1986 FC EP Race Car Build Thread

#26

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

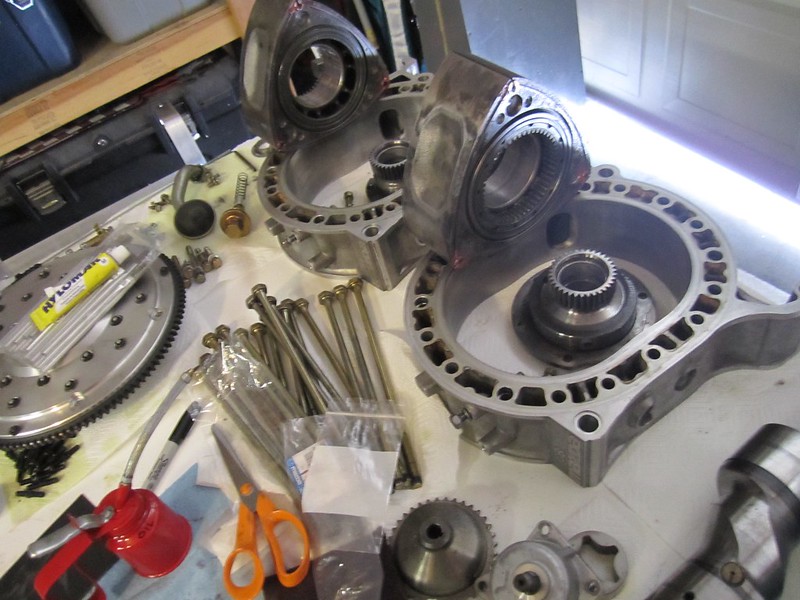

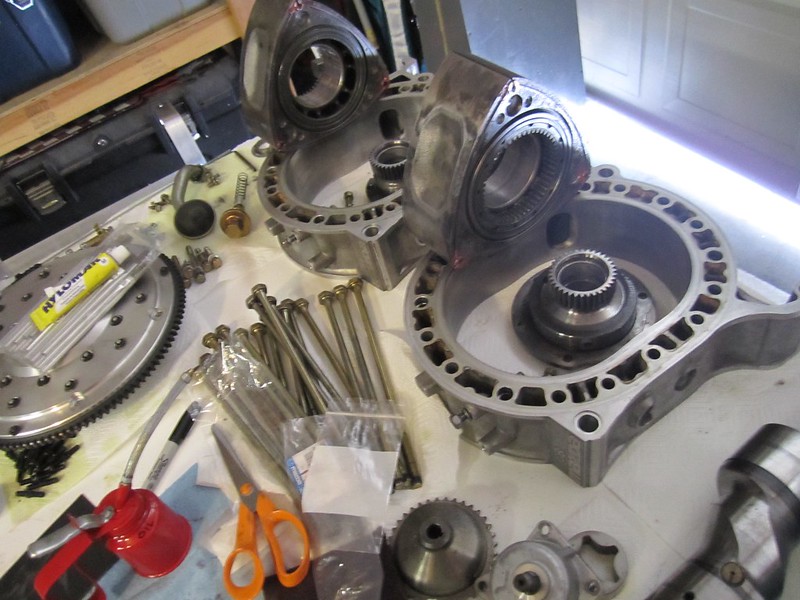

Time for a few updates. SO, at my April event I developed a rather serious engine issue, my oil catch can would fill up and overflow within 10min. I packed up early and headed home, tore the engine down and found that about a half of one of the rear side, rear rotor side seals was gone.

I'm nearly certain that the combination of extremely high oil temps (280+) early in the engine's life, some real flooding problems with an extremely out of control float level (maybe even hydraulic locking during attempts to start it with completely dripping boosters), and generally 'amateur learning' led to it failing.

