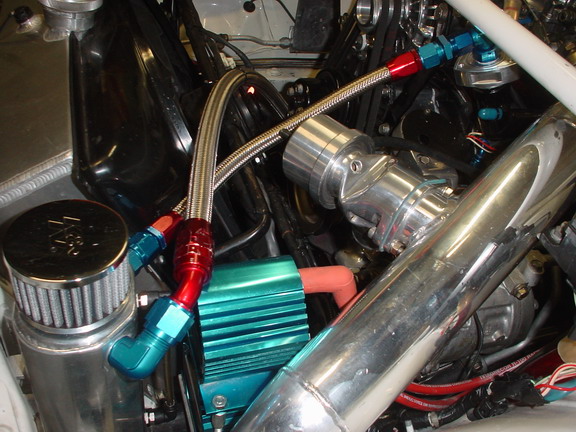

Here is my modified GReddy oil catch can. I enlarged the two side openongs towards the top for 1/2" npt and 3/8" npt to -an adapter fittings. On the top is a large K&N breather. On the bottom of the catch can is a quick drain fitting.

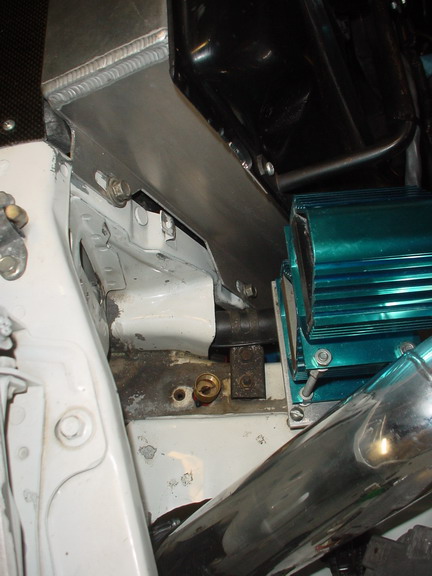

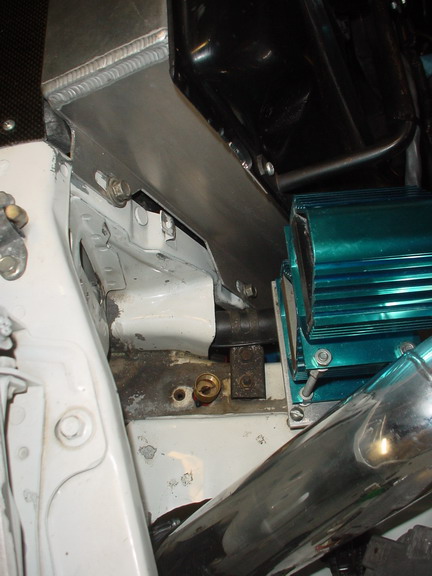

The hose attachment for the quick drain fitting is permanently located in the frame rail and protrudes out the bottom for quick and easy draining. Here you can see the top of the hose and its screw on fitting. Of course I unscrew the hose so the catch can is sealed when driving about and drain it between sessions.

Here you can see where the orange hose from the quick drain protrudes through the rail out the bottom of the car.

Here is where I drilled the hole for the 1/2" npt to -10 an fitting. This is obviously a 2nd gen front cover and I have the mop blocked off since I use pre-mix. I'm pretty sure it would work with the mop installe too. This location does not interfere with the turbo drain line or anything else for that matter.

The casting of the front cover is just thick enough to get some threads into it from a tap for the npt/an adapter.

Here is my modified GReddy oil catch can. I enlarged the two side openongs towards the top for 1/2" npt and 3/8" npt to -an adapter fittings. On the top is a large K&N breather. On the bottom of the catch can is a quick drain fitting.

The hose attachment for the quick drain fitting is permanently located in the frame rail and protrudes out the bottom for quick and easy draining. Here you can see the top of the hose and its screw on fitting. Of course I unscrew the hose so the catch can is sealed when driving about and drain it between sessions.

Here you can see where the orange hose from the quick drain protrudes through the rail out the bottom of the car.

Last edited by RX-Heven; 11-23-05 at 01:19 AM.