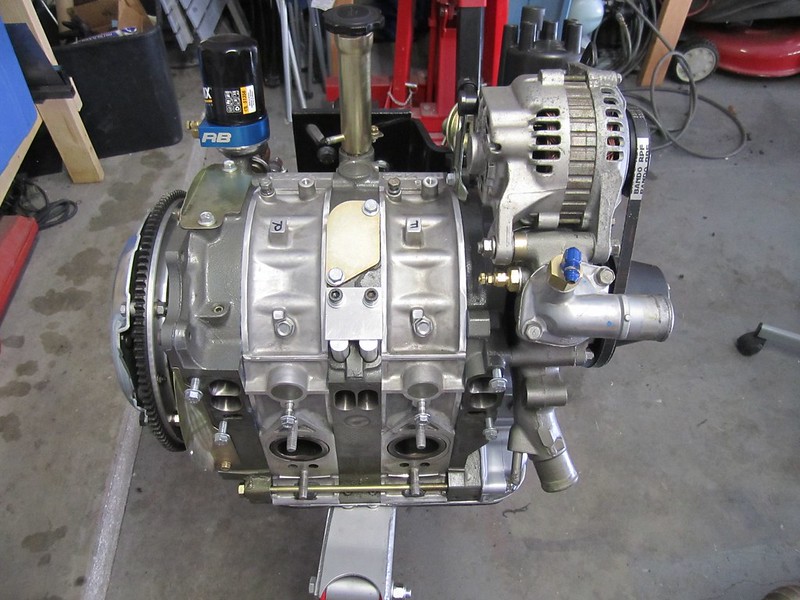

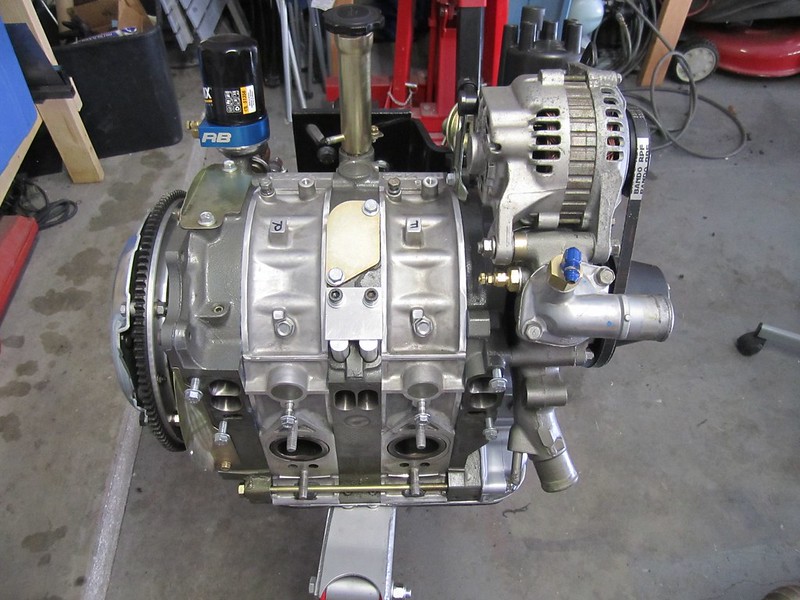

The good news was that all other surfaces, bearings, housings, seals, ect were in excellent shape and within tolerances. I also inspected the 'scissoring' and rounding over of the street port edges - the porting was perfect and left plenty of support for the corner seal and leading edge of the side seal. So it was relatively straight forward. Thanks to the excellent Mazda Comp tech tips and Mazdatrix/KMR DVD, I had it back together in a few evenings - my first attempt to rebuild a 13B.

Failed side seal and associated visual combustion leakage paths.

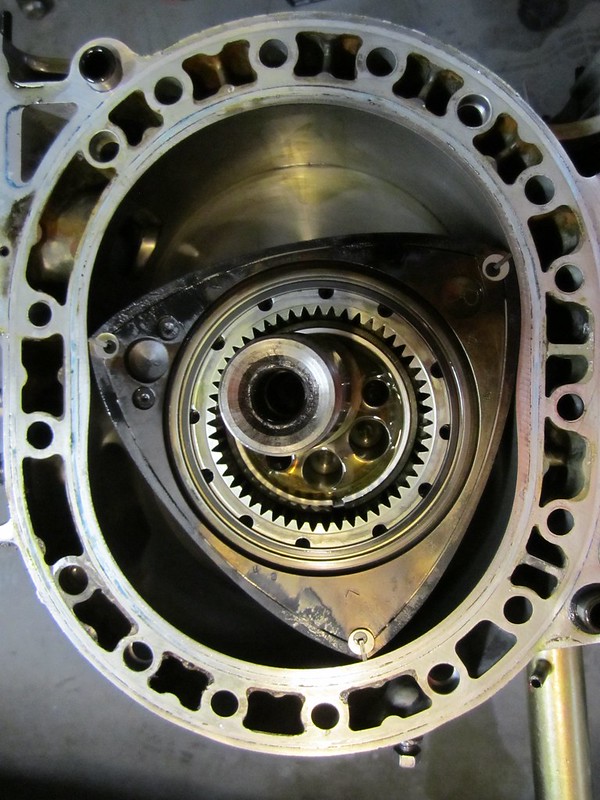

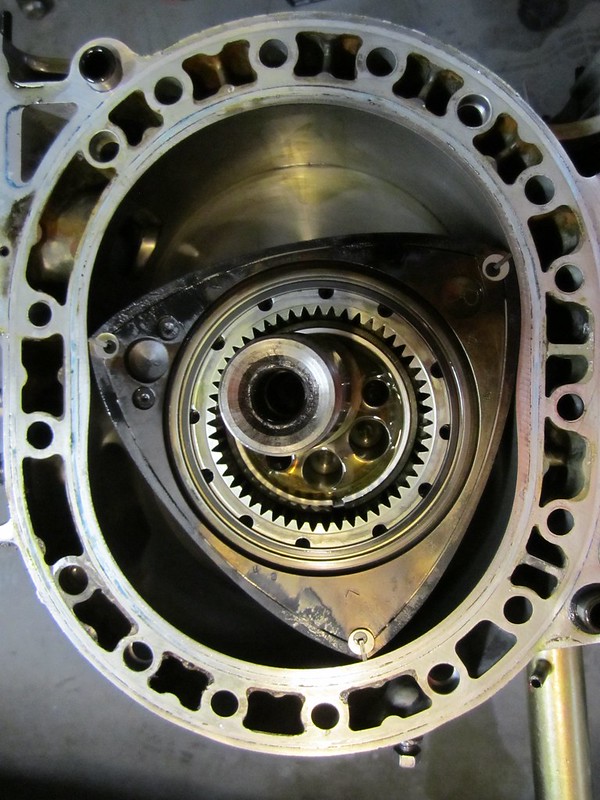

Everything cleaned up and passed inspections, time to go back together.

Thank goodness for Harbor Freight, pretty good quality digimatic.

I'm nearly certain that the combination of extremely high oil temps (280+) early in the engine's life, some real flooding problems with an extremely out of control float level (maybe even hydraulic locking during attempts to start it with completely dripping boosters), and generally 'amateur learning' led to it failing.

The good news was that all other surfaces, bearings, housings, seals, ect were in excellent shape and within tolerances. I also inspected the 'scissoring' and rounding over of the street port edges - the porting was perfect and left plenty of support for the corner seal and leading edge of the side seal. So it was relatively straight forward. Thanks to the excellent Mazda Comp tech tips and Mazdatrix/KMR DVD, I had it back together in a few evenings - my first attempt to rebuild a 13B.

Failed side seal and associated visual combustion leakage paths.

Everything cleaned up and passed inspections, time to go back together.