#211

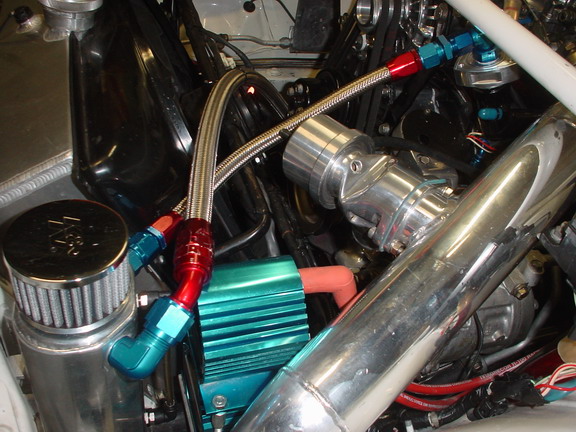

Here you can see it all installed. There is also a -8an line coming out the top of the oil filler cap that goes to the oil catch can that I had previously installed.

I thought of teeing into the turbo oil return line as some others have suggested but decided against it. The reurn line is obviously used for returning oil so in turn the line will contain oil...duh. These lines are not under any pressure, or should not be in any case, otherwise you will be pushing oil past the seals in the turbo. Because the line is not supposed to be under pressure, it might work but I wanted something I can be sure of. The return line sees the same pressure as the inside of the oil pan. I figured the necessary venting would just push some of the oil that is always present in the return line into the oil catch can since it's role would become dual purpose if t'eed into. T'eeing into the drain line may also hinder the lines abilty to properly drain oil from the turbo as the vented air is pushing in the opposite direction the oil needs to be draining in.

In the end, it would probably help, i cannot see how it wouldn't. However, I want to eliminate the problem of pushing oil into the catch can, not just reduce it.

I will report on the results in late January after Laguna Seca

I thought of teeing into the turbo oil return line as some others have suggested but decided against it. The reurn line is obviously used for returning oil so in turn the line will contain oil...duh. These lines are not under any pressure, or should not be in any case, otherwise you will be pushing oil past the seals in the turbo. Because the line is not supposed to be under pressure, it might work but I wanted something I can be sure of. The return line sees the same pressure as the inside of the oil pan. I figured the necessary venting would just push some of the oil that is always present in the return line into the oil catch can since it's role would become dual purpose if t'eed into. T'eeing into the drain line may also hinder the lines abilty to properly drain oil from the turbo as the vented air is pushing in the opposite direction the oil needs to be draining in.

In the end, it would probably help, i cannot see how it wouldn't. However, I want to eliminate the problem of pushing oil into the catch can, not just reduce it.

I will report on the results in late January after Laguna Seca

Last edited by RX-Heven; 11-23-05 at 01:20 AM.

#212

Senior Member

iTrader: (2)

Join Date: Mar 2001

Location: Boston, MA 02130

Posts: 495

Likes: 0

Received 0 Likes

on

0 Posts

Return line

I like your set up however I have one comment to make. I would run the return line to the motor from the bottom of the catch can rather from the side. If you allow the catch can to get that full before allowing oil to return to the motor, you will have oil slushing out of your filter due to high g's in braking and cornering.

#213

Lives on the Forum

Originally Posted by Jack

I like your set up however I have one comment to make. I would run the return line to the motor from the bottom of the catch can rather from the side. If you allow the catch can to get that full before allowing oil to return to the motor, you will have oil slushing out of your filter due to high g's in braking and cornering.

#215

Lives on the Forum

Originally Posted by Jack

So please tell me.... when making a high speed right hander, such as the down hiil at Lime rock, this system prevents oil from climbing up the oil necK?

#216

Senior Member

iTrader: (2)

Join Date: Mar 2001

Location: Boston, MA 02130

Posts: 495

Likes: 0

Received 0 Likes

on

0 Posts

Unfortuately...the g force's of high speed right hander's and heavy braking zones are not going to prevent this system from working as its intended. Oil is going to find the path of least resistance. However the return line to the oil pan is (with fingers crossed) the way to go. I still believe the return line mounted to the bottom of the catch can will be the only effective way of keeping oil from slushing out the filter.

#217

Lives on the Forum

Originally Posted by Jack

I still believe the return line mounted to the bottom of the catch can will be the only effective way of keeping oil from slushing out the filter.

Have you gone through this entire thread? It gets confusing if you haven't read the whole thing.

#218

Originally Posted by Jack

So please tell me.... when making a high speed right hander, such as the down hiil at Lime rock, this system prevents oil from climbing up the oil necK?

The reason the oil is pushed up the neck is that the pressure in the pan has nowhere to go but out through the neck. The problem is that oil is blocking the venting path but the pressure still needs to get out, so in turn, the oil is pushed out of the way and into the catch can.

The vent line in the front cover I added is NOT a return line in any way. The added line will provide an additional path for the pressure to escape without being blocked by oil and pushing the oil out as a result.

During right hand corners, oil sloshes to the left side of the engine blocking venting paths. If the oil is on the left side of the engine, the added vent line is on the right side of the engine free and clear of oil. Not to mention, the problem occurs mainly during acceleration (under boost) and the oil will want to go towards the rear of the engine.

Originally Posted by Jack

Unfortuately...the g force's of high speed right hander's and heavy braking zones are not going to prevent this system from working as its intended.

The engine is experiencing vacuum during braking and blowby is minimal to non-existent under those conditions. Besdies, even if there is blowby and the vent line in the front cover is blocked by oil, the vent line in the oil filler neck should be free and clear.

Originally Posted by Jack

Oil is going to find the path of least resistance.

#221

Mad Man

I too think the bottom would be better. AWhy did you opt for the side, and not the bottom of the can? I only see positives to the bottom return/drain. Thoughts? Like I mentioned mine is T'd where you see the open orange gasket in Dave's pics. I have not run it on the track yet though. Carl

Last edited by Carl Byck; 11-23-05 at 04:21 PM.

#222

Carl, this is not a return line. Again, this is not a return line to drain oil from the catch can to the oil pan.

This additional line is to vent the blowby gases only.

Blowby gases contain gasoline. I do not want to return that to my oil pan via a drain from my catch can.

With this setup, I predict there will be little to no oil at all pushed into the catch can, hence not needing a return line. When I/we were pushing out a quart or so in 20 minutes, I could see the need for a return line to keep all that oil where it belongs but in this case I do not think that applies.

This additional line is to vent the blowby gases only.

Blowby gases contain gasoline. I do not want to return that to my oil pan via a drain from my catch can.

With this setup, I predict there will be little to no oil at all pushed into the catch can, hence not needing a return line. When I/we were pushing out a quart or so in 20 minutes, I could see the need for a return line to keep all that oil where it belongs but in this case I do not think that applies.

#223

A thought: Dave this looks like a great setup and I for one hope it works. My thought builds upon comments made by others about a return line. Is there any reason why this setup could not be used as a "surge" can rather than a "catch" can? I agree the location of the vent lines from the front cover and filler neck are well placed...or as good as we can get them.... but instead of routing the line fromt he fornt cover to the top of the can route it to the bottom of the can. This way any oil that is pushed into the can, can, if possible given the "pressure" level in the oil pan, make it's way back to the oil pan. The oil filler neck line is obviously too high but the front cover line can flow *both ways.* In the event oil is pushed from the pan to the catch can, if the line is connected to the bottom of the can it will merely burp oil and gas through what ever is already in the bottom of the can. But as soon as pressure equalizes between pan and can (via the vent line to the top of the filler neck)would it not make for a effective path for oil to drain back into the pan? The line certainly is big enough to address any viscosity issues.

Just a thought.

Crispy

PS I'd keep an eye on the theaded connection into the front cover as engine torquing (movement) and vibration may work it loose over time. Not a lot of threads in that tapped hole.

Just a thought.

Crispy

PS I'd keep an eye on the theaded connection into the front cover as engine torquing (movement) and vibration may work it loose over time. Not a lot of threads in that tapped hole.

#224

Mad Man

"I'd keep an eye on the theaded connection into the front cover as engine torquing (movement) and vibration may work it loose over time. Not a lot of threads in that tapped hole."

Knowing Dave, he was careful about this, also the relatively coarse pipe threads(I assume) will resist stripping to a point. This was however one of my biggest reasons for the set-up with a "T" into the drain. GL dave, Carl

Knowing Dave, he was careful about this, also the relatively coarse pipe threads(I assume) will resist stripping to a point. This was however one of my biggest reasons for the set-up with a "T" into the drain. GL dave, Carl

#225

Some preliminary results.

I just got back from Turkey Day and while I was with the other lunatics in my family, I gave a bunch of them a ride in the car as I do every year. I did about 7-8 laps around a huge cloverleaf freeway intersection, all right handers both uphill and downhill. I pushed the car a little bit through some of the turns...well at least until some of the passengers started freaking out, but certainly enough to induce blowing a significant amount of oil out with my previous setup (venting through the filler cap only).

fwiw, I'm only running off the wg spring right now at ~12 psi.

I couldn't wait to see the contents of the can when I got back after the last joyride. There was less than an 1/8" of fluid in the catch can and guess what...not a drop of oil That also included the 250+ mile drive to the insane asylum.

That also included the 250+ mile drive to the insane asylum.

All the fluid was gasoline as far as I could tell. It was clear, had the consistency of water and certainly smelled like gas. I couldn't be more pleased at this point. I'll see how it does on a real track though and post an update then. Carl would most likely be at the same event to verify the results too.

Things sure looks promising though.