Thank goodness for Harbor Freight, pretty good quality digimatic.

Last edited by Andrew-s; 06-10-17 at 04:50 PM.

#27

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

While it was apart, I took the opportunity to swap in a manual rack I had sitting around.

I also added a few more bits to the under tray to help direct the air.

All back together and ready to go in.

I also added a few more bits to the under tray to help direct the air.

All back together and ready to go in.

#28

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Pretty much every time the tech inspection crew would note that 'your muffler's still broken' and there were heavy hints that I needed to quiet things down.

The car originally had 2x 2" tubing to a collector under the rear axle, a totally burned out resonator, and a 5" supertrapp with 12 discs - kids-crying-in-the-paddock-and-dogs-barking-loud.

So to shape things up, I picked up the RB road race dual pre silencer, an RB universal, turn down piping, and some more 2" tubing, all out of stainless.

Old and new.

Note that I learned I had the RB road race header that came with the car was *not* compatible with the dual pre silencer (only 1/8" clearance between bottom of pre silencer and floor), so I also had to pick up a pre silencer compatible header as well (I did the 89 to 92 one and used an O2 sensor plug).

My buddy and I welding up the new system (MIG using 308L filler, not as pretty as TIG but super strong).

The turndown is on a v-band clamp so that I can point it as needed.

Hard to see but I was able to route it pretty neatly using the 'passages' in the rear subframe.

I have no idea how many dBs it puts out but I can now idle and rev at midnight and the neighbors will never complain. It sounds great at full rpm too, just quieter. A side bonus is that I can think/focus better while in the car and I can also hear the 'road noise/tires' which really helps to know what the car is doing. I'm sure it might take away a few HP but I have to be friendly to the track/club as well.

The car originally had 2x 2" tubing to a collector under the rear axle, a totally burned out resonator, and a 5" supertrapp with 12 discs - kids-crying-in-the-paddock-and-dogs-barking-loud.

So to shape things up, I picked up the RB road race dual pre silencer, an RB universal, turn down piping, and some more 2" tubing, all out of stainless.

Old and new.

Note that I learned I had the RB road race header that came with the car was *not* compatible with the dual pre silencer (only 1/8" clearance between bottom of pre silencer and floor), so I also had to pick up a pre silencer compatible header as well (I did the 89 to 92 one and used an O2 sensor plug).

My buddy and I welding up the new system (MIG using 308L filler, not as pretty as TIG but super strong).

The turndown is on a v-band clamp so that I can point it as needed.

Hard to see but I was able to route it pretty neatly using the 'passages' in the rear subframe.

I have no idea how many dBs it puts out but I can now idle and rev at midnight and the neighbors will never complain. It sounds great at full rpm too, just quieter. A side bonus is that I can think/focus better while in the car and I can also hear the 'road noise/tires' which really helps to know what the car is doing. I'm sure it might take away a few HP but I have to be friendly to the track/club as well.

Last edited by Andrew-s; 06-10-17 at 05:11 PM.

#29

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

I was really nervous about how everything would run after making so many changes between races. I did the 'Lynn Hannover' 2hr @2200rpm break in (in two 1 hr sessions with an overnight cool down in between) and then the first 30min on the track were at only part throttle up to 6k rpm.

Everything ran great, and after a few break in sessions I was back to full throttle up to my 8.5k rpm shift points. Enormous power again, ~1/2" blow-by per racing day, and the exhaust didn't fall off, ha.

At full tilt, the rear rotor still runs richer than the front (~100-200f cooler than the front rotor EGT) and I see 'drips' from the booster if I blip the throttle. I noticed that the carb is tilted back at an angle so I probably need to see about leveling it out.

Back at full power, I was finally able to check on my oil cooling ducting, in 85f ambients, I was at 210f oil and 185f water; problems solved!

Otherwise, huge success; a rebuild that runs strong and a full race weekend tearing it up with the Miata guys.