If I install a return/drain line from the catch tank, it will drain back to my gas tank...jk

Actually, when I was thinking out this new breather setup, I contemplated a return line to the oil pan as several of you have pointed out and has been discussed numerous times in this thread over the years. I decided against it for several reasons, some of which I have already stated, others not so obvious.

1. I aimed to eliminate the oil being pushed into the catch can, not just reduce it, thereby omitting the need for the return line in the first place.

2. Read #1 again.

3. If indeed the oil was eliminated from the catch can as I had hoped, I would not want to return the condensed blowby gases back to the oil pan for obvious reasons.

4. The GReddy catch can I have been using already had the two holes on the side near the top. They only needed to be tapped for the right size fittings. Call it laziness.

5. Routing a drain/return line on the bottom of the existing catch can where it was already mounted is not possible as you may be able to tell by one of the previous pictures.

6. If there was still a problem filling the catch can with oil, relocating the existing catch can or even adding a second catch can (i.e. more work), or surge can as Crispy suggested, on the other side of the engine bay would be required.

7. I was not convinced that this additional line, when and if partially full of oil, would breathe like it should as when the line is clear, causing some oil to be pushed up the oil filler neck as a result. It may not do that all. You could argue it both ways to me but I opted for the easier method and a backup plan was quite simple to implement.

I can't see any reason why this would not work as you describe. However, I just don't think it applies or is even necassary at this point with what I have done. We'll see though....

Not a chance of that happening unless a gorilla overtightens the fitting. As Carl mentioned, 1/2" npt thread is very coarse and there was enough material to get 2-1/2 to 3 full turns in. Additonally, on the left and right sides of the tapped hole, there is more material in the front cover that recieved some threading due to the shape of the casting on the inside.

My engine does not move. The poly engine mounts and a torque brace insure that it doesn't.

I just got back from Turkey Day and while I was with the other lunatics in my family, I gave a bunch of them a ride in the car as I do every year. I did about 7-8 laps around a huge cloverleaf freeway intersection, all right handers both uphill and downhill. I pushed the car a little bit through some of the turns...well at least until some of the passengers started freaking out, but certainly enough to induce blowing a significant amount of oil out with my previous setup (venting through the filler cap only).

fwiw, I'm only running off the wg spring right now at ~12 psi.

I couldn't wait to see the contents of the can when I got back after the last joyride. There was less than an 1/8" of fluid in the catch can and guess what...not a drop of oil

That also included the 250+ mile drive to the insane asylum.

That also included the 250+ mile drive to the insane asylum.All the fluid was gasoline as far as I could tell. It was clear, had the consistency of water and certainly smelled like gas. I couldn't be more pleased at this point. I'll see how it does on a real track though and post an update then. Carl would most likely be at the same event to verify the results too.

Things sure looks promising though.

If I install a return/drain line from the catch tank, it will drain back to my gas tank...jk

Actually, when I was thinking out this new breather setup, I contemplated a return line to the oil pan as several of you have pointed out and has been discussed numerous times in this thread over the years. I decided against it for several reasons, some of which I have already stated, others not so obvious.

1. I aimed to eliminate the oil being pushed into the catch can, not just reduce it, thereby omitting the need for the return line in the first place.

2. Read #1 again.

3. If indeed the oil was eliminated from the catch can as I had hoped, I would not want to return the condensed blowby gases back to the oil pan for obvious reasons.

4. The GReddy catch can I have been using already had the two holes on the side near the top. They only needed to be tapped for the right size fittings. Call it laziness.

5. Routing a drain/return line on the bottom of the existing catch can where it was already mounted is not possible as you may be able to tell by one of the previous pictures.

6. If there was still a problem filling the catch can with oil, relocating the existing catch can or even adding a second catch can (i.e. more work), or surge can as Crispy suggested, on the other side of the engine bay would be required.

7. I was not convinced that this additional line, when and if partially full of oil, would breathe like it should as when the line is clear, causing some oil to be pushed up the oil filler neck as a result. It may not do that all. You could argue it both ways to me but I opted for the easier method and a backup plan was quite simple to implement.

Originally Posted by CrispyRX7

My thought builds upon comments made by others about a return line. Is there any reason why this setup could not be used as a "surge" can rather than a "catch" can?

Originally Posted by CrispyRX7

PS I'd keep an eye on the theaded connection into the front cover as engine torquing (movement) and vibration may work it loose over time. Not a lot of threads in that tapped hole.

My engine does not move. The poly engine mounts and a torque brace insure that it doesn't.

Last edited by RX-Heven; 11-26-05 at 01:59 AM.