Everything ran great, and after a few break in sessions I was back to full throttle up to my 8.5k rpm shift points. Enormous power again, ~1/2" blow-by per racing day, and the exhaust didn't fall off, ha.

At full tilt, the rear rotor still runs richer than the front (~100-200f cooler than the front rotor EGT) and I see 'drips' from the booster if I blip the throttle. I noticed that the carb is tilted back at an angle so I probably need to see about leveling it out.

Back at full power, I was finally able to check on my oil cooling ducting, in 85f ambients, I was at 210f oil and 185f water; problems solved!

Otherwise, huge success; a rebuild that runs strong and a full race weekend tearing it up with the Miata guys.

#32

Rotary Enthusiast

#34

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for all the compliments.

On the topic of EP street ports, the porting on my current side housings is actually relatively tame/economical (I still have relatively intact 6 port runners) compared to the side housing porting on an all-out, 'spare no expense' EP engine I collected a while back that has lots of work to completely reshape/enlarge the 6 port runners.

My next event is in August and I am really curious to better sort the Weber. On the advice from a few others, I replaced my 3.2 'grose' glass needle valve for a Weber competition 300 brass needle and seat. Running the car in the shop, I can already tell that the 'stop and start' of fuel flow into the bowl is more smooth watching the fuel level in the float gauge - perhaps I had a bum glass needle valve?

On the topic of EP street ports, the porting on my current side housings is actually relatively tame/economical (I still have relatively intact 6 port runners) compared to the side housing porting on an all-out, 'spare no expense' EP engine I collected a while back that has lots of work to completely reshape/enlarge the 6 port runners.

My next event is in August and I am really curious to better sort the Weber. On the advice from a few others, I replaced my 3.2 'grose' glass needle valve for a Weber competition 300 brass needle and seat. Running the car in the shop, I can already tell that the 'stop and start' of fuel flow into the bowl is more smooth watching the fuel level in the float gauge - perhaps I had a bum glass needle valve?

Last edited by Andrew-s; 07-06-17 at 02:43 PM.

#35

spoon!

Originally done by a big money builder. Nationals level motor - got passed over from its original owner after SCCA legalized FC housings and irons in FBs. I did not get the modified 5/6 port sleeves though so I won't post pics of those.

Suffice to say that they had enough weld added to form a very nice runner, a far cry from the Pineapple inserts.

Suffice to say that they had enough weld added to form a very nice runner, a far cry from the Pineapple inserts.I've never had any luck with the Grose jets - I know they're supposed to be the hot thing but everything I put them in has issues with the float level afterwards.

Congrats on the temperatures, that's always a big fight. You and some friends at June Sprints have me thinking about building my own Prod car.

#37

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Thanks for the compliments! The front under tray is indeed sheet aluminum. The only reason this thin aluminum sheet works ok is because it is supported on a 'shelf' specially moulded into the fiberglass front valence/air dam. Being supported in this built-in fiberglass shelf/channel, it is then secured in location by a few quarter-turn fasteners. It's a bit hard to explain, however, unfortunately the aluminum itself is not at all stiff enough to work as a splitter on its own. A lot of race cars that do not have the special AWR 'channel' front air dam kit use plywood coated in epoxy resins which work well, are cheap, and look pretty good. Below is a picture of what these look like - the photo below is from an excellent build thread somewhere here on RX7club.

#38

Hey,

I have the same car, been running SCCA Majors for about 6 years. You can see a few pictures on my profile. I also posted a few race video links in the AV area.

What are you running for a gear box?

Steve

I have the same car, been running SCCA Majors for about 6 years. You can see a few pictures on my profile. I also posted a few race video links in the AV area.

What are you running for a gear box?

Steve

#39

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

Hi Steve. I happened to see your photos in the new members area and I watch your posts on the prod forum, we have very similar cars indeed. I am a rotary guy that also likes race cars - as James May would say I'm sort of collecting and building a love letter to a 2nd gen RX-7 EP car. I am only 3 seasons into club racing here at a 'local' track in Albuquerque, we really don't have much in the way of SCCA sanctioned road racing in NM any more.

I've got a few regular old FC stock transmissions that I run on a 5.12 rear end. So far no issues. This winter I am installing a 5.5" twin disc clutch and the mazdaspeed super light flywheel to spice things up a bit.

Is your car fuel injected or Weber?

I've got a few regular old FC stock transmissions that I run on a 5.12 rear end. So far no issues. This winter I am installing a 5.5" twin disc clutch and the mazdaspeed super light flywheel to spice things up a bit.

Is your car fuel injected or Weber?

#40

Hey Andrew,

I'm one of the only fuel injected RX-7's in E Prod. I run an electromotive ECU. I have the 5.5" quartermaster and the super light flywheel...reves super fast.

I'm going to be switching to a dog ring gearbox for 2018. If you are interested, I have a close ratio gear box with straight cut gears. It was built by Jesse Prather with Houesman gears. It's not cheap but it is top notch.

I spun and got hit at Indy during qualifying. Just got the car back from the frame shop so I'm re-tooling...I've always been over sprung and I've taken the handling as far as it can go. Time to go back to softer springs.

Let me know if I can help with anything.

Steve

414-339-5084

I'm one of the only fuel injected RX-7's in E Prod. I run an electromotive ECU. I have the 5.5" quartermaster and the super light flywheel...reves super fast.

I'm going to be switching to a dog ring gearbox for 2018. If you are interested, I have a close ratio gear box with straight cut gears. It was built by Jesse Prather with Houesman gears. It's not cheap but it is top notch.

I spun and got hit at Indy during qualifying. Just got the car back from the frame shop so I'm re-tooling...I've always been over sprung and I've taken the handling as far as it can go. Time to go back to softer springs.

Let me know if I can help with anything.

Steve

414-339-5084

#41

spoon!

Ha, funny how small the world is. Hey Steve, it's Dan - you've met my dad and I at various points when we came up to see how Jim was doing. If you didn't notice my posts on the prod forum, looking at coming out to join you all in a year or two.

#43

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

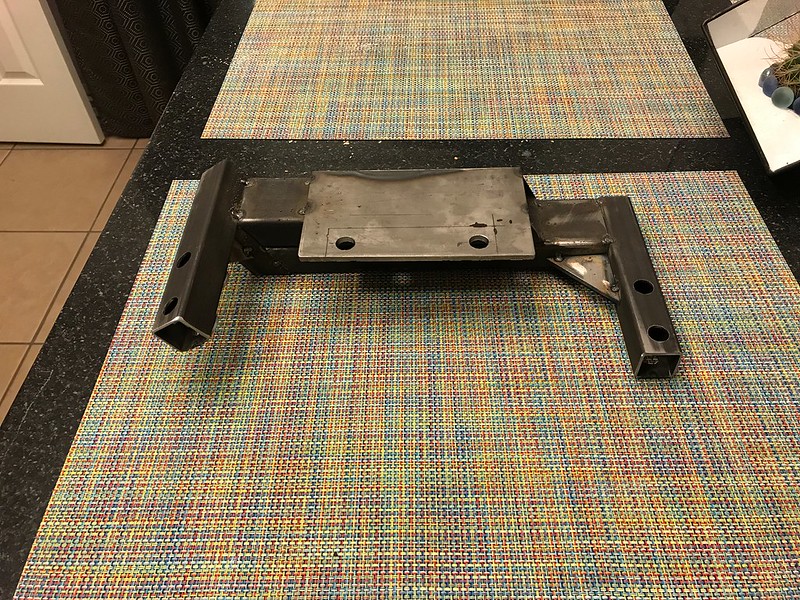

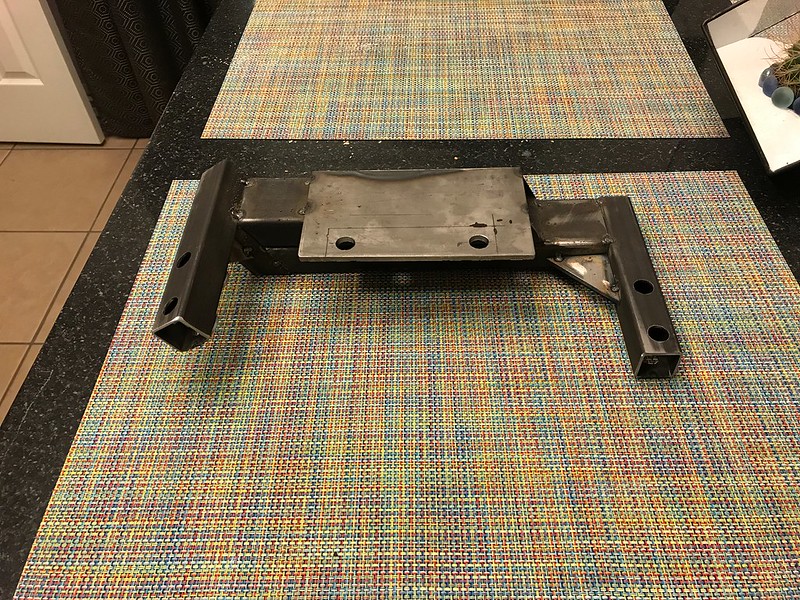

WELL, on my list was to upgrade at some point from the stock FC N/A 5 speed to a more racing-appropriate set of gear ratios. After doing a bit of research and just missing out on a straight-cut FC ratio set, I found a PBS MDR-1 in great shape. Knowing that this would be much more work than a quick weekend drop in, below was the task list for the last months:

1) new transmission mount

2) lengthened clutch slave cylinder rod

3) modifications to the transmission tunnel + new sheet aluminum tunnel cover

4) new driveshaft w/hardened front yoke

5) upgrade to new precision PBS shift mechanism

6) special Quartermaster PBS throwout bearing

New mount tacked-up.

New mount fully welded and painted.

1) new transmission mount

2) lengthened clutch slave cylinder rod

3) modifications to the transmission tunnel + new sheet aluminum tunnel cover

4) new driveshaft w/hardened front yoke

5) upgrade to new precision PBS shift mechanism

6) special Quartermaster PBS throwout bearing

New mount tacked-up.

New mount fully welded and painted.

Last edited by Andrew-s; 03-26-18 at 07:45 PM.

#44

Full Member

Thread Starter

iTrader: (1)

Join Date: Mar 2014

Location: New Mexico

Posts: 66

Likes: 0

Received 0 Likes

on

0 Posts

The transmission now in the car on the new mount. Between the 4130 steel mount and the transmission is a Delrin block to help ever so slightly with engine/transmission vibrations.

Quite a bit of cutting was needed to allow the taller shift selector/mechanism to fit through the transmission tunnel. I sprung for the Jesse Prather Motorsports shifter which is a huge upgrade over the 'stock' PBS shifter design (Jesse provided invaluable help with my PBS conversion...the Mazda Motorsports folks said "just call Jesse" for anything/everything PBS)

New sheet aluminum tunnel cover.

Back on the ground after lots of work (and a lot of McMaster Carr business) feels good.

Quite a bit of cutting was needed to allow the taller shift selector/mechanism to fit through the transmission tunnel. I sprung for the Jesse Prather Motorsports shifter which is a huge upgrade over the 'stock' PBS shifter design (Jesse provided invaluable help with my PBS conversion...the Mazda Motorsports folks said "just call Jesse" for anything/everything PBS)

New sheet aluminum tunnel cover.

Back on the ground after lots of work (and a lot of McMaster Carr business) feels good.